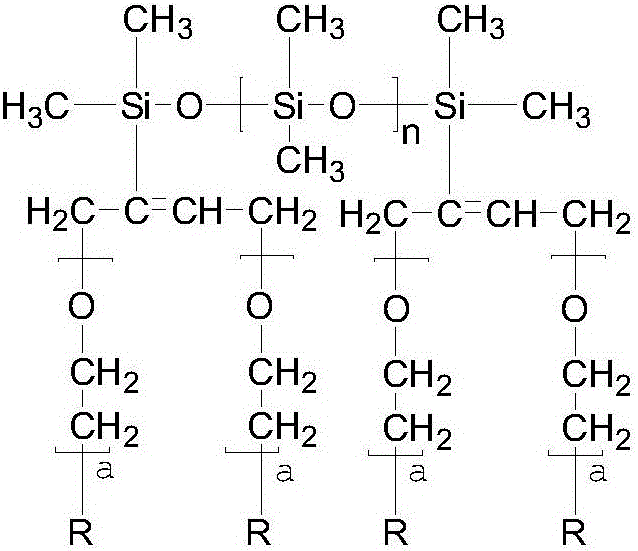

Butynediol ethoxylate modified bola type organosiloxane and preparation method thereof

A technology of ethoxylates and organosiloxanes, applied in the direction of organic chemistry, silicon organic compounds, chemical instruments and methods, etc., can solve the problems of unfavorable industrial production, increased production costs, long reaction time, etc., and achieve good wetting The effect of spreading ability, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

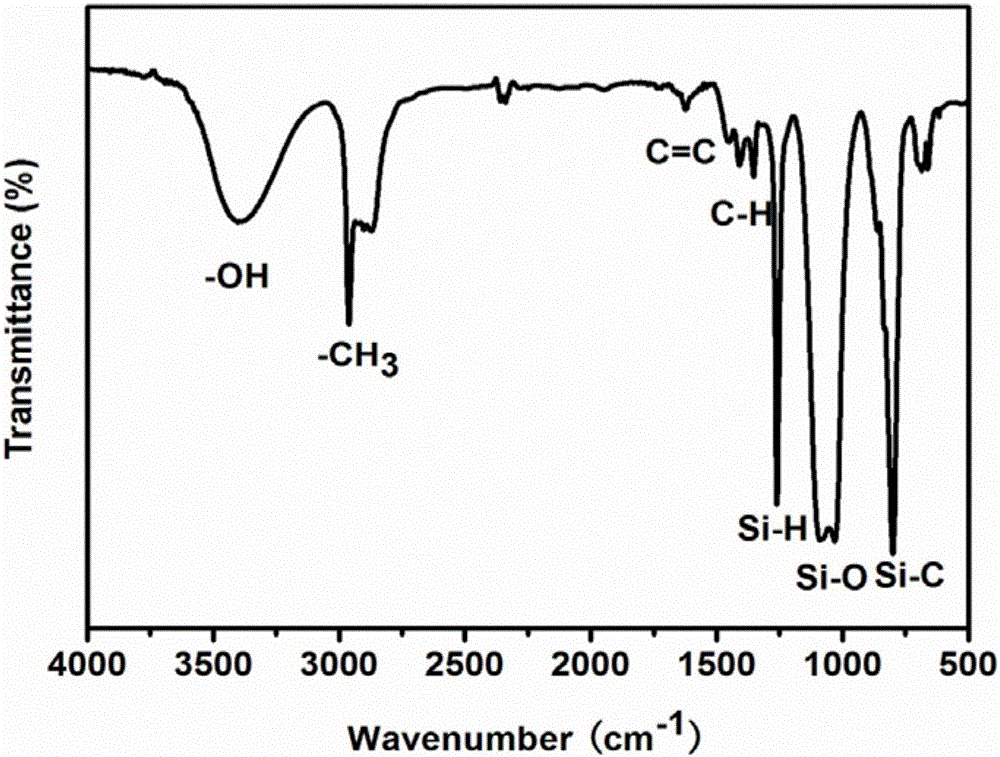

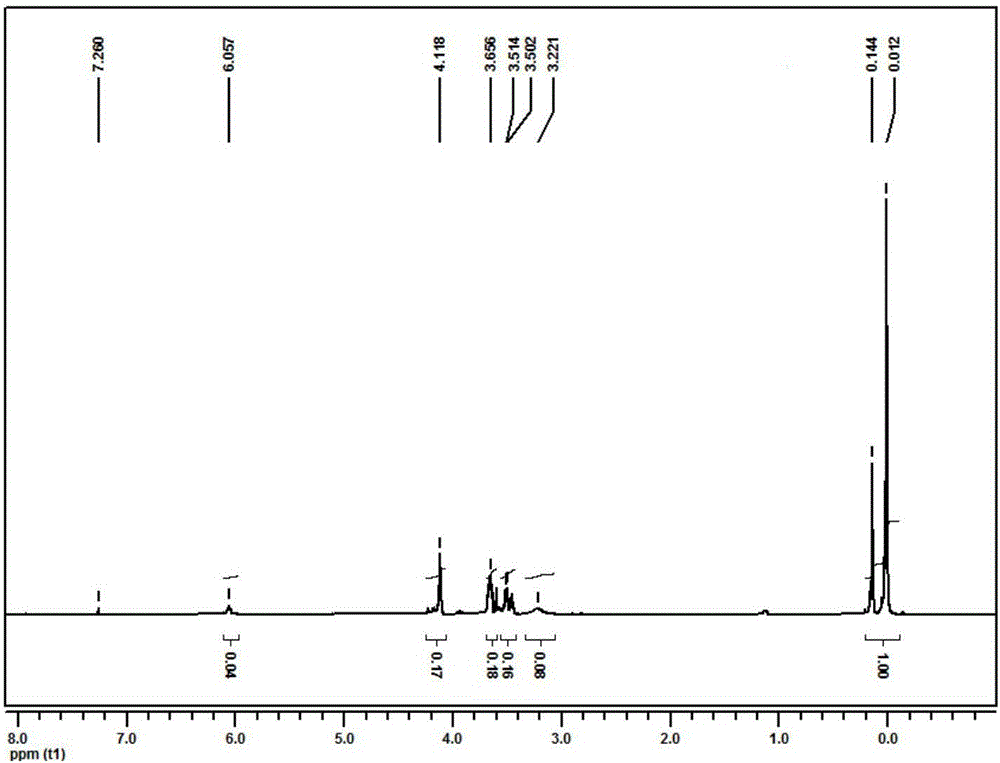

Method used

Image

Examples

Embodiment 1

[0039] (1) Raw materials and dosage

[0040] A butynediol diethoxylate (EO=1) 26.86g, octamethylcyclotetrasiloxane 22.86g, tetramethyldihydrodisiloxane 10.36g, concentrated sulfuric acid 1.0g, chloroplatinic acid Take 60ppm and 0.06ppm respectively with tributylamine catalyst.

[0041] (2) specific preparation method

[0042] Weigh the sample according to the above ratio, mechanically stir butynediol diethoxylate, tetramethyldihydrodisiloxane and chloroplatinic acid at 70°C to fully complex, then add tributylamine catalyst , at 70°C, N 2 Under protective conditions, mechanically stirred for 4 hours to obtain butynediol diethoxylate-modified tetramethyldisiloxane. Then, butynediol diethoxylate modified tetramethyldisiloxane and octamethylcyclotetrasiloxane were catalyzed by concentrated sulfuric acid, 40°C, N 2 Under protective conditions, mechanically stirred for 8 hours and then suction filtered to remove low boilers to obtain a light yellow product, namely butynediol die...

Embodiment 2

[0045] (1) Raw materials and dosage

[0046]A butynediol diethoxylate (EO=15) 55.37g, decamethylcyclopentasiloxane 20.57g, tetramethyldihydrodisiloxane 9.32g, concentrated sulfuric acid 2.28g, castor With tributylamine catalyst 60ppm, 0.18ppm.

[0047] (2) specific preparation method

[0048] Weigh the sample according to the above ratio, mechanically stir butynediol diethoxylate, tetramethyldihydrodisiloxane and Castel catalyst at 75°C to fully complex, then add tributylamine Catalyst, at 90°C, N 2 Under protective conditions, mechanically stirred for 4 hours to obtain butynediol diethoxylate-modified tetramethyldisiloxane. Then, butynediol diethoxylate modified tetramethyldisiloxane and decamethylcyclopentasiloxane were catalyzed by concentrated sulfuric acid, 60°C, N 2 Under protective conditions, mechanically stirred for 8 hours and then suction filtered to remove low boilers to obtain a light yellow product, which is butynediol diethoxylate-modified bola-type organosi...

Embodiment 3

[0051] (1) Raw materials and dosage

[0052] A butynediol diethoxylate (EO=30) 85.97g, hexamethylcyclotrisiloxane 18.51g, tetramethyldihydrodisiloxane 8.34g, concentrated hydrochloric acid 3.13g, chloroplatinic acid and benzotriazole catalyst are 60ppm and 0.3ppm respectively.

[0053] (2) specific preparation method

[0054] Weigh the sample according to the above ratio, mechanically stir the butynediol diethoxylate, tetramethyldihydrodisiloxane and chloroplatinic acid at 80°C to fully complex, then add the benzotriazole catalyst , at 110°C, N 2 Under protective conditions, mechanically stirred for 4 hours to obtain butynediol diethoxylate-modified tetramethyldisiloxane. Then, butynediol diethoxylate modified tetramethyldisiloxane and hexamethylcyclotrisiloxane were catalyzed by concentrated hydrochloric acid, 70°C, N 2 Under protective conditions, mechanically stirred for 8 hours and then suction filtered to remove low boilers to obtain a light yellow product, which is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com