Patents

Literature

66 results about "Potassium bifluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium bifluoride is the inorganic compound with the formula KHF₂. This colourless salt consists of the potassium cation and the bifluoride (HF₂⁻) anion. The salt is used in etchant for glass. Sodium bifluoride is related and is also of commercial use as an etchant as well as in cleaning products.

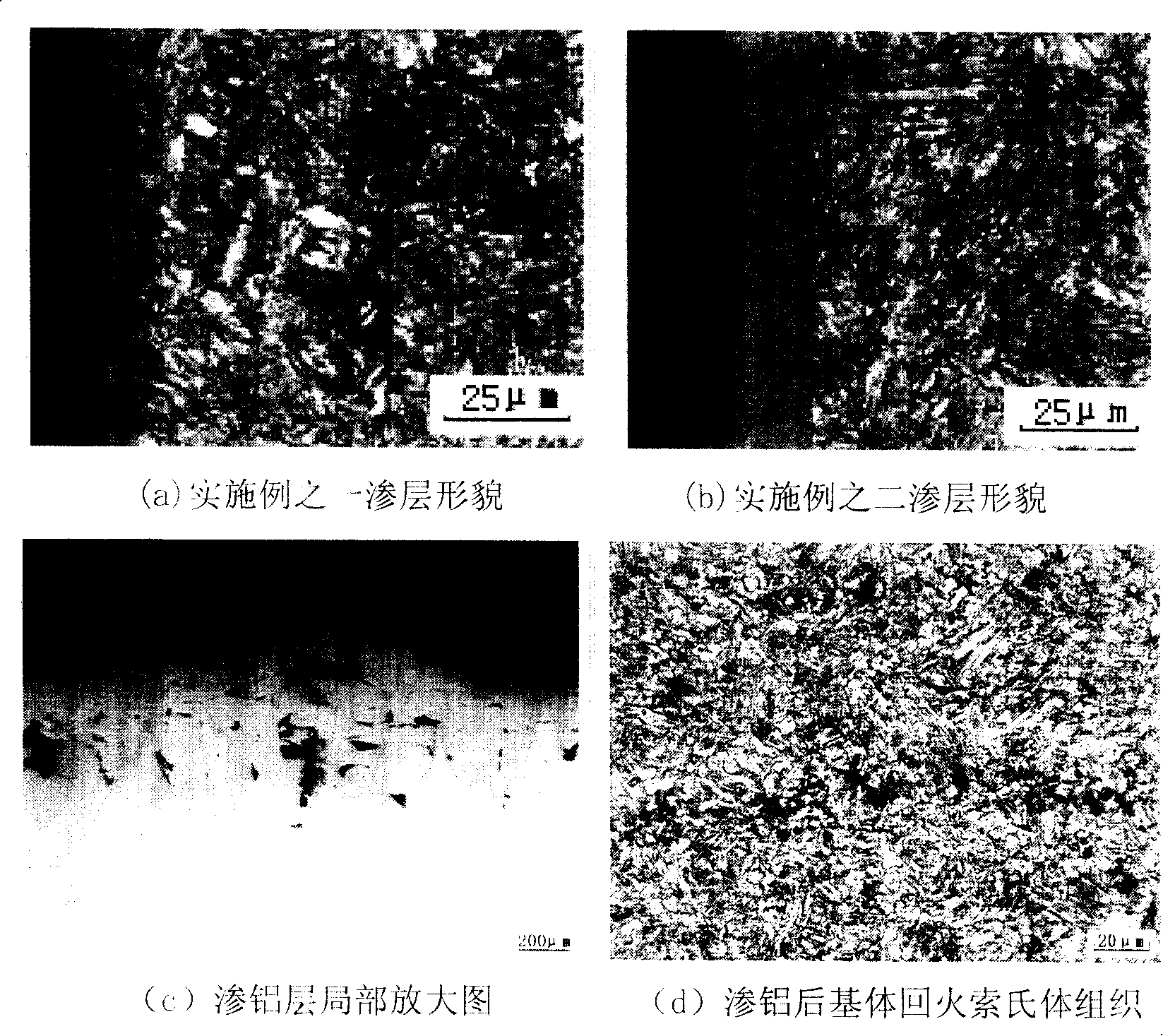

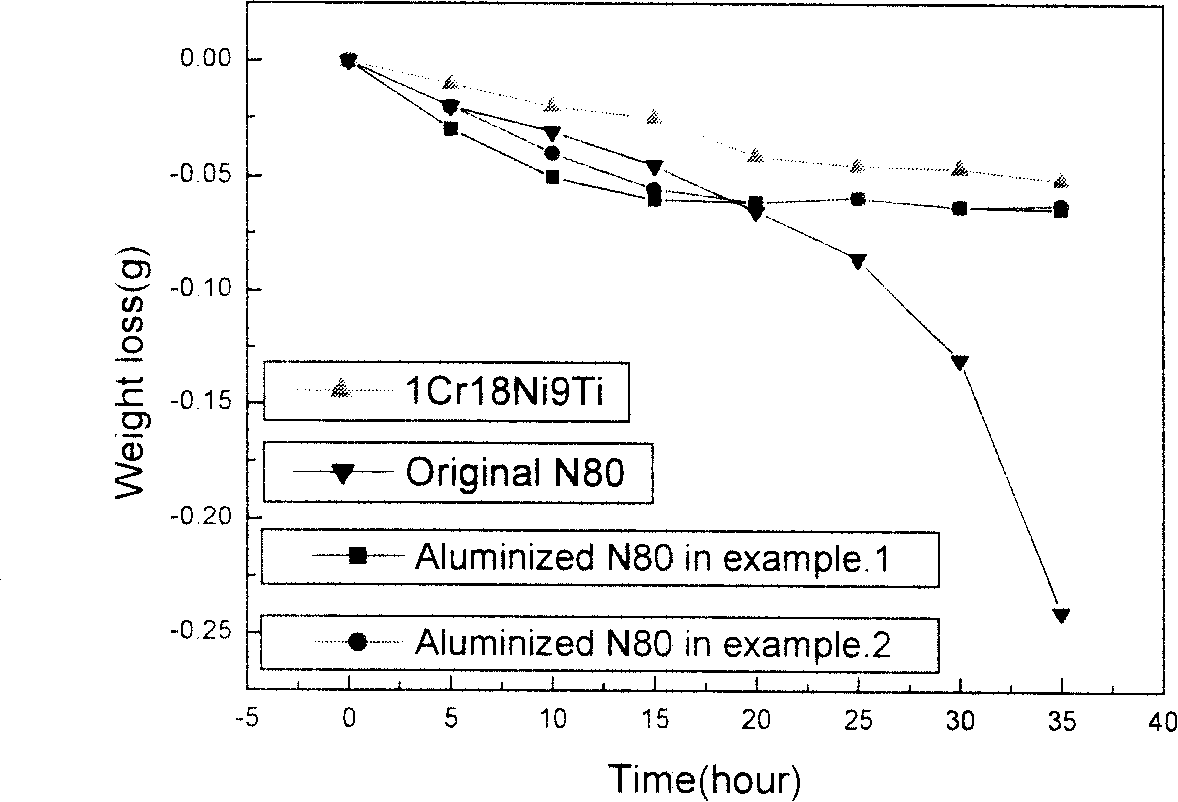

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

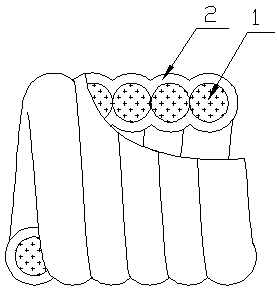

High-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux

ActiveCN105127618AHigh activityStrong ability to remove filmWelding/cutting media/materialsSoldering mediaPotassium borohydridePotassium fluoride

The invention discloses a high-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux. The high-strength and high-toughness composite silver solder ring comprises a silver solder ring body of a hollow structure. The silver solder ring body is formed by winding composite silver solder formed by a silver solder pipe and a flux core with which the silver solder pipe is filled. The flux core is prepared from boron micro-powder, sodium borohydride or potassium borohydride, potassium fluoborate, boric anhydride or boric acid, potassium fluoride or sodium fluoride or lithium fluoride, potassium bifluoride and potassium fluoroaluminate according to a certain proportion. The purpose of in-situ synthesis of the soldering flux through the boron micro-powder in the flux core and metal elements in the silver solder pipe is achieved, so that the content of the flux core is reduced, and when the content of the flux core is low, the solder still achieves good brazing manufacturability; meanwhile, due to the fact that the wall thickness of the solder pipe is increased, good toughness and high stiffness are achieved, the processing performance of the solder is greatly improved, the minimum diameter can be reduced to 0.8 mm, the solder can be easily wound into the solder ring with the intermediate diameter below 6 mm, and application and popularization of the automatic brazing process are facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

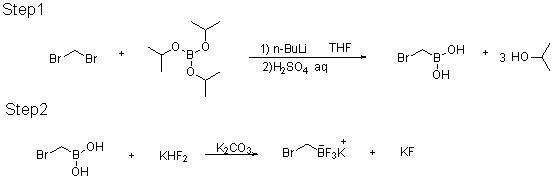

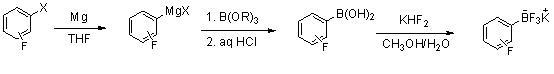

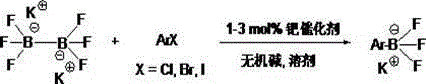

Method for preparing potassium trifluoroborate series compounds

InactiveCN102060867ASolve corrosiveAvoid affecting yieldGroup 3/13 element organic compoundsOrganic baseBoronic acid

The invention relates to synthesis of organic compounds, and provides a method for preparing potassium trifluoroborate series compounds. The method comprises the following steps of: adding organic boric acid or organic borate and solvent (THF (tetrahydrofuran), or MTBE (Methyl Tertiary Butyl Ether), or ethyl acetate, or methanol) into a reaction kettle lined with tetrafluoroethylene plastic at room temperature; adding potassium bifluoride and water at normal temperature, stirring for 1 to 12 hours, and reacting to prepare a solid-liquid mixture; adding solid potassium ion containing inorganic or organic alkali into the solid-liquid mixture after the reaction is completed, neutralizing until the pH is between 7 and 9, and continuously stirring for 1 to 5 hours; directly filtering to obtain a solid coarse product after stirring is completed; dissolving the coarse product with solvent, filtering and concentrating, adding nonpolar solvent, and pulping to obtain high-quality RBF3K series compounds. The method is easy to operate, has mild reaction conditions, and can realize scale-up production; and the product prepared by the method has high yield and excellent purity, and the cost is greatly reduced.

Owner:大连联化医药技术有限公司

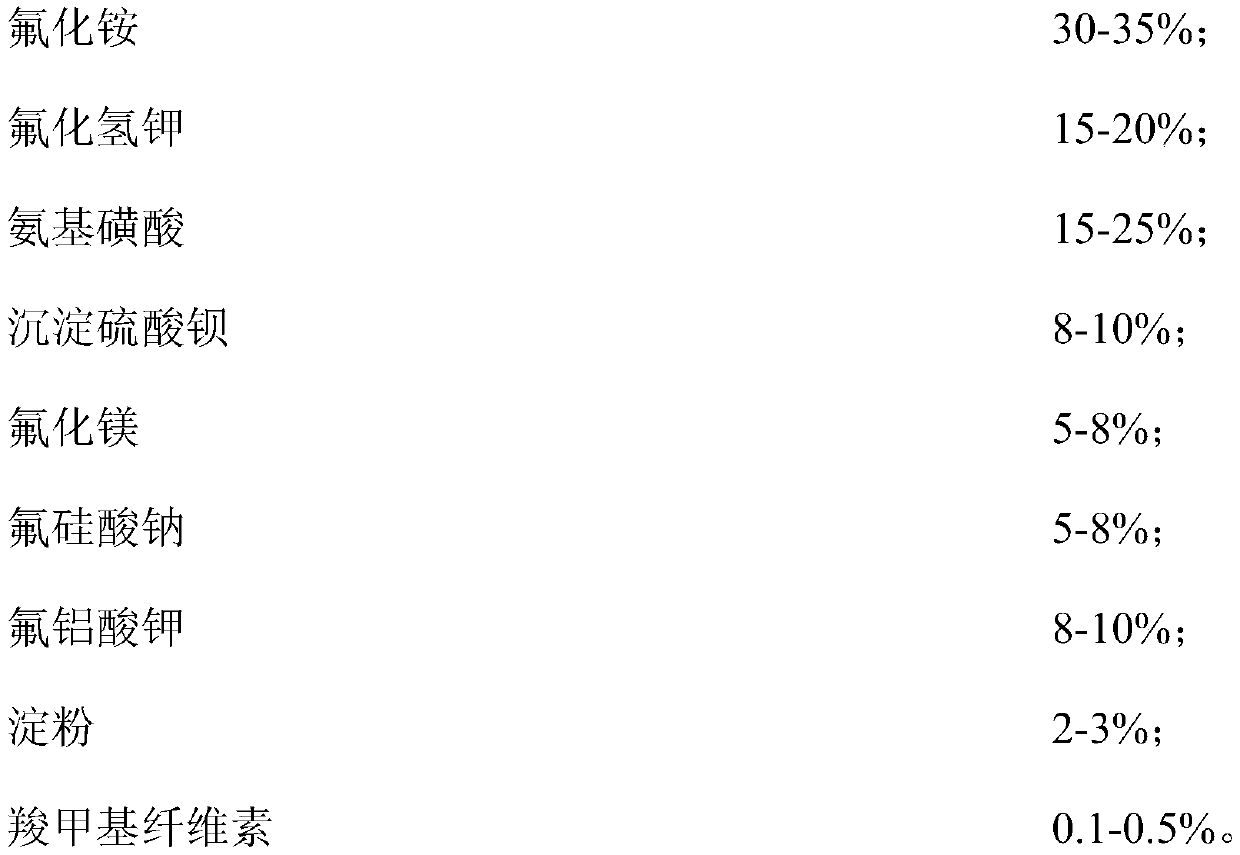

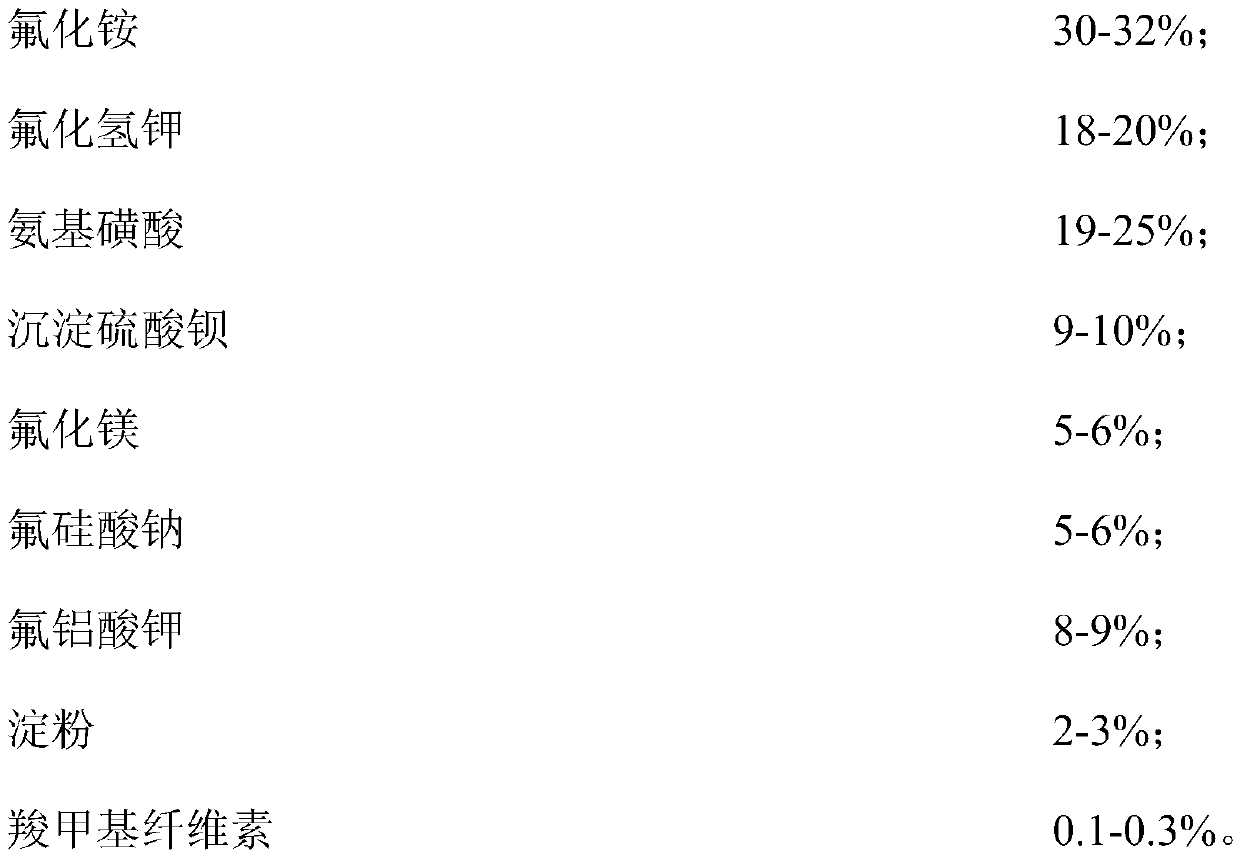

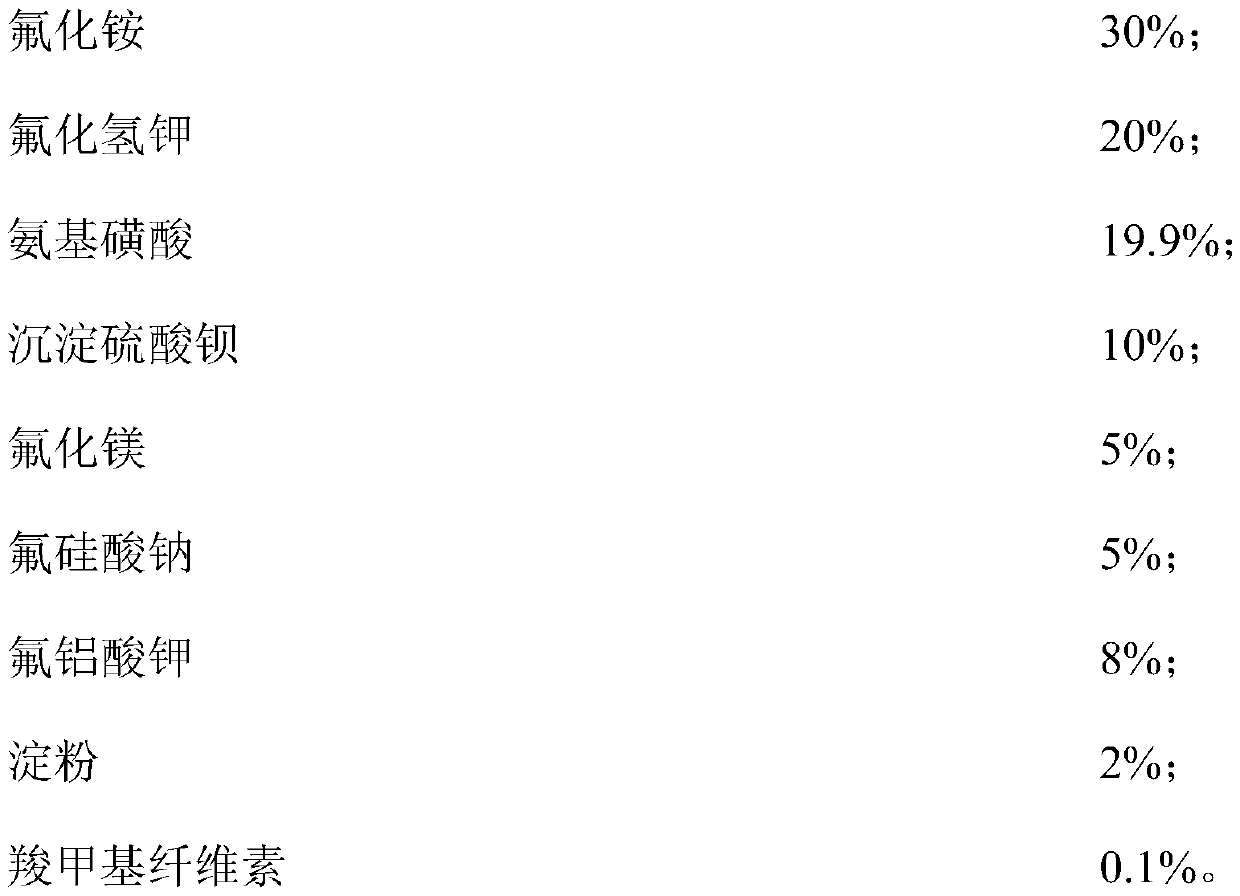

High-alumina glass frosting powder and use method thereof

ActiveCN111204984AModerate acidityAvoid corrosionSurface treatment compositionsStrong acidsPotassium aluminate

The invention relates to a high-alumina glass frosting powder and a use method thereof. The high-aluminum glass frosting powder is prepared from the following components in percentage by mass: 30 to 35 percent of ammonium fluoride, 15 to 20 percent of potassium bifluoride, 15 to 25 percent of sulfamic acid, 8 to 10 percent of precipitated barium sulfate, 5 to 8 percent of magnesium fluoride, 5 to8 percent of sodium fluosilicate, 8 to 10 percent of potassium fluoroaluminate, 2 to 3 percent of starch and 0.1 to 0.5 percent of carboxymethyl cellulose. Sulfamic acid is used as an acidity regulator; the formula is further optimized and limited; the problems of corrosivity, safety, environmental friendliness and the like caused by traditional inorganic strong acid curing are avoided; in addition, the frosting liquid cured by adding water has the advantages of proper acidity and uniform and stable system, the surface roughness Ra of the high-aluminum glass is controlled between 0.1 [mu]m and2.0 [mu]m, the effective frosting and control effects of the high-aluminum glass are realized, and the high-alumina glass frosting powder has wide applicability.

Owner:广州亦盛环保科技有限公司

Etching solution for high-transmittance anti-dazzle glass, and preparation method thereof

The invention discloses an etching solution for high-transmittance anti-dazzle glass, and a preparation method thereof. Raw materials of the etching solution comprise hydrofluoric acid, ammonium fluoride, ammonium bifluoride, magnesium fluoride, aluminum fluoride, calcium fluoride, calcium hydrogen fluoride, potassium hydrogen fluoride, ammonium chloride, zinc chloride, sodium acetate, barium sulfate, sodium fluoroborate, ammonium fluoroborate, sodium phosphate, ammonium biphosphate, potassium phosphate, ethylene diamine tetraacetic acid, nitrilotriacetic acid, a viscosity regulator, a surfactant, a sulfuric acid solution and water. The preparation method of the etching solution for high-transmittance anti-dazzle glass has the advantages of mild process and mild conditions, and the etching solution for high-transmittance anti-dazzle glass, prepared through the method, has the advantages of good stability, high transmittance and atomization rate, and good anti-dazzle effect.

Owner:广东金品科技有限公司

Anti-dazzle glass etching liquid and preparation method thereof

The invention discloses anti-dazzle glass etching liquid which comprises, by weight parts, 35-45 parts of hydrofluoric acid, 5-10 parts of ammonium bifluoride, 12-20 parts of ammonium fluoride, 2-10 parts of calcium fluoride, 1-5 parts of potassium bifluoride, 10-25 parts of ammonium chloride, 3-10 parts of potassium sulfate, 1-5 parts of barium sulfate, 1-5 parts of potassium phosphate, 0.1-3 parts of sodium fluoroborate, 1-3 parts of agar, 1-3 parts of sodium alginate, 2-5 parts of sodium carboxymethyl cellulose, 0.1-2 parts of silica sol, 0.2-1.5 parts of butadiene styrene rubber, 1-3 parts of propylene glycol, 1-5 parts of propylene glycol, 1-5 parts of propanediol, 0.5-2 parts of sucrose, 30-50 parts of sulfuric acid solution and 100-150 parts of water. The invention further provides a method for preparing the anti-dazzle glass etching liquid. A process is simple, the conditions are moderate, the obtained etching liquid is good in stability; and prepared anti-dazzle glass is high in transmittance and degree of atomization, excellent in impact resistance and good in anti-dazzle effect.

Owner:山东御银光电科技有限公司

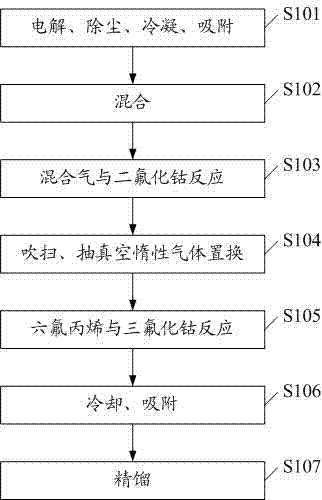

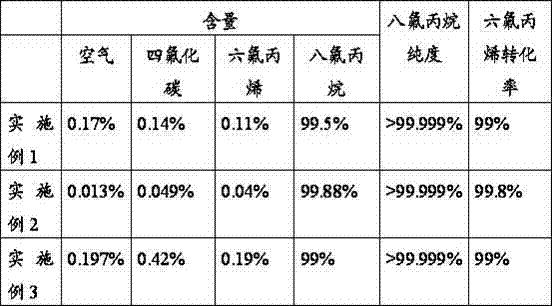

Preparation method of perfluoropropane

InactiveCN103497086AReduce corrosionExtend your lifePreparation by halogen additionElectrolysisHexafluoropropylene

The invention discloses a preparation method of perfluoropropane. The preparation method sequentially comprises the following steps: (1) electrolyzing potassium bifluoride to obtain a mixed fluorine gas, and sequentially carrying out dust extraction, condensation and adsorption treatments on the mixed fluorine gas to purify the mixed fluorine gas to raw material fluoride; (2) pressurizing the raw material fluoride and uniformly mixing the raw material fluoride with an inert gas to obtain a mixed gas; (3) introducing the mixed gas into a reactor filled with cobaltous fluoride to react to obtain cobaltic oxide; (4) carrying out purging and vacuumizing replacement treatments on the reactor and related pipelines and pipe fittings after the reaction; (5) introducing hexafluoropropylene into the reactor to react with the cobaltic oxide to obtain perfluoropropane containing impurities; (6) cooling and adsorbing the perfluoropropane; and (7) introducing the perfluoropropane into a rectifying column through a compressor to be rectified. By adopting the preparation method disclosed by the invention, the corrosion of impurities on the reactor can be reduced, such unfavorable side reactions as hexafluoropropylene pyrolysis, self polymerization, addition, and the like, are inhibited, and perfluoropropane with high purity is prepared.

Owner:FOSHAN HUATE GASES +1

Water-soluble solid etching reagent for anti-dazzle high-aluminum glass, and etching process for high-aluminum glass

PendingCN111908800AReduce usageGood etchingSurface treatment compositionsHydrogen fluorideOrganic solvent

The invention provides a water-soluble solid etching reagent for anti-dazzle high-aluminum glass, and an etching process for the high-aluminum glass. The solid etching reagent comprises the followingraw materials by weight: 15-45 parts of ammonium bifluoride, 20-60 parts of citric acid, 6-15 parts of ammonium sulfate, 2-14 parts of potassium bifluoride or potassium sulfate, 1-10 parts of titaniumdioxide, and 5-50 parts of a thickener. The solid etching reagent disclosed by the invention can be dissolved in water, so strong acid and toxic organic solvents are not used; the high-alumina glasscan be well etched under the condition of normal temperature; and the prepared finished anti-dazzle high-alumina glass product can generate a good anti-dazzle effect.

Owner:海南海控特玻科技有限公司

Fapiravir and preparation method of intermediate thereof

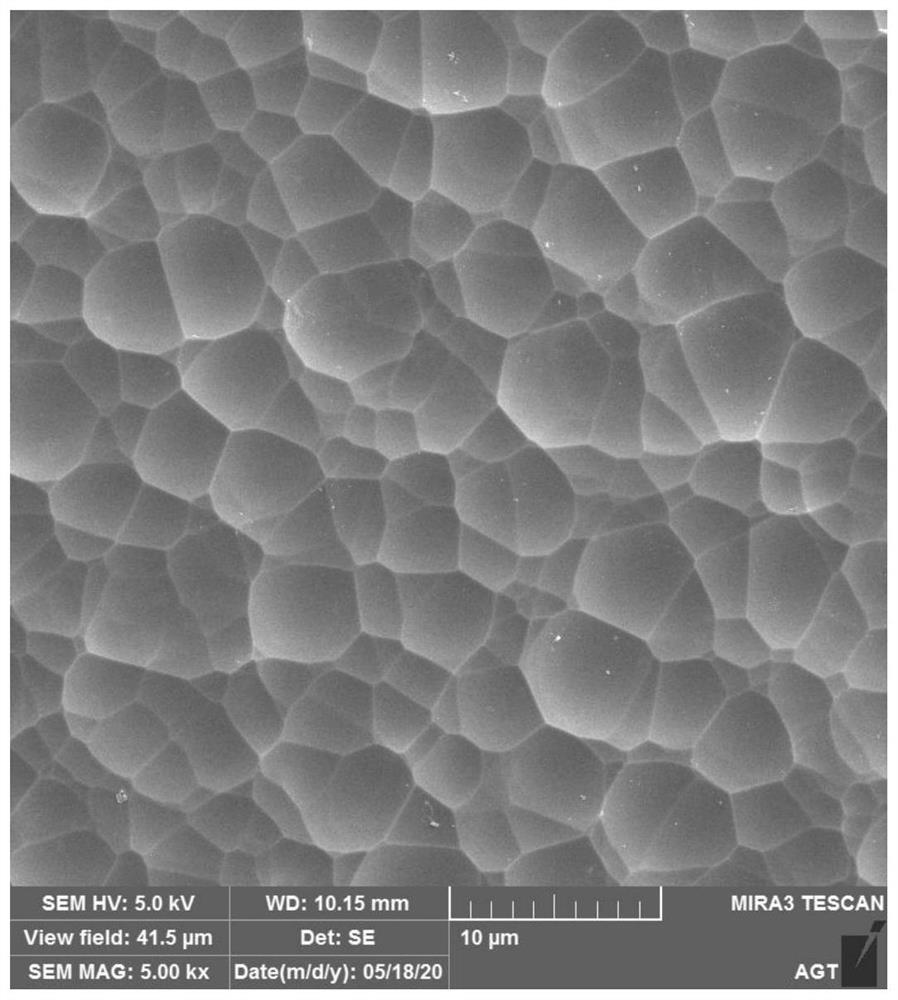

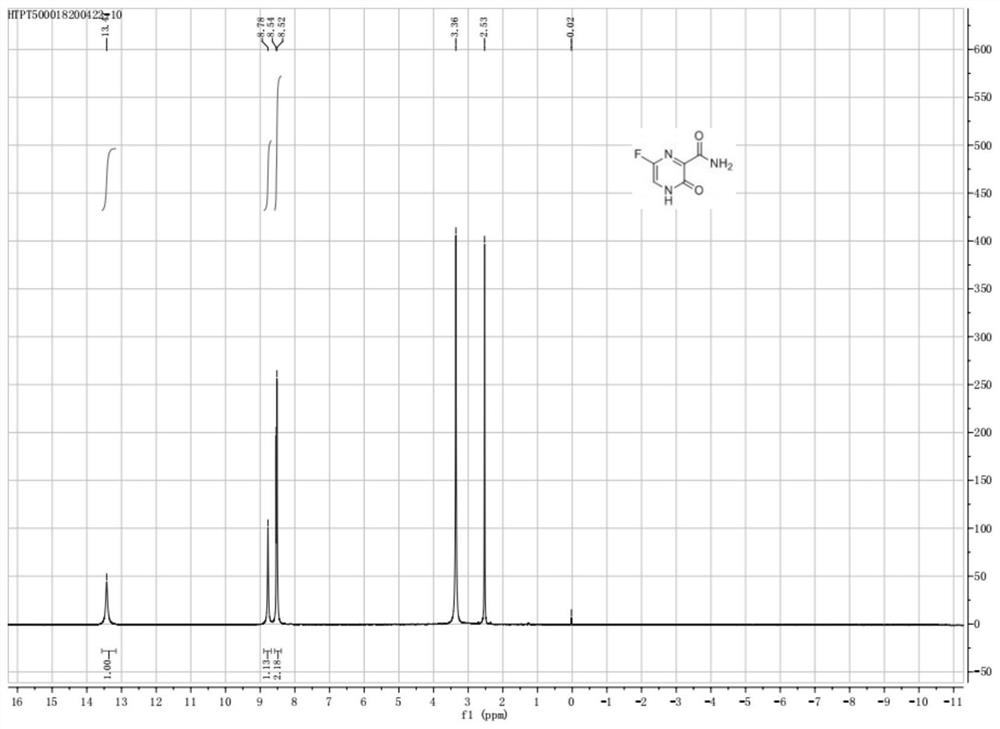

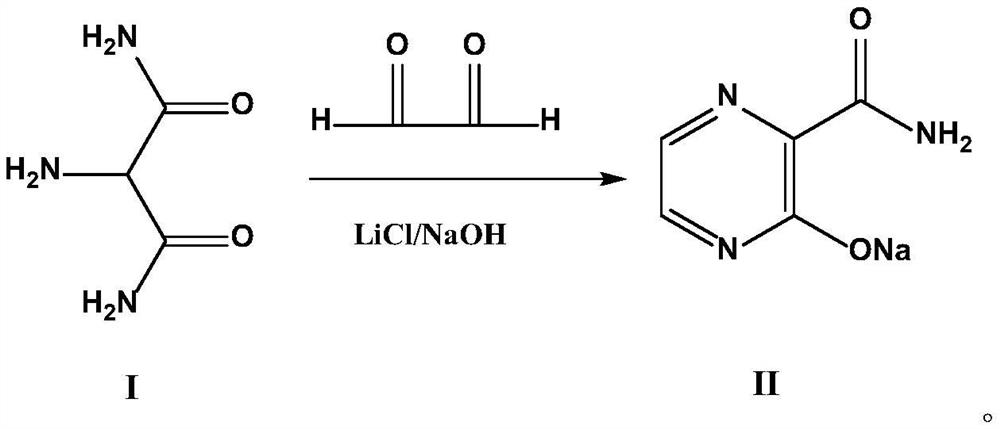

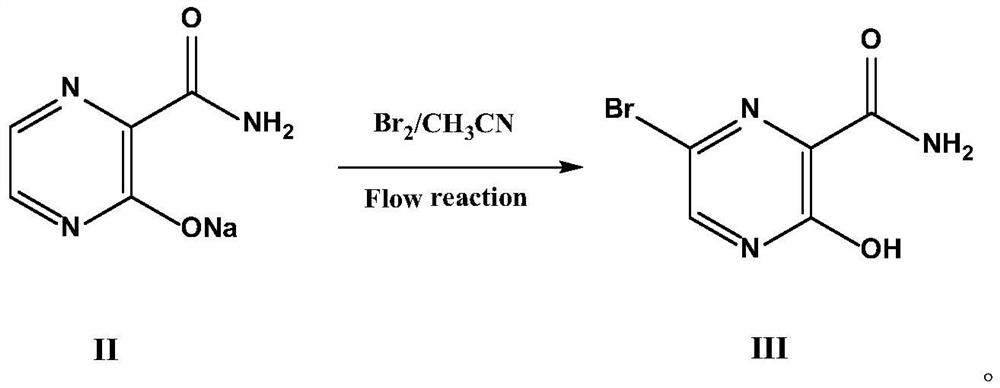

ActiveCN111978263ALow priceShort reaction stepsOrganic chemistryBulk chemical productionLithium chloridePyrazine

The invention relates to a fapiravir and a preparation method of an intermediate thereof, and belongs to the field of pharmaceutical chemicals. The invention provides a preparation method of a fapiravir intermediate 3-hydroxy sodium pyrazine-2-formamide, wherein the fapiravir intermediate 3-hydroxy sodium pyrazine-2-formamide is prepared by reacting aminopropanedioide with lithium chloride in thepresence of a NaOH solution and glyoxal. The invention also provides a preparation method of 6-bromo-3-hydroxy pyrazine-2-formamide, wherein the 6-bromo-3-hydroxy pyrazine-2-formamide is prepared froman acetonitrile solution of 3-hydroxy sodium pyrazine-2-formamide and an acetonitrile solution of liquid bromine in a microchannel reactor. The invention also provides a preparation method of 3, 6-difluoropyrazine-2-formamide, wherein the 3, 6-difluoropyrazine-2-formamide is prepared by reacting 6-bromo-3-hydroxy pyrazine-2-formamide with potassium bifluoride in the presence of PEG-400 and DMF. Finally, the invention also provides a total synthesis method for preparing fapiravir from the intermediate. The reactions avoid the use of highly dangerous diazotization reactions, and the methods have the advantages of high safety, low raw material price, short steps, low cost and simple post-treatment, and are suitable for industrial enlarged production.

Owner:长沙创新药物工业技术研究院有限公司

Glass etching solution, high alumina-silica glass etching method and high alumina-silica glass with textures on surface

ActiveCN111233339ARaise the ratioSame sizeTelephone set constructionsSurface treatment compositionsHydrogen fluorideVitrification

The invention belongs to the technical field of glass chemical etching, and particularly relates to a glass etching solution, a high alumina-silica glass etching method and high alumina-silica glass with textures on the surface. The glass etching liquid comprises the following raw materials in percentage by mass: 5-15 wt% of ammonium fluoride; 10-22 wt% of ammonium bifluoride; 8-18 wt% of potassium bifluoride, 5-15 wt% of hydrochloric acid, 15-30 wt% of nitric acid, 3-8 wt% of potassium chloride, 1.5-6 wt% of copper sulfate, 3-8 wt% of NaNO3, 3-8 wt% of NaH2PO4, 2-5 wt% of FeCl3 and 10-30 wt%of H2O. The glass etching solution can be used for etching high alumina-silica glass to form snowflake-like concave-convex textures on the surface of the high alumina-silica glass.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Method for preparing high purity tetrafluoromethane through combination of rectification and adsorption

InactiveCN102399126AContinuous and stable purificationSolve the disadvantages of unstable purificationHalogenated hydrocarbon separation/purificationHydrogen fluoridePhysical chemistry

The invention discloses a method for preparing high purity tetrafluoromethane through combination of rectification and adsorption. The method is mainly characterized in that: equipment for generating tetrafluoromethane continuously supplies the tetrafluoromethane, and fluorochloromethane and potassium bifluoride are subjected to gas-phase reaction to form the tetrafluoromethane. In the method for preparing the high purity tetrafluoromethane, a raw material preparation system, a tetrafluoromethane gas preparation system and a liquefying and gasifying system for the tetrafluoromethane purified through combination of rectification and adsorption. The method has the advantages that: the product has high yield and high purity (99.0-99.9 percent), has a few impurities which are easy to separate; and besides the product, other harmful and toxic byproducts are absent, the operation is convenient, and the method is an ideal technology for preparing the high purity tetrafluoromethane.

Owner:TIANJIN TAIYUAN INDAL GAS

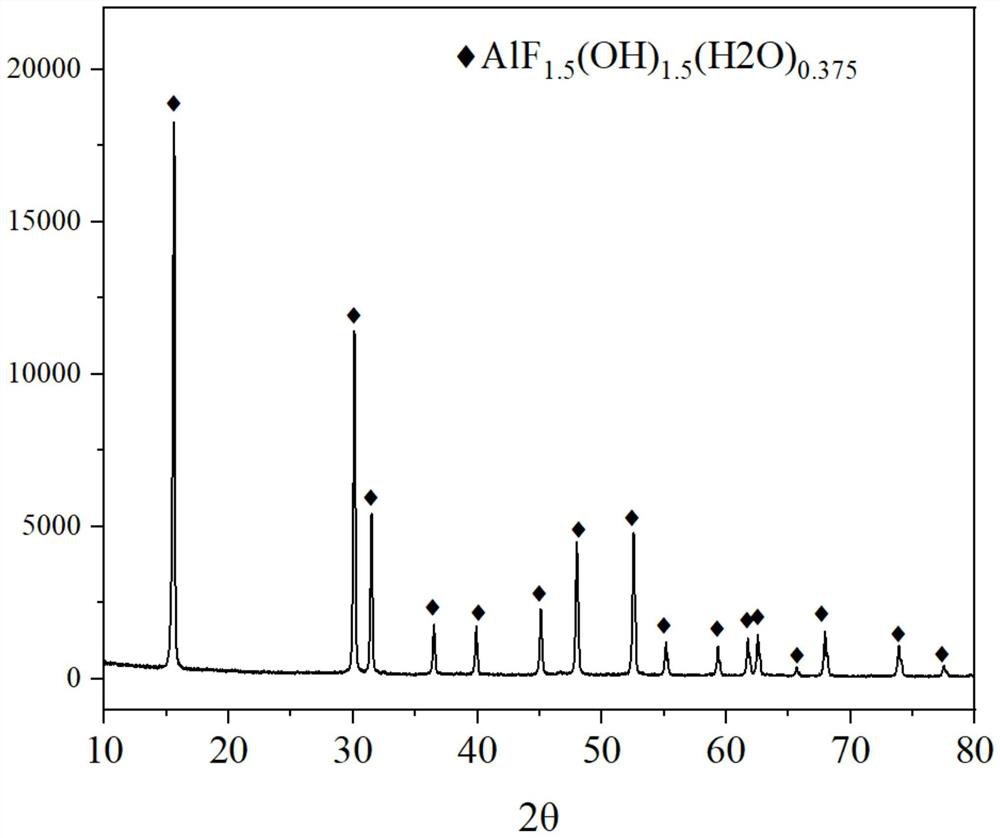

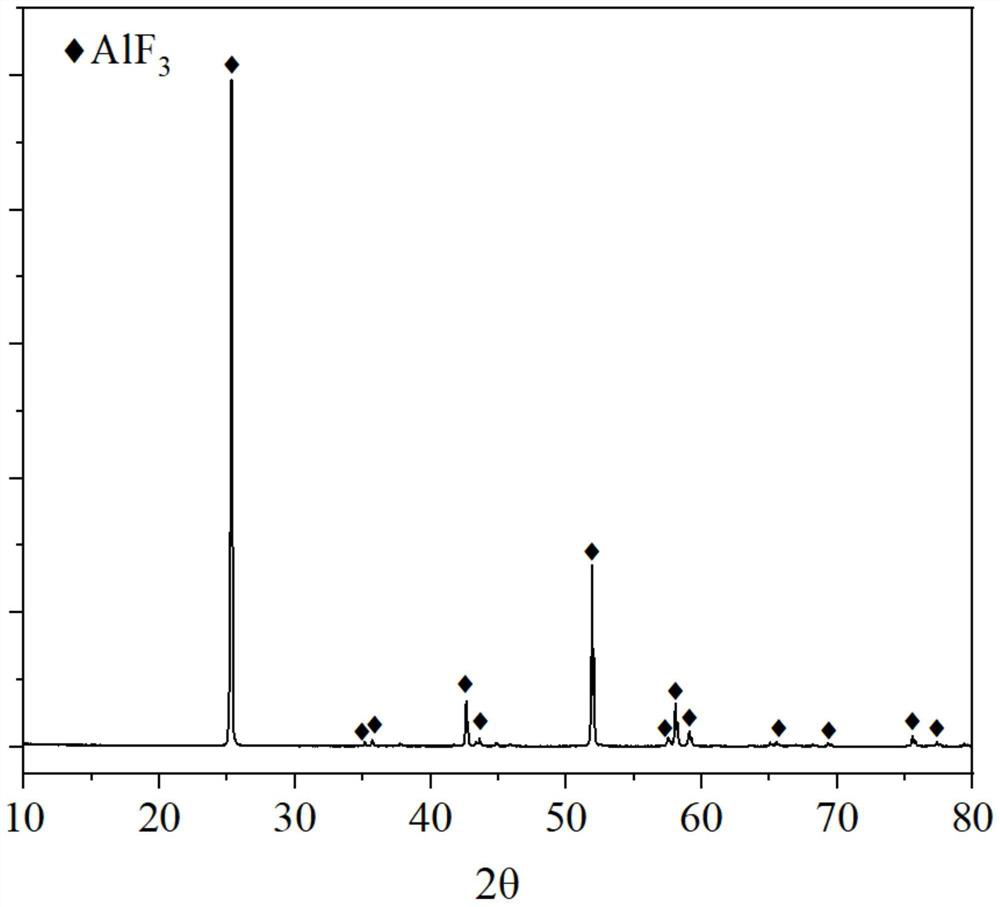

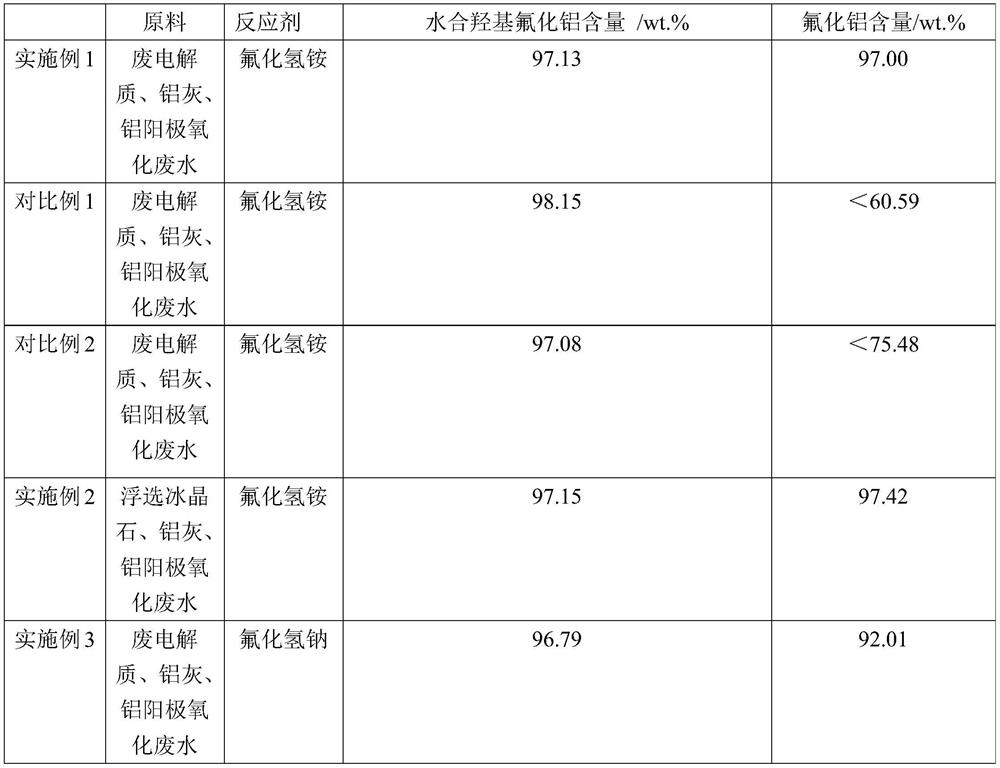

Method for preparing aluminum fluoride product through combined treatment of multiple wastes and aluminum fluoride product

PendingCN113501536AHigh feasibilitySimple processAluminium fluoridesAluminum fluorideHydrogen fluoride

The invention relates to a method for preparing an aluminum fluoride product through combined treatment of multiple wastes and the aluminum fluoride product. The method comprises mixing and leaching fluorine-containing waste particles, aluminum ash powder and to-be-treated aluminum anodic oxidation wastewater, and then performing solid-liquid separation to obtain leachate and filter residues; adjusting the pH value of the leachate to 3-5, carrying out solid-liquid separation to obtain a solid phase, drying the solid phase to obtain aluminum hydroxyfluoride powder, uniformly mixing the aluminum hydroxyfluoride powder with a reactant, and carrying out heat treatment to obtain a heat treatment product; when the reactant comprises at least one of potassium hydrogen fluoride, sodium hydrogen fluoride and lithium hydrogen fluoride, washing and drying the heat treatment product to obtain an aluminum fluoride product; when the reactant is composed of at least one of ammonium fluoride and ammonium bifluoride, determining that the heat treatment product is the aluminum fluoride product. According to the method, fluorine-containing waste, aluminum ash and aluminum anodic oxidation waste water in the aluminum smelting and processing industry are integrated, valuable aluminum and fluorine elements are efficiently recycled in the form of aluminum hydroxyfluoride, the process is simple, and the feasibility is high.

Owner:CENT SOUTH UNIV

Preparation method of flux coated silver solder ring

ActiveCN108326475AHigh activityWeak moisture absorptionWelding/cutting media/materialsSoldering mediaCopper sulfateMaterials science

The invention relates to a preparation method of a flux coated silver solder ring. The method comprises the steps of 1, preparing the following raw materials: 10-50% of Ag, 15-45% of Cu, 17-40% of Zn,1-3% of Sn, 0.1-0.5% of P, 0.5-2% of Ni, 0.1-0.3% of Ge, and 0.1-0.3% of Li; adding the raw materials to an intermediate-frequency smelting furnace crucible; performing smelting, casting, extruding and drawing to obtain silver solder wires; and preparing multi-coil spring shaped silver solder ring through the silver solder wires; 2, preparing 1-5% of boron micro powder, 5-10% of sodium borohydride, 15-30% of potassium fluoborate, 25-40% of boric anhydride, 10-30% of sodium fluoride, 2-5% of potassium bifluoride, 1-5% of copper sulfate, 0.1-2% of polystyrene, and 0.2-2% of dibutyl phthalate; mixing the materials; adding 45% of ethyl acetate; and uniformly stirring to obtain a flux coating solution for later use; and 3, spraying the flux coating solution to cover the outer parts of the spring shaped silver solder ring; and drying to obtain the flux coated silver solder ring. The flux coated silver solder ring prepared by the method is high in wettability, high in flowability, and capable of self-fluxing; zinc is hard to volatilize; and moreover, the flux coating is high in activity, low in moisture absorption capacity, few in carbon residues, high in ductility and toughness, and isparticularly applicable to soldering of pipeline assemblies such as a stainless steel pipeline assembly and a manganese brass pipeline assembly.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Preparation method of potassium hexafluorophosphate

ActiveCN107758701AHigh yieldReduce usageSodium/potassium compoundsPotassium hexafluorophosphateEvaporation

The invention relates to the field of synthesis of an inorganic compound, and particularly relates to a preparation method of potassium hexafluorophosphate. The preparation method of the potassium hexafluorophosphate comprises the following steps: performing an initial reaction under a certain condition by taking potassium bifluoride (or potassium chloride), anhydrous hydrogen fluoride and phosphorus oxychloride as reaction raw materials to obtain a potassium hexafluorophosphate crude product, adjusting the acidity by using potassium hydroxide, eliminating iron ions, adsorbing and decoloring by activated carbon, performing evaporation and concentration on the crude product after removing impurities, and performing recrystallization to obtain the potassium hexafluorophosphate finished product. Compared with the traditional preparation method, the preparation method of the potassium hexafluorophosphate has the following advantages: the preparation method is simple in operation, mild in reaction and easy to control, and the use of a large amount of unstable, corrosive and toxic raw materials is avoided, so that the operation dangerousness is reduced; by adopting the potassium hexafluorophosphate produced by the method, the yield is up to 88 percent and the purity exceeds 99 percent.

Owner:JIANGXI DONGYAN PHARMA

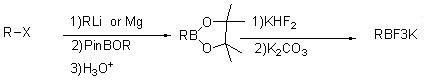

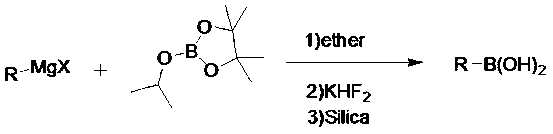

Method for preparing fatty boric acid by utilizing isopropoxyboric acid pinacol ester

InactiveCN103183695AAvoid generatingAchieve securityGroup 3/13 element organic compoundsHydrocarbon solventsOrganic solvent

The invention discloses a method for preparing fatty boric acid by utilizing isopropoxyboric acid pinacol ester. The method comprises the steps of adding a Grignard reagent dropwise in isopropoxyboric acid pinacol ester under the temperature condition of subzero 5 DEG C to 0 DEG C, stirring for 1-2 hours at the room temperature, adding a potassium bifluoride aqueous solution dropwise into a reaction liquid, stirring for 2-3 hours at the room temperature, adding silica gel, stirring for 2-3 hours at the room temperature, filtering, and extracting a water layer by an organic solvent A; adding an organic solvent B into an organic layer, filtering again, adding a nonpolar hydrocarbon solvent into the filtrate for pulping, and filtering to obtain organic boric acid. The method has the advantages of simplicity and convenience in operation, safety, environmental protection, lower cost and higher yield, is an appropriate method for preparing fatty boric acid, and is suitable for the industrial production; and further, the raw materials are easy to obtain.

Owner:DALIAN NETCHEM CHIRAL TECH

Process for reclaiming a contaminated electrolyte from an electrolytic cell used in the production of gaseous fluorine

Owner:HONEYWELL INT INC

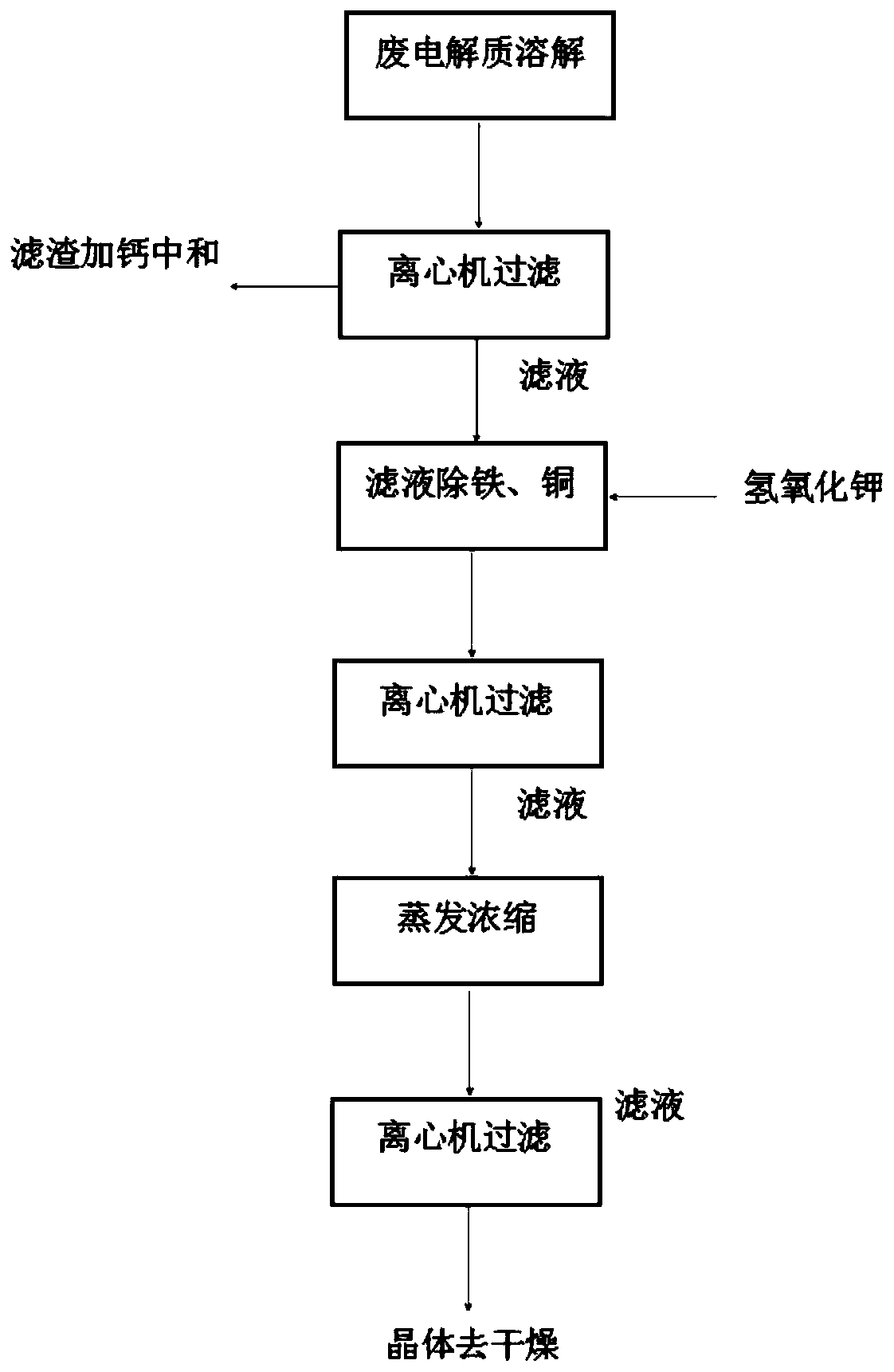

Electrolytic fluorine waste electrolyte recovery method

ActiveCN111020632AIncrease ion productPolycrystalline material growthElectrolysis componentsElectrolysisPotassium hydrogenfluoride

The invention belongs to the technical field of uranium conversion electrolysis fluorine production, and particularly relates to an electrolysis fluorine production waste electrolyte recovery method.The method comprises the following steps: (1) dissolving a waste electrolyte; (2) carrying out pH adjustment; and (3) carrying out crystallization of potassium bifluoride. Dissolving and filtering canbe adopted to obtain a clear electrolyte dissolved solution, copper is removed, the pH value is controlled to be 10 to 12, and is adjusted to be 3 to 4 before crystallization, the recovered electrolyte with indexes similar to those of newly purchased electrolyte can be prepared. Through research, alkaline wastewater and acidic wastewater treated by an electrolytic cathode can be used for dissolving the waste electrolyte, and the ion product of potassium bifluoride during electrolyte crystallization can be increased by adjusting the pH value.

Owner:中核二七二铀业有限责任公司

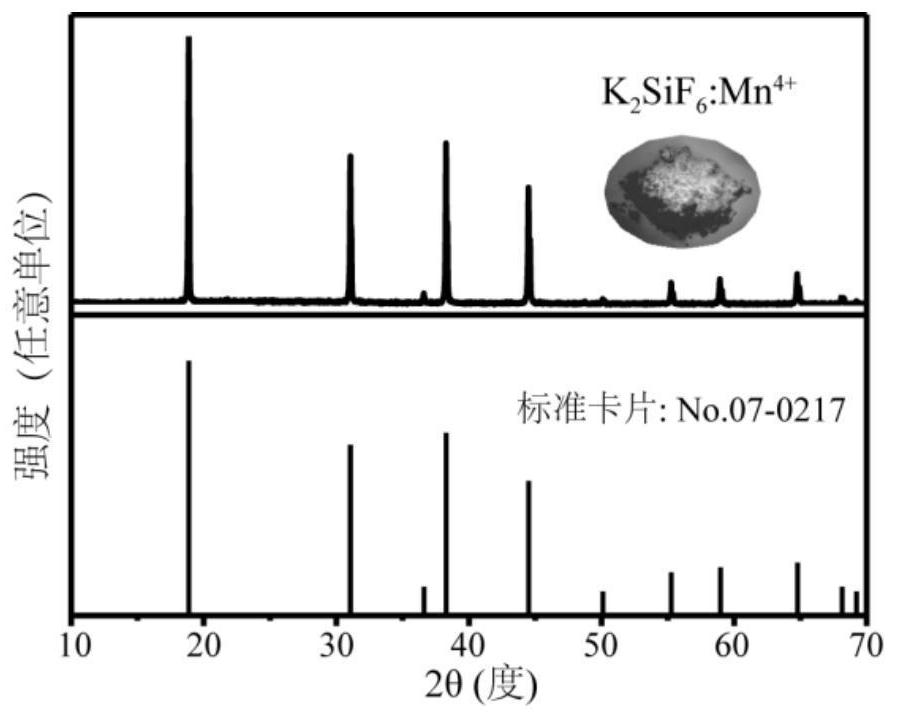

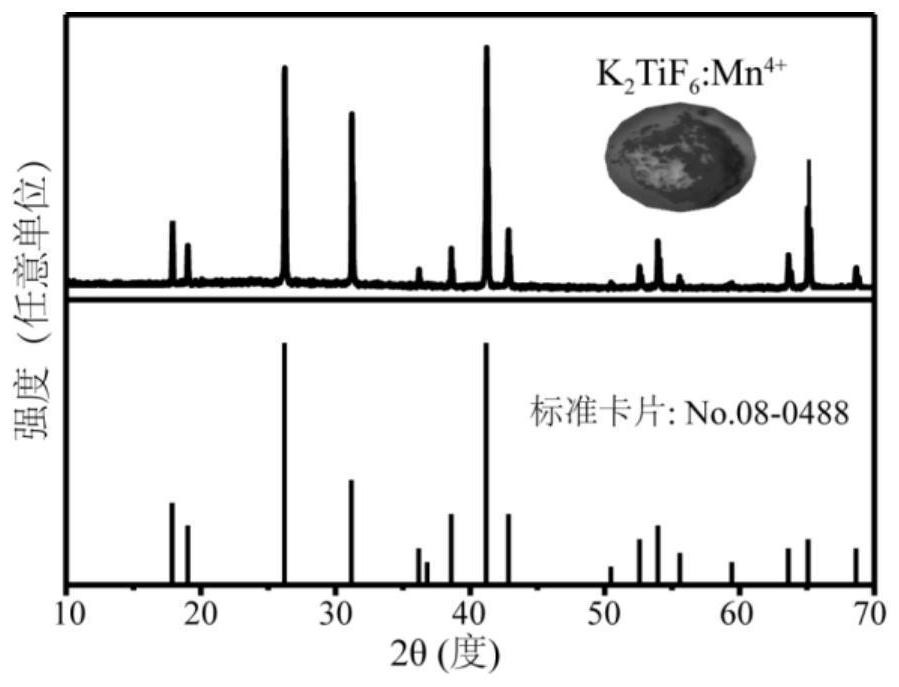

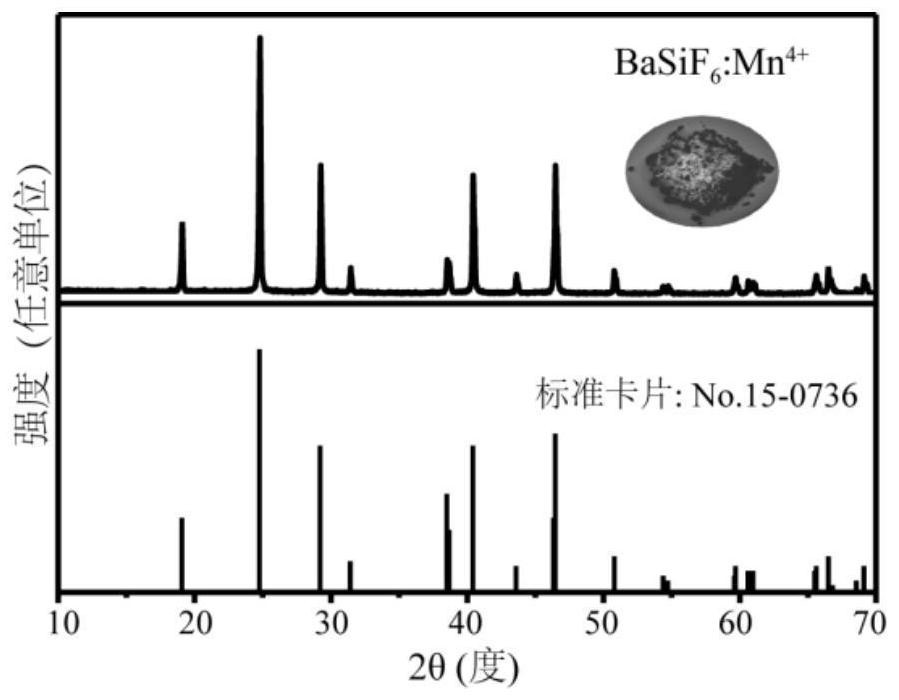

Green synthesis method of tetravalent manganese ion activated fluoride red luminescent material

PendingCN114381260AMild conditionsSynthesis speedLuminescent compositionsSemiconductor devicesBarium dichloridePotassium fluoride

The invention discloses a green synthesis method of a tetravalent manganese ion activated fluoride red luminescent material. The synthesis method comprises the following steps: adding potassium hexafluoromanganate into a fluosilicic acid solution or a fluotitanic acid solution until the potassium hexafluoromanganate is completely dissolved to obtain a solution 1, adding potassium fluoride, potassium bifluoride or barium chloride into water until the potassium fluoride, potassium bifluoride or barium chloride is completely dissolved to obtain a solution 2, the molar concentration of the potassium fluoride, potassium bifluoride or barium chloride in the solution 2 is 0.25-3.00 mol / L, and stirring to obtain a solution 3; mixing and stirring the solution 1 and the solution 2 to obtain a solution 3, centrifuging the solution 3 to obtain a precipitate, and washing and drying the precipitate to obtain a final product, namely the tetravalent manganese ion activated fluoride red luminescent material. The synthesis method provided by the invention has the advantages of greenness, environmental protection (no hydrofluoric acid), mild conditions (normal temperature, normal pressure and aqueous solution reaction), high synthesis speed (several minutes) and the like, and is convenient for large-scale industrial preparation.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

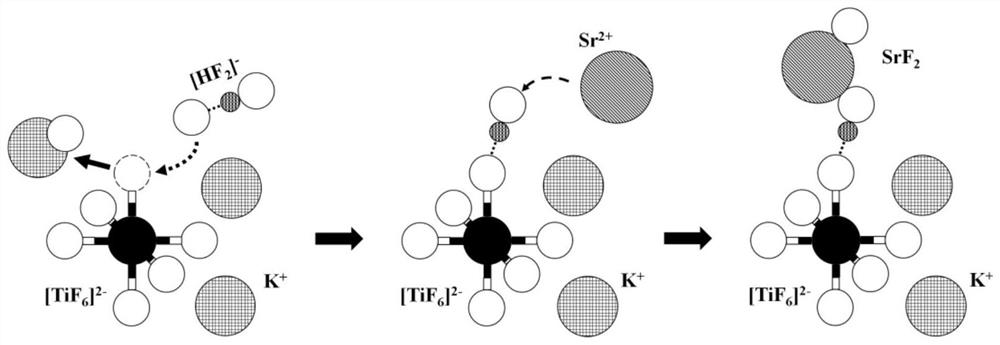

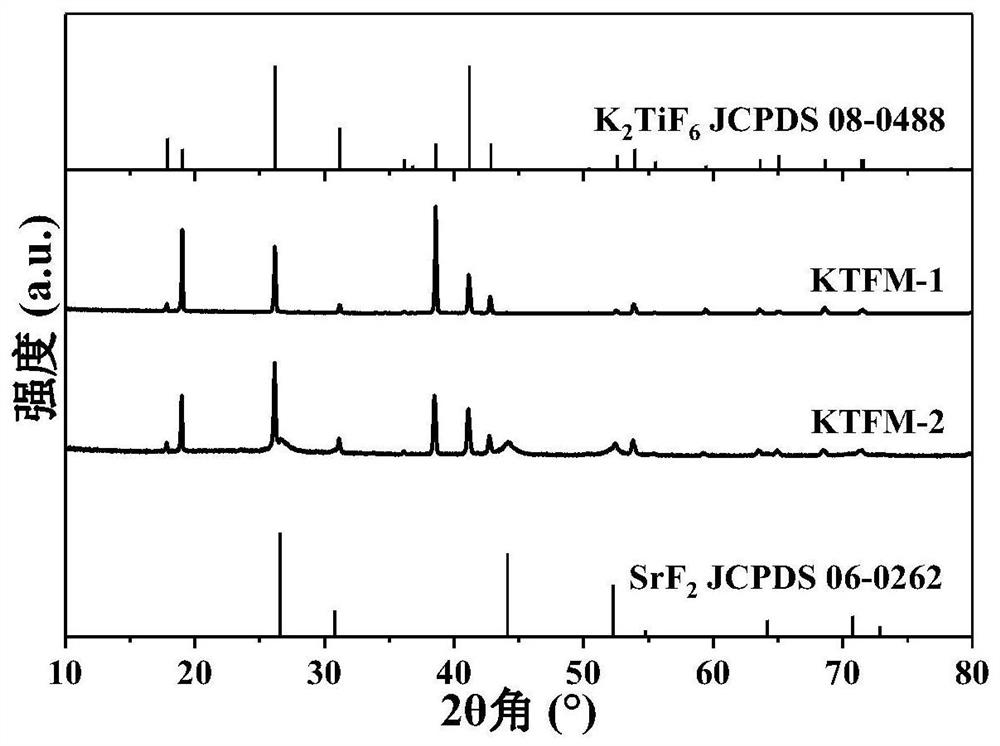

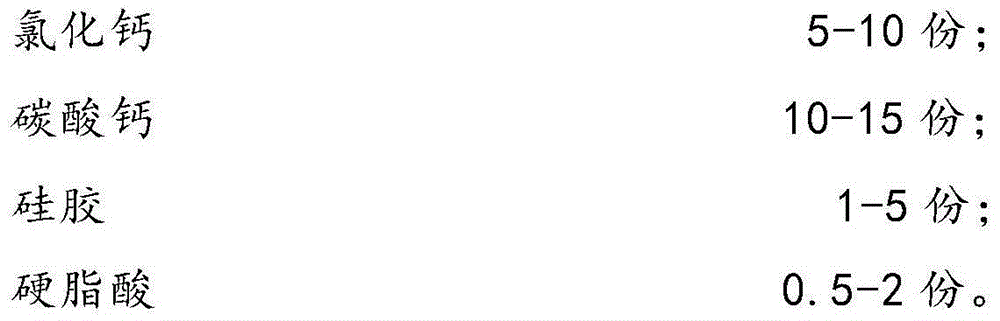

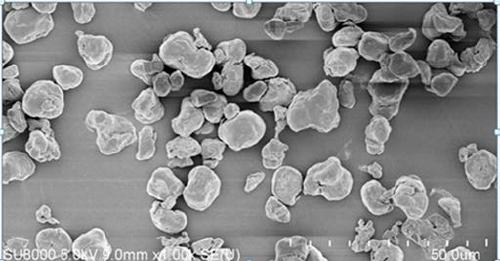

Moisture-resistant fluoride red fluorescent powder and preparation method thereof

PendingCN112251219AAvoid wrapping failureImprove stabilityLuminescent compositionsAlkaline earth metalHigh humidity

The invention discloses moisture-resistant fluoride red fluorescent powder, which comprises Mn<4+>-doped fluoride red fluorescent powder and an alkaline earth metal fluoride waterproof layer, whereinthe alkaline earth metal fluoride waterproof layer coats the surface of the Mn<4+>-doped fluoride red fluorescent powder; and the alkaline earth metal fluoride waterproof layer is one or a mixture ofmore than one of CaF2, SrF2 and BaF2. The preparation method comprises the steps of puttingMn<4+>-doped fluoride red fluorescent powder into a potassium bifluoride aqueous solution, fully stirring, dropwise adding an aqueous solution of alkaline-earth metal salt, standing, filtering, washing the obtained precipitate, and drying to obtain the moisture-resistant fluoride red fluorescent powder. On the basis that the luminous efficiency is not obviously reduced, the stability of the Mn<4+>-doped fluoride red fluorescent powder in a high-humidity environment is remarkably improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

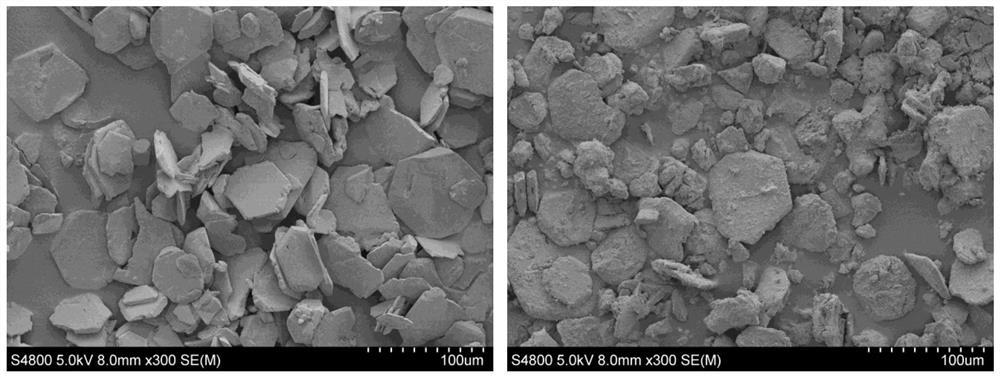

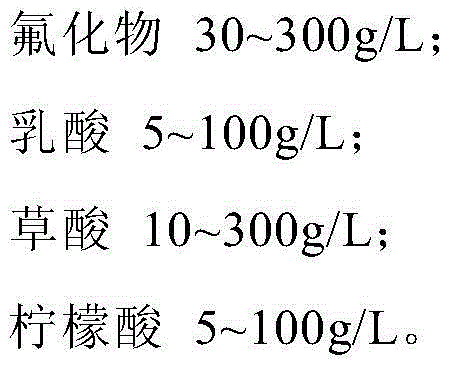

Solution for deashing and processing surface of silicon aluminum composite material

The invention discloses a solution for deashing and processing the surface of a silicon aluminum composite material and belongs to the technical field of metal surface treatment. The solution consists of 30-300 g / L of fluoride, 5-100 g / L of lactic acid, 10-300 g / L of oxalic acid and 5-100 g / L of citric acid; the silicon content in the silicon aluminum composite material is 10-80 percent. A preparation method of the solution comprises, but not limited to the following steps: powder metallurgy and injection molding; the fluoride is more than one of ammonium fluoride, sodium fluoride and potassium bifluoride. According to the solution disclosed by the invention, an ash hanging film on the surface of the silicon aluminum composite material can be quickly and effectively removed, the negative effect of silicon particles on the surface of the silicon aluminum composite material is avoided, the adhesive force of a coating layer is greatly improved, and the surface of the coating layer is guaranteed to be uniform and compact and be free from bump, falling-off and the like.

Owner:南京驰韵科技发展有限公司

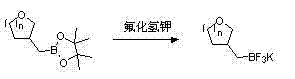

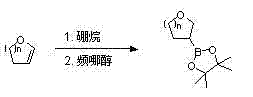

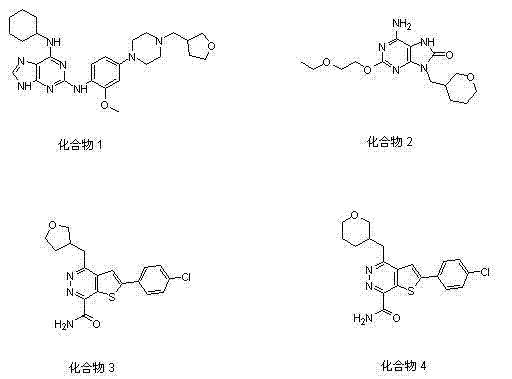

Synthesis method of 3-cyclic ether methyl trifluoro-potassium borate

ActiveCN103896975ALow priceReduce manufacturing costGroup 3/13 element organic compoundsPtru catalystCyclic ether

The invention relates to 3-cyclic ether methyl trifluoro-potassium borate, in particular relates to a synthesis method of 3-cyclic ether methyl trifluoro-potassium borate, mainly solving the technical problems of the existing preparation method that the catalyst is expensive, the reaction condition is severe, the synthesis process is long and the like. According to the technical scheme, the synthesis method comprises the following steps: performing an addition reaction on 2-cyclic ether olefin taken as a raw material and borane; quenching with pinacol so as to obtain 3-cyclic ether-based pinacol boric acid ester; removing protons from the 3-cyclic ether-based pinacol acid ester by using a strong alkali and reacting with chlorobromomethane so as to obtain 3-cyclic ether methyl pinacol boric acid ester; and finally, performing a reaction on the 3-cyclic ether methyl pinacol boric acid ester and potassium bifluoride so as to obtain the 3-cyclic ether methyl trifluoro-potassium borate. The 3-cyclic ether methyl trifluoro-potassium borate is an important medicinal compound structure-modified micromolecule in the research field of a novel medicine.

Owner:SUNDIA MEDITECH COMPANY LTD

Etching liquid for conductive glass, and preparation method of etching liquid

InactiveCN107226624ASolve the problem of reducing yieldReasonable activityPhosphoric acidSilicon dioxide

The invention discloses etching liquid for conductive glass, and a preparation method of the etching liquid. The etching liquid comprises the following raw materials in parts by weight: 30 to 50 parts of hydrofluoric acid, 20 to 30 parts of phosphoric acid, 5 to 10 parts of calcium fluoride, 1 to 6 parts of ammonium sulfate, 1 to 6 parts of magnesium sulfate, 5 to 10 parts of potassium phosphate, 1 to 6 parts of potassium bifluoride, 6 to 12 parts of sodium silicate, 5 to 10 parts of sodium fluoborate, 1 to 5 parts of agar, 1 to 6 parts of sodium alginate, 1 to 3 parts of nanosilicon dioxide, 0.2 to 0.6 part of an anti-freezing agent, 0.01 to 0.05 part of an anionic surfactant, 40 to 60 parts of a sulfuric acid solution and 120 to 160 parts of deionized water. The etching liquid provided by the invention can achieve the technical effect of removing impurities from the surface of a substrate by dissolving and etching the impurities on the surface of the conductive glass substrate, so that the problem that the yield of the substrates is reduced due to granular attachment is effectively solved.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

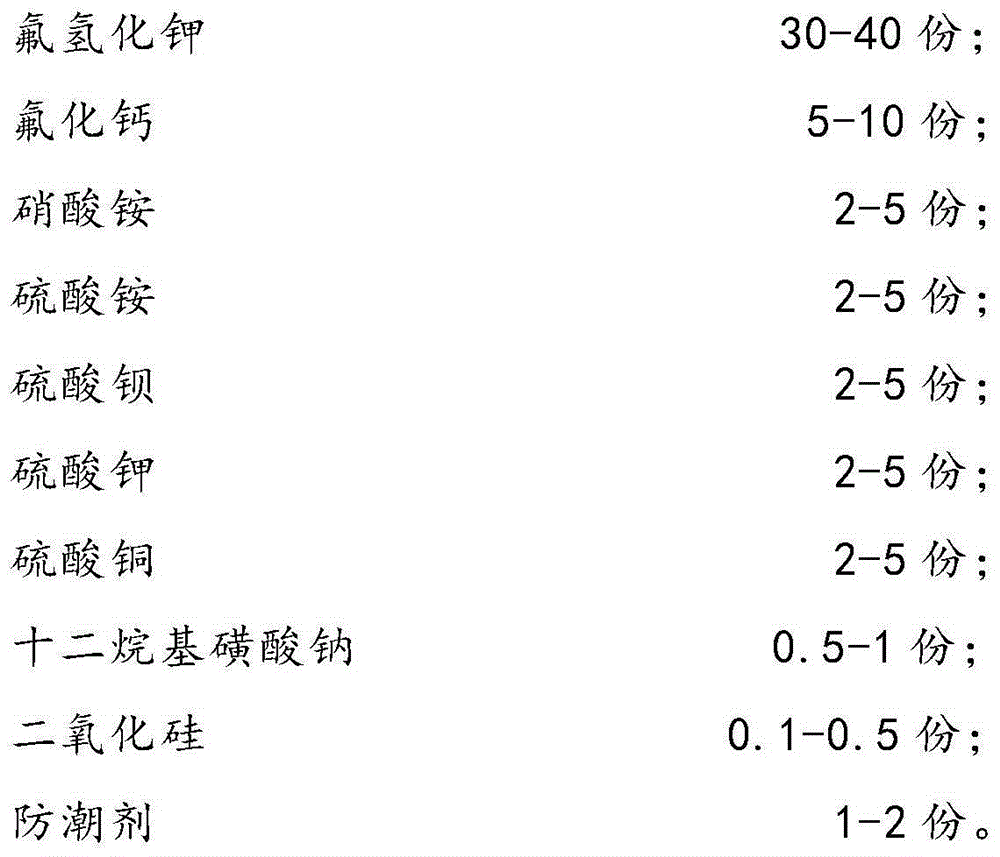

Glass frosting powder for processing anti-dazzle glass and preparation method thereof

The invention discloses glass frosting powder for processing anti-dazzle glass and a preparation method of the glass frosting powder. The glass frosting powder comprises the following components: ammonium fluoride, potassium bifluoride, calcium fluoride, ammonium nitrate, barium sulfate, potassium sulfate, copper sulfate, sodium dodecyl sulfate, silicon dioxide and a moisture-proof agent. The preparation method of the glass frosting powder comprises the following steps: grinding ammonium fluoride, potassium bifluoride, calcium fluoride, ammonium nitrate, barium sulfate, potassium sulfate, copper sulfate, sodium dodecyl sulfate, silicon dioxide and the moisture-proof agent respectively through a grinder, filtering the raw materials through a 200-mesh filter screen, continuously grinding filter residues, adding all the raw materials into a stirring kettle after all the raw materials pass through the 200-mesh filter screen, controlling the rotation rate of the stirring kettle to be 1000-1500 rpm, controlling the temperature to be 30-50 DEG C, controlling the relative humidity to be 10-30% and stirring for 20-30 minutes to prepare the glass frosting powder. Compared with the prior art, the glass frosting powder is relatively low in production cost and low in possibility of deteriorating during storage.

Owner:上海光和光学制造大丰有限公司 +1

Method for recovering and preparing potassium bifluoride by using waste electrolyte generated in fluorine gas production process

ActiveCN111410213AIncrease productivityRunning balance and stabilitySemi-permeable membranesElectrolysis componentsHydrogen fluorideSocial benefits

The invention relates to a method for recovering and preparing potassium bifluoride (KHF2) by using waste electrolyte (the main component is KF.2HF) generated in a fluorine gas production process. Theinvention relates to a method for preparing a high-purity potassium bifluoride product through the steps of impurity removal, refining, reaction, crystallization, separation, drying and the like. Theprepared potassium hydrogen fluoride has better indexes than the existing commercially available products, can be recycled for fluorine production, enhances the utilization ratio of fluorine resources, solves the environmental protection problems of high difficulty in waste solid treatment and high cost in the industrial production of fluorine, and enhances the competitiveness of the fluorine production device. The production process is simple, feasible, clean and environment-friendly, and has better economic and social benefits.

Owner:浙江博瑞中硝科技有限公司

A kind of preparation method of potassium hexafluorophosphate

ActiveCN107758701BHigh yieldReduce usageSodium/potassium compoundsPotassium hexafluorophosphateEvaporation

The invention relates to the field of synthesis of an inorganic compound, and particularly relates to a preparation method of potassium hexafluorophosphate. The preparation method of the potassium hexafluorophosphate comprises the following steps: performing an initial reaction under a certain condition by taking potassium bifluoride (or potassium chloride), anhydrous hydrogen fluoride and phosphorus oxychloride as reaction raw materials to obtain a potassium hexafluorophosphate crude product, adjusting the acidity by using potassium hydroxide, eliminating iron ions, adsorbing and decoloring by activated carbon, performing evaporation and concentration on the crude product after removing impurities, and performing recrystallization to obtain the potassium hexafluorophosphate finished product. Compared with the traditional preparation method, the preparation method of the potassium hexafluorophosphate has the following advantages: the preparation method is simple in operation, mild in reaction and easy to control, and the use of a large amount of unstable, corrosive and toxic raw materials is avoided, so that the operation dangerousness is reduced; by adopting the potassium hexafluorophosphate produced by the method, the yield is up to 88 percent and the purity exceeds 99 percent.

Owner:JIANGXI DONGYAN PHARMA

Preparation method of trifluoroacetate

ActiveCN104402714AThe synthesis process is simpleNot corrosivePreparation from carboxylic acid halidesOrganic compound preparationAlcoholOrganic solvent

The invention relates to a preparation method of trifluoroacetate. The preparation method of trifluoroacetate is characterized by comprising the following steps: (1) uniformly mixing potassium fluoride with alcohol, adding an organic solvent and then adding trifluoroacetyl fluoride to react; (2) filtering potassium fluoride-potassium hydrofluoride solid out of a reaction mixture; (3) rectifying to obtain trifluoroacetate, wherein the organic solvent in the step (1) is selected from one or mixture of both of C2H4C12 and ethyl ether; the volume ratio of the organic solvent to the alcohol is (1:0.5)-(1:4). By virtue of the method, the preparation process of the trifluoroacetate is simplified; waste acid and waste catalyst are not generated in the reaction process; reaction byproducts can be recycled and reused; the problem of the environmental protection of synthesis of the trifluoroacetate can be solved.

Owner:SANMING HEXAFLUO CHEM CO LTD

Process for reclaiming a contaminated electrolyte from an electrolytic cell used in the production of gaseous fluorine

InactiveUS20090246603A1Electrolysis componentsPrimary cell maintainance/servicingHydrofluoric acidLithium compound

A process for reclaiming a contaminated electrolyte in an electrolytic cell used in the production of gaseous fluorine. The contaminated electrolyte is a mixture of potassium bifluoride and hydrofluoric acid having metal ions therein. The process has the following steps: a) removing the contaminated electrolyte from the cell to a treatment tank; b) adding a lithium compound to the contaminated electrolyte in the treatment tank to induce settlement of at least part of the metal ions; c) allowing the metal ions to settle to the bottom of the treatment tank; d) removing the settled metal ions from the bottom of the treatment tank to form a reclaimed electrolyte; and e) returning the reclaimed electrolyte to the cell.

Owner:HONEYWELL INT INC

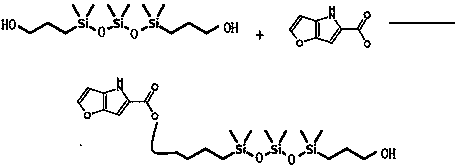

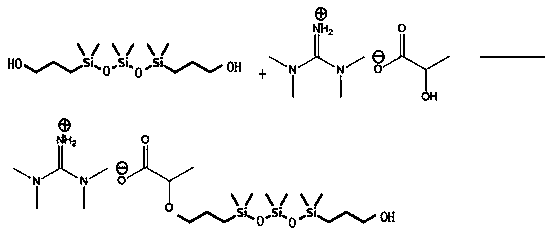

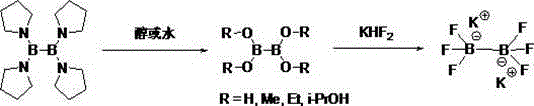

Novel method for synthesizing potassium aryl trifluoroborate

ActiveCN104945426AImprove stabilityAvoid the disadvantage of having to go through two steps to getGroup 3/13 element organic compoundsAlcoholCombinatorial chemistry

The invention discloses a novel method for synthesizing potassium aryl trifluoroborate. The novel method comprises the following steps: enabling backflow reaction of tetra(pyrrolidine) diboron in excessive alcohol or water to obtain tetra(alkoxy) diboron, and adding a potassium bifluoride water solution so as to obtain potassium trifluoroborate diboron acid, wherein a boronizing agent is white crystalline solid, is stable in air and moisture and is suitable for being stored for a long time. The agent and aryl halide are adopted to be subjected to Suzuki coupling so as to obtain the potassium aryl trifluoroborate salt, the operation is simple and convenient, the yield is high, and corrosion to glass equipment and reaction kettles can be avoided.

Owner:CANGZHOU PURUI DONGFANG SCI & TECH +2

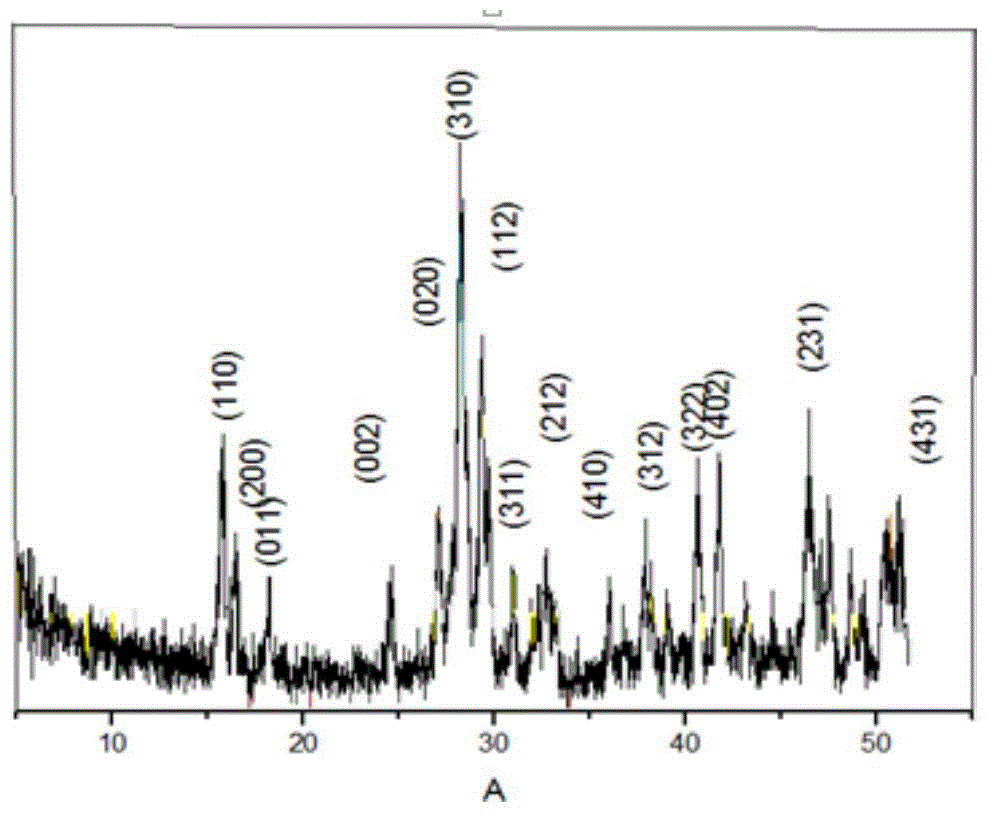

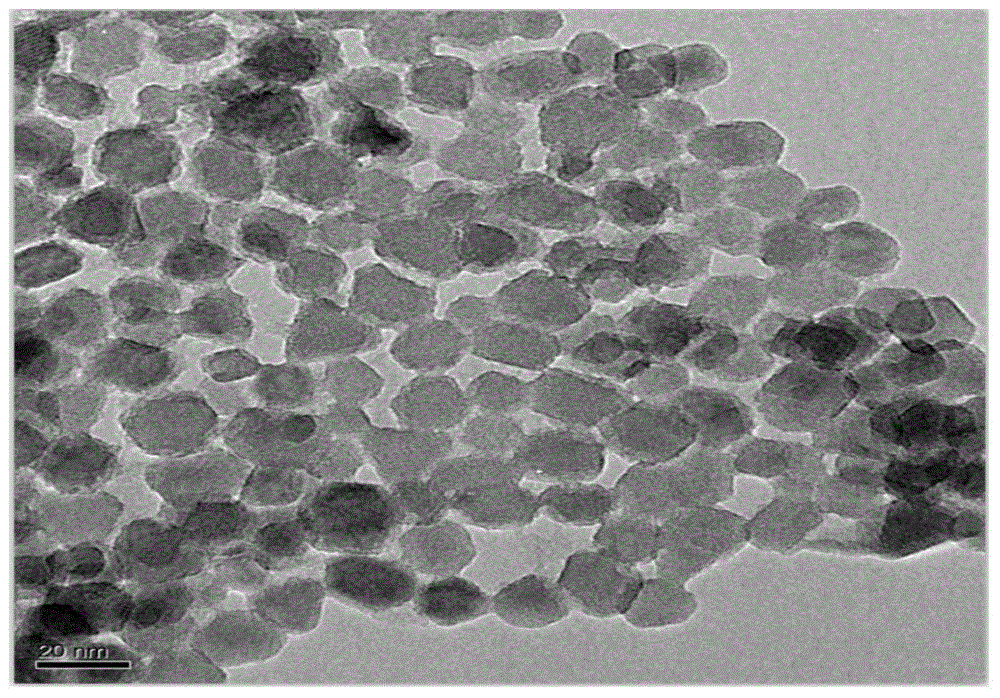

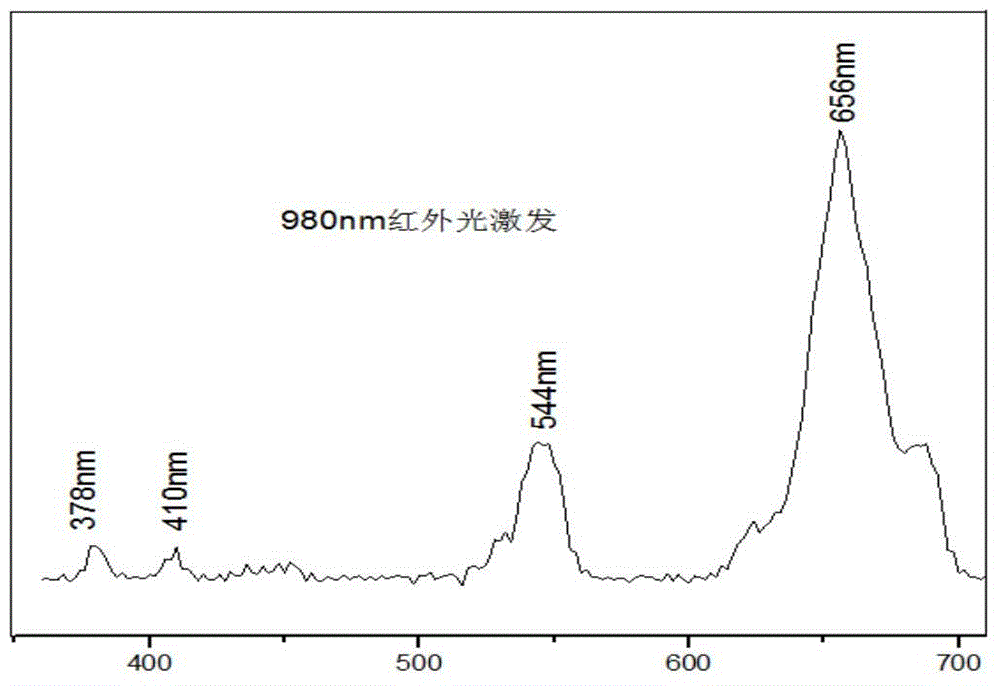

Method for synthesizing rare-earth metal codoped yttrium potassium pentafluoride nano crystal from waste fluorescent powder

InactiveCN104861978ALow costNo secondary pollutionNanoopticsRecycling and recovery technologiesLuminous intensityFluorescence

The invention discloses a method for synthesizing rare-earth metal codoped yttrium potassium pentafluoride nano crystal from waste fluorescent powder. The method comprises the following steps: heating to disperse rare-earth ions, potassium bifluoride and potassium hydroxide in oleic acid so as to form a homogenized solution, and enabling the mixed components to react under a high temperature condition so as to generate ytterbium, europium and erbium codoped yttrium potassium pentafluoride nano crystal. By controlling the factors such as the concentration of rare-earth doped ions and the ratio of additives such as a potassium source, a fluorine source and oleic acid, the particle size and the intensity of visible light can be adjusted and controlled, and conversion of ultraviolet light and near-infrared light to visible light of multiple wavelengths can be achieved. The product prepared by using the method is uniform in morphology, controllable in size, high in light emission intensity, and can be used in fields such as photo-electron devices, electric light source illumination, solar batteries and biological fluorescent markers. The method is simple in preparation process, free of special equipment, low in cost, green and environment-friendly, and applicable to preparation and large-scale industrial production of multiple types of rare-earth up-conversion luminescence nano crystals.

Owner:WUHAN UNIV OF TECH

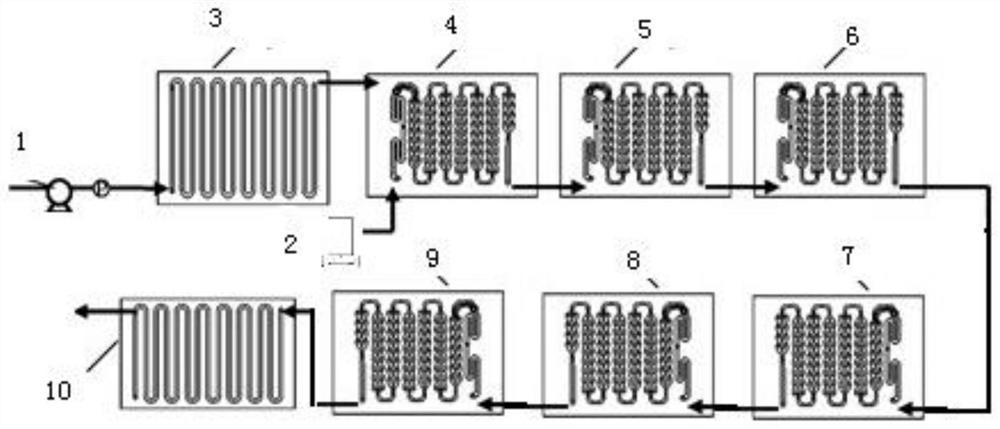

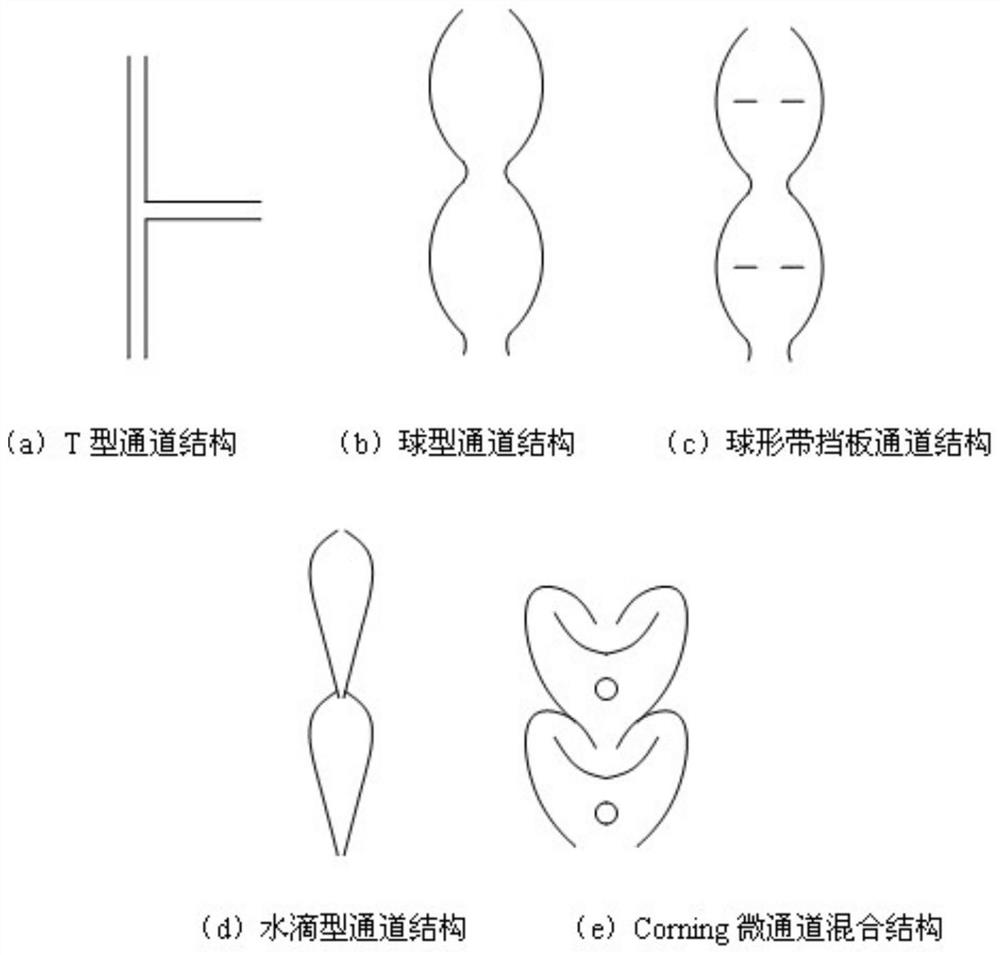

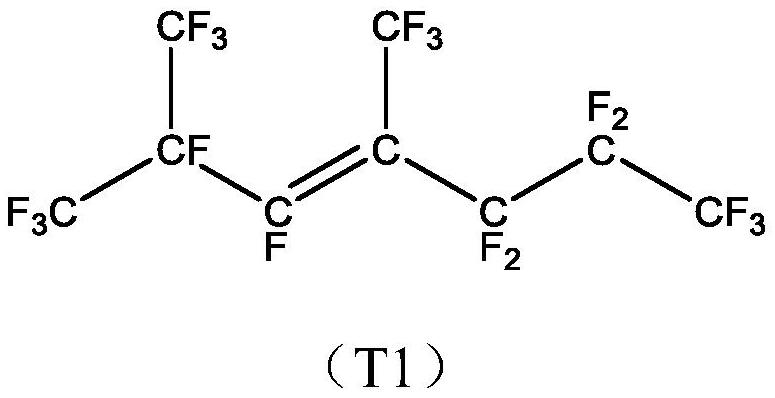

Continuous preparation method of hexafluoropropylene tripolymer

ActiveCN113548943AHigh selectivityAccurate temperature controlHeat-exchange elementsChemical recyclingPtru catalystMeth-

The invention discloses a continuous preparation method of a hexafluoropropylene tripolymer. The continuous preparation method comprises the following step: in a micro-channel reactor, reacting hexafluoropropylene with a liquid-phase catalyst preheated by a preheating module at 70-140 DEG C to obtain the hexafluoropropylene tripolymer. The liquid-phase catalyst is prepared from a component A, a component B, a component C and a component D; the component A is selected from at least one of potassium fluoride, cesium fluoride and potassium bifluoride; the component B is selected from at least one of 18-crown ether-6, beta-cyclodextrin and polyethylene glycol, the component C is selected from at least one of nitrile compounds, glycol ether compounds and amide compounds; and the component D is selected from at least one of perfluoro-4-methyl-2-pentene, perfluoro-2-methyl-2-pentene and perfluoro-2-ethyl-3, 3-dimethyl ethylene oxide. The continuous preparation method has the advantages of accurate temperature control, good selectivity, continuous feeding, catalyst reutilization and the like.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com