Patents

Literature

124results about How to "Good wetting and spreading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

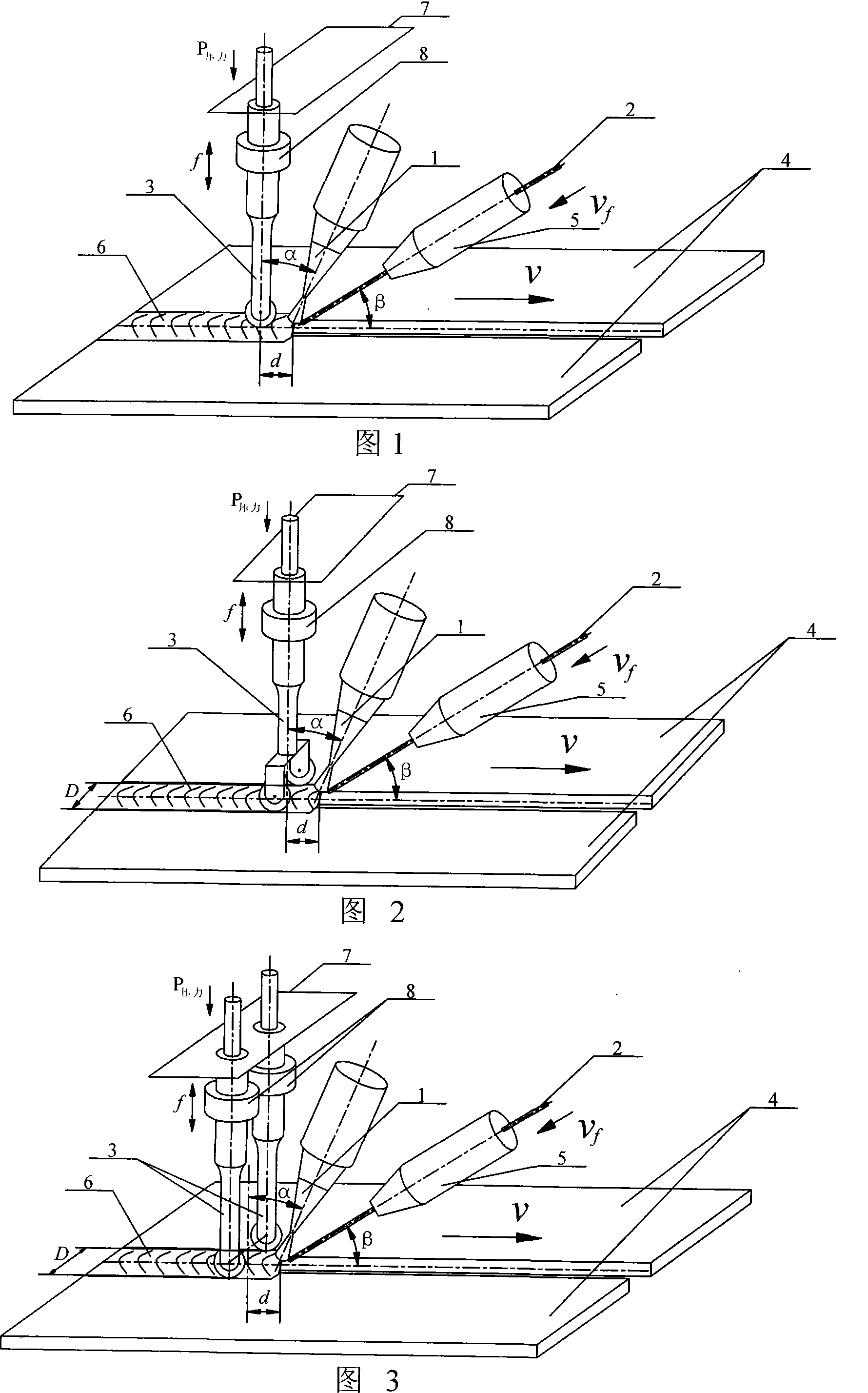

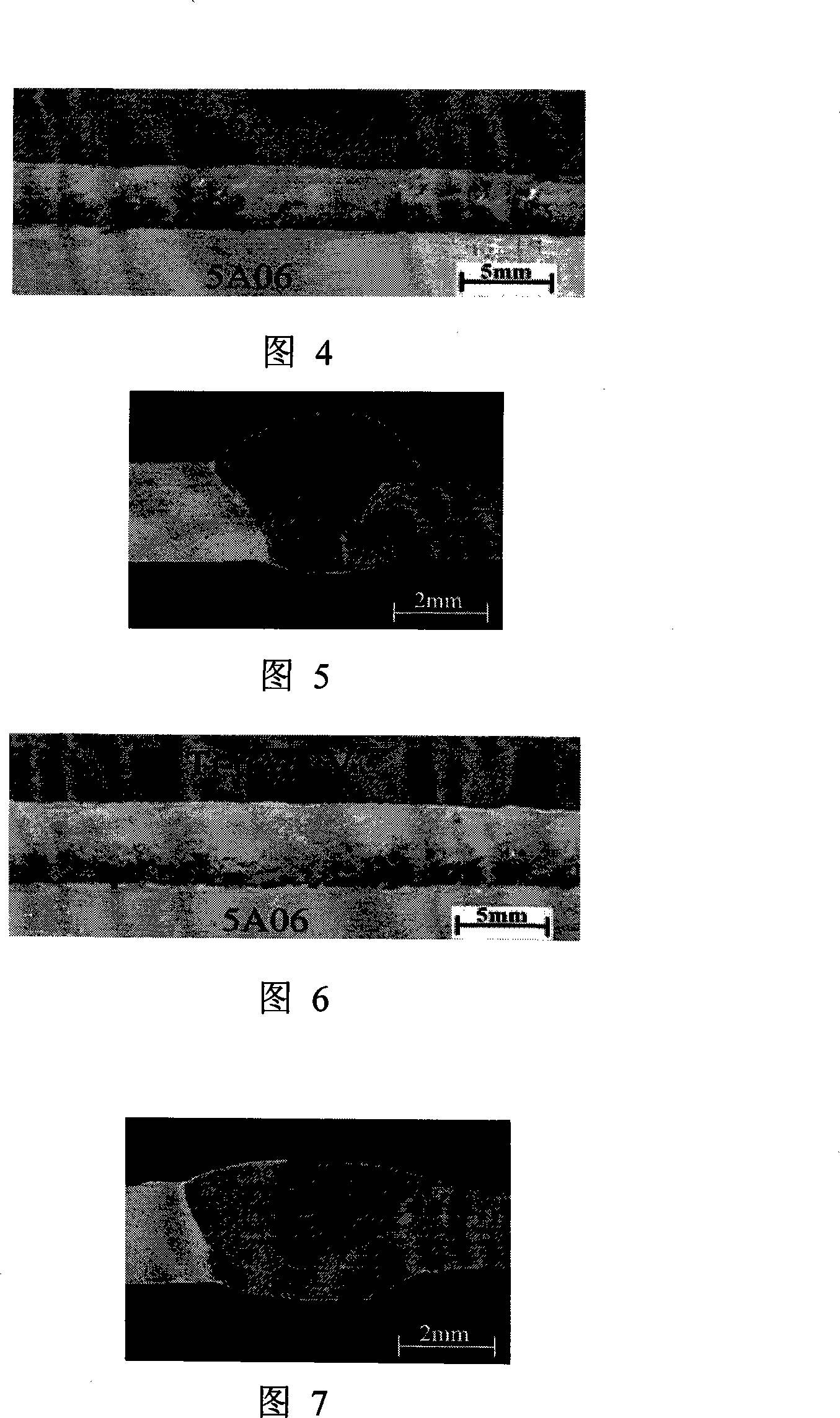

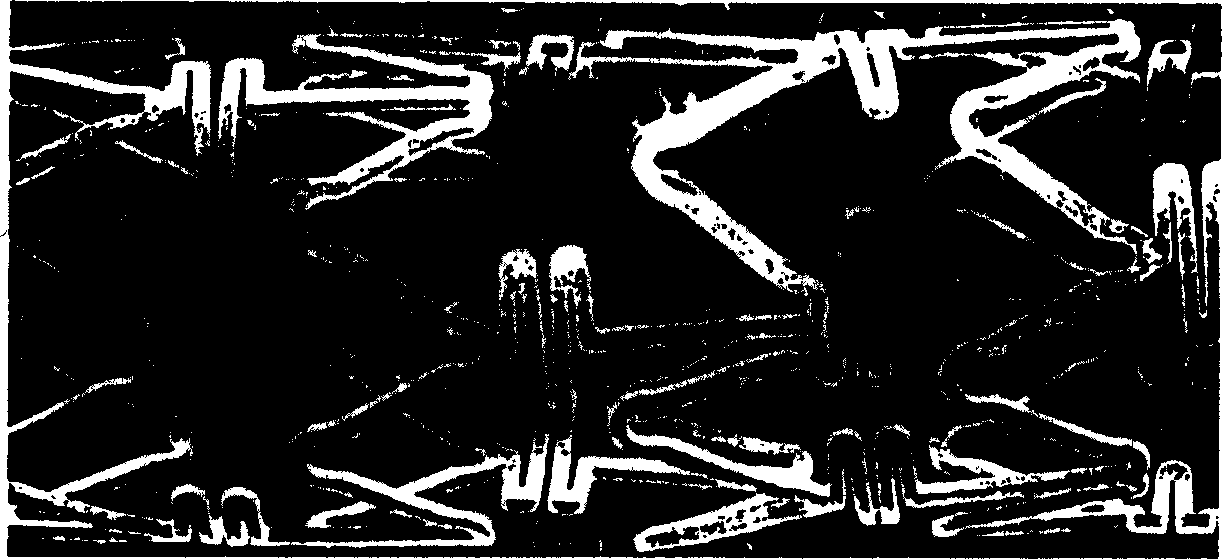

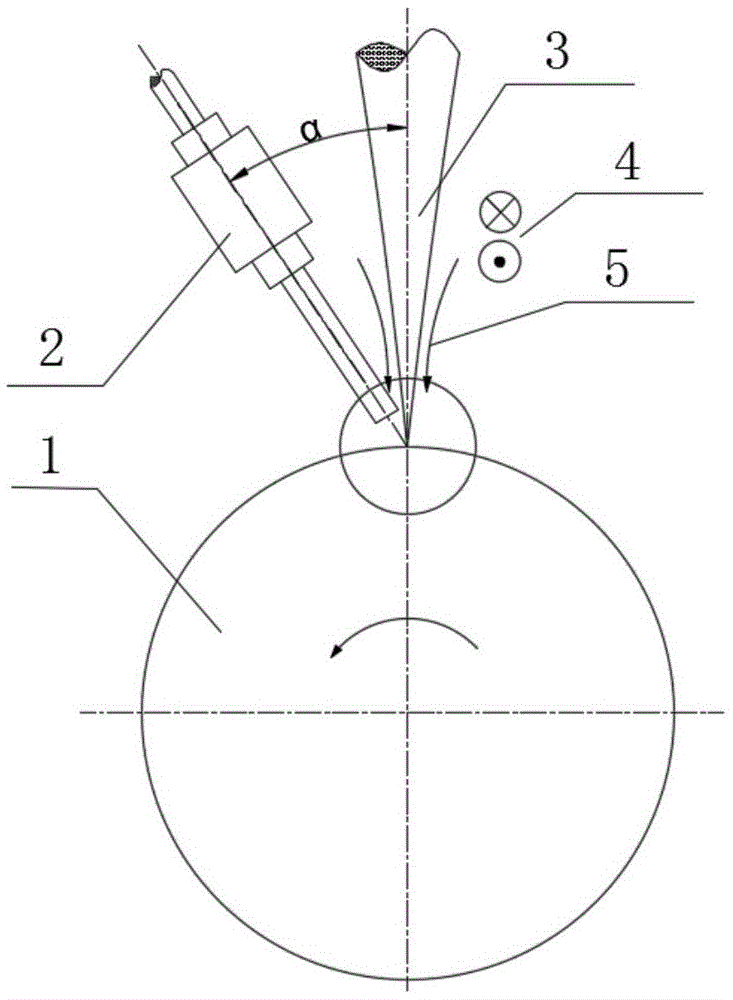

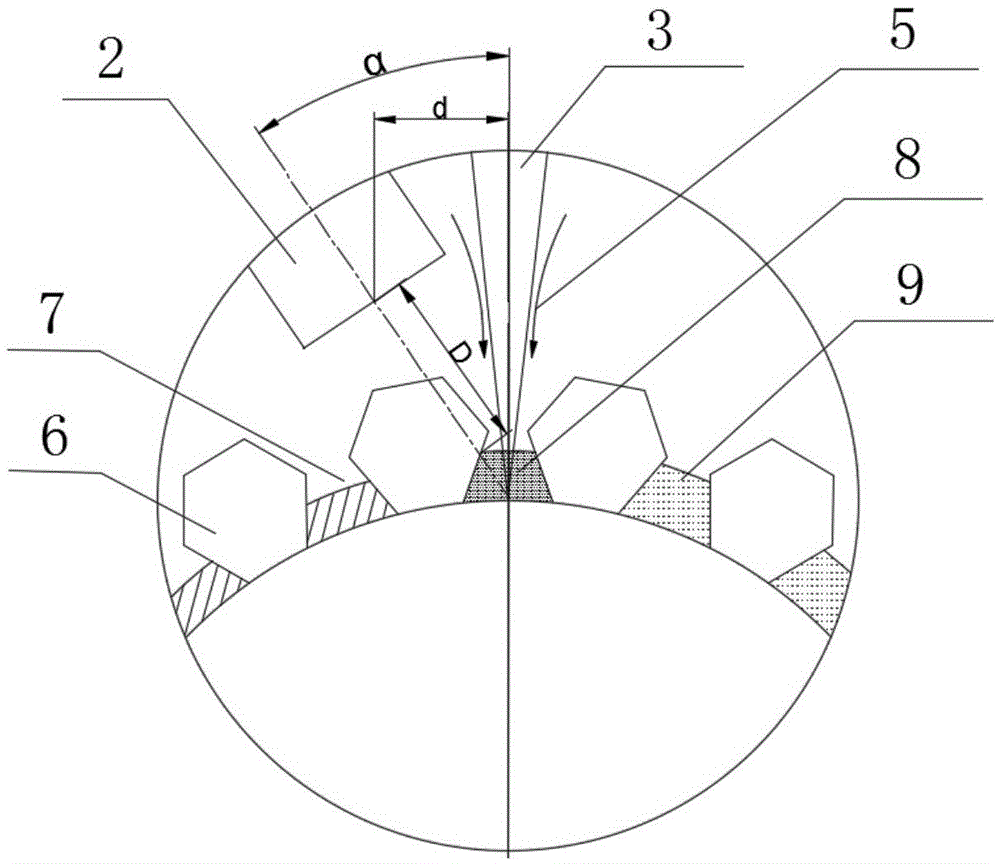

Ultrasound wave auxiliary laser braze (fuse) welding method

InactiveCN101195183AIncrease the amount of weld fillerImproved weld formationSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedWeld strength

Owner:HARBIN INST OF TECH

Method for preparing cardiovascular drug eluting stent

ActiveCN1569270AGood wetting and spreadingHigh bonding strengthSurgeryPharmaceutical delivery mechanismCardiovascular drugCardiovascular stent

A process for preparing cardiovascular stent with a drug coating layer on its surface is disclosed. It includes the steps of: 1. pretreatment for the stent surface by plasma 2. dipping or spraying of the stent surface in routine method by hyperplasia proof drug and coating polymer containing solution The drug coated stent prepared by the present invention can endure long period washing by all kinds of stress and body fluid in the stent transportation and dilation process, with the coating layer not easy to falling off.

Owner:SHANGHAI REBONE BIOMATERIALS +1

Method for brazing diamond tool through lasers with assistance of ultrasonic waves

ActiveCN105479025AControl the amount of thermal deformationShort manufacturing cycleOther manufacturing equipments/toolsMetal working apparatusHeating furnaceLaser beams

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

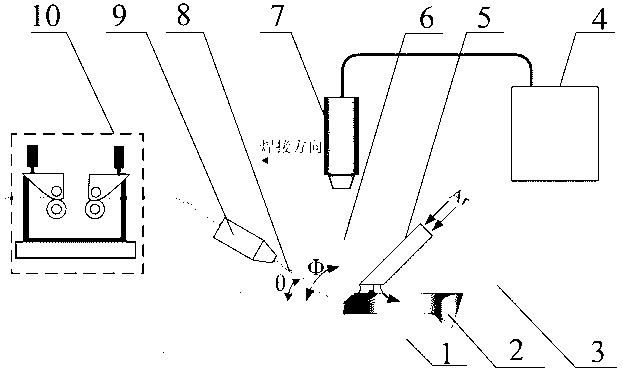

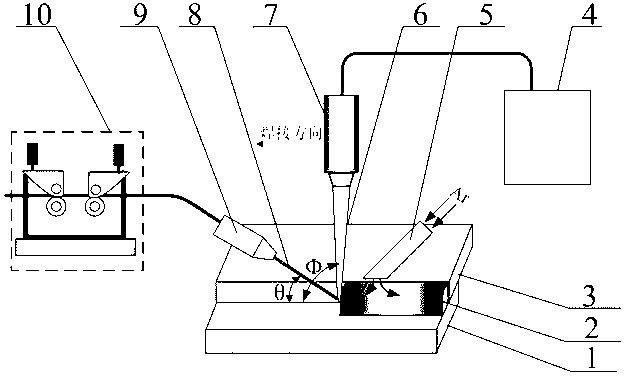

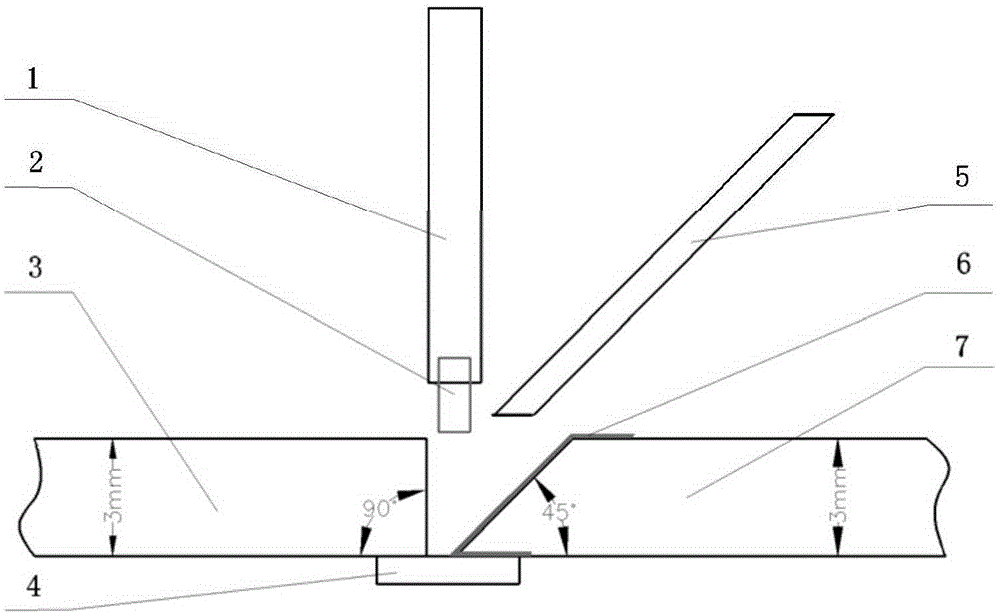

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535AFull overflowReduce or avoid the generation ofWelding/cutting media/materialsWelding/soldering/cutting articlesLaser beamsMaterials science

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

Mesothermal copper based solder without cadmium, and preparation method

ActiveCN1759974AShort processImprove product qualityWelding/cutting media/materialsSoldering mediaIntermediate frequencySoldering

A medium-temp non-Cd Cu-based soldering wire contains Cu (74.9-82.96 Wt%), Ni (1-5.5), Sn (10-12), P (6-7), Ce (0.02-0.3) and La (0.02-0.3). Its preparing process features that after the electrolytic Cu and Ni in the graphite crucible of MF induction furnace is heated to 600-800 deg.C, the covering agent is added. Its advantages are low smelting temp, narrow smelting zone, better wet spreading performance and certain plasticity.

Owner:浙江信和科技股份有限公司

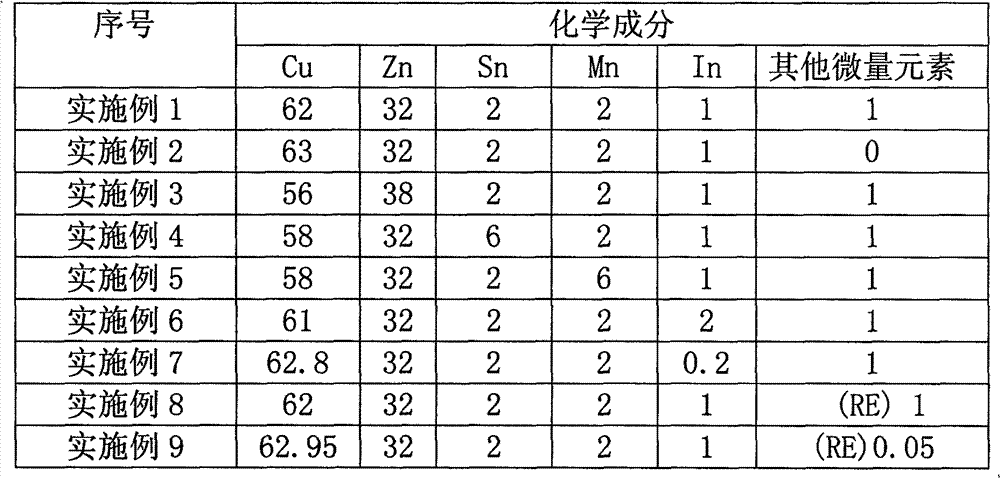

Silver-free copper based solder and preparation method thereof

InactiveCN102862003AImprove mechanical propertiesLittle impact on performanceWelding/cutting media/materialsSoldering mediaIngotSoldering

The invention relates to a silver-free copper based solder and a preparation method thereof, particularly to the silver-free copper based solder for soldering of compressor case covers and copper tubes. The silver-free copper based solder comprises, by weight, 56-68% of Cu, 29-38% of Zn, 0.5-8% of Sn, 0.5-8% of Mn, 0.1-2% of In and other microelements. The preparation method includes fully melting the Cu, the Sn, the Mn, the In and the other microelements to obtain a master alloy; adding Zn into the cooled master alloy with full stirring; taking the alloy out of a furnace; preparing an ingot through pouring; and preparing the ingot into solder wires through extrusion and drawing. The silver-free copper based solder and the preparation method thereof have the advantages that the soldering temperature is 815-865 DEG C and satisfies the process requirement, high silver based solders can be replaced, the cost is low, and the metallographic grain size after welding is low.

Owner:佛山市泓实机械制造有限公司

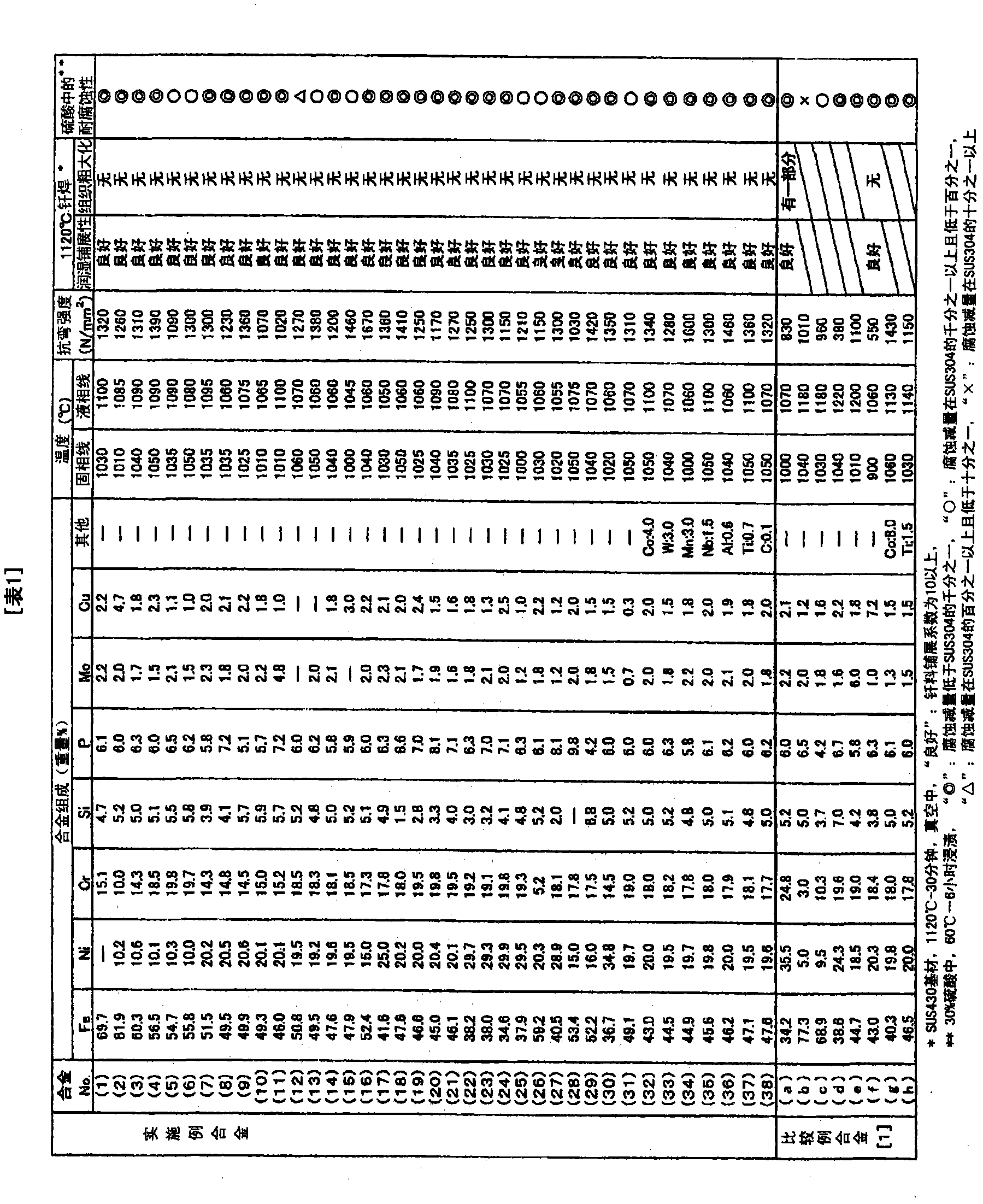

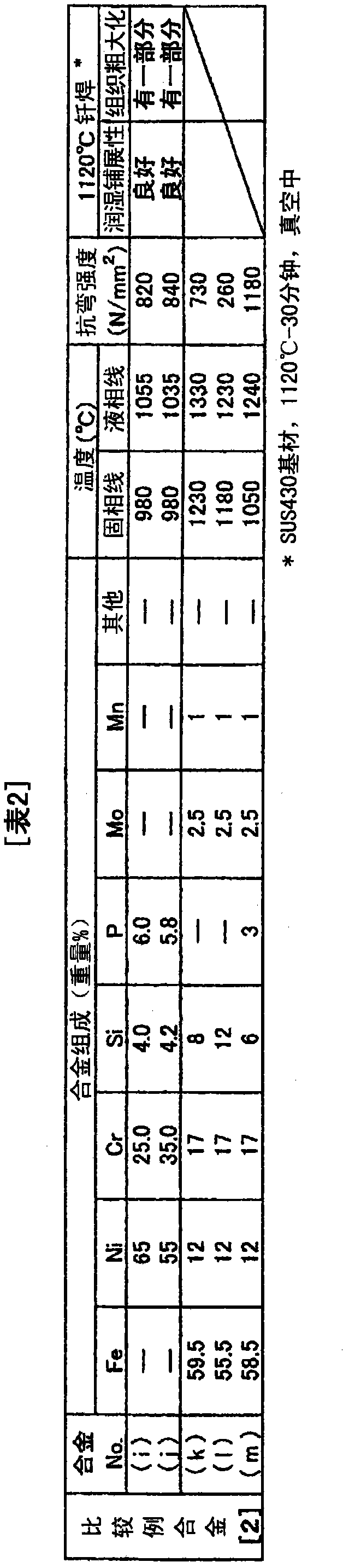

Iron-base heat- and corrosion-resistant brazing filler metals

ActiveCN102006968APractical BrazingImprove heat resistanceTransportation and packagingWelding/cutting media/materialsFiller metalCorrosion resistant

The invention provides at a low cost iron-base heat- and corrosion-resistant brazing filler metals which make it possible to braze parts made of a base metal selected from among various stainless steels, particularly ferritic stainless steels, at a practical temperature (of 1120 DEG C or below) and are excellent in the wetting property against the base metal and which can attain excellent resistance to corrosion by sulfuric acid or nitric acid and high strength without coarsening the structure of the base metal. An iron-base heat- and corrosion-resistant brazing filler metal characterized by comprising 30 to75wt% of Fe, at most 35wt%of Ni and 5 to 20wt% of Cr in a total content of Ni and Cr of 15 to 50wt%, and at most 7wt% of Si and 4 to 10wt% of P in a total content of Si and P of 9 to 13wt%, preferably, an iron-base heat- and corrosion-resistant brazing filler metal as described above, characterized by further containing 0.5 to 5wt% of Mo and / or 0.3 to 5wt% of Cu in a total amount of Mo and Cu of 1 to 7wt%.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

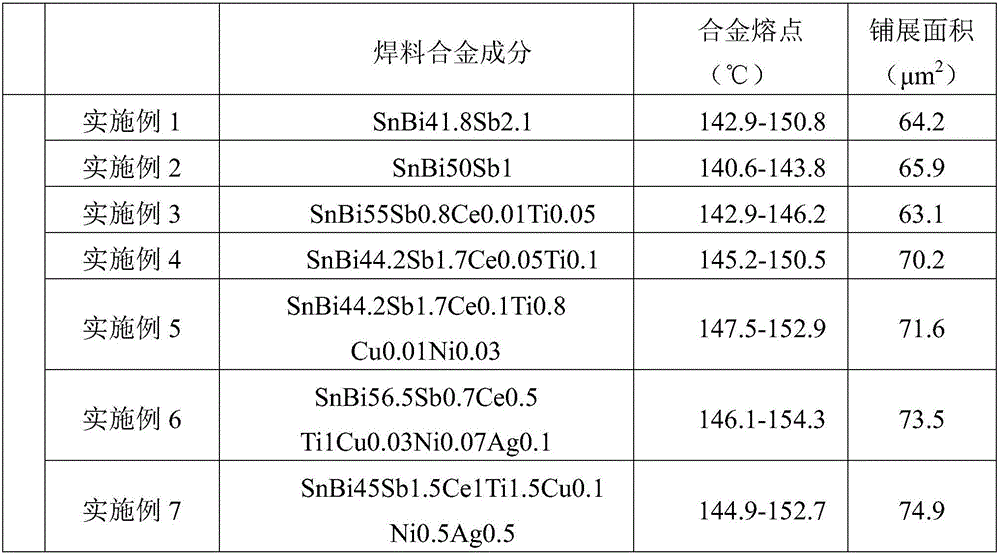

SnBiSb-series low-temperature lead-free solder and preparation method thereof

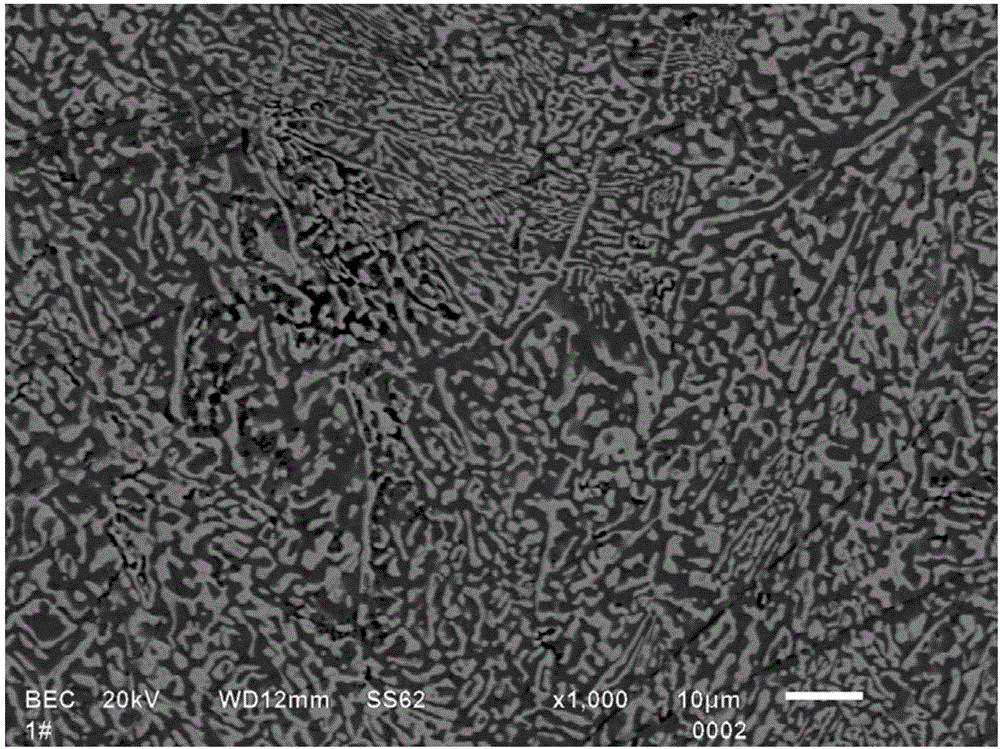

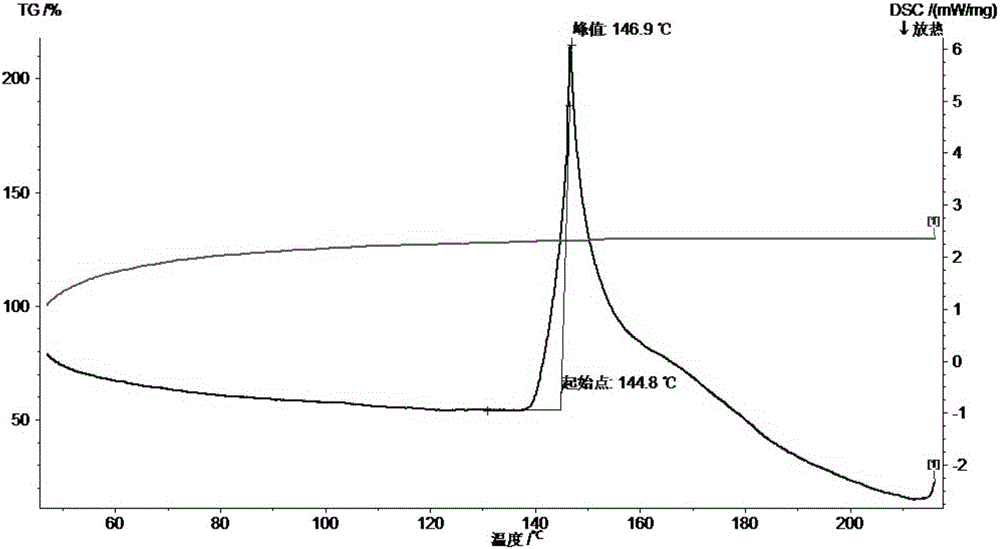

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

Rare-earth plating aid for hot dip tinning and preparation method thereof

InactiveCN102660724AImprove thermal stabilityGood removal effectHot-dipping/immersion processesTinningCopper plating

The invention discloses a rare-earth plating aid for hot dip tinning and a preparation method thereof. 1 liter of rare-earth plating aid comprises the following raw materials by weight: 80 to 150 grams of inorganic salt, 50 to 100 grams of organic acid, 15 to 25 grams of organic amine salt, 2 to 12 grams of rare-earth compounds and a solvent, wherein the raw materials are mixed, and the solvent is added to 1 liter of constant volume. According to the rare-earth plating aid, the heat stability and the capacity of removing an oxidation film of the plating aid are improved, the corrosivity is reduced, and the capacity of molten tin liquor to the adsorption, moistening and spreading of copper matrixes (copper plating layers) is improved obviously under the modified action of the rare-earth compounds; and a tinning layer of which the thickness is 6 to 9 micrometers can be obtained by one-time dip plating, and powerful guarantee is provided for the weldability and oxidation resistance of products such as electronic leads.

Owner:HEFEI UNIV OF TECH

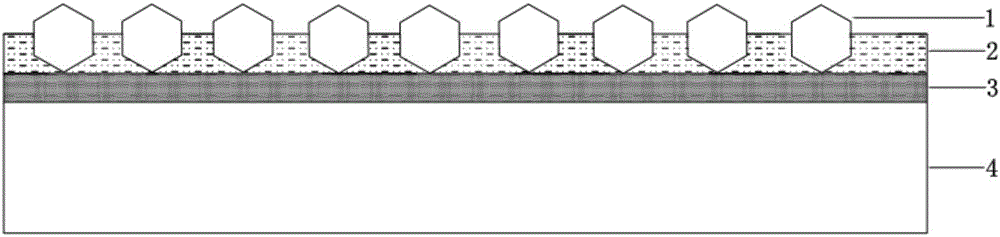

Brazed superhard abrasive tool and preparation method thereof

ActiveCN106737244AReduce heat damageReduce bond strengthBonded abrasive wheelsGrinding devicesSuperhard materialCopper

The invention belongs to the technical field of superhard material products, and particularly relates to a brazed superhard abrasive tool and a preparation method thereof. The brazed superhard abrasive tool comprises a substrate and a brazing filler metal layer arranged on the substrate. The brazing filler metal layer comprises a nickel-based brazing filler metal layer close to the substrate, and a copper-based brazing filler metal layer arranged on the surface of the nickel-based brazing filler metal layer. Superhard abrasive grains are embedded in the copper-based brazing filler metal layer. The thickness of the copper-based brazing filler metal layer is smaller than the grain size of the superhard abrasive grains. According to the brazed superhard abrasive tool, the substrate, nickel-based brazing filler metal, copper-based brazing filler metal and superhard abrasive composite structure is formed, the bonding strength between the substrate, the brazing filler metal and the superhard abrasive is improved, and meanwhile the brazing temperature is low, so that thermal damage to the superhard abrasive during brazing is reduced.

Owner:FUNIK ULTRAHARD MATERIAL

SMT no-lead tinol

InactiveCN101088695AOvercoming lead problemsLead issues comply withWelding/cutting media/materialsSoldering mediaOrganic acidSuccinic acid

The SMT no-lead tinol includes solvent, thixotropic agent, adhesive, composite activating agent, surfactant and antioxidant, and the composite activating agent consists of methyl succinic acid, organic acid and halogen salt. The SMT no-lead tinol has the features of high wettability, good printing performance, homogeneous and fine paste, light color of the soldered residue, low corrosion and high storage stability, and is suitable for use in twice reflux soldering of double-sided circuit board in electronic industry.

Owner:SHENZHEN UNIBRIGHT TECH

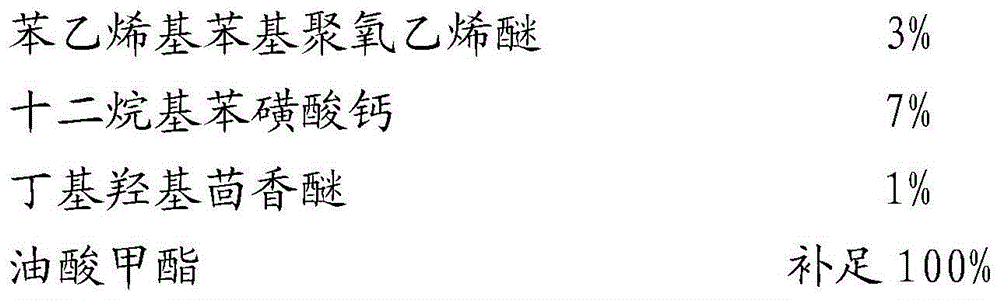

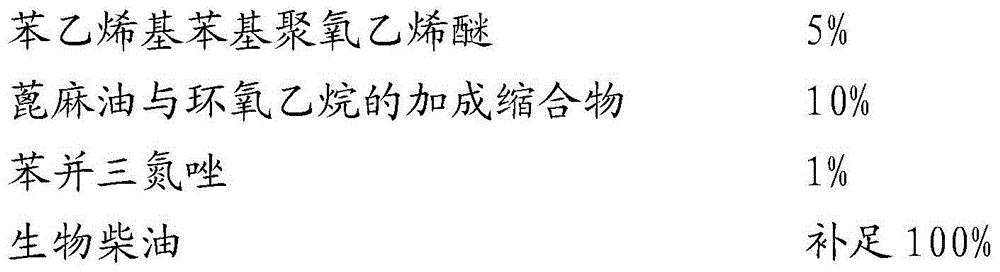

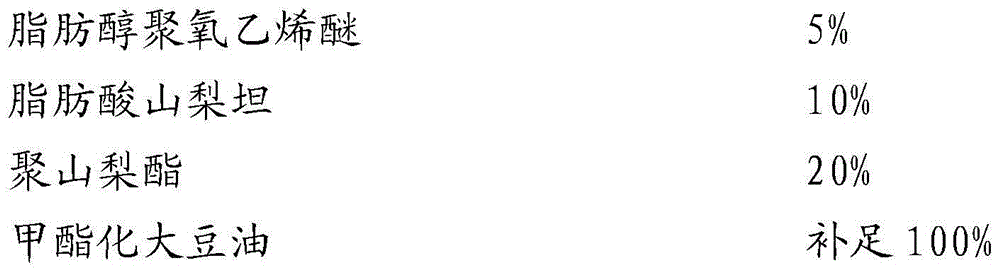

Pesticide synergist and preparation method

InactiveCN104823972AGood wetting and spreadingExtended spreading timeBiocideFungicidesPesticide productPesticide synergists

The invention discloses a pesticide synergist and a preparation method and belongs to the technical field of pesticide. The pesticide synergist serving as a pesticide auxiliary and a synergist can be directly added during production of pesticide preparations, and can be sprayed before field atomizing of peasant households and after being mixed uniformly in a pesticide preparation product bucket. The pesticide synergist can be used as a functional auxiliary during processing of the pesticide preparations and can server as the pesticide synergist to lower surface tension, so that pesticide efficacy is improved. The pesticide synergist is suitable for all pesticide products and can be popularized and applied in pesticide preparation processing enterprises and peasant households.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

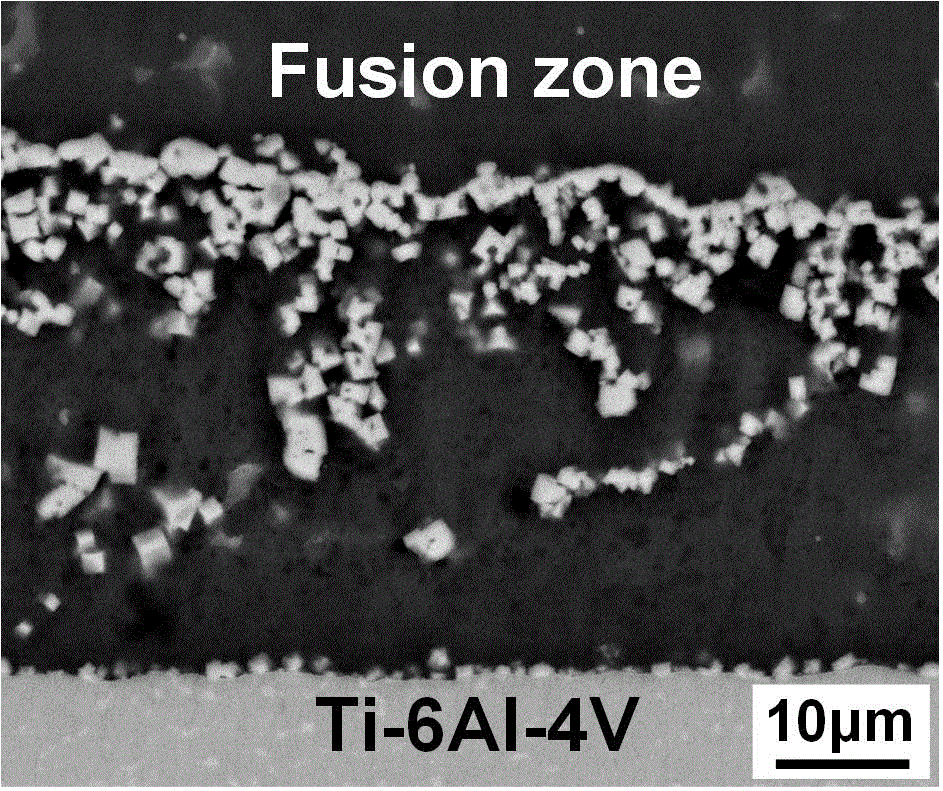

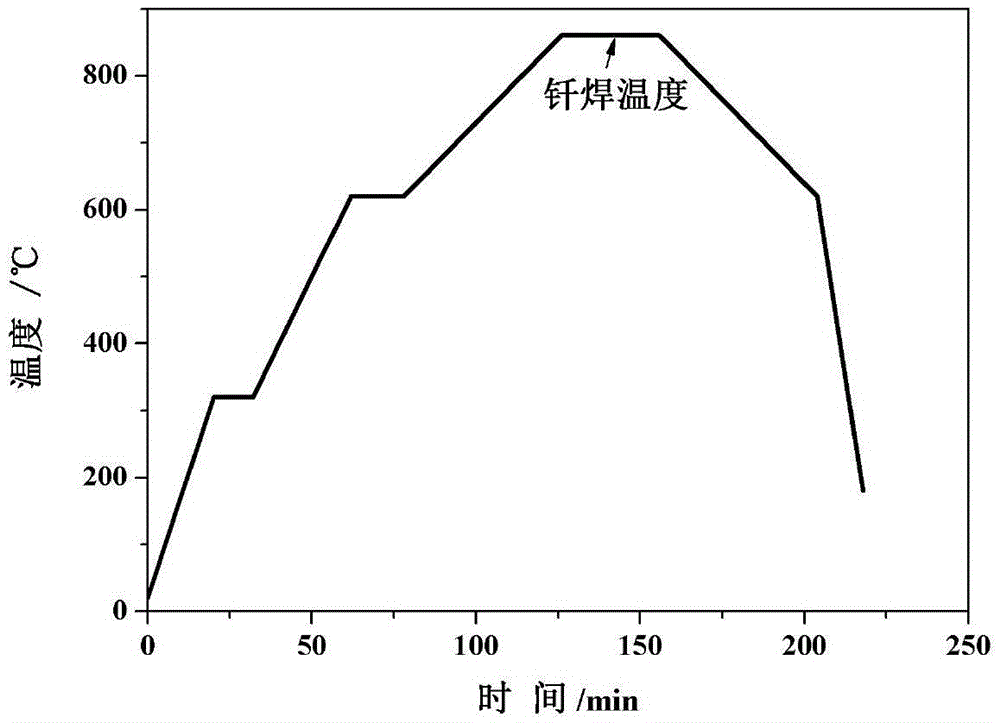

Brazing filler metal precoating vacuum brazing method for titanium alloy and aluminum alloy

ActiveCN103143802AGood wetting and spreadingRestrict growthSoldering apparatusSurface cleaningTitanium

The invention relates to a brazing filler metal precoating vacuum brazing method for a titanium alloy and an aluminum alloy. The method comprises the steps of: (1) conducting surface cleaning on a titanium alloy plate and an aluminum alloy plate, (2) coating and airing a plating assistant at a to-be-brazed part of the titanium alloy plate, (3) placing the to-be-brazed part of the titanium alloy plate in a brazing filler metal pool for processing for a period of time, (4) grinding a brazing filler metal layer coated on the titanium alloy plate, requiring the brazing filler metal layer to be smooth and uniform in thickness, and (5) overlapping the to-be-brazed parts of the titanium alloy plate and the aluminum alloy plate, and placing in a vacuum brazier for brazing. With the adoption of the brazing method, the connection is reliable and is not broken; the technique is simple; the manufacturing cost is low; the brazing is conducted in the vacuum brazier; an oxidation film is prevented from being generated on the surface of the aluminum alloy due to a vacuum atmosphere; titanium is prevented from reacting with active gas; smooth wet spreading is ensured; and the method facilitates improving the quality of a brazed joint.

Owner:浙江润光照明科技有限公司

Water-based environment-friendly metal welding base metal protective agent and preparation method thereof

ActiveCN106141501ALow costSimple processWelding/cutting media/materialsSoldering mediaWater basedFilm-forming agent

The invention discloses a water-based environment-friendly metal welding base metal protective agent. The water-based environment-friendly metal welding base metal protective agent is prepared from, by weight percent, 9%-15% of a polymer film-forming agent, 8%-16% of a spreading agent, 5%-10% of a wetting flatting agent, 0.5%-5% of a rust-inhibiting additive, 12%-18% of a cosolvent and 45%-65% of deionized water. The raw materials adopted in the protective agent are environment-friendly, non-poisonous and degradable components; the prepared metal welding base metal protective agent can effectively avoid welding splash adhesion, is easy to clean and moderate in viscosity, and has excellent antirust performance; and the protective agent is suitable for multiple welding positions of flat welding, transverse welding, vertical welding, overhead welding and the like. The invention further discloses a preparation method of the water-based environment-friendly metal welding base metal protective agent. According to the preparation method, no heating is needed, operation is easy, the application range is wide, and cost is low.

Owner:南京尚易环保科技有限公司

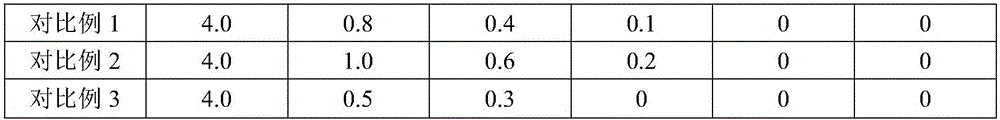

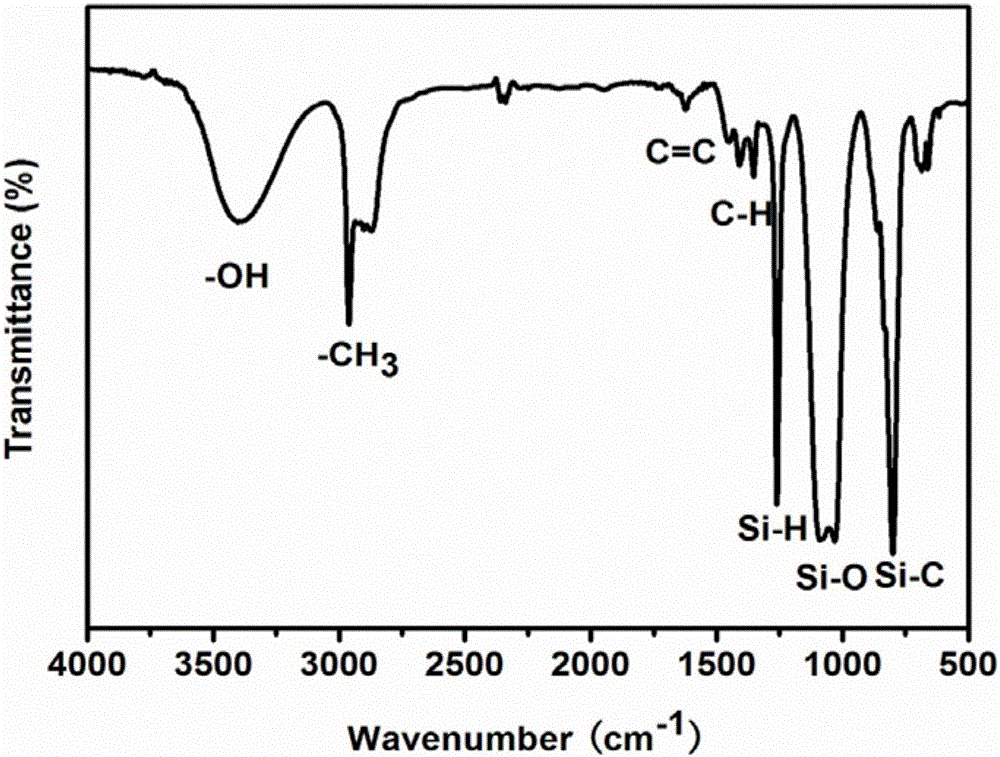

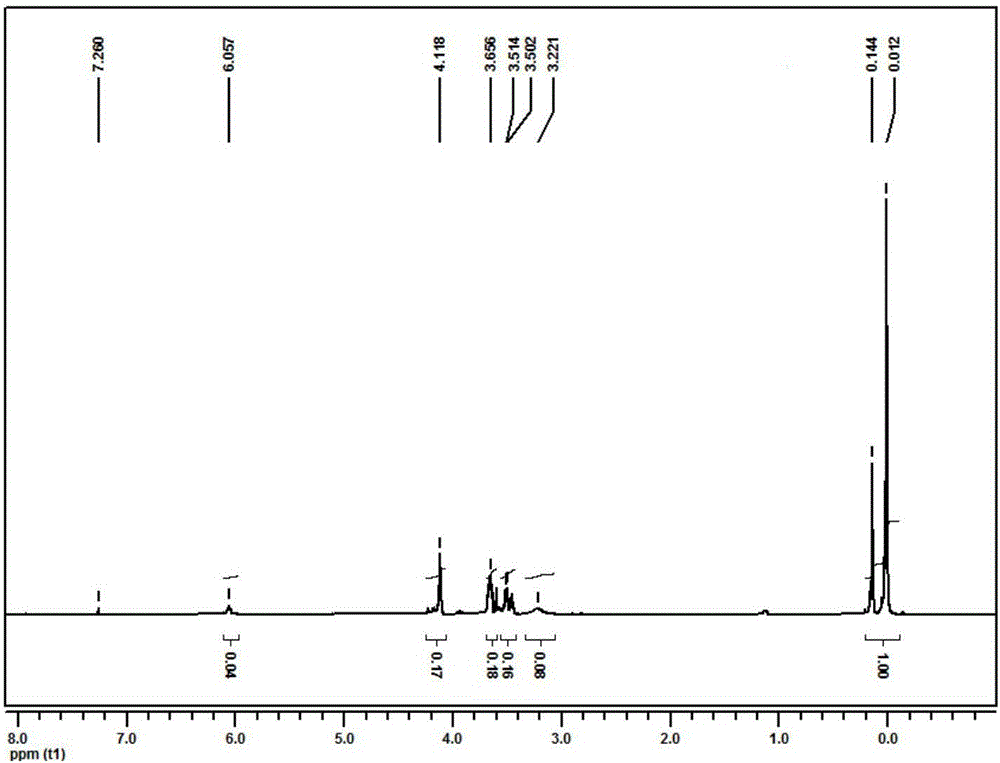

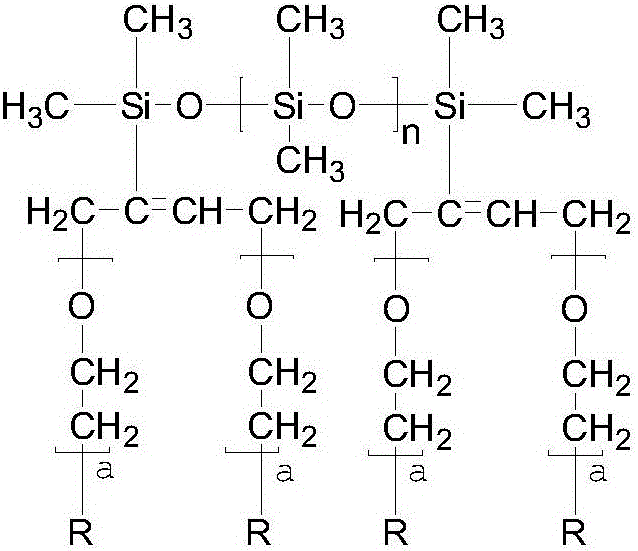

Butynediol ethoxylate modified bola type organosiloxane and preparation method thereof

The invention discloses butynediol ethoxylate modified bola type organosiloxane and a preparation method thereof. The preparation method includes: butynediol ethoxylate and tetramethyl dihydro disiloxane have reaction under the effects of a platinum catalyst and an amine composite catalyst to obtain butynediol ethoxylate modified tetramethyl disiloxane; balanced copolymerization is performed under the effect of a catalyst to obtain the butynediol ethoxylate modified bola type organosiloxane. The preparation method has the advantages that the method is large in grafted hydrophilic group proportion, high in grafting rate, free of solvent adding and suitable for large-scale industrial production; the prepared hydrophilic group butynediol ethoxylate modified bola type organosiloxane is good in water solubility, good in wetting and spreading ability, high in surface activity and high in defoaming / foam inhibiting performance.

Owner:CHINA RES INST OF DAILY CHEM IND

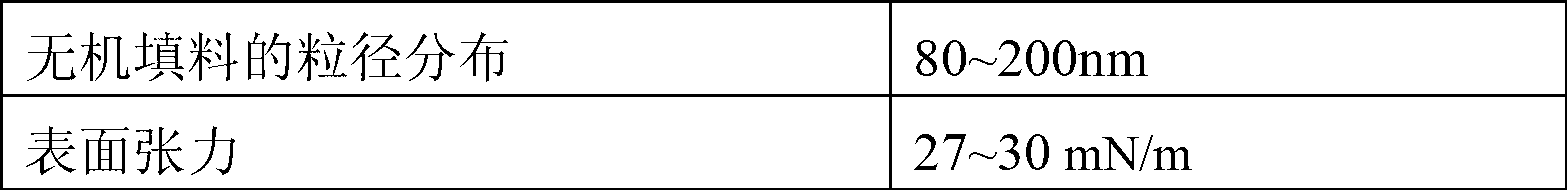

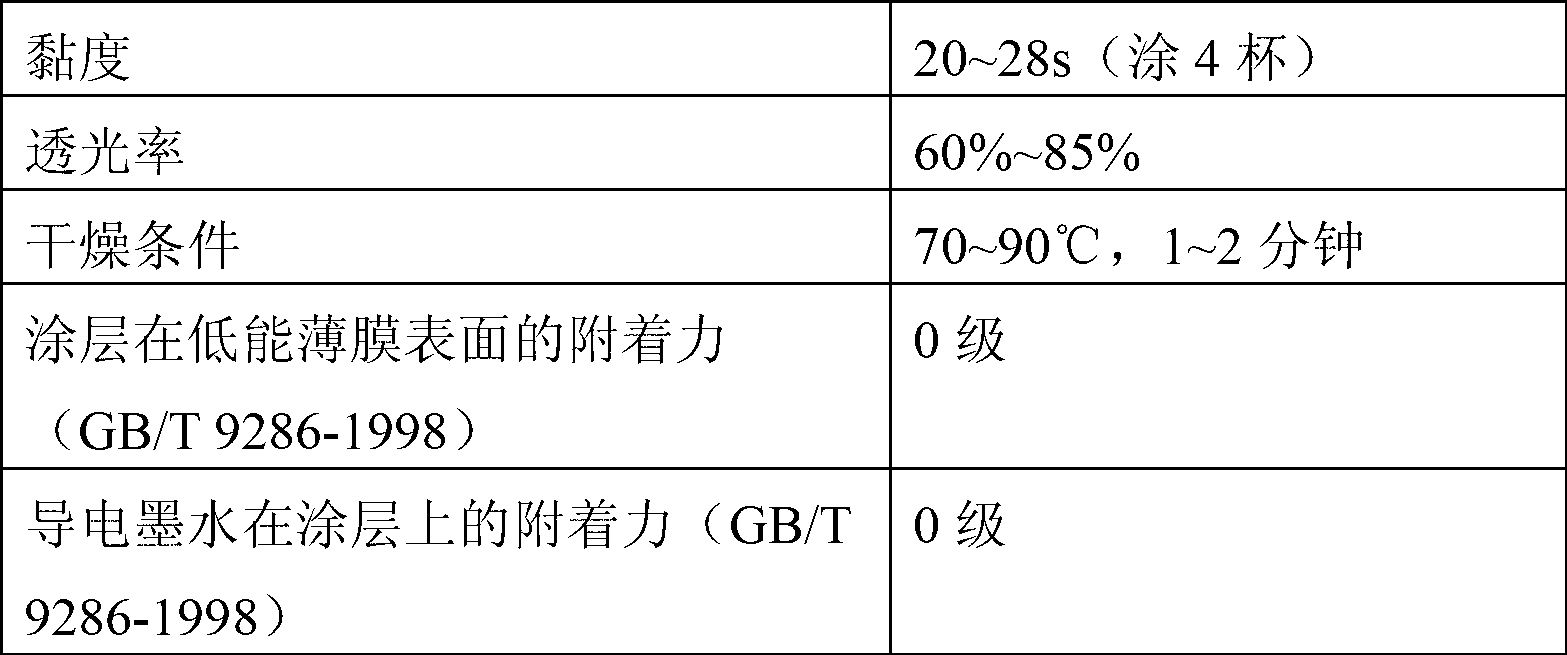

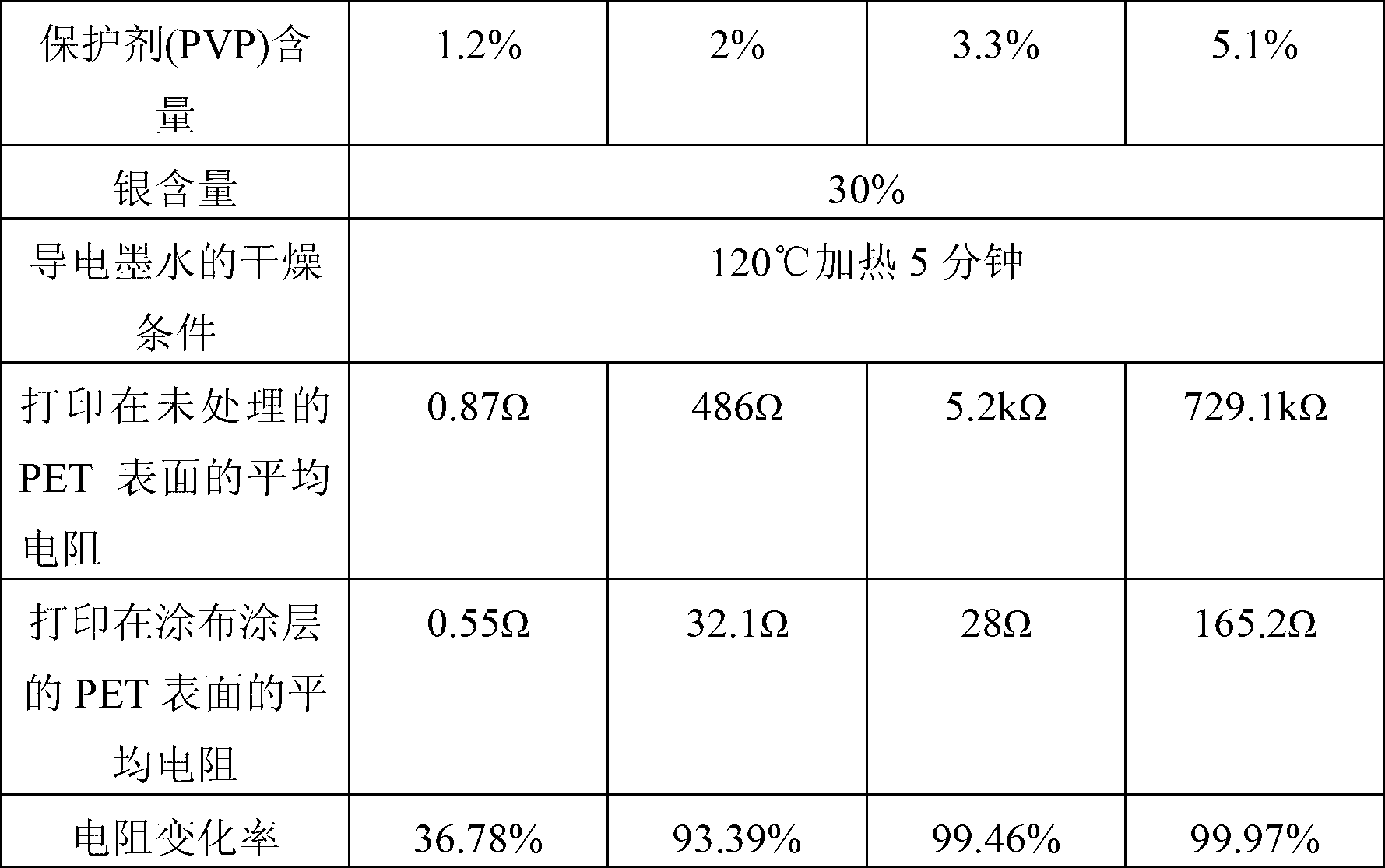

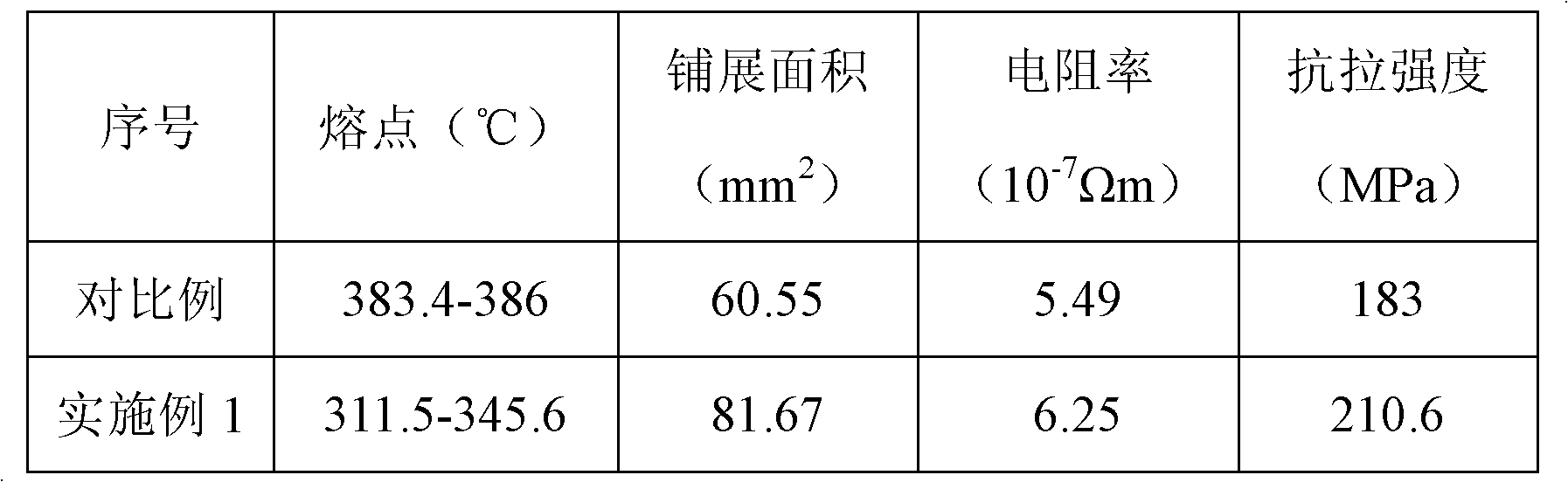

Environment-friendly nano-silver conductive ink adhesive force promoting coating slurry and preparation method thereof

ActiveCN103013317ASimple preparation processNo pollution in the processPolyurea/polyurethane coatingsNano al2o3Slurry

The invention relates to an environment-friendly nano-silver conductive ink adhesive force promoting coating slurry and a preparation method thereof, belonging to coating industry. The slurry comprises the following components in parts by weight: 10-24 parts of resin vehicle, 52-70 parts of solvent, 15-25 parts of inorganic filler and 5-8 parts of addition agent. The coating slurry provided by the invention is simple in a preparation technology and suitable for coating and basically has no pollution to environments. A coating with high adhesive force can be obtained with low resin content through compounding of polyurethane and chlorinated polypropylene. A coupling agent can generate a both-way junction effect in a low surface energy thin film-coating interface and a coating-conductive ink interface so that the binding force of the interfaces is reinforced. The wear resistance and absorbing capacity of the coating are increased due to the addition of nanometer aluminium oxide and silicon dioxide, the wetting spreading performance of the conductive ink is facilitated, and the resistance can be reduced by 30%-99.9% according to the difference of components of the conductive ink.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

ZnSn-base high-temperature lead-free soft solder and preparation method thereof

InactiveCN102672367ALow melting pointGood brazing processWelding/cutting media/materialsSoldering mediaRare earthLanthanum

The invention belongs to the technical field of braze soldering flux for electronic packaging and assembly, and discloses a ZnSn-base high-temperature lead-free soft solder and a preparation method thereof. The ZnSn-base high-temperature lead-free soft solder consists of the following components in percentage by weight: 15 to 40 percent of tin, 0.5 to 8 percent of copper, 0.1 to 1 percent of lanthanum and neodymium mixed rare earth, 0.1 to 3 percent of magnesium and / or 0.1 to 2 percent of bismuth and the balance of zinc. The ZnSn-base high-temperature lead-free soft solder has the advantages of no toxicity and no pollution, is high in wetting spreadability and high in tensile strength and mechanical property, and can meet the using requirement of brazing and replace high-lead solders which are applied widely at present or Au-base solders with high price to meet the requirements of the fields of electronic packaging and assembly; and a melting point is between 250 and 450 DEG C.

Owner:HENAN UNIV OF SCI & TECH

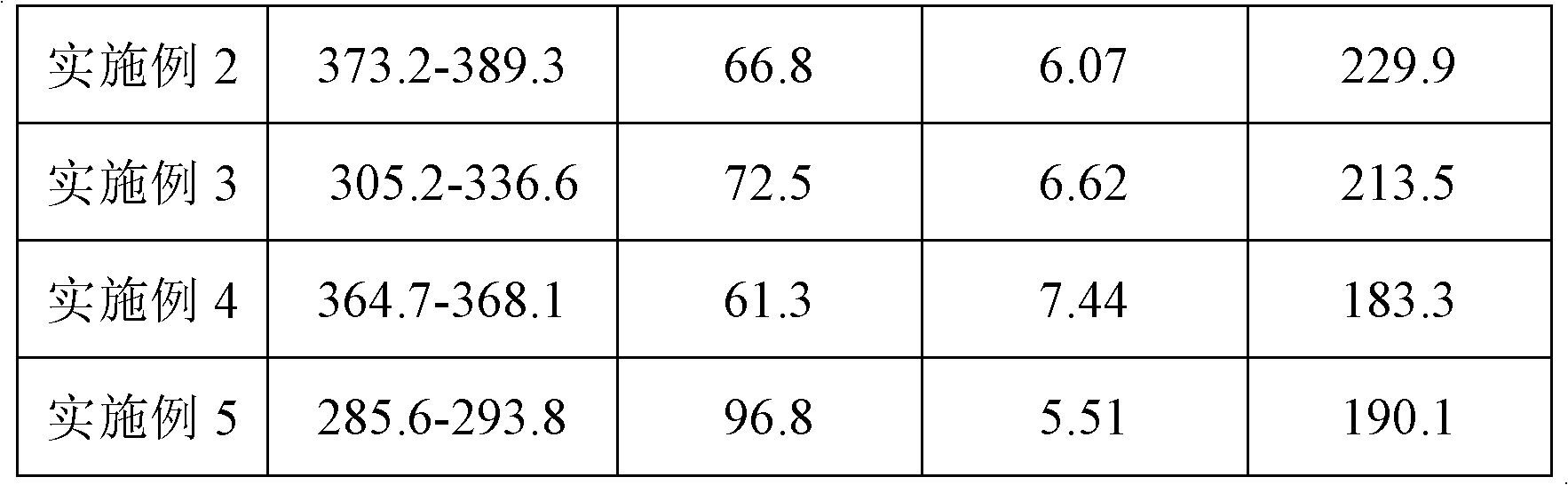

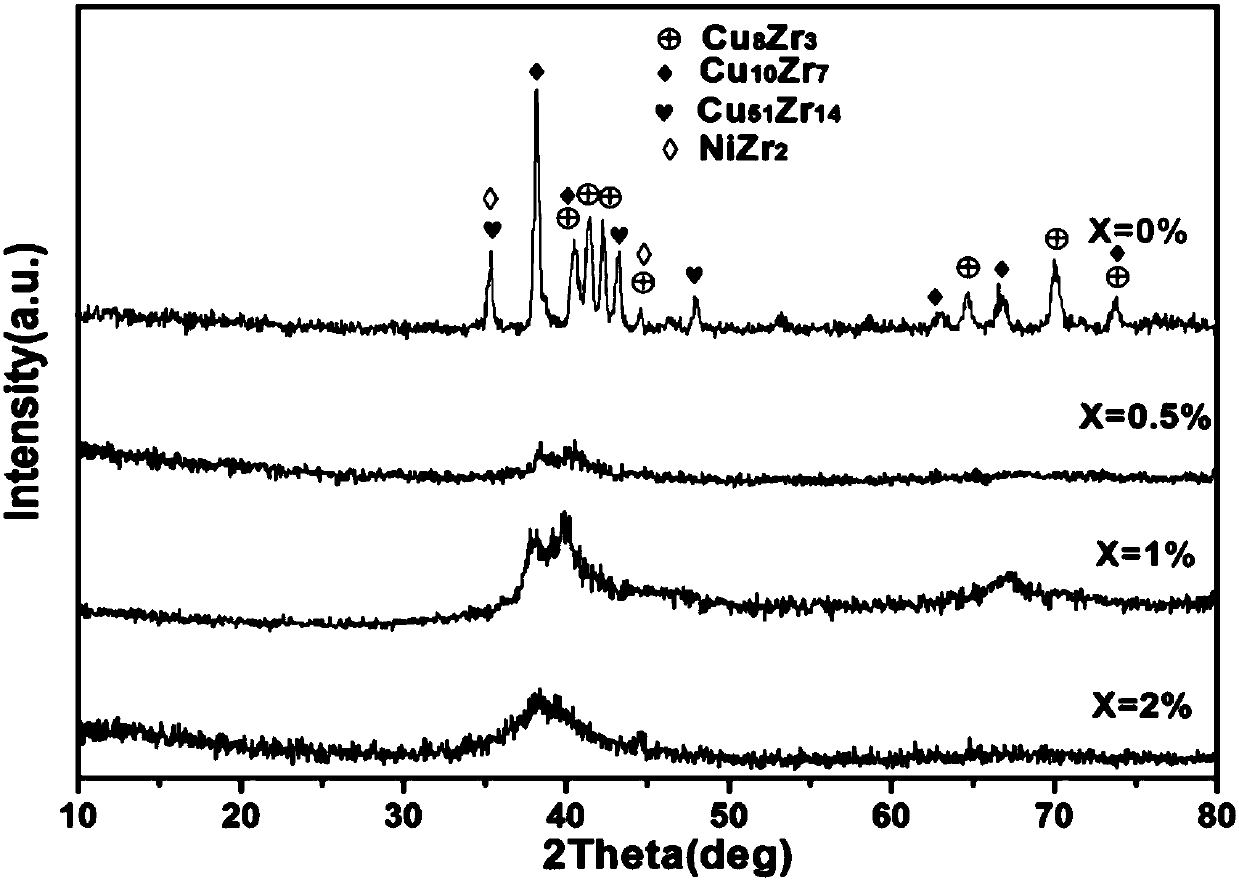

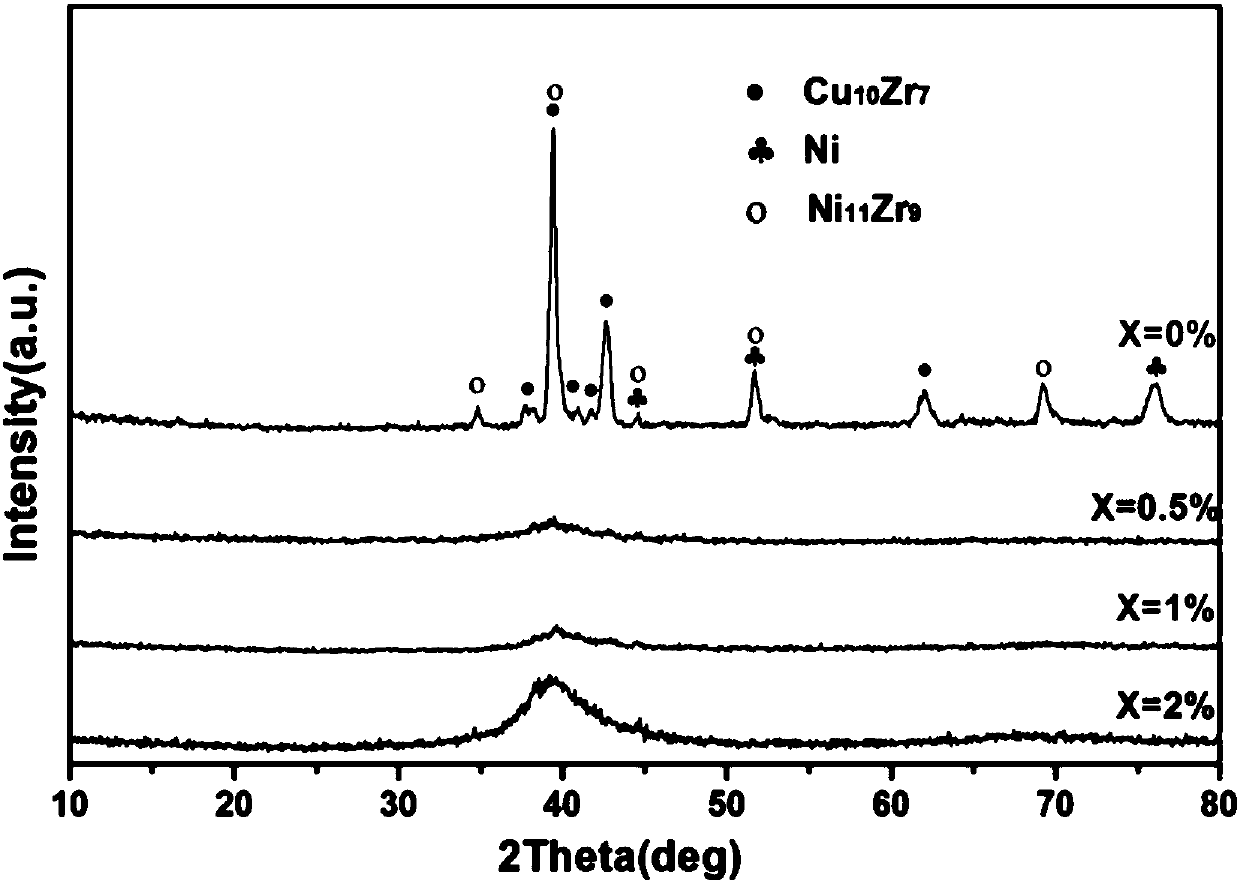

Si element contained Ti-based amorphous alloy and preparing method thereof

ActiveCN107620016AEnhanced Amorphous Formation AbilityGood wetting and spreadingChemical compositionFiller metal

The invention discloses a Si element contained Ti-based amorphous alloy. The Si element contained Ti-based amorphous alloy is characterized in that the amorphous alloy comprises five components including Ti, Cu, Zr, Ni and Si, and the chemical component is (TiaCubZrcNid)1-eSie, wherein 45at.%<=a<=55at.%, 14at.%<=b<=20at.%, 15at.%<=c<=27at.%, 10at.%<=d<=13at.%, 0at.%<e<=2at.%, and a+b+c+d=100%. According to the Si element contained Ti-based amorphous alloy, the Si element is selected as an alloy component, and the amorphous forming ability of the Ti-Cu-Zr-Ni alloy is improved. In addition, theelements including the Cu and the Ni are added, and therefore the melting point of Ti-based amorphous brazing filler metal can be reduced, the wetting spreadability of the brazing filler metal is better improved, and the Ni and the Zr can improve the stability performance of subcooled liquid and the possibility of amorphous formation.

Owner:CHINA UNIV OF MINING & TECH

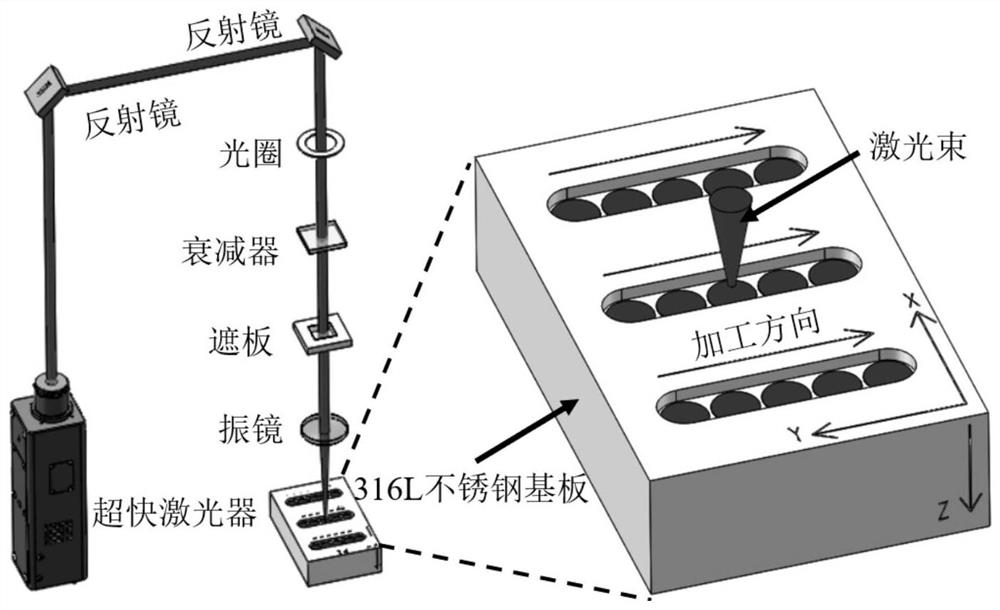

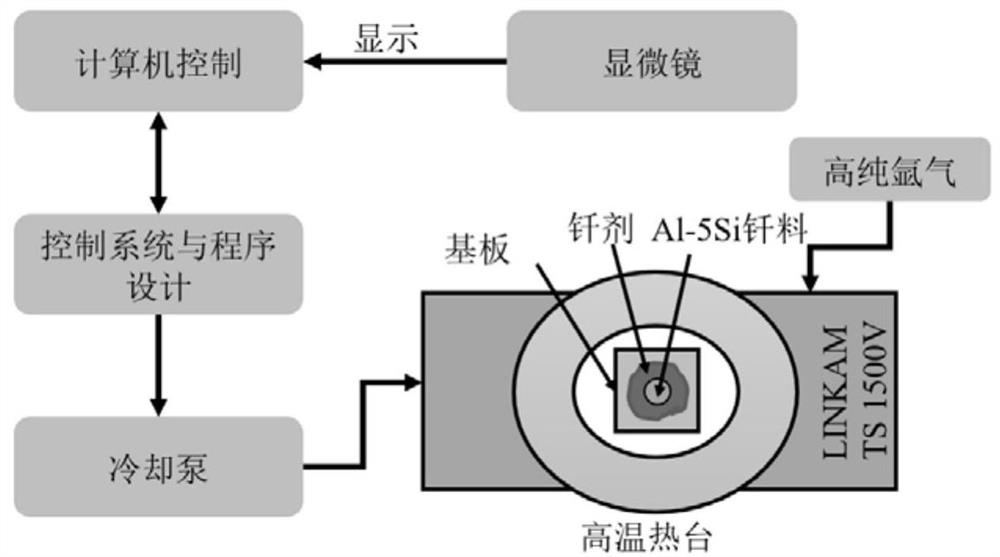

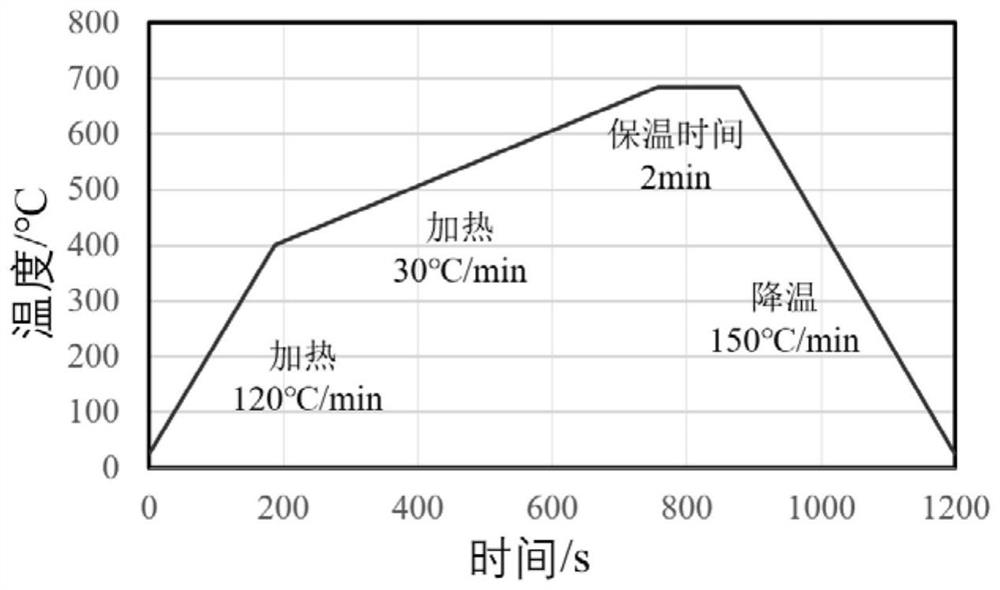

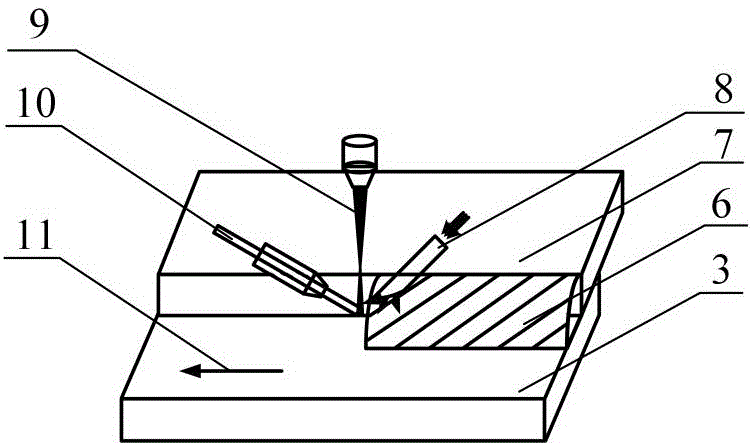

Method for improving wetting and spreading performance of reaction wetting system material

PendingCN111673284AChange surface topographyUnique surface topographyLaser beam welding apparatusMicro nanoLaser processing

The invention discloses a method for improving the wetting and spreading performance of a reaction wetting system material. The method comprises the following steps that the surface of a stainless steel base plate is scanned and processed by adopting an ultrafast laser processing technology to obtain a micro-nano stripe texture of which the stripe average width is 1.2-1.4 microns and the stripe average spacing is 1.4-1.6 microns; and the wetting angle of the same brazing filler metal on the scanned and processed stainless steel base plate is 0.9 degrees - 3.3 degrees smaller than the wetting angle of the same brazing filler metal on an unprocessed stainless steel base plate. According to the method, microtexture processing is carried out on the surface of the reaction wetting system material through ultrafast laser, the surface appearance of the reaction wetting system material is changed, the surface roughness is changed, the unique morphology of the micro-nano stripe texture is obtained, and the unique morphology of the micro-nano stripe texture can greatly enhance the capillary action in the brazing filler metal wetting and spreading process, so that the wetting and spreading power of the brazing filler metal on the surface of the reaction wetting system material is improved, the brazing filler metal reacts with the base plate more sufficiently, and the application prospectis great.

Owner:SHANGHAI UNIV OF ENG SCI

Brazing flux used for melt-brazing of aluminum alloy/stainless steel

InactiveCN105215575APromote spreading wettingGood jointWelding/cutting media/materialsSoldering mediaMechanical propertyTetrafluoroaluminate

The invention relates to brazing fluxes used for welding, in particular to a brazing flux used for melt-brazing of aluminum alloy / stainless steel. The brazing flux is characterized in that the brazing flux is prepared by mixing and grinding powder of potassium tetrafluoroaluminate+potassium hexafluoroaluminate (KAlF4+K3AlF6) eutectic, potassium fluorosilicate, potassium fluoroborate, aluminum, zinc, tin and copper; the brazing flux comprises, by weight, 40%-60% of potassium tetrafluoroaluminate+potassium hexafluoroaluminate (KAlF4+K3AlF6) eutectic, 0-10% of potassium fluorosilicate (K2SiF6), 0-10% of potassium fluoroborate (KBF4), 10%-30% of aluminum (Al), 0-10% of zinc (Zn), 0-10% of tin (Sn), and 0-10% of copper (Cu); the sum of the weight percents of all the raw materials is 100%. According to the brazing flux, the good wetting spreading property of an existing brazing flux is maintained, and meanwhile, the texture of a connector is improved, and forming of brittle intermetallic compounds is reduced, so that the mechanical property of the connector of melt-brazing is improved, and finally dissimilar metal of the aluminum alloy and the stainless steel is connected reliably with high quality. The brazing flux further has the advantages that the melt-brazing process is relatively simple; the energy consumption and the cost of the raw materials are low; the residual quantity of the brazing flux is small after welding; and residues are easy to clean up.

Owner:WUHAN UNIV OF TECH

Tin-zinc-bismuth-copper leadless solder with low cost and welding spot thereof

InactiveCN101733575ALow costEasy to solderWelding/cutting media/materialsSoldering mediaWeld seamTin

The invention relates to a leadless solder with low cost, in particular to a tin-zinc-bismuth-copper leadless solder with low cost and a welding spot (or a welding seam) formed by the same, and belongs to the fields of the technique and the application of brazing materials. The solder comprises the following components by mass percent: 6.0-10.0% of Zn, 1.0-3.0% of Bi, 0.5-1.0% of Cu and the balance of Sn. Compared with an Sn-Pb solder and a traditional Sn-Zn solder, the invention provides leadless solder alloy which has no pollution and is easy to weld. The solder has the following advantages: (1) the melting point is lower than 200 DEG C, the temperature is lower than the heat resistance temperature of the packaging of an IC and approaches to the eutectic melting point of Sn-Pb, the properties of wetting and spreading are excellent, and the solder is easy to weld; and (2) the solder completely adopts alloying elements with low cost of raw materials. The welding spot (seam) formed by the solder has better bonding strength and use reliability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Silver-based cadmium-free medium-temperature solder and preparation method thereof

InactiveCN102248323AImprove liquidityGood wetting and spreadingWelding/cutting media/materialsSoldering mediaElectrolysisIndium

The invention provides silver-based cadmium-free medium-temperature solder and a preparation method thereof and relates to medium-temperature solder and a preparation method thereof. The invention aims to solve the problems of high cost and high melting temperature of silver-based cadmium-free solder produced in the prior art. The silver-based cadmium-free medium-temperature solder is prepared from the following components in part by weight: 49 to 52 parts of silver, 14 to 16 parts of electrolytic copper, 2 to 3 parts of indium, 8 to 12 parts of stannum, 8 to 13 parts of zinc, 1.0 to 2.0 parts of copper phosphorus alloy, 1.0 to 1.5 parts of manganese, 0.2 to 0.7 part of zirconium and 5.05 to 10.8 parts of copper foil wrapped rare earth lanthanum. The preparation method particularly comprises the following steps of: 1, melting and mixing; 2, casting; and 3, extruding. The silver-based cadmium-free medium-temperature solder and the preparation method thereof have the advantages that: 1,the preparation cost is low and the prepared silver-based cadmium-free medium-temperature solder is low in temperature; 2, cadmium is not contained, so damage to a human body and environmental pollution are reduced; and 3, the plastic toughness is high, so a welding wire and a welding ring with the diameter of 0.5 to 2.0 can be prepared. The method is mainly used for preparing the silver-based cadmium-free medium-temperature solder.

Owner:HARBIN INST OF TECH

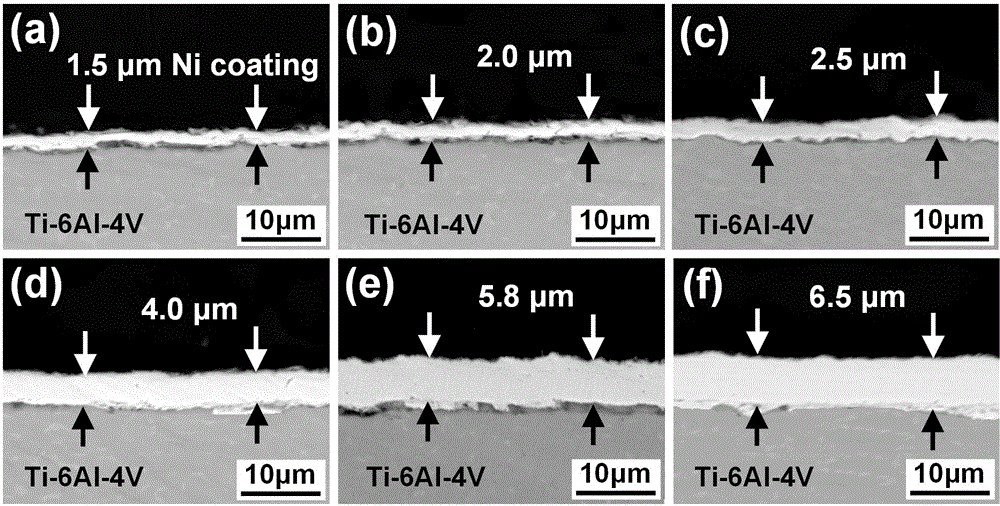

Magnesium/titanium laser melting braze welding method assisted by nickel-plated layer

InactiveCN106270878AAchieve metallurgical connectionGuaranteed to meltSoldering apparatusLap jointTitanium

The invention discloses a magnesium / titanium laser melting braze welding method assisted by a nickel-plated layer. The method is applicable to the field of dissimilar metal welding and is used for solving the problems of no occurrence of metallurgic reaction and great melting point difference between the existing magnesium / titanium. The method is characterized in that firstly, nickel is electroplated on a titanium plate subjected to acid cleaning is used as a middle layer; then, a lap joint mode that a magnesium plate is positioned at the upper part and the titanium plate is positioned at the lower part is used; meanwhile, high-pure argon gas is used for positive and opposite side protection; the magnesium / titanium connection is realized through magnesium alloy wire filling. The method has the advantages that the moistening spreading capability of the magnesium alloy on the titanium plate is effectively improved; joints without obvious defects can be obtained; the tensile strength can reach 243 N / mm; the joint efficiency is 90 percent of a magnesium plate; higher practical values are realized.

Owner:HARBIN INST OF TECH AT WEIHAI

Pb-free Sn-Bi alloy solder and preparation method thereof

InactiveCN106695161AImprove bindingImprove use reliabilityWelding/cutting media/materialsSoldering mediaSemiconductor materialsAlloy

The invention discloses Pb-free Sn-Bi alloy solder and a preparation method thereof and belongs to the technical field of Pb-free new material manufacturing. The Pb-free Sn-Bi alloy solder comprises the following components in percentage by weight: 16-18% of Bi, 0.3-0.8% of Ag, 0.1-0.3% of Fe, 0.1-0.3% of Zn, 0.1-0.3% of Sb and the balance Sn. The melting point of the Pb-free Sn-Bi alloy solder is 156-165 DEG C and meets the welding temperature requirement of components in the microelectronic industry. Moreover, the Pb-free Sn-Bi alloy solder has good wettability and spreadability, high bonding strength and good ductility for various semiconductor materials with different properties in the microelectronic industry.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

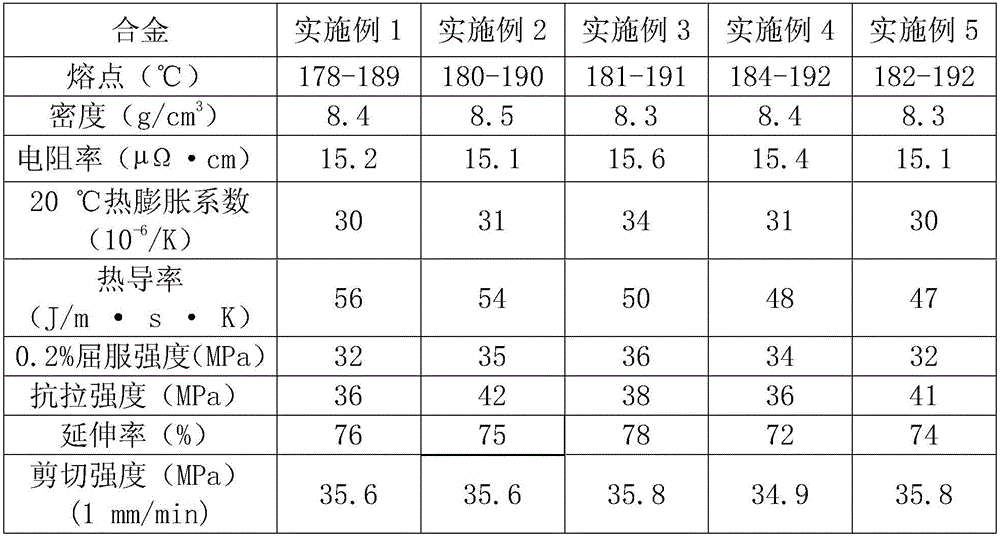

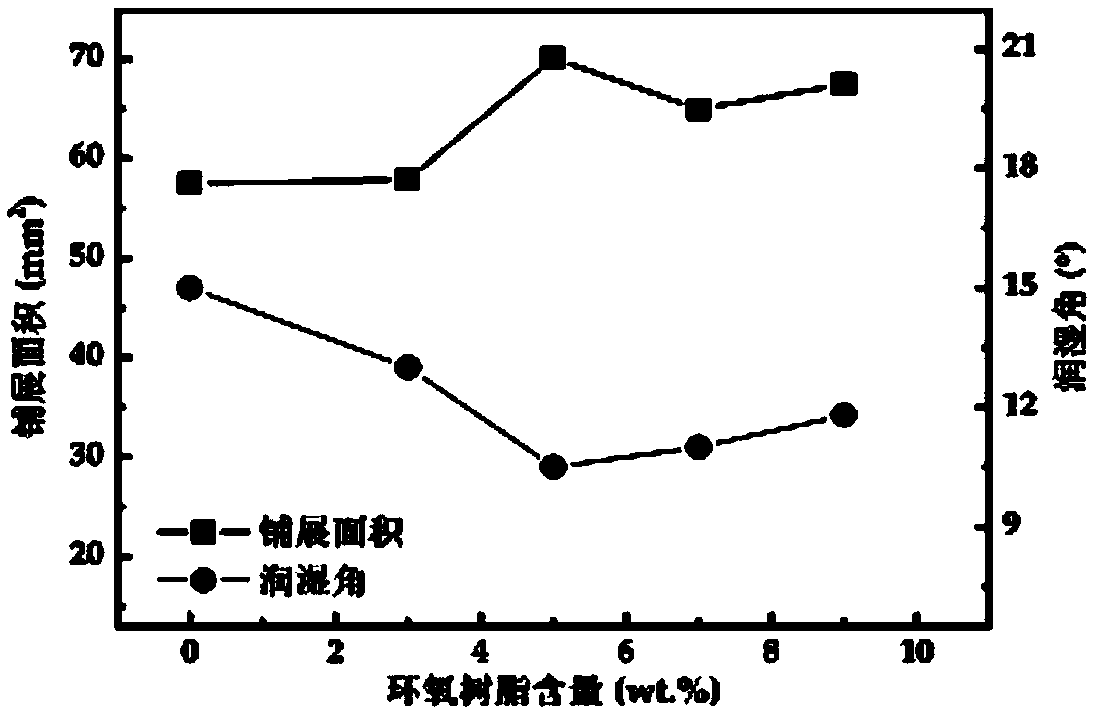

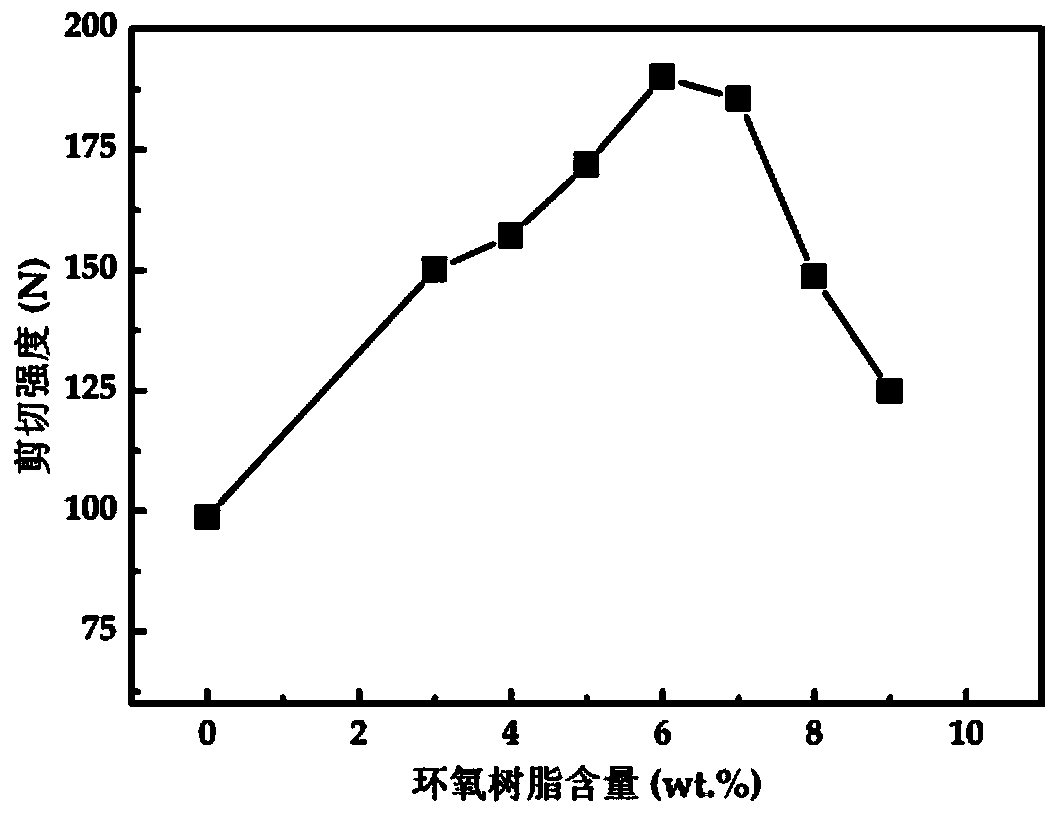

Epoxy resin composite Sn-Bi lead-free soldering paste

InactiveCN109175771AGood wetting and spreadingIncreased shear strengthWelding/cutting media/materialsSoldering mediaEpoxy resin compositeSolder paste

The invention provides an epoxy resin composite Sn-Bi lead-free soldering paste. The soldering paste is characterized by comprising the following components of, in percentage by mass, 3%-8% of epoxy resin, a curing agent, an accelerant (the ratio of the epoxy resin to the curing agent to the accelerant is 100:8-30:1-10), and the balance a commercially available Sn-Bi soldering paste. The epoxy resin is a combination of one or any two or three among Npel-127 H type bisphenol A, E44 type bisphenol A, and E51 type bisphenol A in any proportion; the curing agent is a combination of one or any twoor three among m-phenylenediamine, p-phenylenediamine, and dicyandiamide in any proportion; and the accelerant is a combination of one or any two or three of SH-A80, SH-A85, SH-A90, SH-A95, SH-A100, SH-A150 in any proportion. The composite Sn-Bi lead-free soldering paste has good wetting and spreading performances, the shear strength of a soldering head can be remarkably improved, and the soldering paste can be used for reflow soldering of components in the electronic industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Serrate double-layer wire mesh corrugated packing

ActiveCN102908976AIncreased lateral mixing performanceAchieve a breakthroughChemical/physical/physico-chemical processesEngineeringIsotope

The invention relates to a serrate double-layer wire mesh corrugated packing which forms a serrate corrugated packing sheet structure by mechanically rolling double-layer wire mesh materials, wherein the top end of the wave crest and the top end of the wave trough of a corrugated packing sheet are respectively formed by connecting smooth arc surfaces, and an arc serrate corrugated structure with a smooth tooth top is formed, and a formed corrugated ridge and the axial direction of the packing form an included angle. Compared with the prior art, the serrate double-layer wire mesh corrugated packing is easy to manufacture, excellent in fluid mechanics and mass transfer performance, especially applicable to separating of small-coefficient mixtures which are difficult to separate, such as separation preparing of isotopes, and capable of being popularized and used in the precise separation field of traditional purification of flavors, fragrances and medical intermediates.

Owner:SHANGHAI RES INST OF CHEM IND

Brazing rare earth magnesium alloy brazing filler metal and preparation method and brazing process

ActiveCN106077994AUniform compositionGood wetting and spreadingWelding/cutting media/materialsSoldering mediaRare earthFiller metal

The invention discloses brazing rare earth magnesium alloy brazing filler metal and a preparation method and a brazing process. The brazing rare earth magnesium alloy brazing filler metal comprises the following element components in percentage by weight: 13-19% of Zn, 1.0-3.0% of Ni, 1.8-4.4% of Al, 0.4-1.0% of Ti, 5.1-7.0% of Cu, 0.3-0.8% of Mn, 0.004-0.01% of La, 0.004-0.01% of Nd, and the balance of Mg. The magnesium alloy brazing filler metal reaches the brazing temperature of 420-460 DEG C, and is proper in melting temperature and uniform in components; and a magnesium alloy brazing filler metal foil piece facilitates acceleration of dispersion and interface reaction of all alloy elements in the brazing connecting process, so that the wetting spreadability and the gap filling performance of the brazing filler metal in a rare earth magnesium alloy are improved, the grains are refined, the residual stress is reduced, and the joint bonding strength is improved.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

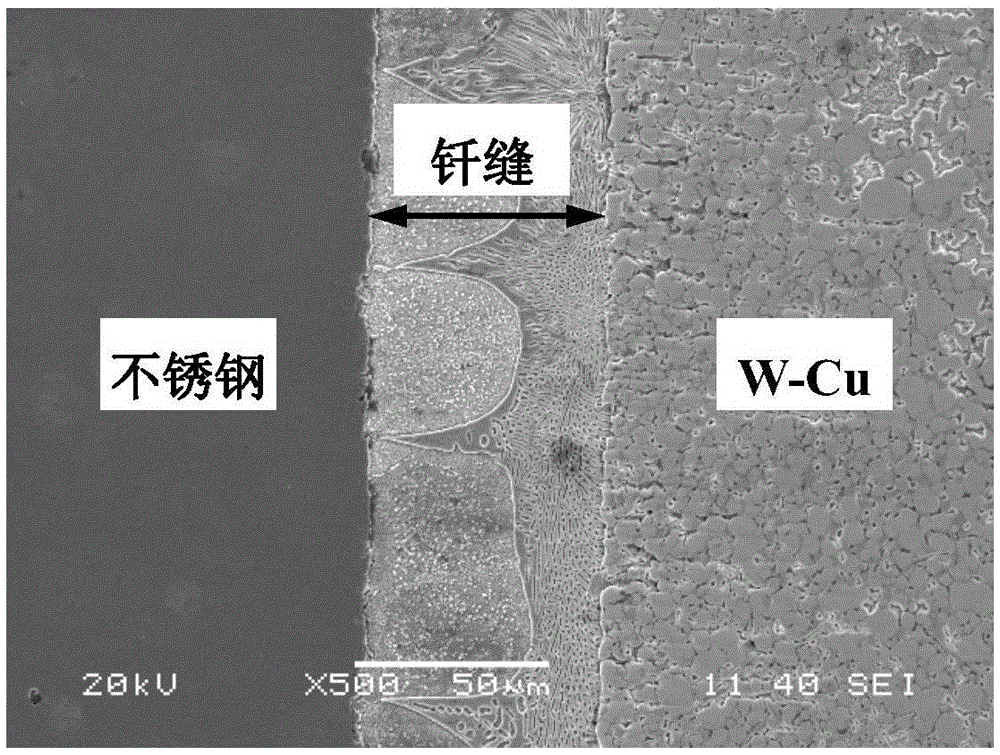

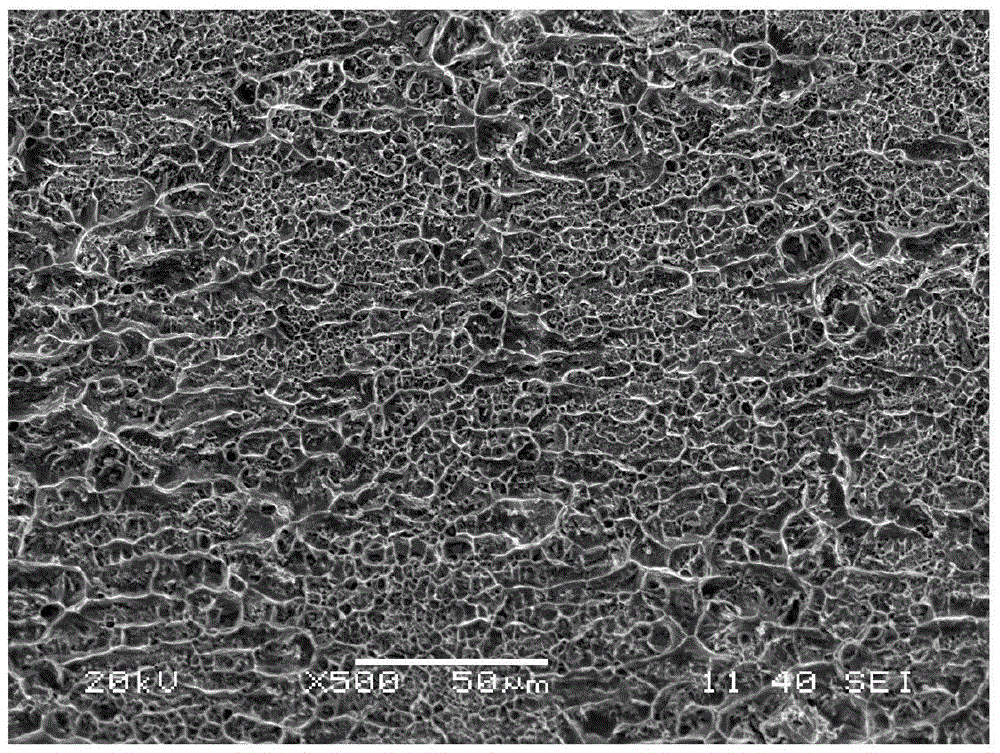

Solder used for vacuum active brazing process of W-Cu composite material and stainless steel and method

InactiveCN105618958AImprove performanceLower melting temperatureWelding/cutting media/materialsSoldering mediaUltimate tensile strengthMelting temperature

The invention discloses solder used for the vacuum active brazing process of a W-Cu composite material and stainless steel and a preparation method. The selected solder comprises, by weight, 25%-33% of Cu, 1.0%-3.5% of Ti, 3.0%-5.0% of Ni, 1.0%-2.2% of Zr, 3.5%-7.0% of Mn and the balance Ag. The solder has good lubricity for the W-Cu composite material and the stainless steel, the melting temperature is low, and melting of the solder is uniform. The vacuum active brazing process by using the solder to connect the W-Cu composite material with the stainless steel is stable and reliable. Under the vacuum condition, a component is in a vacuum state in the heating process, and the whole component is free of deformation, microscopic cracks, pores, mixed impurities and other defects; by means of the high diffusibility and interface reaction ability of the active elements (the Ag, the Cu, the Ti, the Ni and the Zr), distribution of the active elements is uniform, crystal grains are fine, and residual stress is small; the overall strength of the connector is high, and the plastic deformation ability is high; operation is easy, convenient and efficient, and repeated representation can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Nickel-based brazing filler metal for oil cooler quickly brazed in low vacuum condition

InactiveCN108247235AImprove antioxidant capacityGood wetting and spreadingWelding/cutting media/materialsSoldering mediaChemical compositionManganese

The invention relates to a nickel-based brazing filler metal for an oil cooler quickly brazed in a low vacuum condition. The nickel-based brazing filler metal comprises the following chemical components in percentage by weight: 28.0-30.0% of Cr, 5.0-7.0% of P, 3.5-4.5% of Si, 0.3-0.5% of Mn, 0.1-0.2% of Ti, 2.0-5.0% of Fe, 0-0.2% of sum of impurity elements S, O and N, 0-0.2% of C and the balanceof Ni. By adding ferrochromium powder, resistance to oxidation of an alloy in the low vacuum condition can be improved, so that a blackening problem is solved; by adding titanium and manganese, traceoxygen can be removed in the low vacuum condition, so that the wetting spreadability property of the brazing filler metal on stainless steel is improved. The novel nickel-based paste brazing filler metal has a relatively good flowing property, is moderate in cost, meets the demand on strength, and has good corrosion resistance.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL +1

RE no-lead welding alloy for wave soldering

InactiveCN1974109AExcellent brazeabilityPrevent oxidationWelding/cutting media/materialsSoldering mediaRare earthAlloy

The RE no-lead soldering alloy for wave soldering is one kind of environment friendly no-lead soldering material for soft soldering. It consists of Cu 0.1-2.5 wt%, P 0.001-1.0 wt%, Ni 0.01-1.5 wt%, RE elements Ce, Er and / or Y 0.001-1 wt%, and Sn for the rest. It is superior to available Sn-Cu no-lead soldering alloy, which has excessive metal oxide in the surface of soldering material pot, poor soldering point bridging, poor wetting and other demerits. It may be processed into soldering rod, soldering wire, soldering ball, etc. for PCB assembling, SMT, etc.

Owner:ZHUZHOU SITE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com