Patents

Literature

52results about How to "Good brazing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness cadmium-free silver solder and preparation method thereof

ActiveCN101693325AImprove wettabilityHigh temperature toughnessWelding/cutting media/materialsSoldering mediaIntermediate frequencyManganese

The invention relates to a high-toughness cadmium-free silver solder and a preparation method thereof. The solder comprises the following materials by weight percent: 22-58 percent of Ag, 15-35 percent of Cu, 13-38 percent of Zn, 4-8 percent of Mn, 1.5-5 percent of Ni, 0.8-3 percent of Co, 0.01-0.45 percent of B, 0-1.5 percent of V, 0-1.5 percent of Nb, 0.005-0.9 percent of Ce, 0.005-0.9 percent of La and 0-0.5 percent of Sr. The preparation method comprises the following steps of smelting the metal with high-melting point and partial copper into a preliminary alloy A, smelting oxidized metal and partial copper in a vacuum furnace into a preliminary alloy B, smelting silver and the remained copper in an intermediate-frequency furnace and then adding the preliminary alloy A, adding metals of manganese and zinc and then adding the preliminary alloy B after complete fusion, fusing completely again and standing for 60 minutes, and casting to form a silver alloy ingot, performing even annealing and scaling on the alloy ingot, extruding the alloy into a stripe shape or a bar shape by an isothermal extrusion method, and then rolling into a band or drawing and reducing to a filament.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

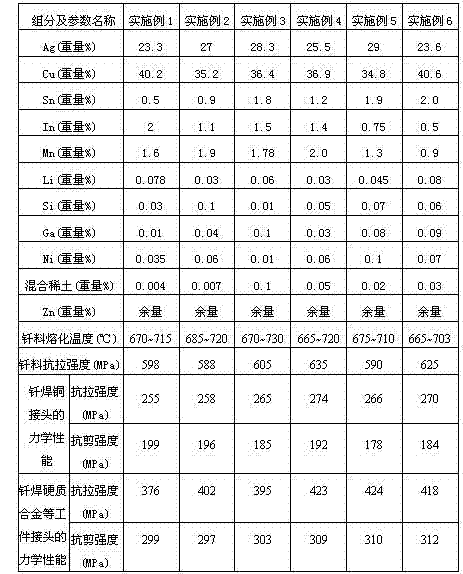

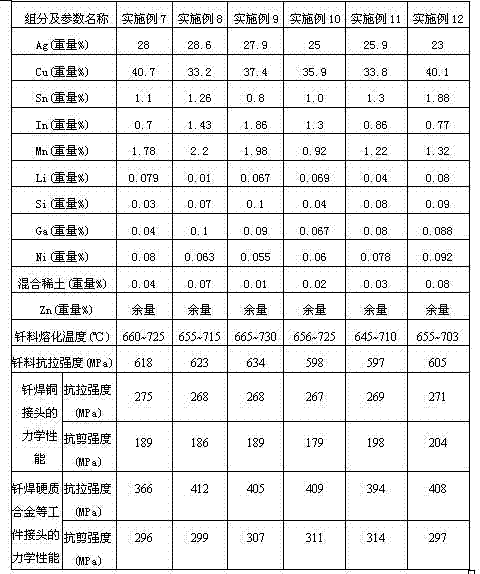

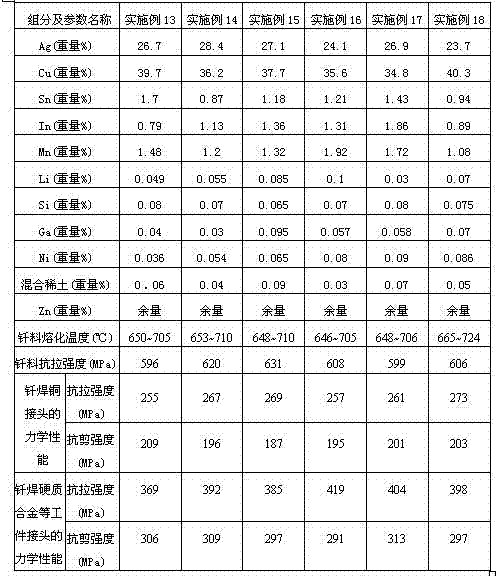

Multielement rare-earth silver solder

InactiveCN102240870AReduce contentImprove plasticityWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention relates to a multielement rare-earth silver solder which contains elements, such as manganese, indium, tin and the like. The multielement rare-earth silver solder is suitable for soldering metallic materials, such as red copper, brass, carbon steel, hard alloy, stainless steel and the like. The multielement rare-earth silver solder consists of the following components in percentage by weight: 23-29 wt% of Ag, 32-42 wt% of Cu, 0.5-2 wt% of Sn, 0.5-2.0 wt% of In, 0.5-2.2 wt% of Mn, 0.01-0.1 wt% of mischmetal, 0.01-0.1 wt% of Si, 0.01-0.1 wt% of Ni, 0.01-0.1 wt% of Li, 0.01-0.1 wt% of Ga and the balance of Zn. The multielement rare-earth silver solder has the advantages of high cost performance, capability of replacing BAg50CuZnSnNi and BAg50CuZnCd, exclusion of cadmium (Cd), lower melting temperature and good soldering property.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

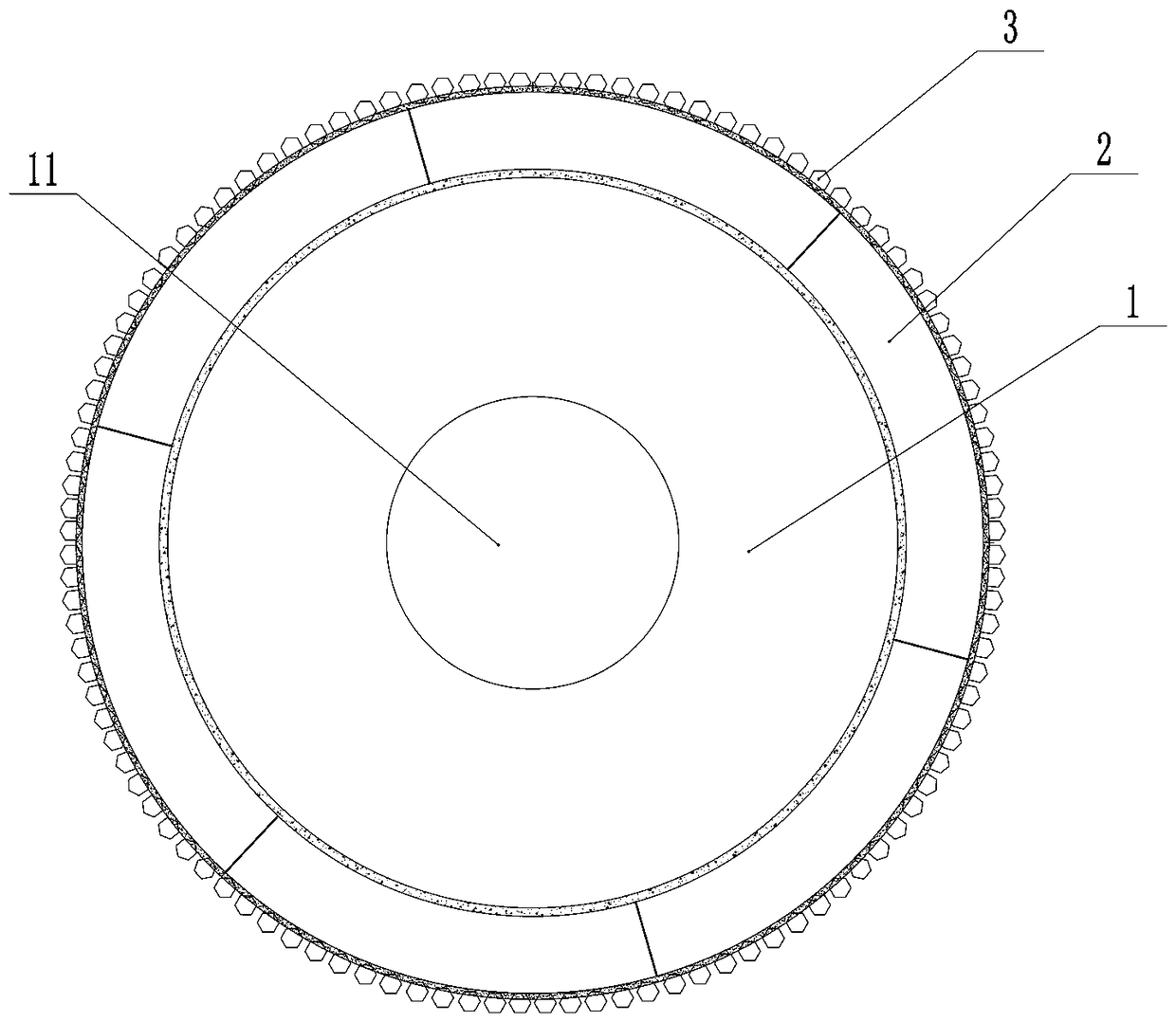

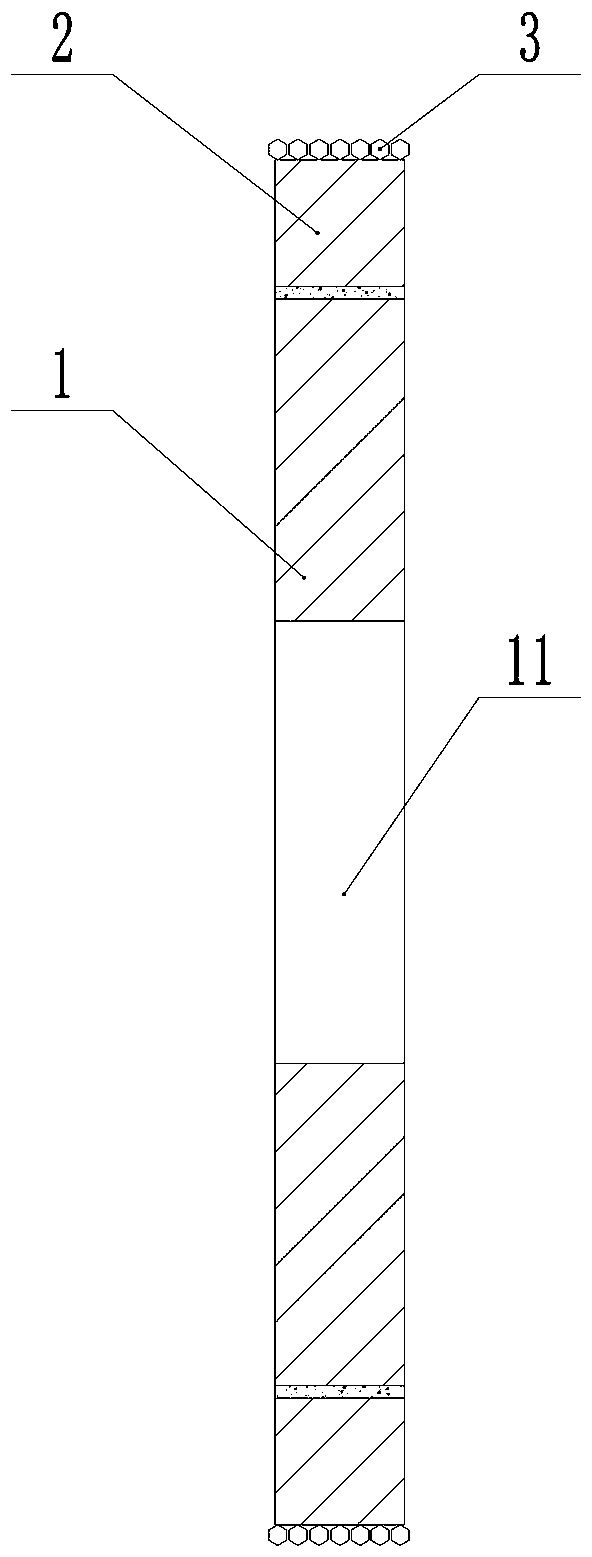

High-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux

ActiveCN105127618AHigh activityStrong ability to remove filmWelding/cutting media/materialsSoldering mediaPotassium borohydridePotassium fluoride

The invention discloses a high-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux. The high-strength and high-toughness composite silver solder ring comprises a silver solder ring body of a hollow structure. The silver solder ring body is formed by winding composite silver solder formed by a silver solder pipe and a flux core with which the silver solder pipe is filled. The flux core is prepared from boron micro-powder, sodium borohydride or potassium borohydride, potassium fluoborate, boric anhydride or boric acid, potassium fluoride or sodium fluoride or lithium fluoride, potassium bifluoride and potassium fluoroaluminate according to a certain proportion. The purpose of in-situ synthesis of the soldering flux through the boron micro-powder in the flux core and metal elements in the silver solder pipe is achieved, so that the content of the flux core is reduced, and when the content of the flux core is low, the solder still achieves good brazing manufacturability; meanwhile, due to the fact that the wall thickness of the solder pipe is increased, good toughness and high stiffness are achieved, the processing performance of the solder is greatly improved, the minimum diameter can be reduced to 0.8 mm, the solder can be easily wound into the solder ring with the intermediate diameter below 6 mm, and application and popularization of the automatic brazing process are facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

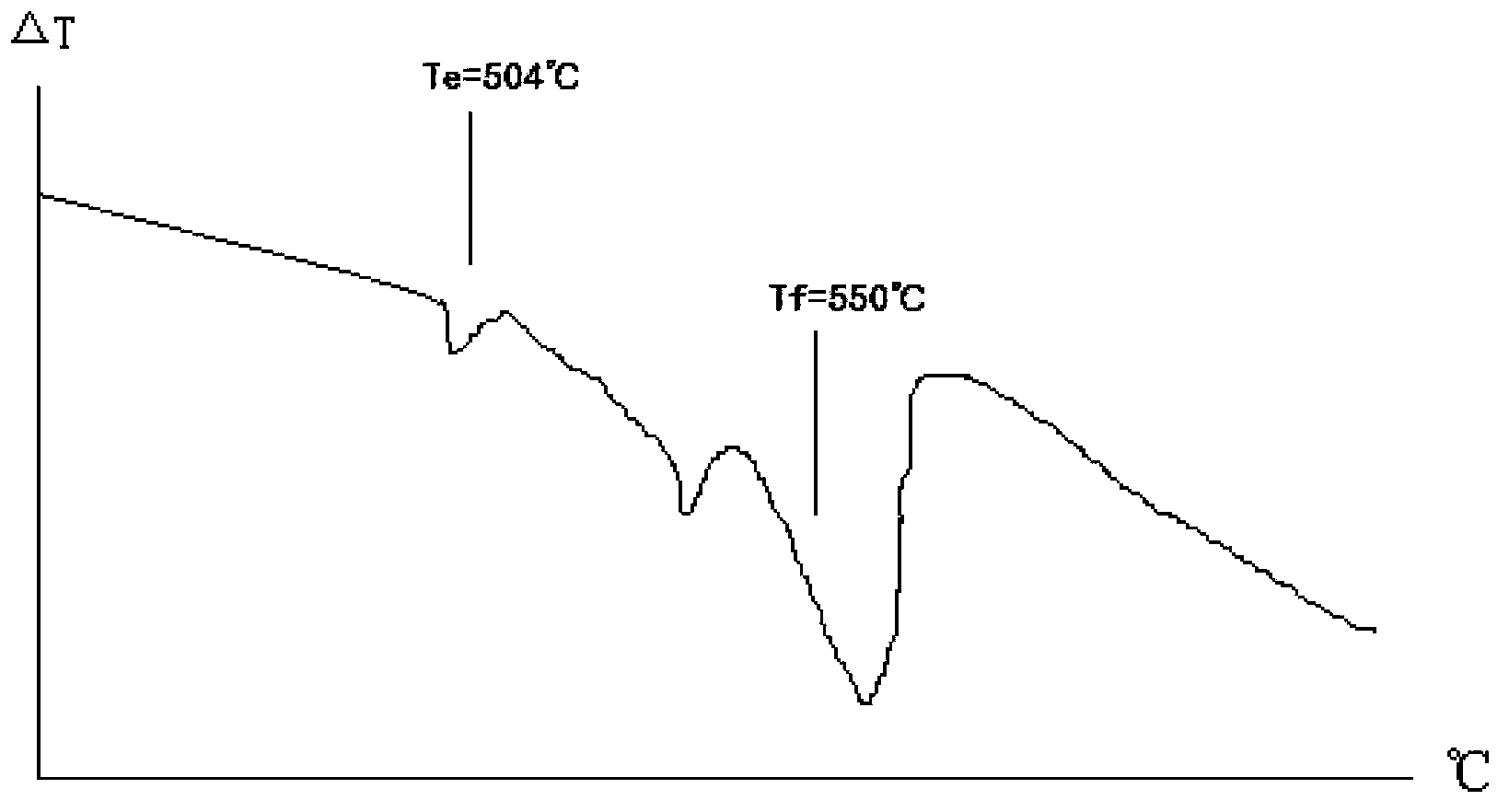

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

Al-Si-Cu-Mg aluminum-base alloy foil solder and preparation method thereof

ActiveCN103567655AGood brazing processImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderingUltimate tensile strength

Al-Si-Cu-Mg aluminum-base alloy foil solder and a preparation method thereof are mainly applied to vacuum soldering of aluminum alloy. The solder is made with 10.5-13.5wt% of Si, 3.5-5.5wt% of Cu, 1.0-2.2wt% of Mg, and the balance of Al. The solder is low in melting temperature, good in soldering efficiency, good in wetting property, higher than 85% in welding area ratio, not smaller than 100MPa in weld tensile strength alpha b, not smaller than 50MPa in shear strength tau, and applicable to medium-temperature or graded vacuum soldering of various aluminum alloys such as 3A21, 2A50, 6063 and 6061. The preparation method includes: preparation of materials, preparation of intermediate alloy, alloy casting, heat treatment, hot extrusion, rolling and the like. The preparation method is simple and is convenient for batch production. The foil solder 0.10mm in thickness and 320mm in width prepared by the method is better applicable to vacuum soldering of large-sized aluminum alloy components.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

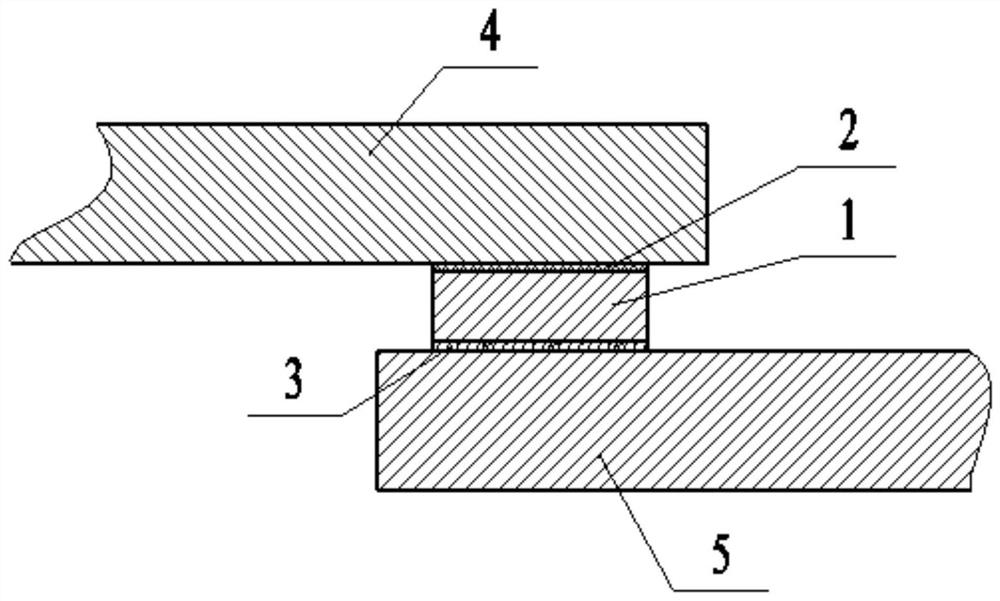

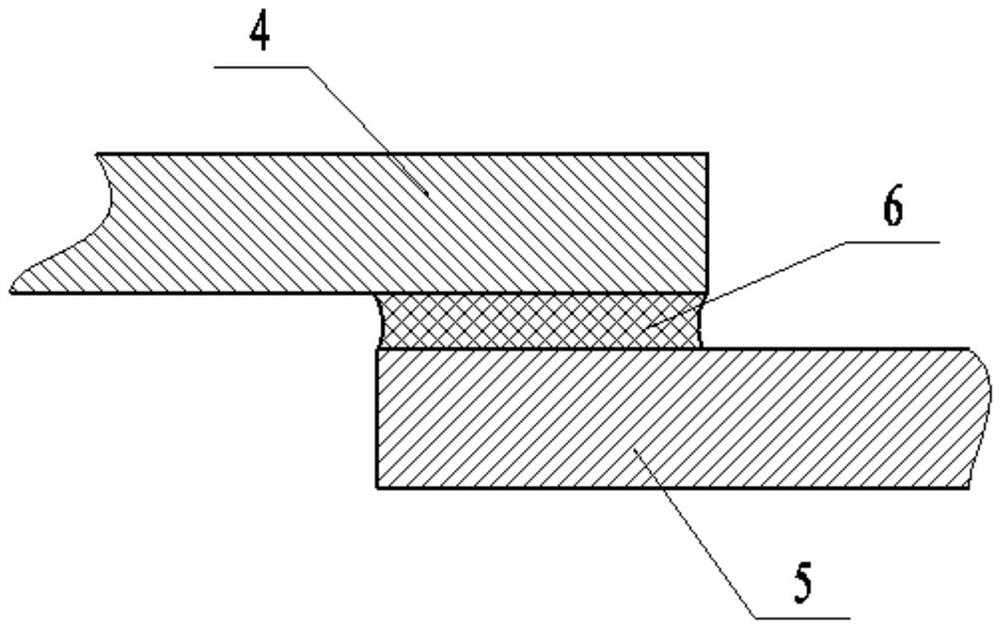

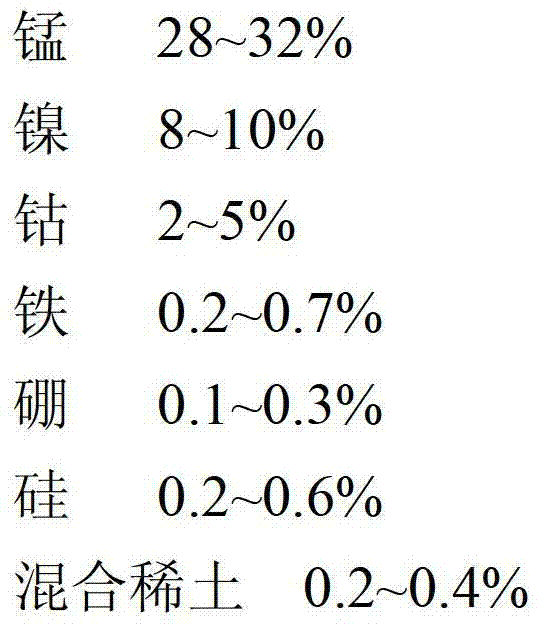

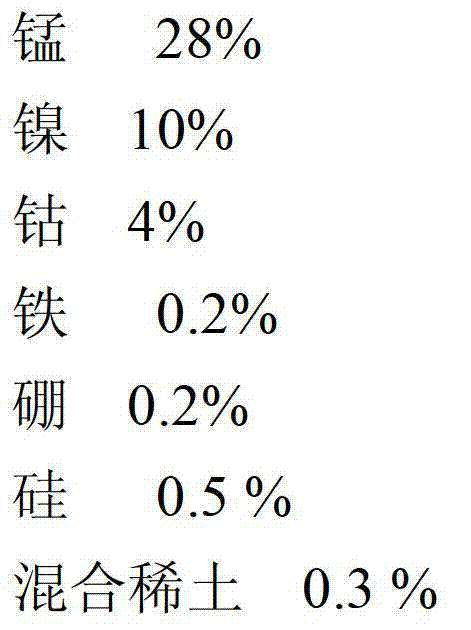

Copper-based solder and preparation method thereof

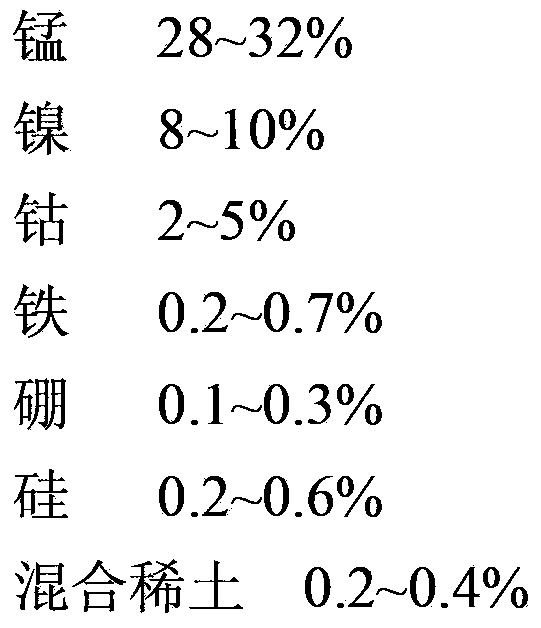

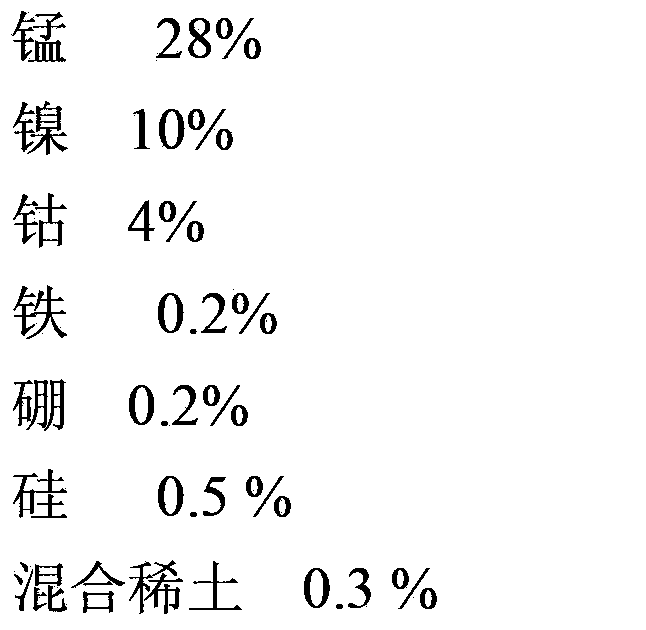

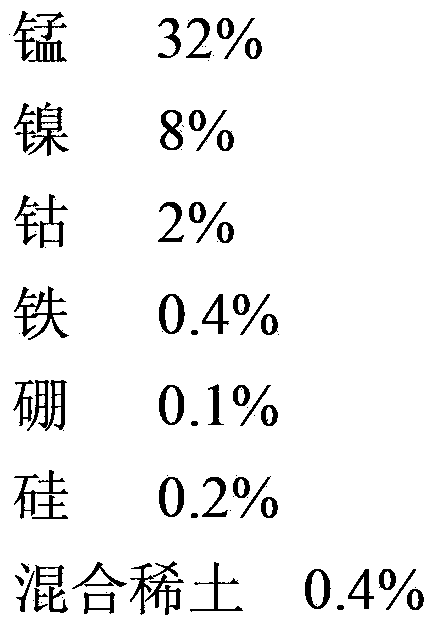

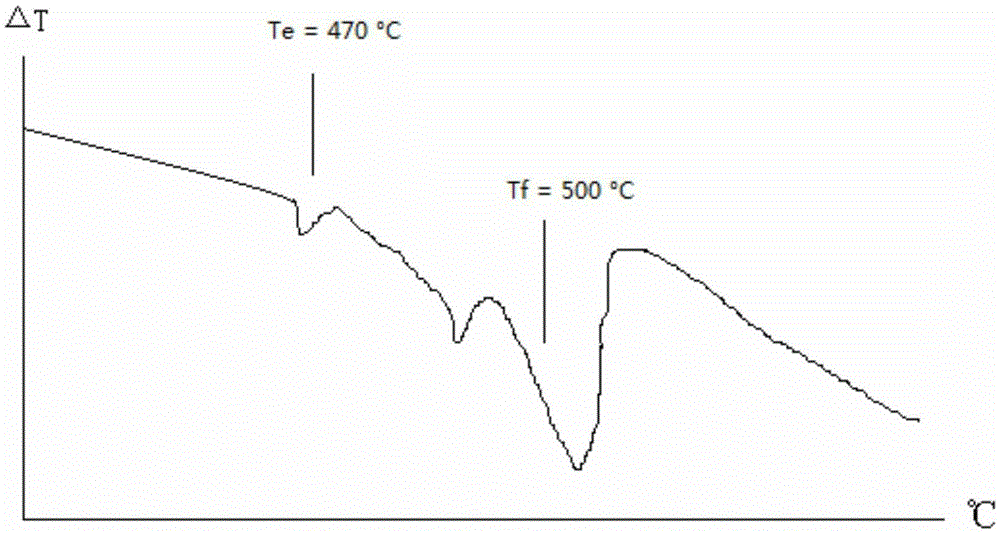

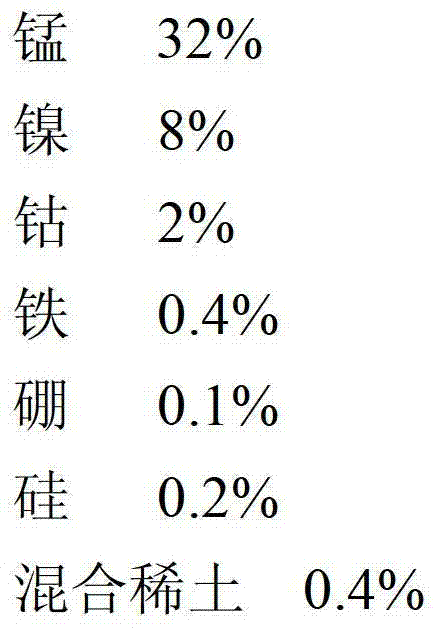

ActiveCN103358051ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCorrosionSmelting process

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Medium-temperature aluminum-based foil strap brazing material and preparation method thereof

InactiveCN103008909AGood brazing processSimple preparation processWelding/cutting media/materialsSoldering mediaTorchShear strength

The invention discloses a medium-temperature aluminum-based foil strap brazing material and a preparation method thereof. The brazing material comprises the following components by mass percentage: 6.5-9.6 of Si, 16.0-20.0 of Cu, 8.0-10.0 of Ge, 2.0-6.0 of Zn, 0.5-1.0 of La and the balance of Al. The brazing material is prepared by rapid cooling of a melt, the melting point is lower than 495 DEG C, a foil strap is suitable for brazing of aluminum alloy with the solidus temperature higher than 520 DEG C, torch brazing, induction brazing, furnace brazing, gas protection brazing and the like can be performed, the brazing temperature is 510-520 DEG C, and the brazing material can be applied in brazing of precision components made of aluminum alloy. When the brazing material is used with 5083 aluminum alloy for QJ201 brazing, the shear strength of a brazed joint is higher than 80MPa.

Owner:ZHEJIANG UNIV +1

Ceramic phase reinforced copper-based composite solder and preparation method thereof

InactiveCN102211260ALow costLow melting pointWelding/cutting media/materialsSoldering mediaWhiskersComposite solder

The invention discloses a ceramic phase reinforced copper-based composite solder and a preparation method thereof, relates to a copper-based composite solder and a preparation method thereof, and aims to solve the problems that an Ag-Cu-Ti solder has high cost, and low joint strength caused by residual stress in the conventional ceramic connection method. The ceramic phase reinforced copper-based composite solder comprises Cu powder, Sn powder, Ti powder and B powder. The method comprises the following steps of: mixing the Cu powder, the Sn powder, the Ti powder and the B powder to obtain mixed powder; and adding the mixed powder and ceramic balls into a ball-milling tank of a planetary ball mill, and performing ball milling for 1 to 5 hours at a rate of 300r / min under the protection of argon gas to obtain a uniformly mixed Cu-Sn-Ti-B composite solder. Soldering cost is reduced, and thermal mismatching between metal and ceramic is adjusted by growing TiB crystal whiskers in a joint in situ, so that the usability of the soldered joint is improved. The solder is applied to the soldering connection of the ceramic.

Owner:HARBIN INST OF TECH

Polybasic silver solder

ActiveCN103111770AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Medium-temperature high-strength aluminum alloy powder solder and preparation method thereof

ActiveCN102773630ASmall tissueUniform compositionWelding/cutting media/materialsSoldering mediaSolution treatmentChemical composition

The invention discloses medium-temperature high-strength aluminum alloy powder solder, comprising the following components by weight: 6.0-8.5% of Si, 10.0-12.0% of Cu, 3.0-4.0% of Ge, 3.0-4.0% of Ni, 0.5-0.8% of La and the balance of A1. The invention also discloses a method for preparing the medium-temperature high-strength aluminum alloy powder solder by adopting a melt rapid cooling technology. The melting temperature range of the solder disclosed by the invention is 515-539 DEG C, and the brazing temperature is 545-560 DEG C. The solder is suitable for the brazing the aluminum alloy of which a solidus is higher than 560 DEG C, especially suitable for the heat-treatable strengthening aluminium alloy which is subjected to a solution treatment after being brazed and is of the solution temperature no more than 545 DEG C. The solder is also suitable for furnace brazing, vacuum brazing, induction brazing, torch brazing, and the like. The solder disclosed by the invention is adopted to be matched with QJ201 brazing flux for brazing the 6061 aluminum alloy in a furnace; after being brazed, the 6061 aluminum alloy is subjected to a T6 heat treatment; and the shear strength of a brazing joint is more than 94MPa.

Owner:ZHEJIANG UNIV

Germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder

InactiveCN103008908AThe process is simple and easy to controlLow content of Ge elementWelding/cutting media/materialsSoldering mediaCeriumCopper

The invention discloses germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder. The solder comprises the following components in mass percent: 6.5 percent of silicon (Si), 15.0 percent of copper (Cu), 0.1-8.0 percent of Ge, 6.0 percent of stannum (Sn), 1.0 percent of cerium (Ce) and the balance aluminum (Al). The solder is prepared by adopting the rapid cooling technique. The melting point of the solder is lower than 520 DEG C, and the brazing temperature is 540-550 DEG C. The Ge-contained corrosion-resistant aluminum-based solder is suitable for brazing of aluminum alloy of which the solidus is higher than 550 DEG C, such as flame brazing, induction brazing, furnace brazing and gas shield brazing. The solder is matched with a QJ201 brazing aluminum plate 3003, so that the shear strength of a brazed joint is higher than 82MPa. When the percentage composition of the Ge is 2.5, the corrosion resistance of solder alloy is optimal, and the corrosion current density is 3.562muAcm<-2>.

Owner:ZHEJIANG UNIV +1

Al-Ag-Cu-Mg aluminium base alloy-state brazing filler metal and preparation method thereof

InactiveCN105364335AGood welding rateImprove welding strengthWelding/cutting media/materialsSoldering mediaAdditive ingredientFiller metal

The invention discloses an Al-Ag-Cu-Mg aluminium base alloy-state brazing filler metal and a preparation method thereof. The brazing filler metal is mainly used for vacuum brazing for aluminium alloys. The brazing filler metal is composed of the following ingredients with the following contents: 35-45wt% of Ag, 18-22wt% of Cu, 1.0-2.0wt% of Mg and the balance Al. The brazing filler metal has a low melting temperature, high brazing manufacturability, high wettability, and a high welding area ratio of greater than 90%; the brazing filler metal has a welding joint tensile strength sigma of not less than 90MPa and a shear strength tau of not less than 60MPa, and is applicable to intermediate-temperate or step vacuum brazing for many aluminium alloys of 3A21, 2A50, 6063, 6061, LF6 and the like. The preparation method comprises the steps of material preparation, intermediate alloy preparation, alloy casting, heat treatment, hot forging, rolling and the like. The preparation method is simple in method and beneficial to batch production. Foil-shaped brazing filler metal with a thickness of 0.03-2.00mm can be prepared by virtue of the method, and the brazing filler metal is more applicable to vacuum brazing for aluminium alloy members with large specifications.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

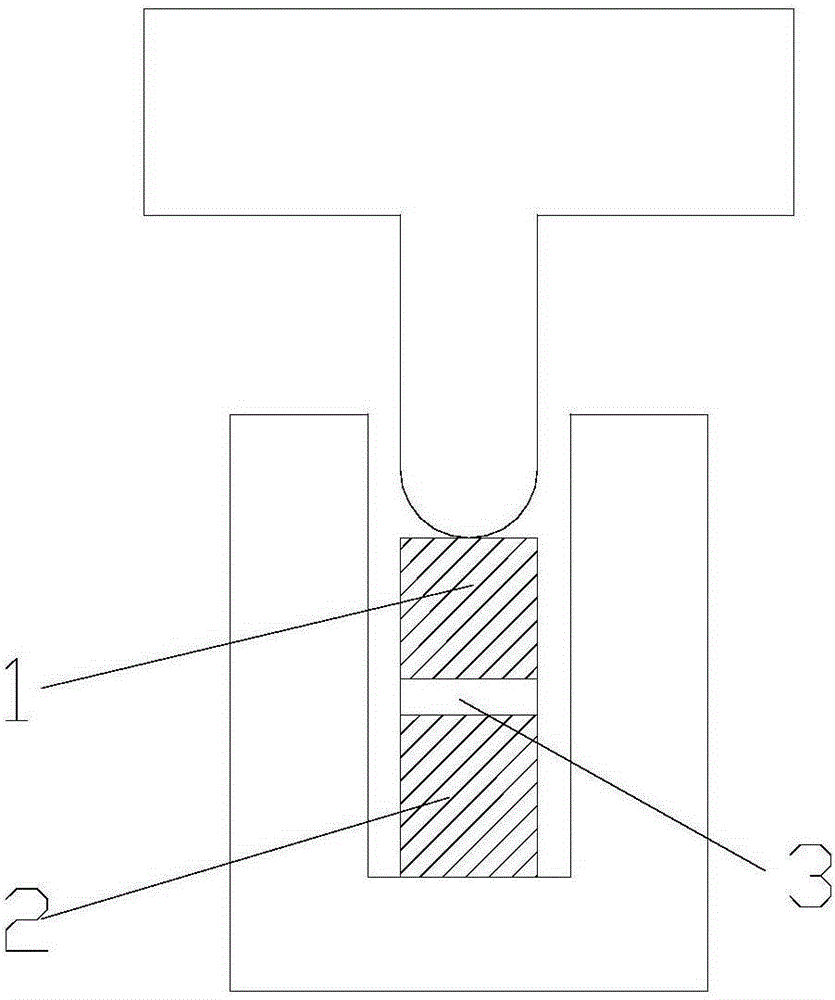

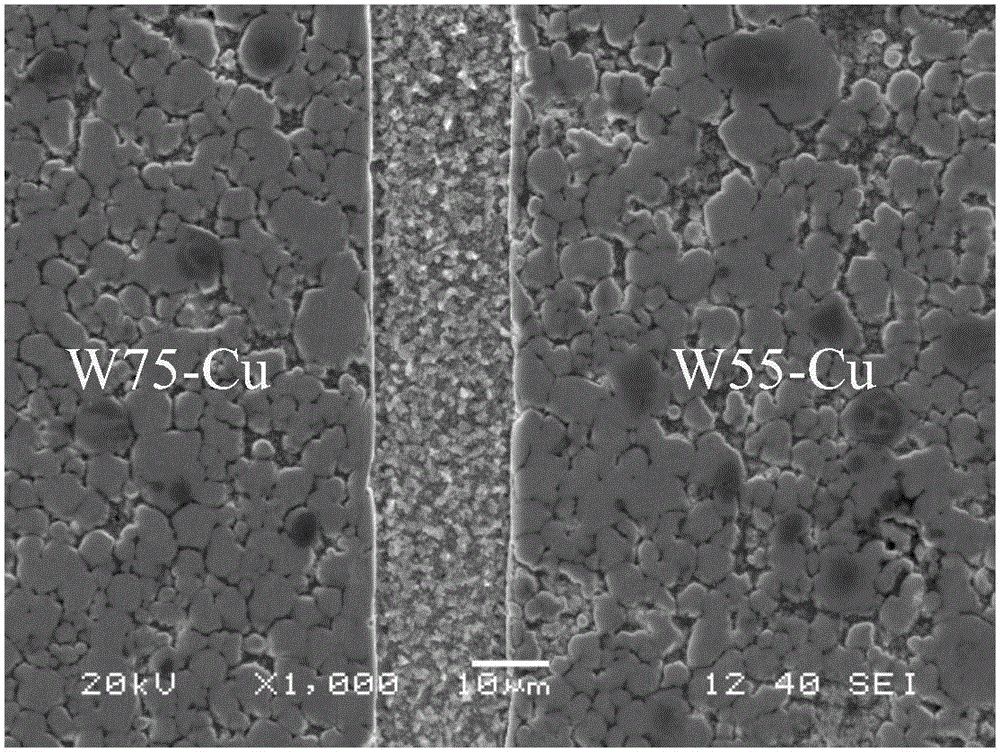

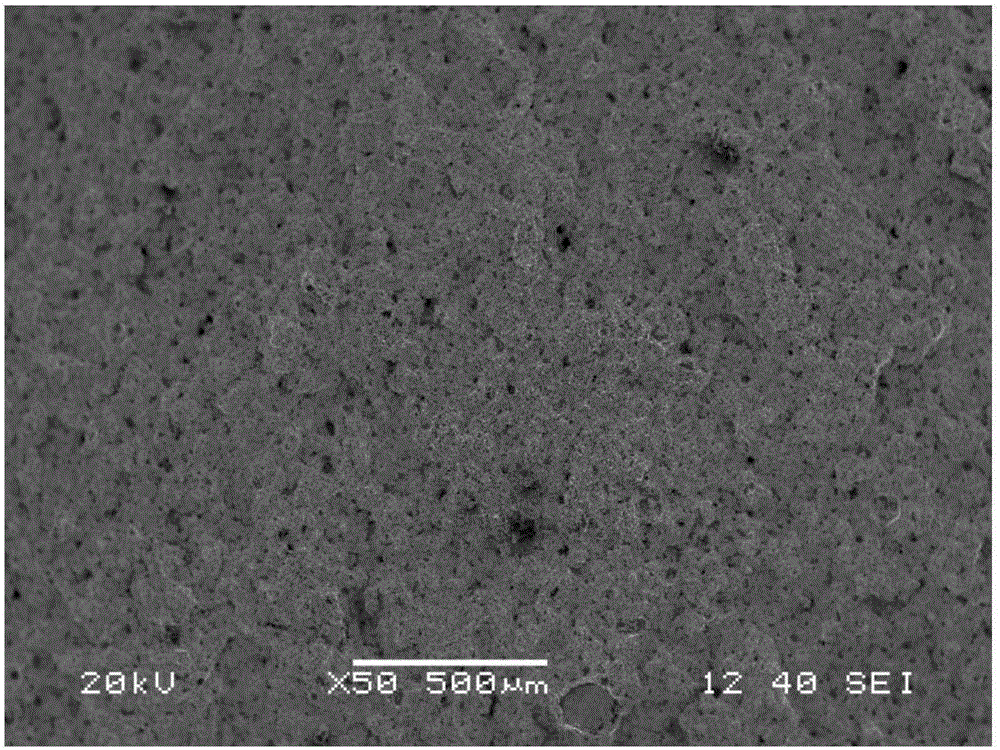

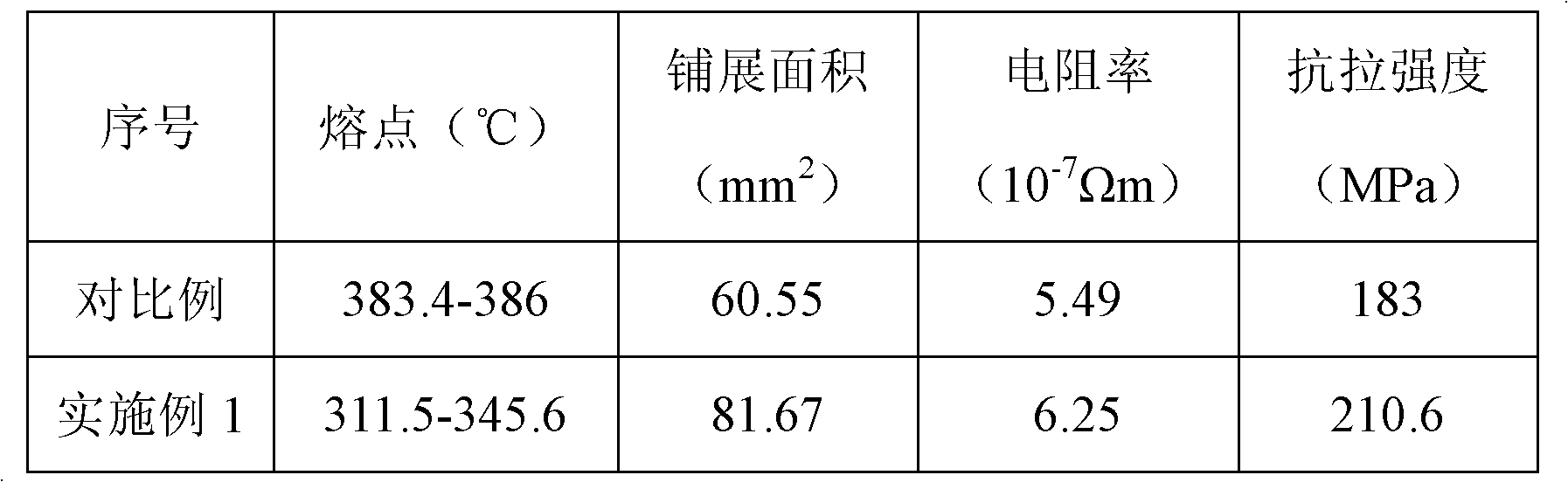

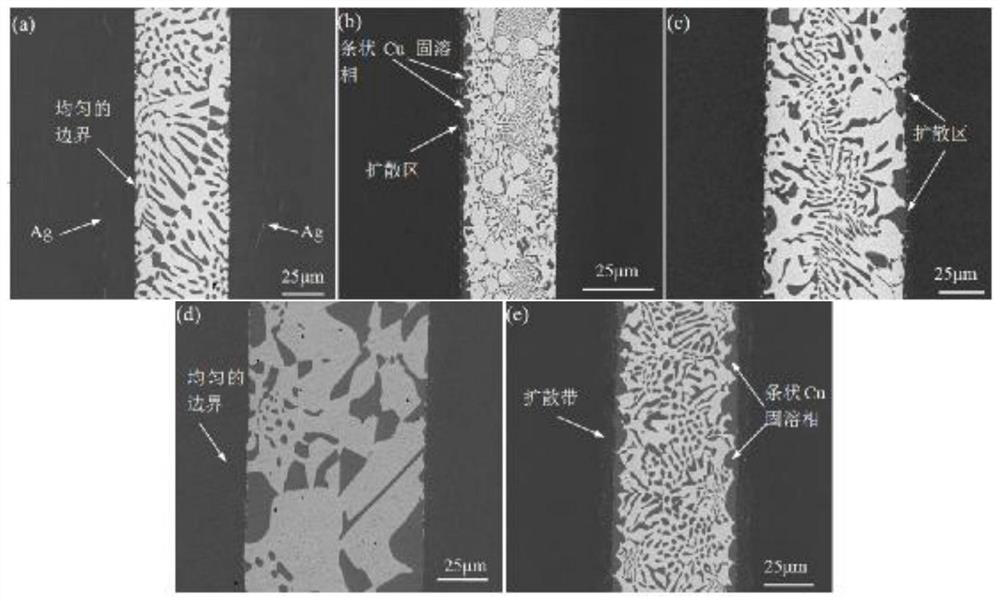

Solder for soldering different-component W-Cu alloy, preparing method and soldering method thereof

ActiveCN105171270AAccelerated corrosionEasy to processWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingCopper

The invention discloses a solder for soldering a different-component W-Cu alloy, a preparing method and a soldering method thereof. The mass percents of the components of the solder are described as follows: 10.0-16.0% of Mn, 0.5-3.5% of Co, 1.0-5.0% of Ni, 1.0-4.0% of Ti, 0.2-0.6% of Si, 0.1-.03% of B, and the balance of Cu. The soldering temperature of the copper-based solder is 1000-1050 DEG C. Moderate fusing temperature of the solder and high fusion uniformity of the solder are realized. Through adding related beneficial elements, good wetability and high metallurgical miscibility of the solder to the W-Cu alloy are realized. An obtained solder joint has high strength and high corrosion resistance and can be totally applied in a complicated environment. The solder is an economical solder with high comprehensive performance. A prepared copper-based solder foil has functions of facilitating diffusion and interface reaction between alloy elements in a soldering connecting process, improving wetting and spreading capabilities of the solder on the surface of the W-Cu alloy, and facilitating forming of a compact solder joint.

Owner:无锡腾达海川新材料有限公司

ZnSn-base high-temperature lead-free soft solder and preparation method thereof

InactiveCN102672367ALow melting pointGood brazing processWelding/cutting media/materialsSoldering mediaRare earthLanthanum

The invention belongs to the technical field of braze soldering flux for electronic packaging and assembly, and discloses a ZnSn-base high-temperature lead-free soft solder and a preparation method thereof. The ZnSn-base high-temperature lead-free soft solder consists of the following components in percentage by weight: 15 to 40 percent of tin, 0.5 to 8 percent of copper, 0.1 to 1 percent of lanthanum and neodymium mixed rare earth, 0.1 to 3 percent of magnesium and / or 0.1 to 2 percent of bismuth and the balance of zinc. The ZnSn-base high-temperature lead-free soft solder has the advantages of no toxicity and no pollution, is high in wetting spreadability and high in tensile strength and mechanical property, and can meet the using requirement of brazing and replace high-lead solders which are applied widely at present or Au-base solders with high price to meet the requirements of the fields of electronic packaging and assembly; and a melting point is between 250 and 450 DEG C.

Owner:HENAN UNIV OF SCI & TECH

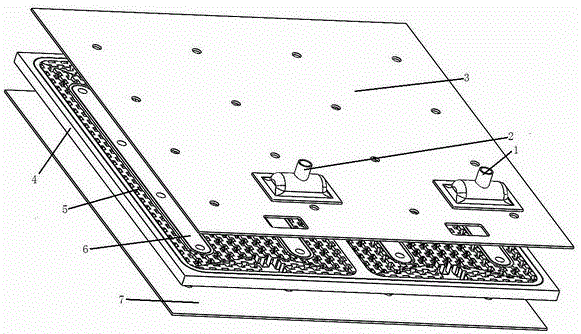

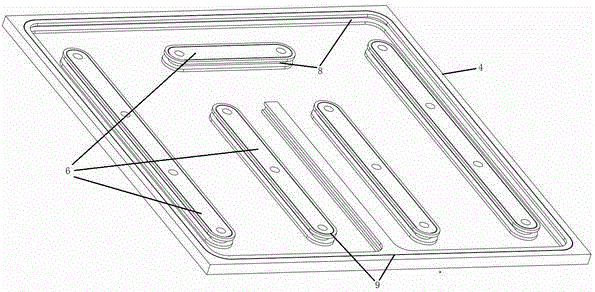

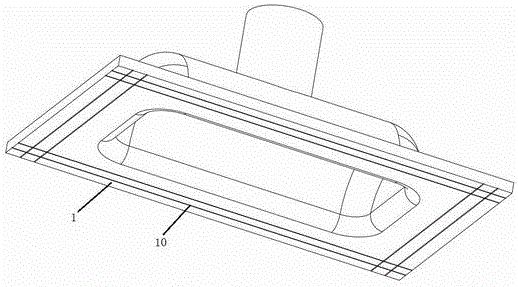

Liquid-cooling cold plate

ActiveCN105682431AImprove temperature uniformityReduce flow dead zoneCooling/ventilation/heating modificationsEngineeringCold plate

The invention discloses a liquid-cooling cold plate, which comprises a liquid inlet connector, a liquid outlet connector, an upper cover plate, frame strip seal, fins, pad blocks and a bottom board, wherein the pad blocks and the fins are arranged in the frame strip seal; the upper cover plate and the bottom board are connected to the two sides of frame strip seal through vacuum brazing to form a sealed heat exchange cavity; the two sides of the pad blocks are connected with the upper cover plate and the bottom board through vacuum brazing respectively; the liquid inlet connector and the liquid outlet connector are connected with the upper cover plate through vacuum brazing; and the inner side surface of the frame strip seal or / and the outer side surfaces of the pad blocks contacted with a heat exchange medium are respectively provided with a groove. The liquid-cooling cold plate is simple in structure, low in cost, high in heat exchange efficiency, good in brazing process, high in welding finished product rate, more beautiful in appearance, small in flow dead zone and good in temperature uniformity.

Owner:XINXIANG TEMEITE HEAT TRASFER EQUIP CO LTD

Low-silver copper based high-performance brazing filler metal and preparation method thereof

InactiveCN108465974AReduce contentReduce dosageWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses low-silver copper based high-performance brazing filler metal. The low-silver copper based high-performance brazing filler metal is prepared from the following raw materials inpercentage by mass: 1.5-2.5% of Ag, 6.5-7.5% of P, 0.5-1.5% of Sn, 0.01-2% of Ni, 0.001-0.1% of Si, 0.01-0.05% of Ce and the balance of copper and inevitable impurities, wherein purity of each raw material is 99.9% or higher. A preparation method for the low-silver copper based high-performance brazing filler metal comprises the following steps of: separately preparing Ni and Cu, P and Cu, Si andCu and Ce and Cu into intermediate alloys in specific proportions; then, sequentially adding metal Cu, Cu-P, Cu-Ni, Cu-Si and Cu-Ce to melt, and adding Sn and Ag after metal is completely molten; andimmediately adding borax after adding is completed, and performing post-treatment to obtain the low-silver copper based high-performance brazing filler metal. Production cost is greatly reduced, improved brazing filler metal is high in mechanical strength and is strong in production process, and a joint is attractive in appearance and is excellent in shearing strength; according to use feedback of a user, braze-welding process performances are excellent, the braze-welding joint is stable in quality, fatigue performance is good, the service life of the braze-welding joint can be effectively prolonged, and BCu80AgP braze-welding can be replaced.

Owner:JIANGSU YUANFANG POWER TECH CO LTD

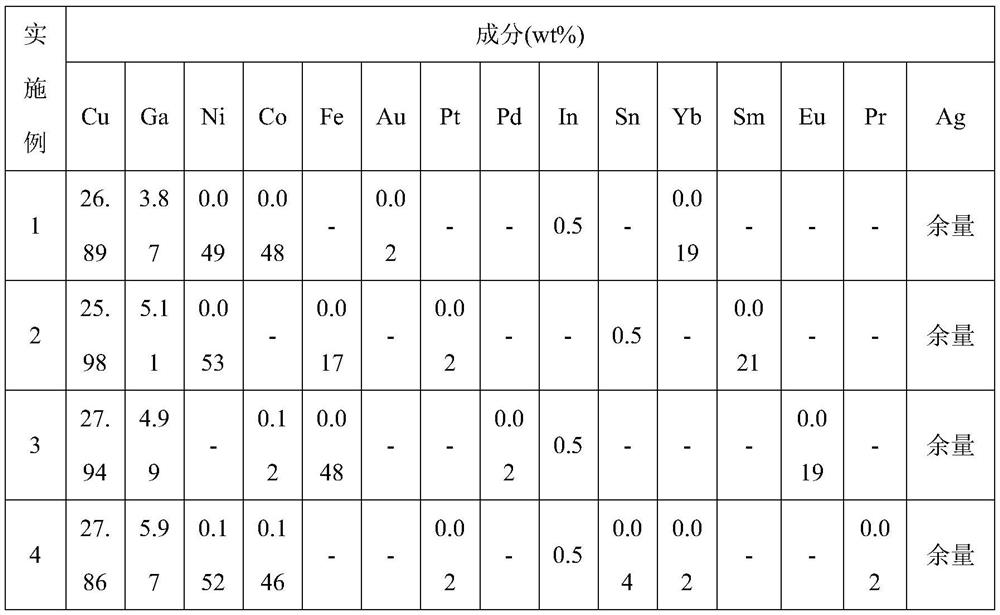

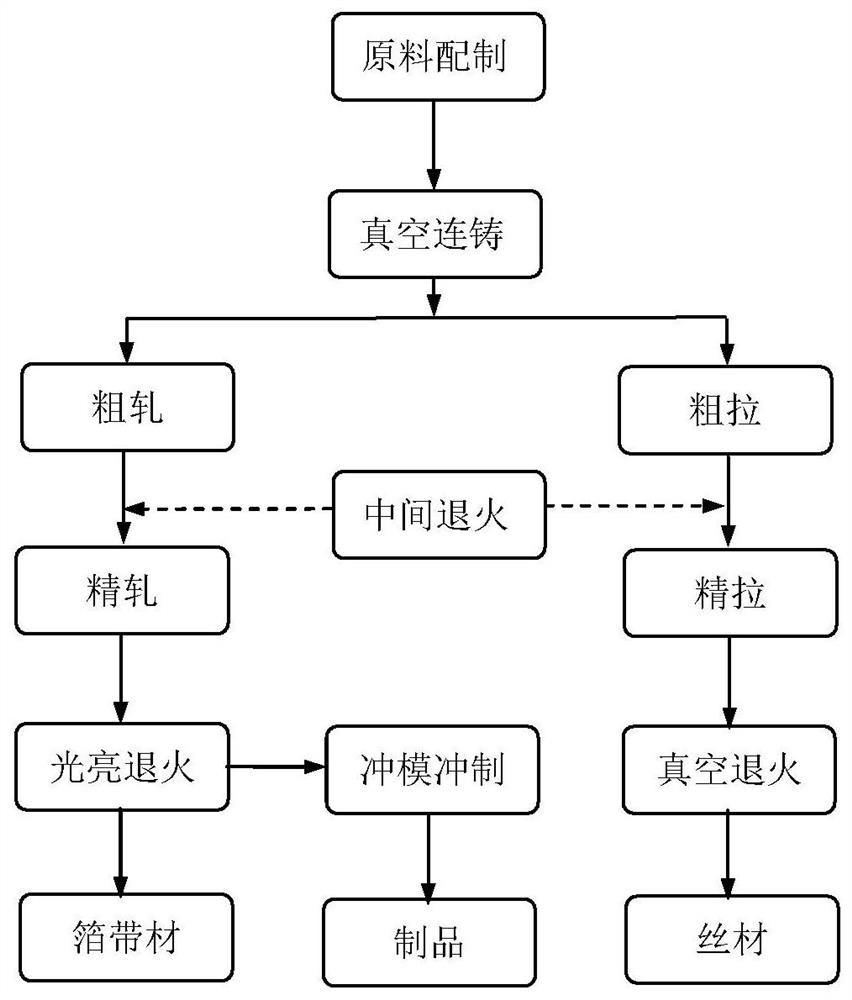

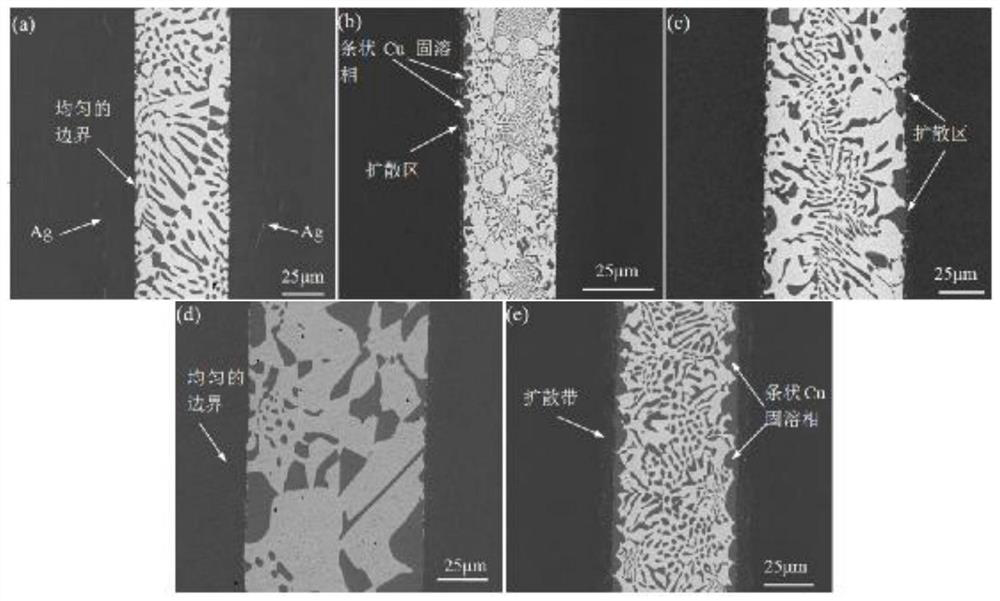

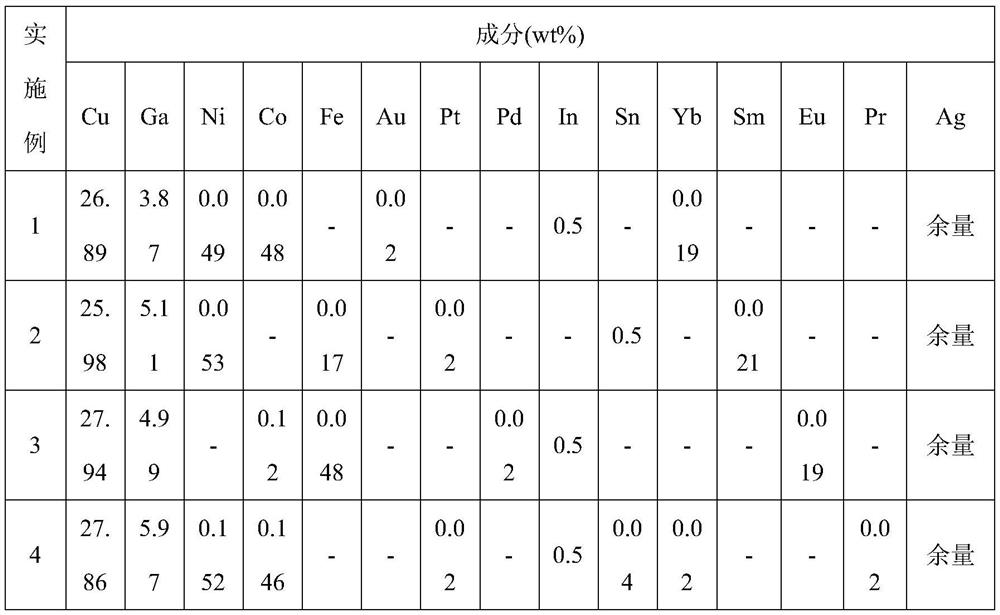

Silver-based brazing filler metal alloy, preparation method of silver-based brazing filler metal alloy, and preparation methods of foil strip and wire

ActiveCN112059468ASolve the problem of high welding temperature and inconsistent melting pointEliminates nickel plating processWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses a silver-based brazing filler metal alloy. The silver-based brazing filler metal alloy comprises the following components of, in percentage by mass, 26%-28% of Cu; 3.5%-5.5% ofGa; at least two of the following elements of 0.001%-0.5% of Ni; 0.001%-0.5% of Co; 0.001%-0.5% of Fe; at least one of the following elements of 0.001%-0.5% of Au; 0.001%-0.5% of Pt; 0.001%-0.5% of Pd; at least one of the following elements of 0.001%-0.5% of In; 0.001%-0.5% of Sn; at least one of the following elements of La, Ce, Pr, Nd, Sm, Eu, Er, Yb, Y and Sc; and the balance Ag. The inventionfurther provides a preparation method of the silver-based brazing filler metal alloy and preparation methods of a foil strip and a wire. When the silver-based brazing filler metal alloy is used for welding a vacuum electronic device, a nickel plating process is omitted, and environmental pollution is prevented; meanwhile, the problems of high welding temperature and inconsistent melt flow pointsof Ag-28Cu-xNi alloy are solved; and the brazing filler metal alloy is good in brazing manufacturability and good in wettability, the brazing rate of kovar alloy, stainless steel and the like is higher than 95%, and the shear strength sigma b of a brazed joint is larger than or equal to 285 MPa.

Owner:KUNMING INST OF PRECIOUS METALS

Tin-based solder for aluminum/copper brazing and preparing method thereof

InactiveCN103317252AHigh strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaIndiumCerium

Provided are a tin-based solder for aluminum / copper brazing and a preparing method thereof. The tin-based solder, by mass percent, contains 18-25% of copper, 4-7% of indium, 0.1-1% of nickel, 0.01-0.1% of rare earth lanthanum or cerium, and the balance tin. The tin-based solder is formed by simple substances of Sn, Cu, In, Ni and intermediate alloy Cu-La or Cu-Ce. The preparing method includes the following steps: 1 calculating and weighing raw materials; 2 smelting Sn-Cu-In-Ni alloy; 3 adding the intermediate alloy; 4 performing heat preservation; 5 performing cooling and taking out the solder. The tin-based solder is good in welding process performance, high in joint strength and good in corrosion resistance, and is applicable to furnace brazing and vacuum brazing of aluminum / copper dissimilar metals.

Owner:UNIV OF SCI & TECH BEIJING +1

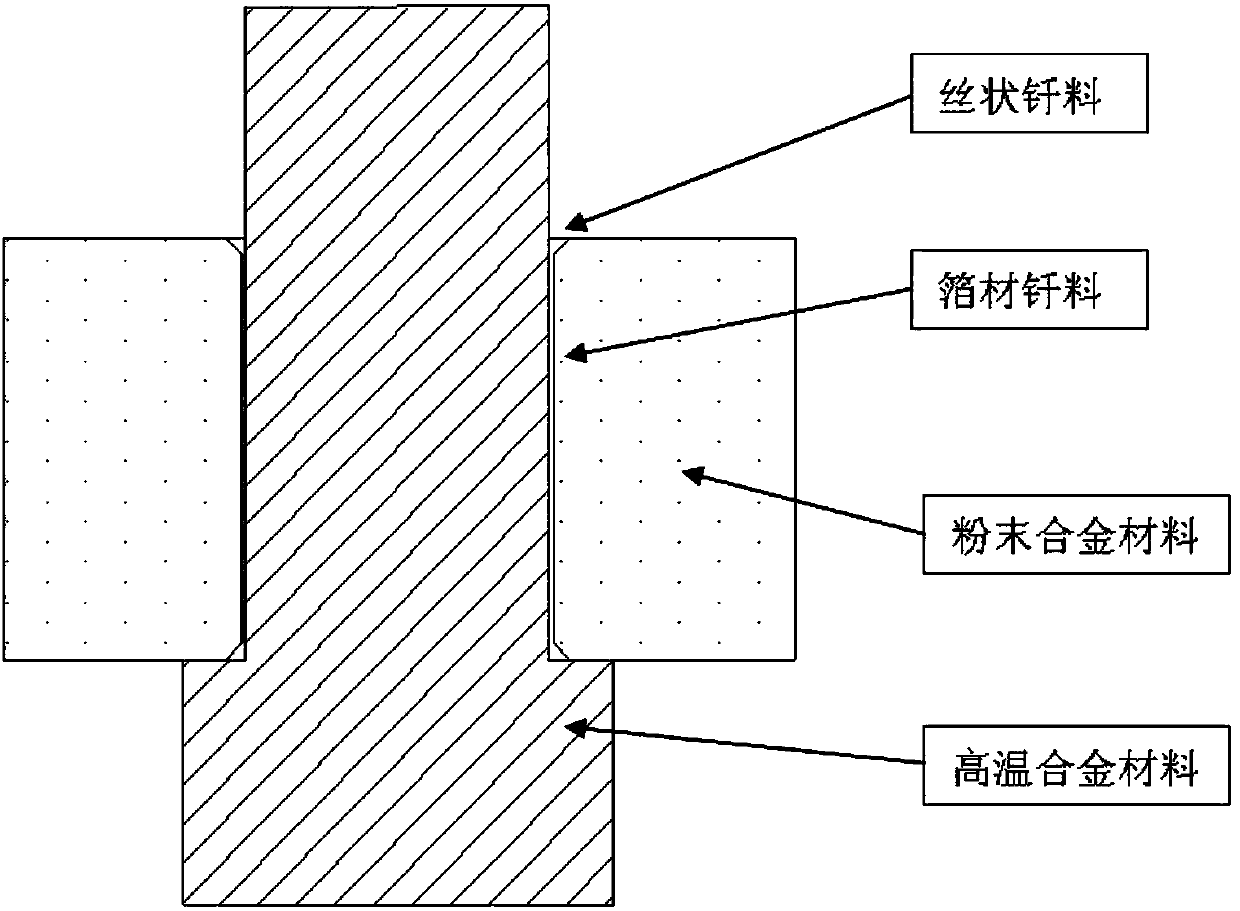

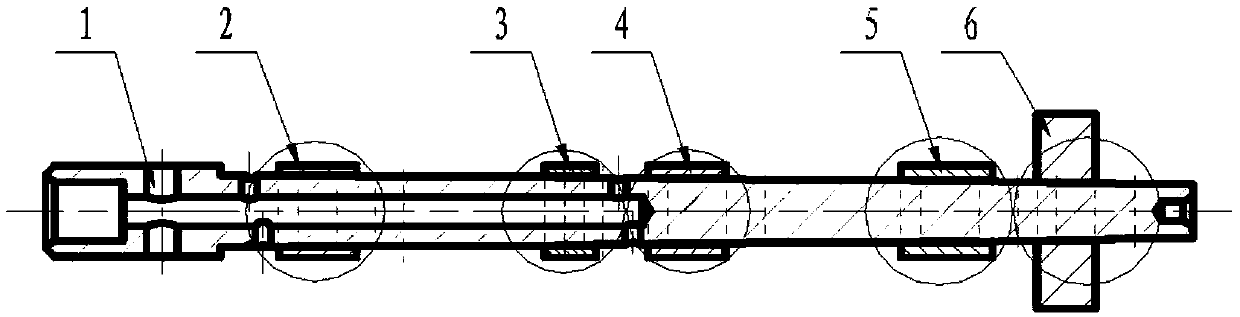

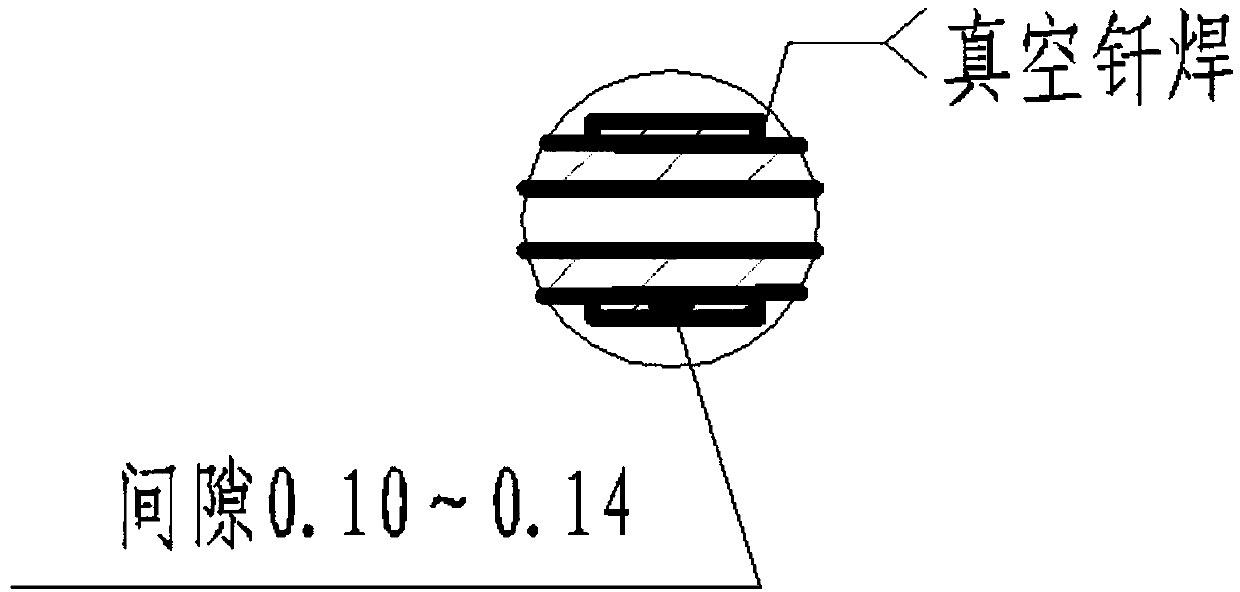

Vacuum brazing method of high-temperature alloy and cobalt-based powder metallurgy material

InactiveCN108031941AGood weld uniformityGuaranteed dimensional accuracy of coaxialitySoldering apparatusWelding/soldering/cutting articlesPowder metallurgySpare part

The invention discloses a vacuum brazing method of a high-temperature alloy and cobalt-based powder metallurgy material, which includes confirmation of a brazing gap; combined layout method of a gold-based brazing filler and a brazing technique. The invention realizes the preparation of a cobalt-based powder metallurgy wear-resisting material layer with excellent friction performance at the surface of a precise spare part. According to the precise spare part processed by the brazing technique, the brazing filler fills the weld joint completely, and the weld joint is good in uniformity; the coaxial dimension precision of the welding spare part is guaranteed, and the shear intensity of the weld joint is over 280 MPa.

Owner:GUIZHOU HONGLIN MACHINERY

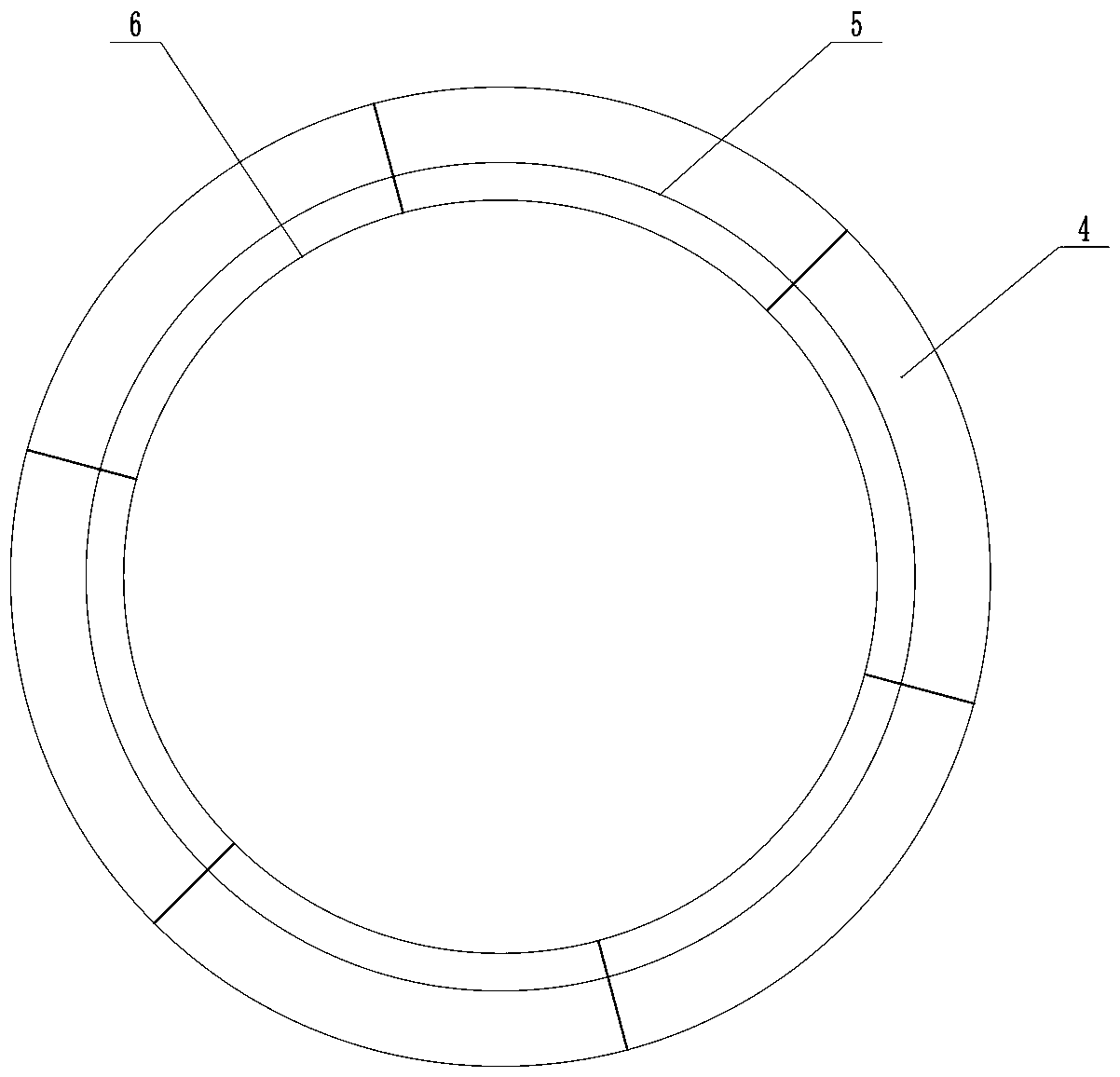

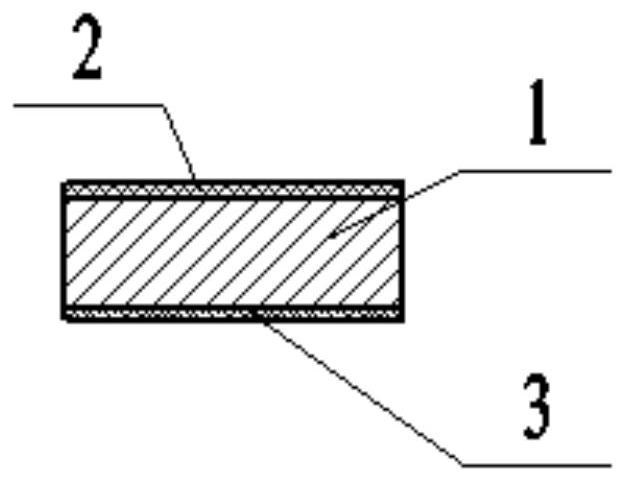

Single-layer high-precision brazed superabrasive grinding wheel and manufacturing method thereof

ActiveCN108857940AHigh precisionImprove manufacturing precisionBonded abrasive wheelsGrinding devicesAdhesiveThermal deformation

The invention provides a single-layer high-precision brazed superabrasive grinding wheel and a manufacturing method thereof. The grinding wheel comprises a metallic basic body, and multiple metallic embedded blocks adhere to the peripheral face of the metallic basic body and are sequentially spliced to form an annular structure; abrasive layers are brazed on the peripheral faces of all the metallic embedded blocks respectively. The manufacturing method includes the steps that 1, female die blocks are manufactured; 2, an inner shape face is machined; 3, abrasive particles are fixed through electroplating or with high-temperature adhesive; 4, the metallic embedded blocks are manufactured; 5, high-temperature brazing is performed; 6, criterion alignment is performed; 7, a metallic matrix is bonded; 8, the metallic matrix is machined; 9, a female die and an electroplating layer or a high-temperature glue layer are removed. With the method, influences on thermal deformation of the basic body of the grinding wheel can be effectively reduced during high-temperature brazing, then the manufacturing precision of the grinding wheel is ensured, and the single-layer high-precision brazed superabrasive grinding wheel is easily applied and popularized in the field of precision machining.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Foil strip brazing filler metal for brazing sintered neodymium-iron-boron permanent magnet materials and preparation method

ActiveCN111151916AThe ingredients are scientific and reasonableGood brazing processWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses a foil strip brazing filler metal for brazing sintered neodymium-iron-boron permanent magnet materials and a preparation method. The brazing filler metal comprises the following components in percentage by mass: 7.0-8.0% of Nd, 19.0-20% of Al, 8.0-9.0% of Si, 4.0-5.0% of Zn, 1.0-2.0% of Ge, 3.0-4.0% of Ag, 0.5-0.6% of Ga, 0.35-0.45% of Bi, and the balance Cu. The brazing filler metal is prepared by a melt quick cooling technology, has a melting point lower than 580 DEG C, is suitable for vacuum brazing of sintered neodymium-iron-boron magnet homogeneous materials, in particular high-coercivity H, UH magnets, and can be used for vacuum brazing of sintered neodymium-iron-boron magnets and carbon structural steel heterogeneous materials such as 10# steel; the brazing temperature is 590-605 DEG C; and the brazing joint shearing strength is higher than 55MPa.

Owner:ZHEJIANG UNIV

Brazing filler metal for braze welding of sintered neodymium-iron-boron magnet with nickel-plated layer and preparation method

ActiveCN111151917ALow melting pointThe ingredients are scientific and reasonableWelding/cutting media/materialsSoldering mediaCopperUltimate tensile strength

The invention discloses a brazing filler metal for braze welding of a sintered neodymium-iron-boron magnet with a nickel-plated layer and a preparation method. The brazing filler metal comprises the following components in percentage including, by mass, 10.0-12.0% of Al, 8.0-9.5% of Si, 4.5-5.0% of Zn, 3.0-4.0% of Ge, 5.0-6.0% of Ag, 4.5-5.0% of Ni, 0.35-0.40% of Bi, 0.40-0.45% of La, 0.40-0.55% of Ce, and the balance copper. The brazing filler metal is prepared by using the rapid metal cooling technology, the melting point is lower than 532 DEG C, and the brazing filler metal is suitable forvacuum braze welding of the sintered neodymium-iron-boron magnet with the nickel-plated layer and heterogeneous materials, such as 10# steel and pure iron, wherein the braze welding temperature is 545-560 DEG C, and the shearing intensity of a braze welding joint is higher than 41 MPa.

Owner:ZHEJIANG UNIV

Low-silver base brazing filler metal and preparation method thereof

InactiveCN106624448AReduce contentReduce dosageWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention provides low-silver base brazing filler metal and a preparation method thereof, and belongs to the technical field of solders. The low-silver copper base brazing filler metal is prepared by the following raw materials in percentage by mass: 1.8-2.2% of Ag, 4.8-5.2% of P, 3-8% of Sn, 1-3% of Ni, 0.1-0.2% of Mn, 0.1-0.3% of In, and the balance of copper and inevitable impurities. The low-silver copper base brazing filler metal is high in mechanical strength, excellent in compactness, low in resistivity, excellent in joint corrosion resistance and creep strength, excellent in brazing process performances after use by customers, stable in brazing joint quality and excellent in fatigue performance, and can effectively prolong the service life of a brazing joint.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

High-strength aluminum alloy brazing filler metal with melting point being lower than 500 DEG C and preparation method thereof

InactiveCN102152024BImprove performanceReduce consumptionWelding/cutting media/materialsSoldering mediaFiller metalShear strength

The invention discloses a high-strength aluminum alloy brazing filler metal with the melting point being lower than 500 DEG C and a preparation method thereof, belonging to the technical field of aluminum alloy welding. The brazing filler metal contains the following components in percentage by mass: 7.9-8.5 percent of Si, 14.0-16.0 percent of Cu, 7.0-8.0 percent of Ge, 2.0-4.0 percent of Ni, 2.0-3.0 percent of Sn, 0.5-1.5 percent of Mg, 0.55-0.65 percent of Sr, 0.1-0.3 percent of Bi, 0.5-1.0 percent of La and the balance of Al. The brazing filler metal is prepared by adopting a melt rapid cooling technology, has the melting point being lower than 500 DEG C and the brazing temperature from 520 DEG C to 530 DEG C, and is suitable for the brazing such as flame brazing, induction brazing, furnace brazing, gas-shielded brazing and the like of aluminum alloy with solidus curve of higher than 520 DEG C,. The brazing filler metal is in cooperation with QJ201 brazing LF21, and the shearing strength of a brazed joint is larger than 70MPa. The brazing filler metal has less content of Ge and lower cost.

Owner:ZHEJIANG UNIV

Method for improving strength of tool body of planer tool

InactiveCN107962362AQuality assuranceReduce dosageFurnace typesHeat treatment furnacesWeld strengthUltimate tensile strength

The invention relates to the field of tool machining methods, and particularly discloses a method for improving the strength of a tool body of a planer tool. The method mainly adopts a brazing step, an isothermal quenching step and a brine quenching step; according to the brazing step, the maximum temperature and the temperature rising speed can be controlled, the time of 45 steel being in austenitization is reduced, the situation that the grain size of the 45 steel is excessively coarse is prevented, it can be ensured that the tool body has the high strength, and the welding strength in the brazing step can be improved accordingly; and meanwhile, the isothermal quenching step and the brine quenching step can enhance the strength of the whole planer tool. According to the schemed of the method for improving the strength of the tool body of the planer tool, the strength of the tool body can be improved, and the strength of the whole planer tool is improved accordingly.

Owner:重庆派斯克刀具制造股份有限公司

Strip-shaped brazing filler metal for lap joint brazing of copper plate and aluminum plate and preparation method thereof

ActiveCN112894191ALow melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaPolyvinyl alcoholLap joint

The invention belongs to the field of welding materials, and relates to strip-shaped brazing filler metal for lap joint brazing of a copper plate and an aluminum plate and a preparation method thereof. The strip-shaped brazing filler metal comprises a brazing filler metal body, a coating I and a coating II, the brazing filler metal body comprises the chemical components of 3.2%-4.5% of nano-zinc oxide, 6.8%-8.2% of selenium, 2.6%-4.2% of aluminum and the balance zinc, the coating I is composed of 90%-92% of surface modified nano-copper and the balance of polyvinyl alcohol, the coating II is composed of 90%-92% of surface modified nano-aluminum and the balance of polyvinyl alcohol, and the molecular weight of the polyvinyl alcohol is 8000 to 12000. According to the strip-shaped brazing filler metal for lap joint brazing of the copper plate and the aluminum plate and the preparation method thereof, the melting point of the brazing filler metal is 330 DEG C + / -10 DEG C, the wettability of the brazing filler metal is good, and due to the existence of the nano-zinc oxide, the nano-copper coating and the nano-aluminum coating, the shear strength of a copper plate and aluminum plate brazed joint is effectively improved and reaches 121 MPa or above. The preparation method is an innovation in the aspect of the strip-shaped brazing filler metal for lap joint brazing of the copper plate and the aluminum plate.

Owner:ZHENGZHOU UNIV

A kind of al-si-cu-zn series low-melting-point aluminum-based solder and preparation method thereof

InactiveCN103934591BGood brazing processLow melting pointWelding/cutting media/materialsSoldering mediaManganeseFiller metal

The invention belongs to the field of welding materials, and discloses Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal and a preparing method of the Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal. The Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal comprises, by mass, 3.50%-4.50% of silicone, 15%-23% of copper, 10%-24% of zinc, 0.80%-1.20% of manganese, 0.80%-1.20% of magnesium, 0.02%-0.08% of strontium and the balance aluminum. Dosing is carried out according to the component contents, then the components are melted in a specific sequence and refined through hexachloroethane two times to carry out casting to obtain an alloy blank, and finally hot rolling is carried out on the alloy blank multiple times to obtain the foil-shaped aluminum-based brazing filler metal. The Al-Si-Cu-Zn low-melting-point aluminum-based brazing filler metal has the advantages of being low in melting point, excellent in brazing technology performance and low in cost, can be widely used for aluminum-based materials, and can be particularly used for brazing Al-Mn alloy materials.

Owner:SOUTH CHINA UNIV OF TECH

A kind of low-silver copper-based solder and preparation method thereof

ActiveCN103624418BReduce contentReduce dosageWelding/cutting media/materialsSoldering mediaRare earthFiller metal

The invention relates to a low-silver-copper-based brazing filler metal and a preparation method thereof. The low-silver-copper-based brazing filler metal comprises Ag, Cu and P, wherein Sn, Ni and rare earth are further added, the weight percentages of the components are as follows: 1.5%-2.5% of Ag, 5.5%-6.6% of P, 5%-7% of Sn, 1.0-2.5% of Ni, not more than 0.05% of rare earth and the balance of Cu; the preparation method of the low-silver-copper-based brazing filler metal comprises the following steps of preparing Sn to filament Sn, smelting, continuously casting, continuously extruding, forming and cleaning to obtain the brazing filler metal. The brazing filler metal has the advantages of reasonable formulation design, lower brazing filler metal melting temperature, good wettability and mobility, stable quality of a soldered joint and long service life; a BCu80AgP copper-phosphorus brazing filler metal can be replaced, and the production cost of motor brazing is greatly reduced. The preparation method of the brazing filler metal can effectively solve a segregation problem of Sn, a preparation process is optimized, and the quality of the prepared brazing filler metal is remarkably improved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

A kind of copper base solder and preparation method thereof

ActiveCN103358051BEasy to processReduced processing performanceWelding/cutting media/materialsSoldering mediaRare earthManganese

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

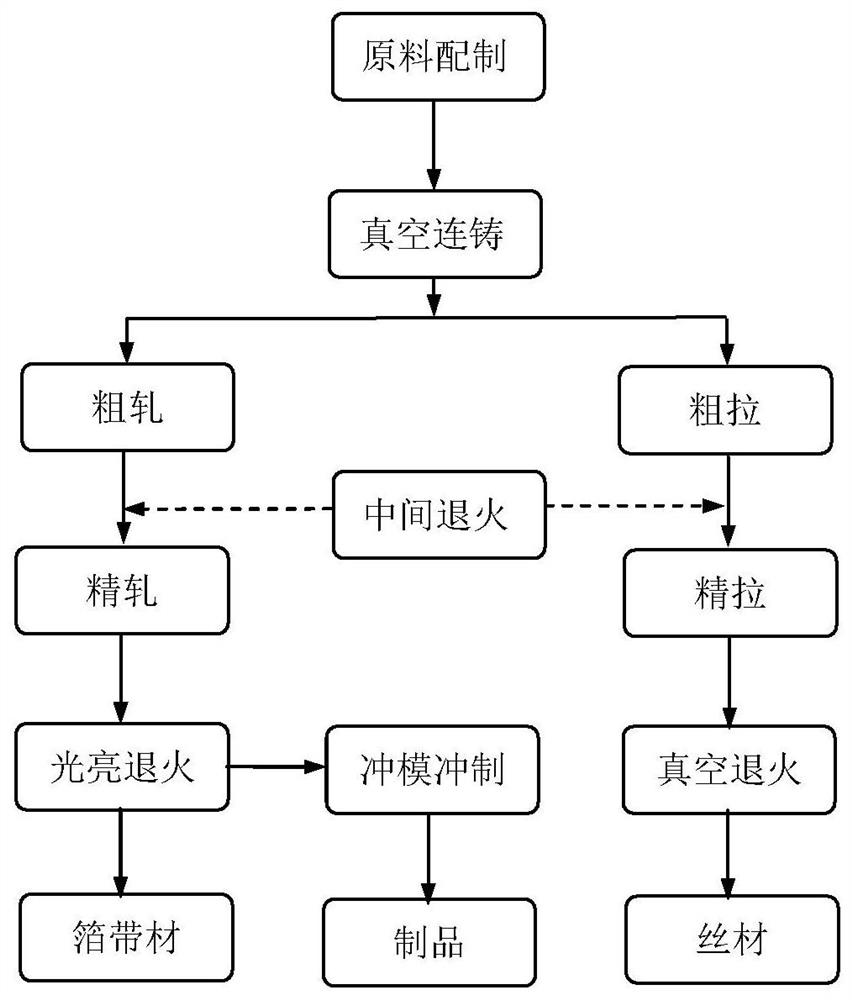

A kind of silver-based solder alloy and its preparation method, the preparation method of foil strip material and wire material

ActiveCN112059468BGuaranteed cleanlinessEasy to realize industrial productionWelding/cutting media/materialsSoldering mediaUltimate tensile strengthKovar

The invention discloses a silver-based solder alloy, which comprises: Cu, 26-28%; Ga, 3.5-5.5%; at least two of the following elements: Ni, 0.001-0.5%; Co, 0.001- 0.5%; Fe, 0.001-0.5%; at least one of the following elements: Au, 0.001-0.5%; Pt, 0.001-0.5%; Pd, 0.001-0.5%; at least one of the following elements: In, 0.001-0.5% %; Sn, 0.001-0.5%; at least one of the following elements: La, Ce, Pr, Nd, Sm, Eu, Er, Yb, Y and Sc; the balance is Ag. The invention further provides a preparation method of silver-based solder alloy and a preparation method of foil strip and wire. The silver-based solder alloy of the present invention saves the nickel-plating process in welding vacuum electronic devices, preventing it from polluting the environment; at the same time, it solves the problems that the welding temperature of the Ag-28Cu-xNi alloy is high and the melting point is inconsistent; the solder The material alloy brazing process is good, has good wettability, the brazing rate of Kovar alloy, stainless steel, etc. is higher than 95%, and the shear strength of the brazed joint is σ b ≥285MPa.

Owner:KUNMING INST OF PRECIOUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com