A method of laser shock wave assisted ion infiltration into metal substrate

A metal matrix, shock wave technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of metal surface damage, easy initiation of fatigue cracks, affecting technology development, etc., to achieve uniform performance and accurate parameters. Controllable and solve the effect of spot overlap problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

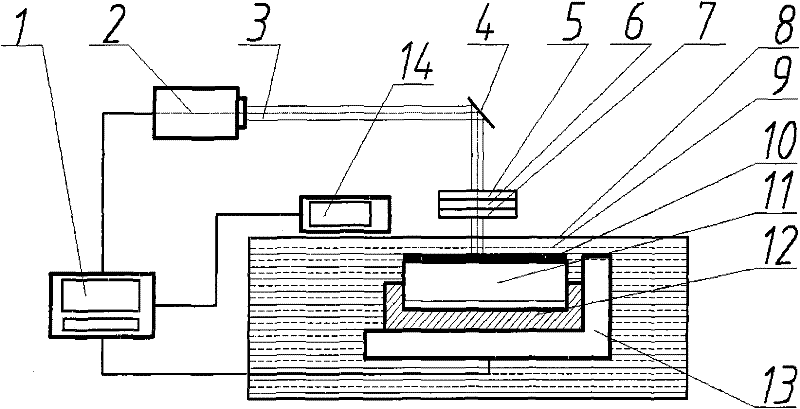

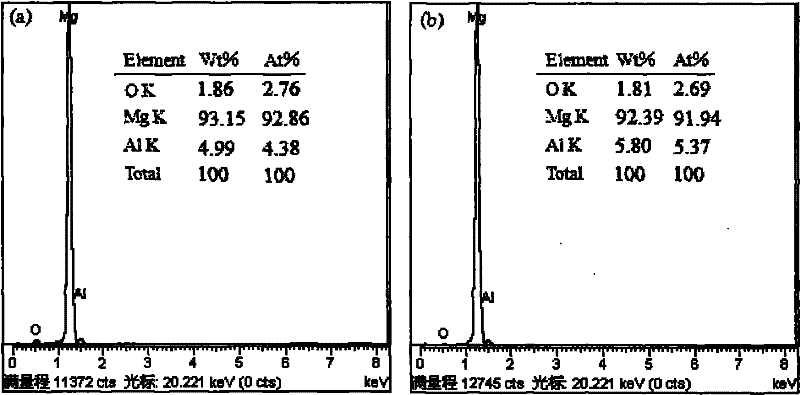

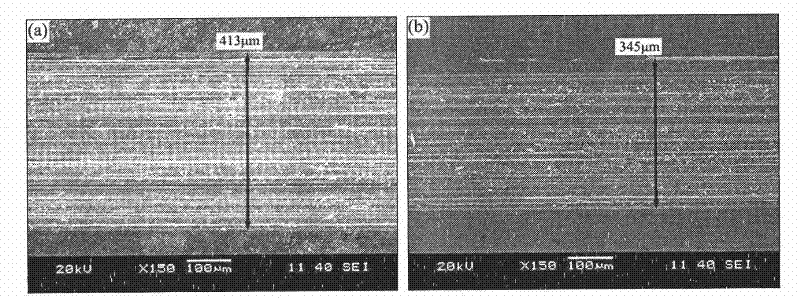

[0033] The following is an example of laser shock wave-assisted ion infiltration into a metal matrix. A laser generator is used to perform laser shock wave-assisted Al ion infiltration into a metal matrix on the surface of AM50 magnesium alloy. The ratio is reacted at 70-90°C for 20 minutes, and after cooling, a flexible film with a thickness of 2mm is formed. The Nd:glass laser with a repetition rate of 0.5 Hz has a spot diameter of 3 mm, a pulse energy of 15 J, a laser wavelength of 1054 nm, and a laser pulse width of 20 ns. The wear test was carried out on the UMT-2 micro-friction and wear test machine, using the ball-plane reciprocating dry friction method, and the test was carried out in the atmosphere and at room temperature, the room temperature was 18°C, and the relative humidity was 65%. The grinding pair is 440-C stainless steel ball with a diameter of 4 mm and a hardness of HRC 62, loaded with 0.1 N, stroke of 5 mm, reciprocating frequency of 1 Hz, and time of 20 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com