Copper-based solder and preparation method thereof

A technology of copper-based brazing material and blank, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as difficulty in adapting to assembly-type precision brazing, limiting the application range of brazing material, and weakening the mechanical properties of joints, etc., to achieve overall Inexpensive, improved oxidation resistance, wettability and gap filling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

[0028] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, and the mass percentage of iron in the copper-iron master alloy is 4.95%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 4.95%, and the balance is copper; the mass percentage of the misch metal in the copper-boron master alloy is 5.00%, The balance is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

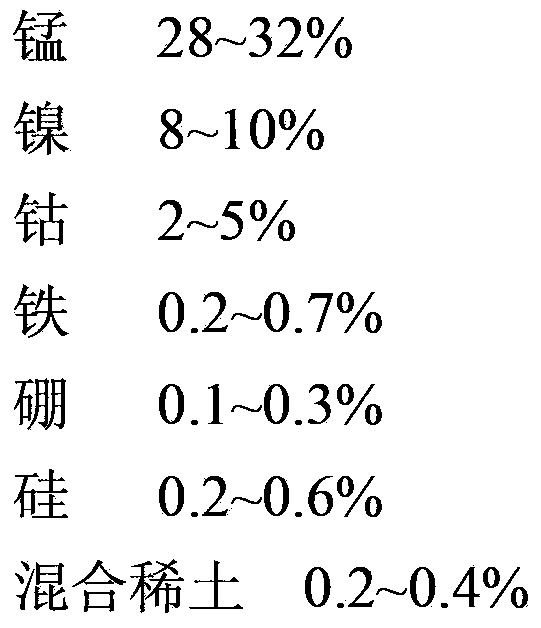

[0029] Prepare the charge according to the mass percentage of the following elements:

[0030]

[0031] The balance is copper;

[0032] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper...

Embodiment 2

[0036] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

[0037] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, and the mass percentage of iron in the copper-iron master alloy is is 5.00%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 5.00%, and the balance is copper; is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

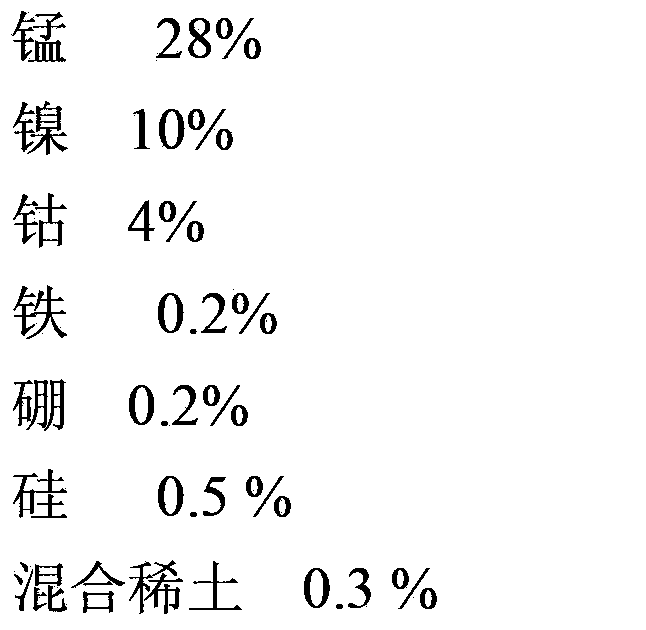

[0038] Prepare the charge according to the mass percentage of the following elements:

[0039]

[0040] The balance is copper;

[0041] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper-mixed rare earth master alloy, copper-iron master alloy, and use medium frequency inductio...

Embodiment 3

[0045] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

[0046] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, and the mass percentage of iron in the copper-iron master alloy is is 5.00%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 5.00%, and the balance is copper; is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

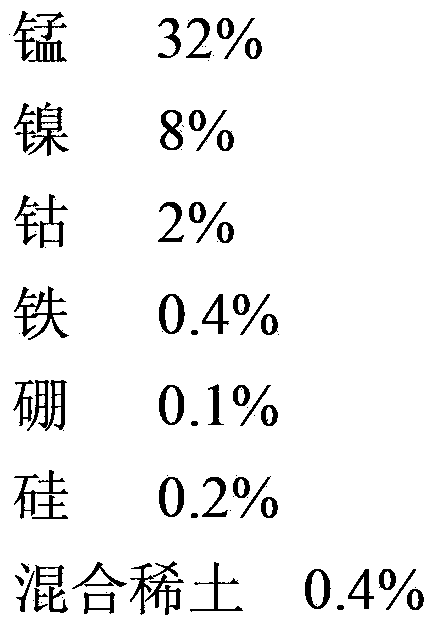

[0047] Prepare the charge according to the mass percentage of the following elements:

[0048]

[0049]

[0050] The balance is copper;

[0051] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper-mixed rare earth master alloy, copper-iron master alloy, and use medium freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com