Solder for soldering different-component W-Cu alloy, preparing method and soldering method thereof

A brazing material and brazing technology, which is applied in welding equipment, metal processing equipment, welding/welding/cutting articles, etc., can solve the problems that have not been seen in the brazing reports of different components of W-Cu alloy, and achieve the promotion of solid solution Effect of metallurgical reaction, improvement of comprehensive performance, improvement of plasticity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

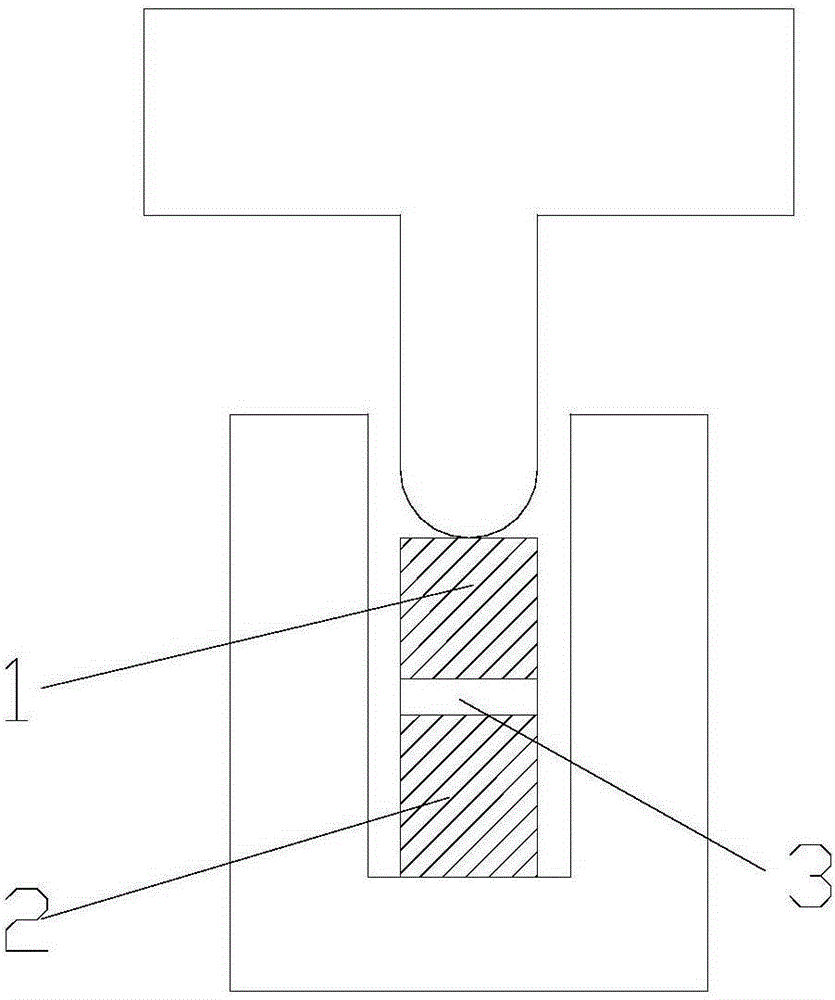

Method used

Image

Examples

Embodiment 1

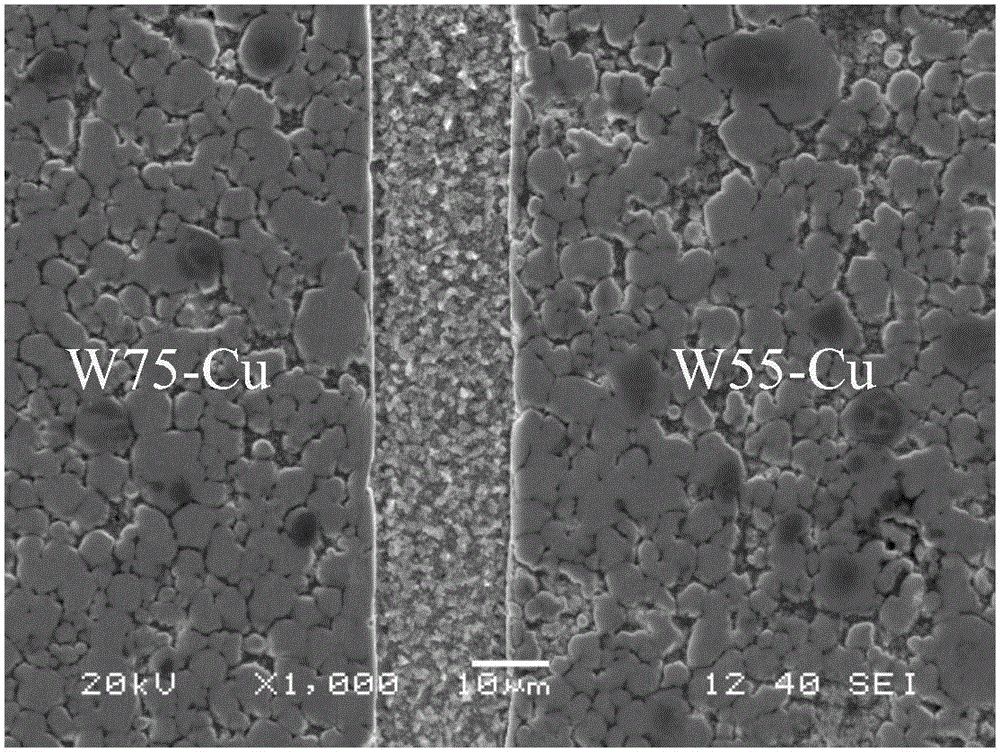

[0036] W75-Cu1 alloy and W55-Cu2 alloy were selected for butt joint vacuum brazing. Among them, the size of W75-Cu1 alloy and W55-Cu2 alloy samples are both 20mm×20mm×6mm, and the surface to be brazed is 20mm×6mm in section.

[0037] The composition and mass percentage ratio of the solder are: Mn13.0%, Co2.5%, Ni3.0%, Ti3.0%, Si0.5%, B0.2%, and the balance is Cu. The thickness of the solder is 100 μm.

[0038] Above-mentioned a kind of solder preparation method of brazing W75-Cu alloy and W55-Cu alloy comprises the following steps:

[0039] 1) Weigh high-purity 130g Mn flakes, 25g Co granules, 30gNi granules, 30gTi granules, 5gSi granules, 2gB granules and 778gCu granules to prepare a mixture according to mass percentage, put it into a container with acetone, and keep it at a temperature of about 20°C Perform ultrasonic cleaning for 15-20 minutes;

[0040] 2) drying the mixture after ultrasonic cleaning in step 1 at a temperature of 30-50° C. to obtain a dried mixture;

[00...

Embodiment 2

[0052] W80-Cu alloy and W60-Cu alloy were selected for vacuum brazing of butt joints. Among them, the size of W80-Cu alloy and W60-Cu alloy sample is 20mm×20mm×6mm, and the surface to be brazed is 20mm×6mm.

[0053] The composition and mass percentage ratio of the solder are: Mn15.0%, Co2.0%, Ni3.0%, Ti3.0%, Si0.3%, B0.15%, and the balance is Cu. The thickness of the solder was 130 μm.

[0054] The brazing process steps are:

[0055] (1) Preparation stage: Clean the end faces of W80-Cu alloy and W60-Cu alloy samples to be brazed, remove surface impurities, oil stains and oxide films, use W28~W3.5 metallographic sandpaper to grind smooth, use W3.5 metallographic sandpaper to grind both sides of the copper-based solder foil smooth, after grinding, put the W80-Cu alloy, W60-Cu alloy and the solder foil together in acetone, and use ultrasonic cleaning for 15-20 minutes, And carry out drying treatment;

[0056] (2) Assembly stage: place the cleaned solder foil between the W80-C...

Embodiment 3

[0060] W70-Cu alloy and W50-Cu alloy were selected for vacuum brazing of butt joints. Among them, the size of W70-Cu alloy and W50-Cu alloy sample is 20mm×20mm×6mm, and the surface to be brazed is 20mm×6mm.

[0061] The composition and mass percentage ratio of the solder are: Mn12.0%, Co3.0%, Ni4.0%, Ti3.0%, Si0.6%, B0.3%, and the balance is Cu. The thickness of the solder is 150 μm.

[0062] The brazing process steps are:

[0063] (1) Preparation stage: Clean the end faces of the W70-Cu alloy and W50-Cu alloy samples to be brazed to remove impurities, oil stains and oxide films on the surface, and use W28~W3.5 metallographic sandpaper to grind and smooth. W3.5 metallographic sandpaper to grind the copper-based solder foil on both sides to smooth, after grinding, put W70-Cu alloy, W50-Cu alloy and solder foil together in acetone, and use ultrasonic cleaning for 15-20min, And carry out drying treatment;

[0064] (2) Assembly stage: place the cleaned solder foil between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com