Method for preparing aluminum fluoride product through combined treatment of multiple wastes and aluminum fluoride product

A combined treatment and aluminum fluoride technology, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of inability to realize resource utilization, waste of valuable acids and aluminum salts, etc., and achieve convenient operation, high feasibility, and aluminum oxide The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

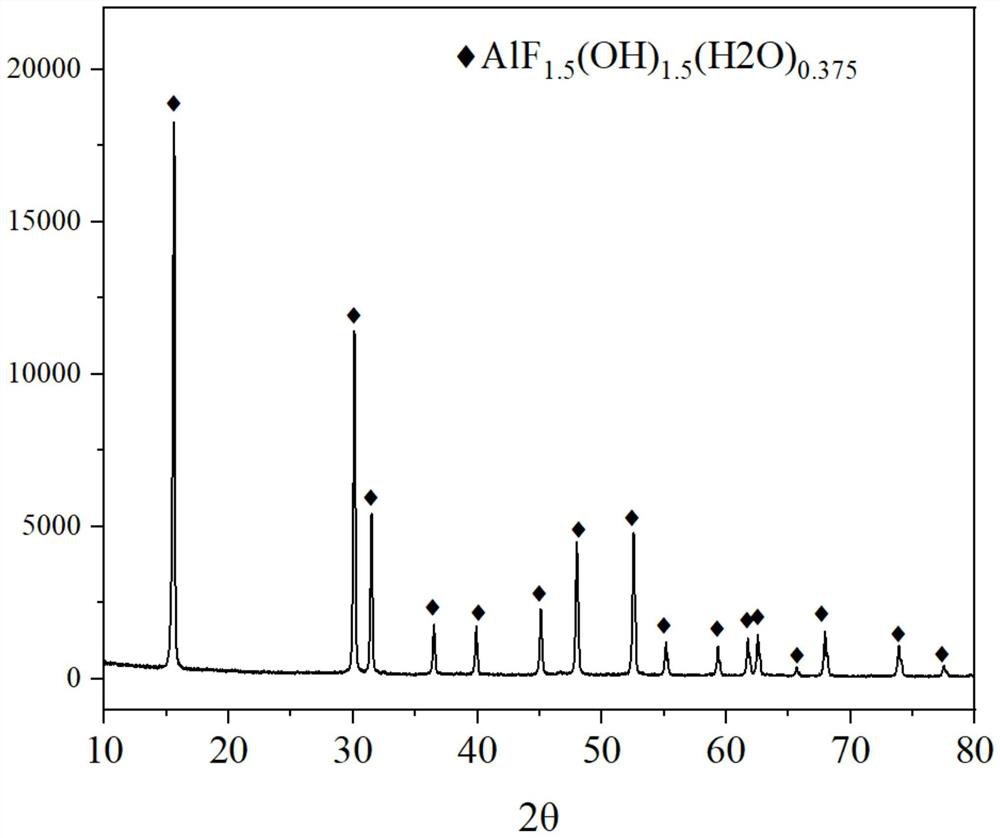

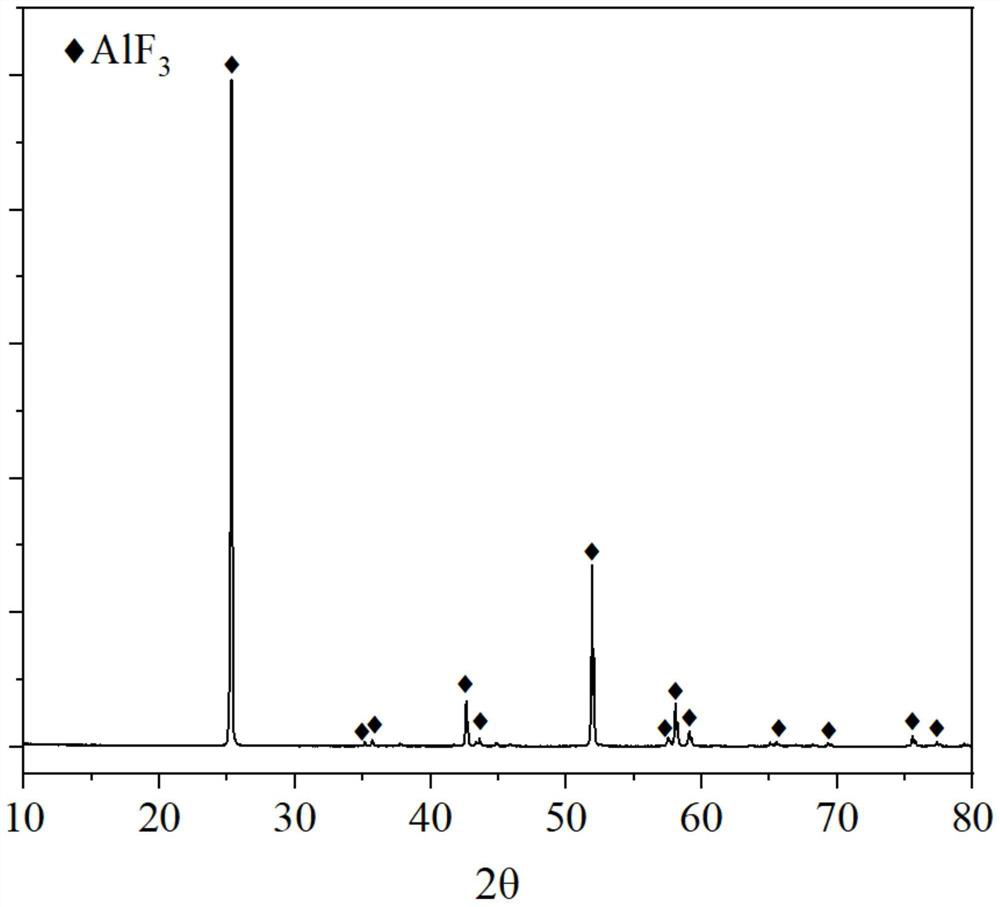

[0051] The steps of the method for treating waste electrolytes containing fluorine in this embodiment are as follows:

[0052] (1) Take 16.00g of waste electrolyte powder from an electrolytic aluminum plant (XRF fluorescence analysis: F 49.68wt.%, Na21.48wt.%, Al 14.48%, Ca 5.46, K 5.13wt.%, O 2.59wt.%, Mg 0.57wt.%, S0.18wt.%), aluminum ash powder 3.20g (Al content 32.15wt.%), aluminum anodic oxidation wastewater 200ml (H 2 SO 4 The concentration is 200g / L, Al 3+ ion concentration is 15g / L), after mixing, ball milling and leaching for 1h in a ball milling tank, wherein the ball milling speed is 350r / min; then filter, and slowly add 4mol / L sodium hydroxide solution in the resulting filtrate, so that the pH of the solution is 3.5 stop, filter and dry to obtain 22.54 g of aluminum hydroxyfluoride hydrate precipitate and filtrate; the filtrate evaporates and crystallizes to obtain 39.72 g of mixed salt with sodium sulfate as the main phase.

[0053] (2) Mix 30.00 g of ammonium ...

Embodiment 2

[0062] Repeat Example 1, the difference is only: change the spent electrolyte powder into flotation cryolite (XRF analysis: F47.32wt.%, Na 22.37wt.%, Al 14.73%, Ca 6.75, K 4.91wt.% in the step (1) %, O 3.11wt.%, Mg0.42wt.%, S 0.13wt.%), the resulting aluminum hydroxyfluoride and aluminum fluoride products are detected, and the results are shown in Table 1 and Table 2.

Embodiment 3

[0064] Repeat Example 1, the only difference being: change the ammonium bifluoride in step (2) to 40.00 g of sodium bifluoride, wash the product after roasting and cooling, filter, and bake at 100° C. for 5 hours to obtain the aluminum fluoride product. Evaporate and crystallize the washing liquid obtained by washing with water to obtain the sodium fluoride product.

[0065] Gained aluminum hydroxyfluoride and aluminum fluoride products are detected, and the results are shown in Table 1 and Table 2.

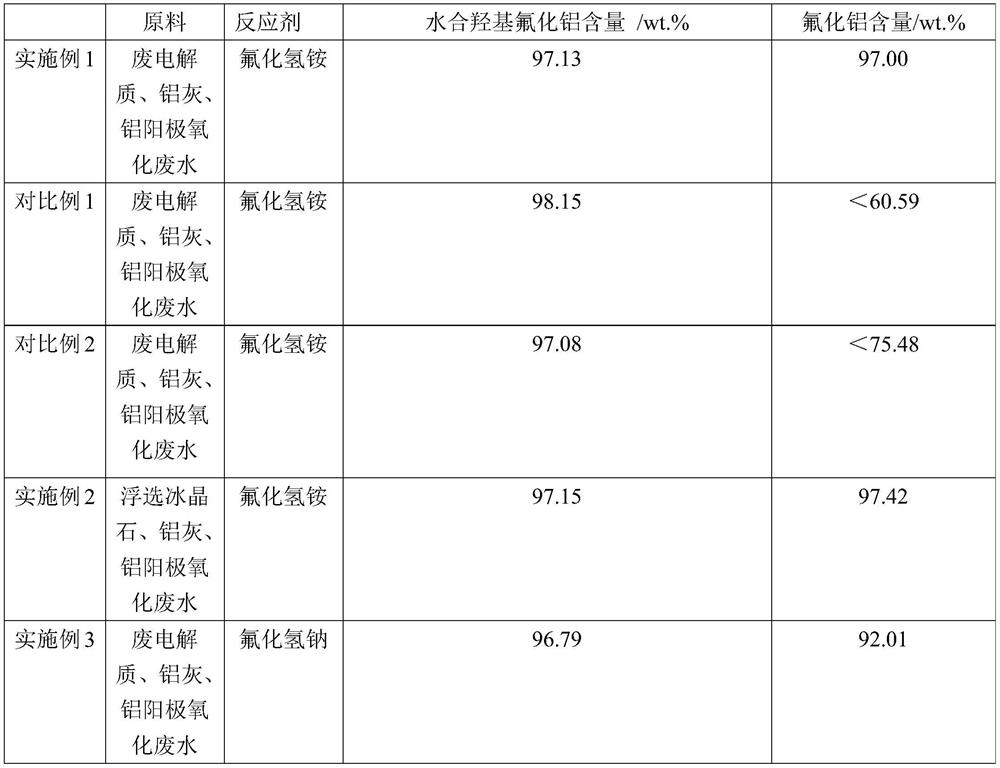

[0066] The relevant process parameter of each embodiment of table 1 and the detection result situation of target substance content in relevant product

[0067]

[0068] Table 2 Contents of some elements in hydrated aluminum hydroxyfluoride and aluminum fluoride products

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com