Method for improving wetting and spreading performance of reaction wetting system material

A system and reaction technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of cumbersome operation, low precision, slow preparation rate, etc., and achieve the goal of improving microstructure, improving connection performance, and fully reacting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for improving the wetting and spreading performance of a reactive wetting system material, the specific steps are as follows:

[0035] (1) Cut the large stainless steel plate into a 5mm×5mm×1mm stainless steel substrate, polish it with 600#, 800#, 1000#, 1200# sandpaper respectively, and then immerse it in absolute ethanol solution for ultrasonic cleaning for 15min, Among them, the composition of stainless steel is Fe-17.2Cr-11.6Ni-2.7Mo-0.8Si-1.5Mn;

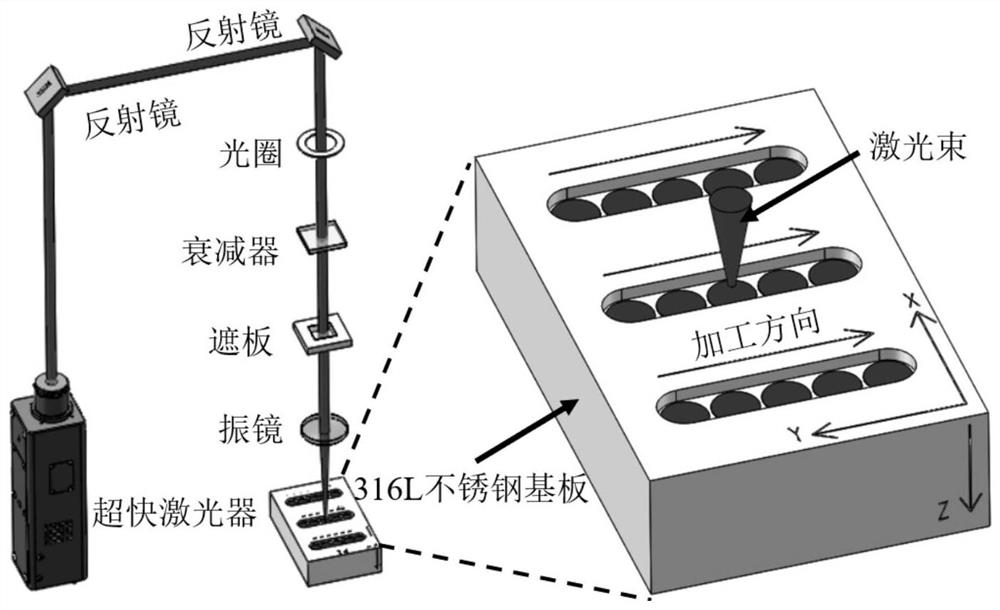

[0036] (2) After placing the stainless steel substrate on the workbench, focus the ultrafast laser on the part to be processed of the stainless steel substrate, and then scan and process on the surface of the stainless steel substrate to obtain a micro-nano stripe texture with an average width of 1.3 μm and an average spacing of 1.5 μm. structure ( Figure 4Group b is the image of the processed substrate under OM, UTM and SEM), wherein the ultrafast laser includes a laser emitter, a mirror, an aperture, an atten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com