Iron-base heat- and corrosion-resistant brazing filler metals

A corrosion-resistant and heat-resistant technology, applied in the field of iron-based solder alloy composition, can solve problems such as low strength, high melting temperature, and reduced strength of brazed parts, and achieve high strength, good heat resistance, and corrosion resistance excellent effect

Active Publication Date: 2011-04-06

FUKUKA METAL FOIL & POWDER CO LTD

View PDF2 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As an iron-based brazing filler metal for heat exchangers based on low-cost Fe, the following patent documents 3 and 4 disclose, but in the composition shown in the examples of patent document 3, it can be seen that Contents that are not practical such as high melting temperature and low strength

Since there is no example in Patent Document 4, it cannot be verified. However, since it contains 20% by weight or more of Cr, when brazing a ferritic stainless steel base material, it is expected that the structure (grains) of the base material will be coarsened, Situations where the strength of brazed parts decreases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

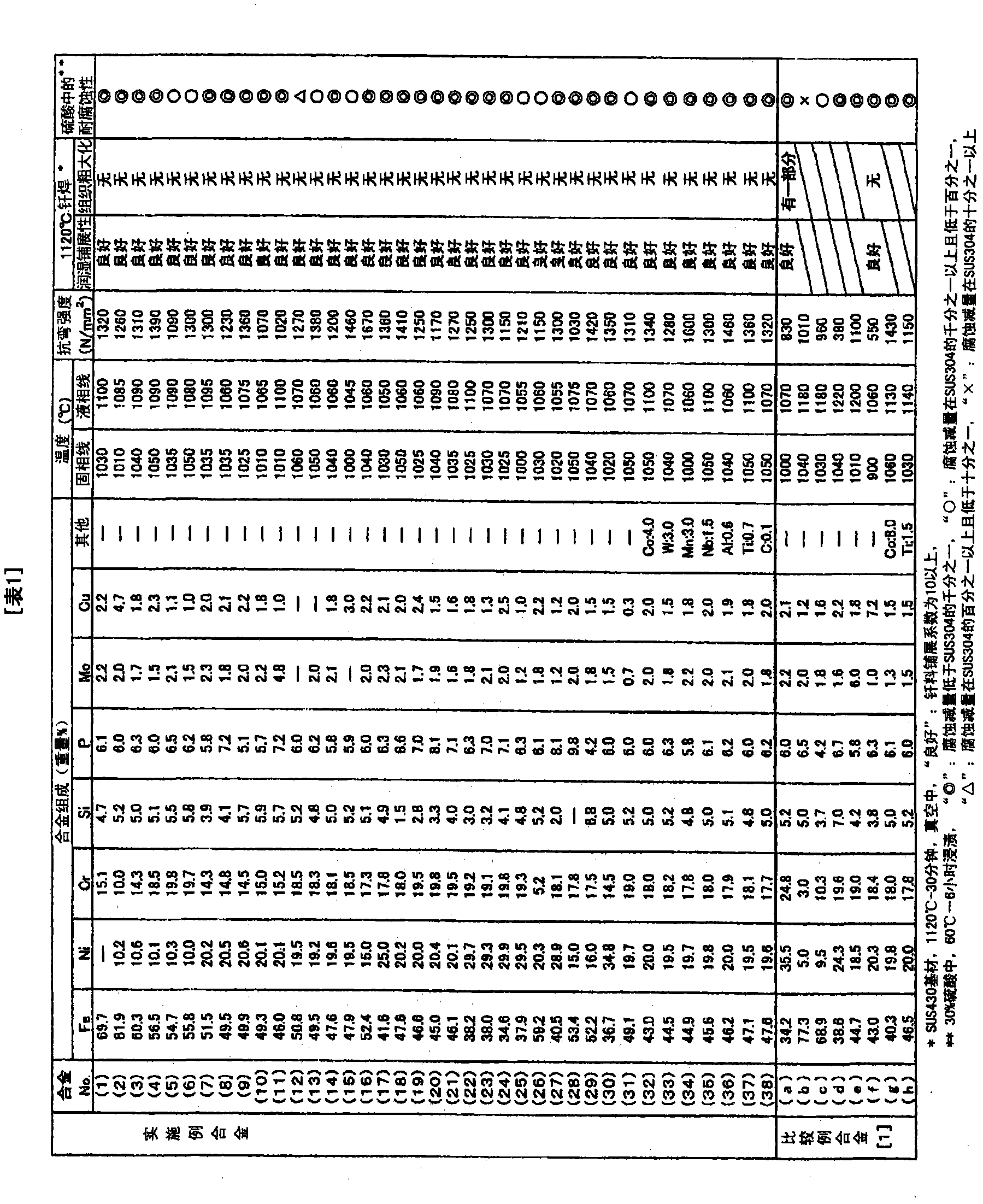

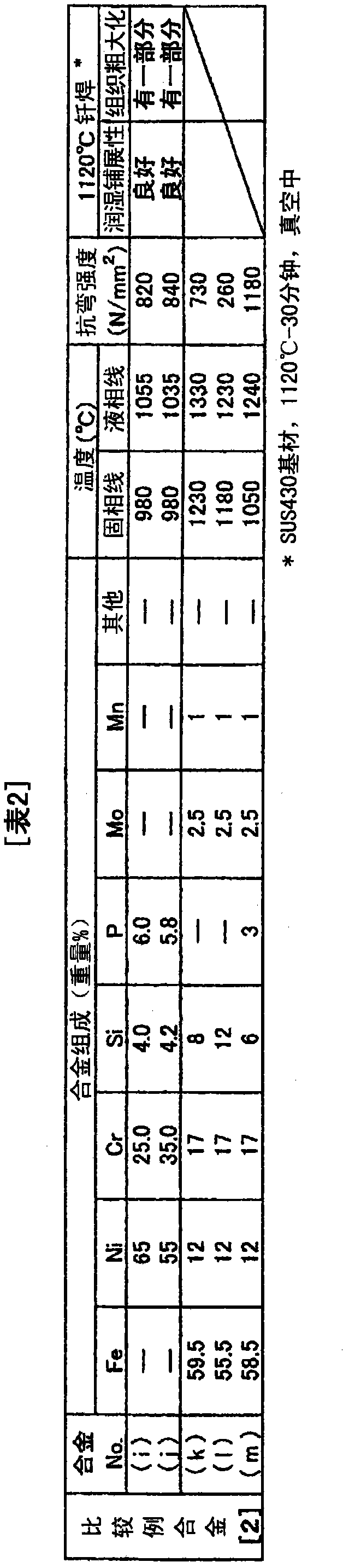

[0033] Hereinafter, representative examples and comparative examples of the present invention are shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides at a low cost iron-base heat- and corrosion-resistant brazing filler metals which make it possible to braze parts made of a base metal selected from among various stainless steels, particularly ferritic stainless steels, at a practical temperature (of 1120 DEG C or below) and are excellent in the wetting property against the base metal and which can attain excellent resistance to corrosion by sulfuric acid or nitric acid and high strength without coarsening the structure of the base metal. An iron-base heat- and corrosion-resistant brazing filler metal characterized by comprising 30 to75wt% of Fe, at most 35wt%of Ni and 5 to 20wt% of Cr in a total content of Ni and Cr of 15 to 50wt%, and at most 7wt% of Si and 4 to 10wt% of P in a total content of Si and P of 9 to 13wt%, preferably, an iron-base heat- and corrosion-resistant brazing filler metal as described above, characterized by further containing 0.5 to 5wt% of Mo and / or 0.3 to 5wt% of Cu in a total amount of Mo and Cu of 1 to 7wt%.

Description

Technical field [0001] The present invention relates to an iron-based solder alloy composition. More specifically, it relates to various stainless steel (especially ferritic) base materials when manufacturing various heat exchangers such as EGR (exhaust gas recirculation) coolers. The brazing used for brazing is an iron-based heat-resistant and corrosion-resistant brazing filler metal with excellent heat resistance and corrosion resistance, good wettability to stainless steel substrates, high strength and low cost. Background technique [0002] The Ni-Cr-P-Si brazing filler metal of the following Patent Document 1 and Patent Document 2 proposed by the inventors has been widely used for brazing of stainless steel parts in the manufacture of various heat exchangers such as EGR coolers. weld. [0003] Patent Document 1: Patent No. 3168158 [0004] Patent Document 2: Patent No. 3354922 Publication [0005] However, in recent years, the type of stainless steel used in component base mate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/30

CPCF28F21/089B23K35/3053B23K35/3066C22C38/42B23K35/02B23K35/3086C22C33/0285C22C38/44C22C38/34B23K35/025B23K35/308B22F2998/00C22C38/002B22F1/107B22F3/115B22F9/082

Inventor 乙部胜则永井省三

Owner FUKUKA METAL FOIL & POWDER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com