Moisture-resistant fluoride red fluorescent powder and preparation method thereof

A red phosphor, fluoride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of reduced luminous intensity, color shift, loss, etc., and achieve the effects of improving stability, simple process and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, Mn 4+ The chemical formula of doped fluoride red phosphor material is K 2 Ti 0.93 f 6 :0.07Mn 4+ .

[0033] The above Mn 4+ Doped Fluoride Red Phosphor K 2 Ti 0.93 f 6 :0.07Mn 4+ The preparation method, the specific process is: 3.765g KF·2H 2 O, 0.173g K 2 MnF 6 Put in the same plastic container, add 20ml 49wt% HF solution, stir until completely dissolved, then add 1.979g (NH 4 ) 2 TiF 6 , continue to stir for 0.5h, stand still, precipitate, then centrifuge to remove the supernatant, the lower sediment is washed with absolute ethanol, then centrifuged, repeatedly washed and centrifuged twice; the obtained precipitate is dried in an oven at 80 ° C to obtain the product K 2 Ti 0.93 f 6 :0.07Mn 4+ (labeled KTFM-1).

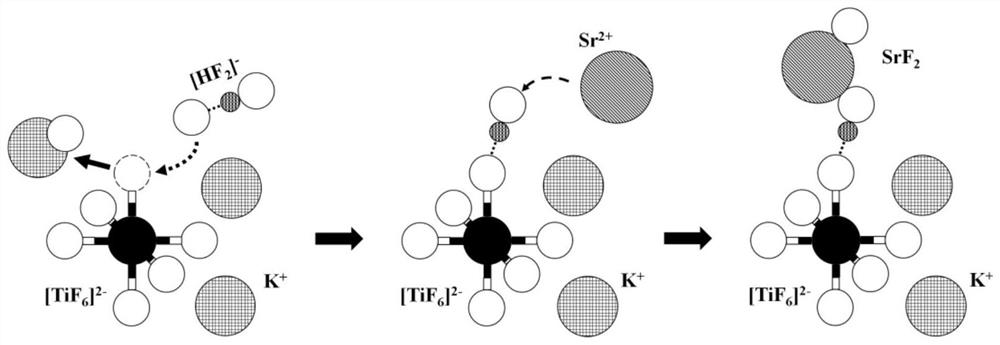

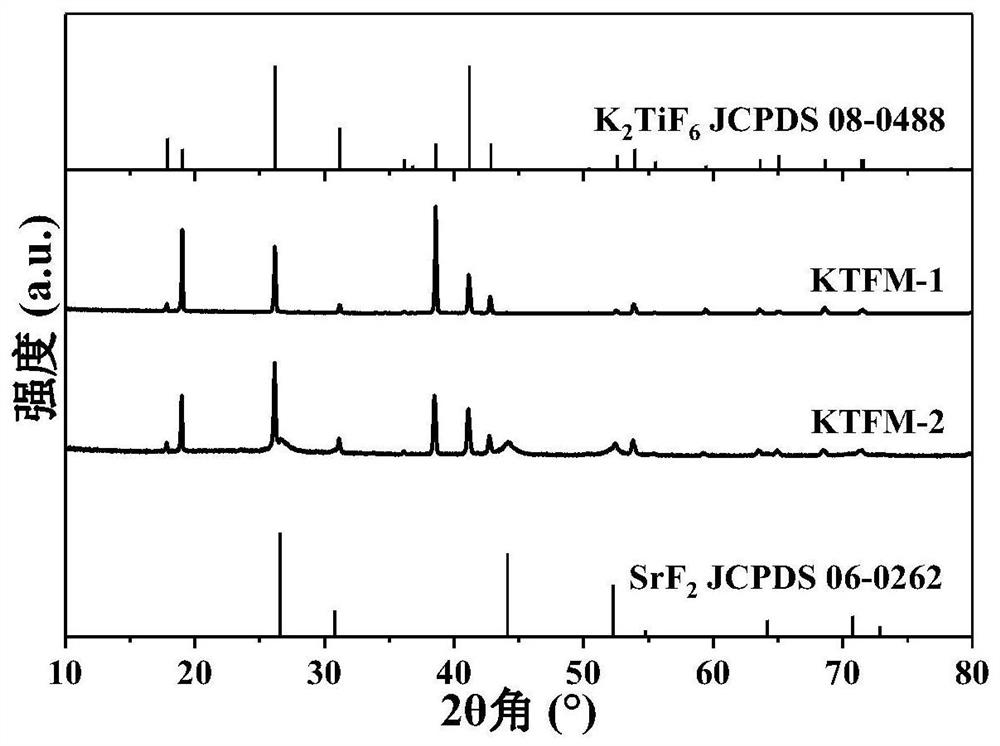

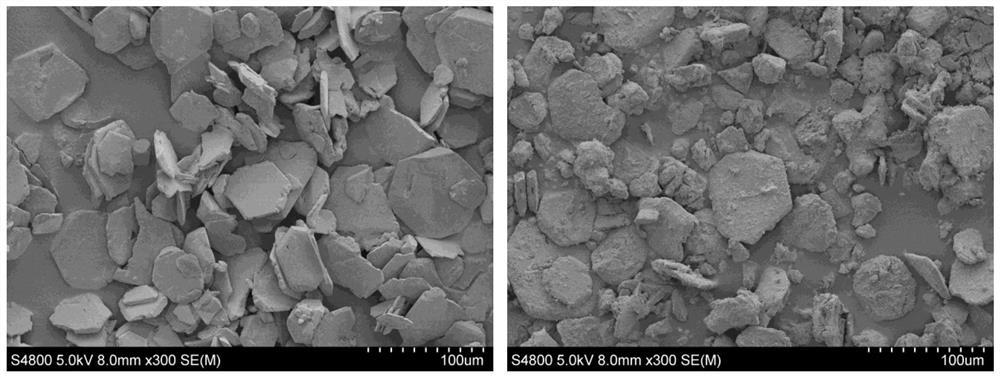

[0034] One of the above Mn 4+ The coating method of doped fluoride red phosphor powder, by Mn 4+ The red fluorescent powder doped with fluoride is coated with the alkaline earth metal fluoride waterproof layer to obtain a m...

Embodiment 2

[0041] In this example, Mn 4+ The chemical formula of doped fluoride red phosphor material is K 2 Si 0.96 f 6 :0.04Mn 4+ (labeled KSFM-3).

[0042] A preparation method of moisture-resistant fluoride red phosphor: weigh 1.823g K 2 Si 0.96 f 6 :0.04Mn 4+ (KSFM-3) Phosphor powder is placed in a plastic container, add 2mol / L KHF 2 30ml aqueous solution, fully stirred for 20min, added dropwise 1mol / L Ca(NO 3 ) 2 6ml of aqueous solution, stirred for 0.5h, left to stand, and precipitated; centrifuged to remove the supernatant, the lower layer of sediment was washed with distilled water, then centrifuged, repeatedly washed and centrifuged twice, and the precipitate was dried in an oven at 80°C to obtain a moisture-resistant fluoride red Phosphor. The chemical formula of the moisture-resistant fluoride red phosphor can be expressed as K 2 Ti 0.96 f 6 :0.04Mn 4+ @CaF 2 (labeled KSFM-4).

[0043] Phosphor powder KSFM-3, KSFM-4 in embodiment 2 are carried out X-ray diffr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com