Liquid-cooling cold plate

A liquid-cooled cold plate and cover plate technology, which is used in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. Low problems, to achieve the effect of small flow dead zone, high welding yield and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

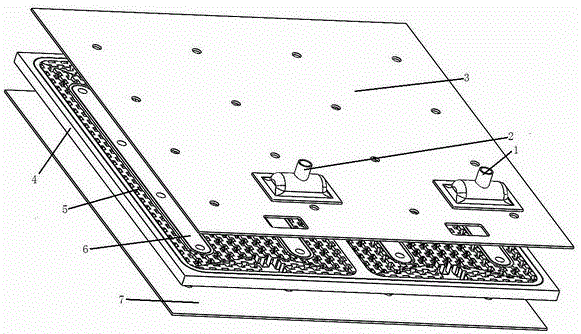

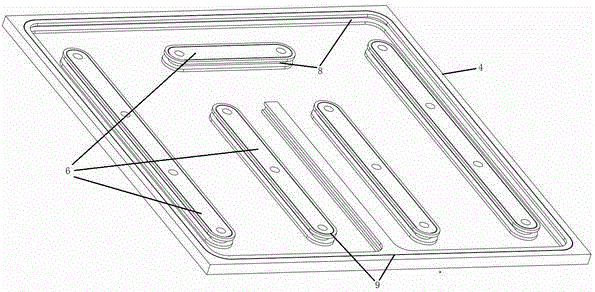

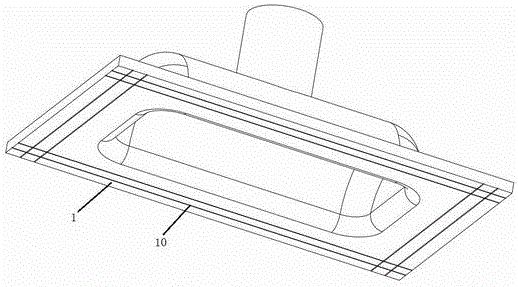

[0017] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. A liquid-cooled cold plate, including a liquid inlet joint 1, a liquid outlet joint 2, an upper cover plate 3, a frame seal 4, a fin 5, a pad 6 and a bottom plate 7, wherein the pad 6 and the fin 5 are arranged on the frame seal 4, the upper cover plate 3 and the bottom plate 7 are connected to both sides of the frame seal 4 by vacuum brazing to form a sealed heat exchange cavity, and the two sides of the spacer 6 are respectively connected to the upper cover plate 3 and the bottom plate 7 by vacuum brazing, The spacer 6 is used to prevent the flow channel from leaking when the mounting holes are processed on the upper cover plate and the bottom plate. The liquid inlet joint 1 and the liquid outlet joint 2 are connected to the upper cover plate 3 by vacuum brazing respectively, and the parts in contact with the heat exchange medium The inner surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com