Environment-friendly nano-silver conductive ink adhesive force promoting coating slurry and preparation method thereof

An adhesion-promoting, conductive ink technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of non-dissolving, swelling ability, low adhesion, and low surface energy of the film, and achieve favorable wetting and spreading performance. , enhance the interface bonding force, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

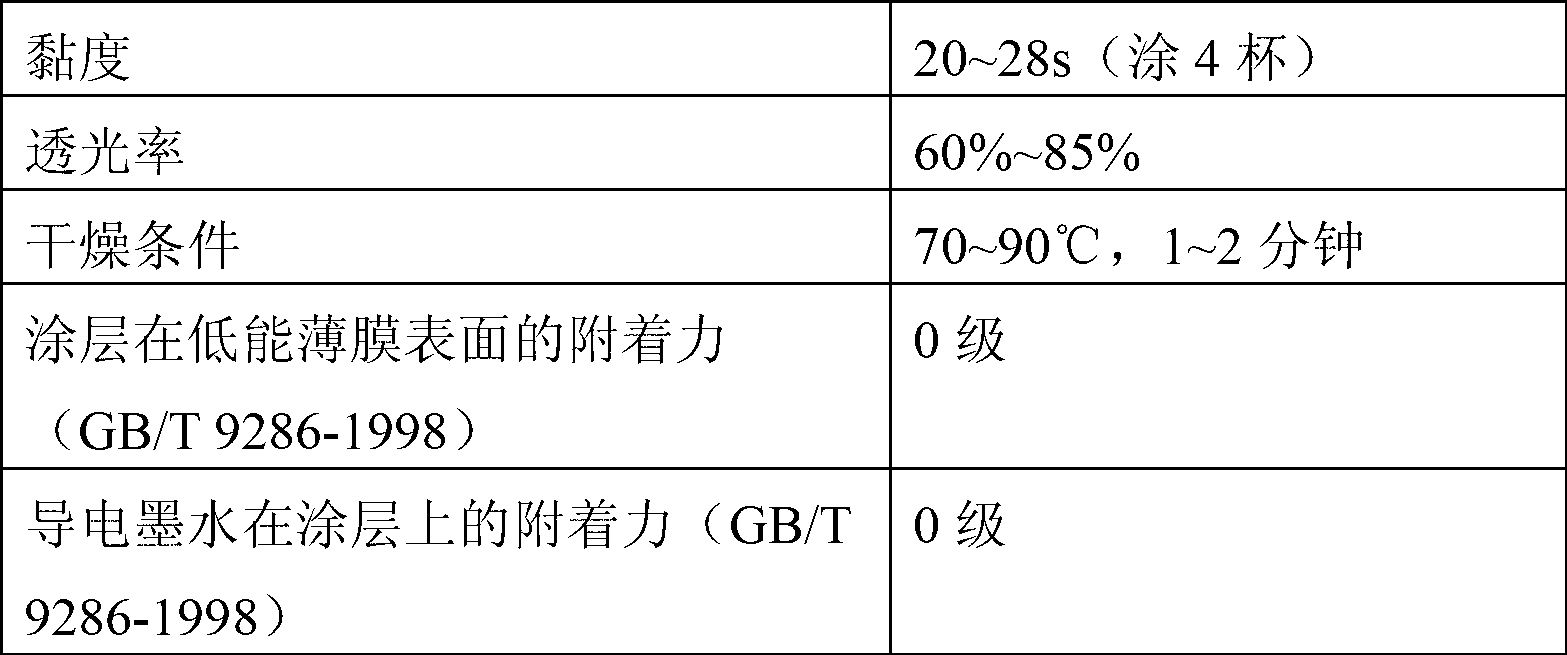

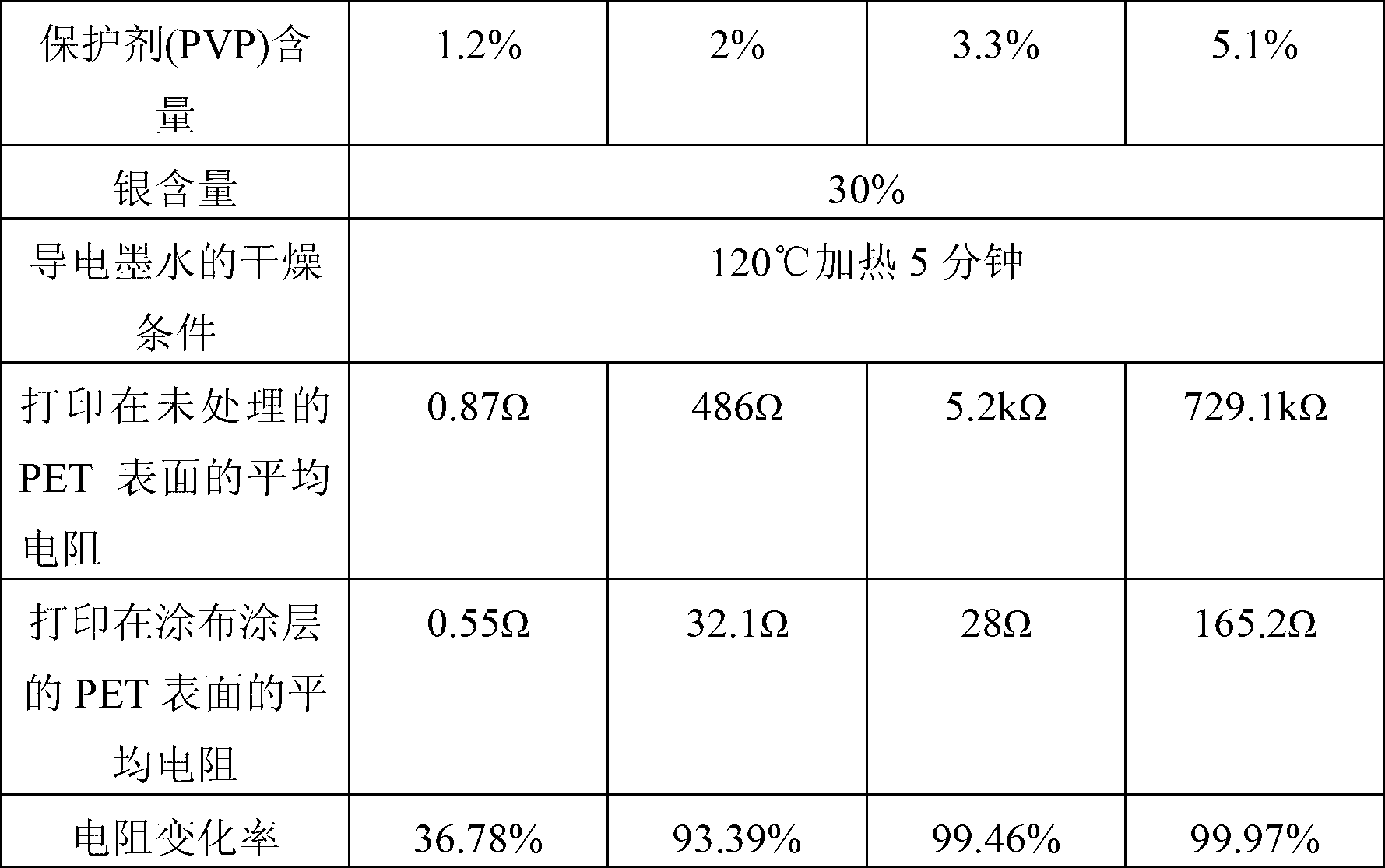

Examples

Embodiment 1

[0035] [Example 1] First add 15 parts of ethyl cellulose to 26 parts of ethylene glycol ether, stir to dissolve; add 3 parts of defoamer BYK-141 and 5 parts of coupling agent KH550 into the remaining 26 parts of ethylene glycol ether After stirring evenly, add 25 parts of nano-calcium carbonate and ultrasonically disperse for 20 minutes; add the ultrasonically dispersed system to the ethyl cellulose solution, add 200 parts of zirconia beads after pre-dispersion, and increase the speed to 2200 revolutions per minute, sand milling and dispersing for 100 minutes to obtain a slurry.

Embodiment 2

[0036] [Example 2] First add 20 parts of aldehyde and ketone resin to 26.5 parts of propylene glycol methyl ether, stir to dissolve; add 3 parts of defoamer BYK-141 and 4 parts of coupling agent KH550 to the remaining 26.5 parts of propylene glycol methyl ether, stir After uniformity, add 20 parts of diatomaceous earth and ultrasonically disperse for 30 minutes; add the ultrasonically dispersed system to the solution of aldehyde and ketone resin, add 200 parts of zirconia beads after pre-dispersion, and increase the speed to 2100 rpm. Sand mill and disperse for 80 minutes to obtain a slurry.

Embodiment 3

[0037] [Example 3] First add 24 parts of chlorinated polypropylene resin to 30 parts of ethyl acetate, stir to dissolve; add 2 parts of defoamer BYK-066N and 4 parts of coupling agent KH560 to the remaining 30 parts of ethyl acetate , after stirring evenly, add 20 parts of kaolin, and ultrasonically disperse for 10 minutes; add the ultrasonically dispersed system to the solution of chlorinated polypropylene resin, add 200 parts of zirconia beads after pre-dispersion, and increase the speed to 1800 rpm Minutes, sanding and dispersing for 90 minutes to obtain a slurry.

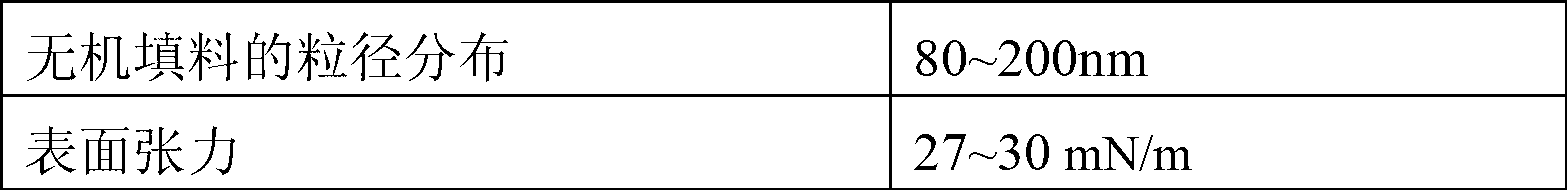

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com