Preparation method of modified diaphragm for lithium-ion secondary battery as well as product and preparation device thereof

A secondary battery and lithium-ion technology, applied in the direction of layered products, battery pack parts, chemical instruments and methods, etc., can solve the problems of inability to truly replace microporous membranes, poor mechanical strength of diaphragms, and potential safety hazards, and achieve suitable Large-scale industrial production, improving environmental protection, and increasing the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

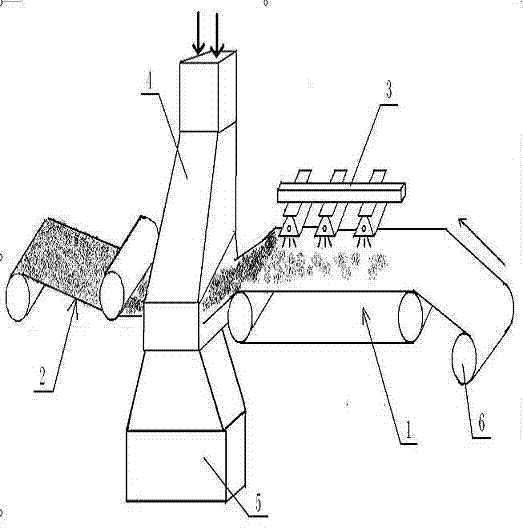

Method used

Image

Examples

Embodiment 1

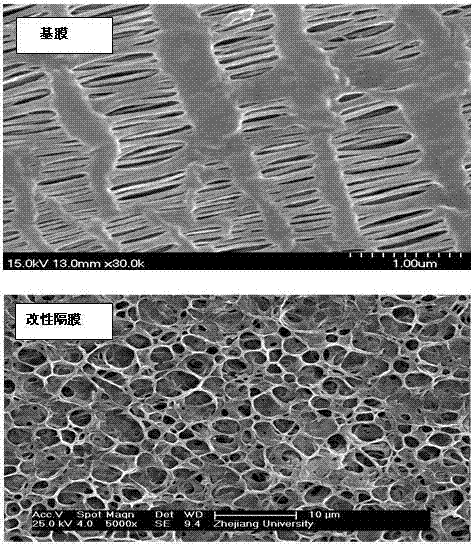

[0043] The first step is to select a single-layer PP diaphragm as the base film with a thickness of 22 microns, and install the base film on the base film conveying section;

[0044] In the second step, put 190 grams of high-purity polybismaleimide (special fiber) in 800 grams of DMAC (N, N-dimethylacetamide), then add 10 grams of LiCl as a co-solvent, and stir through a high-speed stirring disperser After 10 hours, a composite mixed solution was obtained;

[0045] The third step is to heat the composite mixed solution to the spinning temperature of 85°C, at which time a liquid crystal solution is formed, put the composite mixed solution into the spinneret of the electrospinning device, and spray the composite mixed solution evenly on the substrate through high-speed multi-nozzles. On the membrane, a primary composite membrane is formed;

[0046] The fourth step: the primary composite film enters the drying and solvent recovery device, and the air duct of the drying and solve...

Embodiment 2

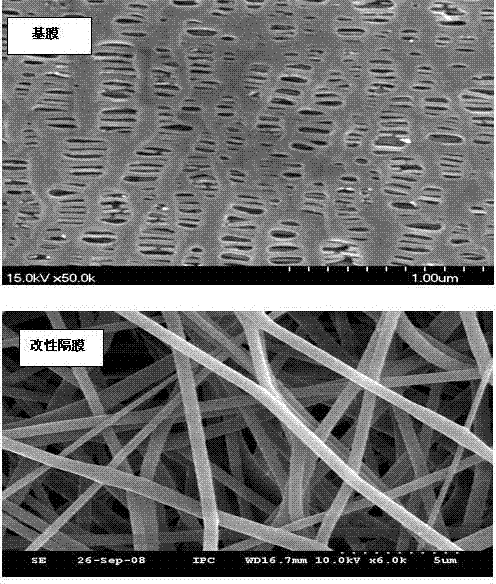

[0049] The first step is to select three layers of PP / PE / PP diaphragm as the base film, the thickness of the base film is 25 microns, and install the base film on the base film conveying section;

[0050] In the second step, 200 grams of polytetrafluoroethylene is placed in 1000 grams of N-methylpyrrolidone, and then 100 grams of sodium benzoate is added as a cosolvent. After stirring at high speed for 3 hours, 900 grams of high-purity alumina powder is then added, passed through a high-speed The stirring disperser was stirred for 5 hours to obtain a composite mixture;

[0051] The third step is to heat the composite mixture to the spinning temperature of 95°C, put the composite mixture into the spinneret of the electrospinning device, and spray the composite mixture evenly on the base film through high-speed multi-nozzles to form a primary composite membrane;

[0052] The fourth step: the primary composite film enters the drying and solvent recovery device, and the air duct ...

Embodiment 3

[0055] The first step is to select a single-layer PE diaphragm as the base film with a thickness of 21.6 microns, and install the base film on the base film conveying section;

[0056] The second step is to place 90 grams of polyvinylidene fluoride in 1000 grams of N-methylpyrrolidone / methanol (1:1 mass ratio) mixed solvent, and then add 50 grams of CaCl 2 As a co-solvent, after 2 hours of high-speed stirring, 900 grams of mixed powder of high-purity alumina and calcium oxide was added, and stirred by a high-speed stirring disperser for 8 hours to obtain a composite mixed solution.

[0057] The third step is to heat the composite mixture to the spinning temperature of 70°C, put the composite mixture into the spinneret of the electrospinning device, and spray the composite mixture evenly on the base film through high-speed multi-nozzles to form a primary composite membrane;

[0058] The fourth step: the primary composite film enters the drying and solvent recovery device, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com