ZnSn-base high-temperature lead-free soft solder and preparation method thereof

A technology of soldering material and high temperature, which is applied in the field of ZnSn-based high-temperature lead-free soldering material and its preparation, can solve the problems of poor mechanical properties of lead-based soldering material, corrosion, and high cost of soldering material, and achieve improved brazing process performance and improved The mechanical properties of the alloy and the effect of meeting the requirements of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

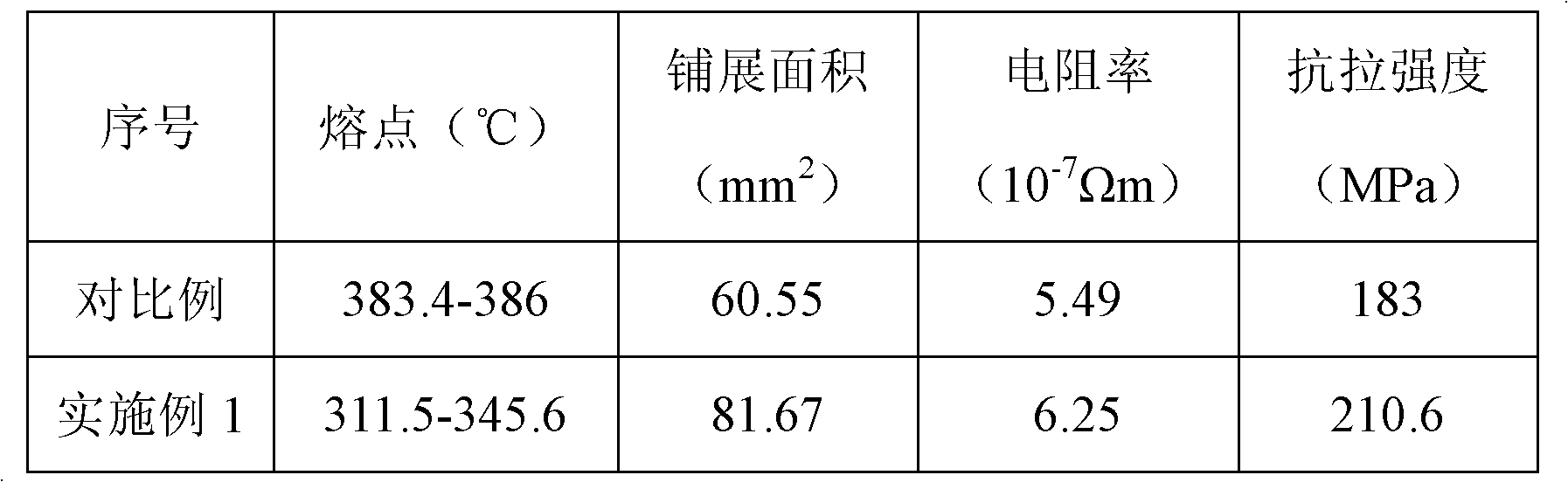

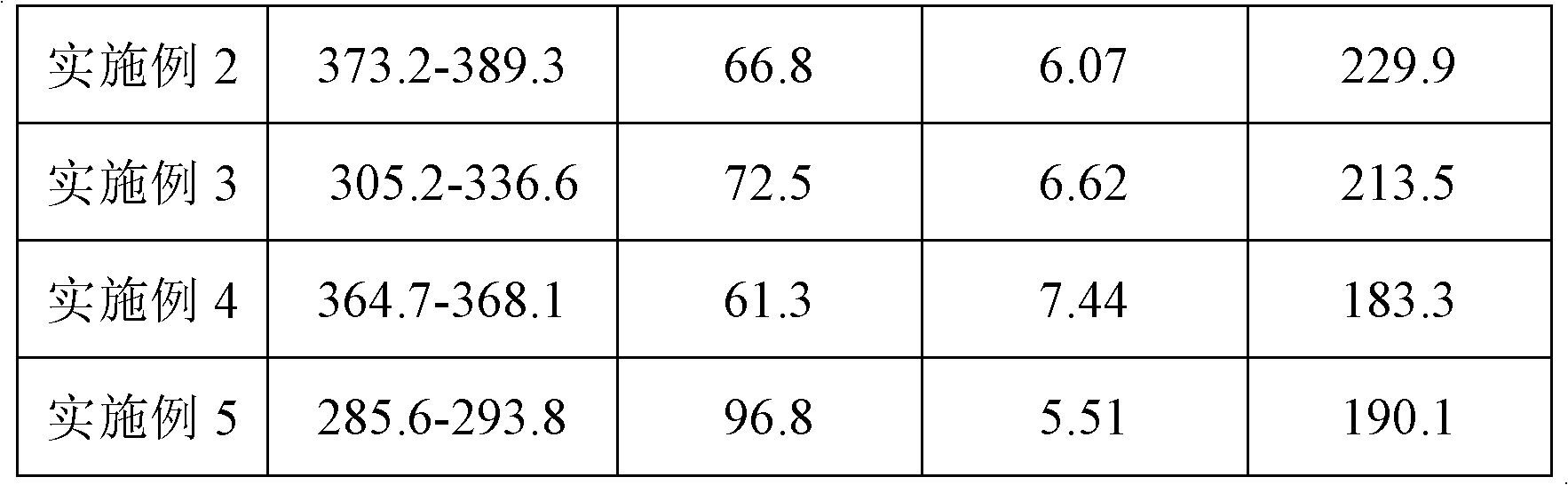

Embodiment 1

[0012] The ZnSn-based high-temperature lead-free solder provided by this embodiment is composed of the following components in weight percentage: 30% tin, 5% copper, 0.3% lanthanum-neodymium mixed rare earth, 1.6% magnesium, 0.1% bismuth , the balance of zinc.

[0013] The preparation method of the ZnSn-based high-temperature lead-free solder provided in this embodiment is as follows: weigh 31.5g zinc, 15g tin, 2.5g copper, 0.8g magnesium, 0.05g bismuth and 0.15g lanthanum neodymium mixed rare earth with an electronic balance, and then Put the weighed raw materials together into the crucible, wherein the mixed rare earth lanthanum and neodymium is placed at the bottom of the crucible, and then cover the raw materials with a protective agent composed of LiCl and KCl, the weight ratio of LiCl and KCl is 1:1, Then put the crucible into a non-vacuum induction furnace for smelting, under normal pressure, heat preservation and smelting at a temperature of 850-900°C for 2 hours, stir...

Embodiment 2

[0015] The ZnSn-based high-temperature lead-free solder provided by this embodiment is composed of the following components in percentage by weight: 20% tin, 4% copper, 0.5% lanthanum-neodymium mixed rare earth, 1.2% bismuth, and the rest of zinc .

[0016] The preparation method of the ZnSn-based high-temperature lead-free solder provided in this example is: weigh 37.2g zinc, 10g tin, 2g copper, 0.6g bismuth, and 0.25g lanthanum-neodymium mixed rare earth with an electronic balance, and then weigh each The raw materials are put into the crucible together, and the mixed rare earth of lanthanum and neodymium is placed at the bottom of the crucible, and then the protective agent composed of LiCl and KCl is covered on the raw material. The weight ratio of LiCl and KCl is 1:1, and then the crucible is put into Smelted in a non-vacuum induction furnace, kept at 850-900°C for 1 hour under normal pressure, stirred every 30 minutes during the smelting process, and then casted to obtai...

Embodiment 3

[0018] The ZnSn-based high-temperature lead-free solder provided in this embodiment is composed of the following components in weight percentage: 30.3% tin, 3% copper, 0.1% lanthanum-neodymium mixed rare earth, 3% magnesium, and the rest zinc .

[0019] The preparation method of the ZnSn-based high-temperature lead-free solder provided in this embodiment is: weigh 31.5g zinc, 15g tin, 1.5g copper, 1.5g magnesium and 0.05g lanthanum-neodymium mixed rare earth with an electronic balance, and then weigh the All the raw materials are put into the crucible together, and the mixed rare earth lanthanum and neodymium are placed at the bottom of the crucible, and then the protective agent composed of LiCl and KCl is covered on the raw materials. The weight ratio of LiCl and KCl is 1:1, and then the crucible is placed Put it into a non-vacuum induction furnace for smelting, under normal pressure, heat preservation and smelting at a temperature of 850-900°C for 2 hours, stir once every 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com