Preparation method of a multi-responsive self-healing self-adhesive hydrogel

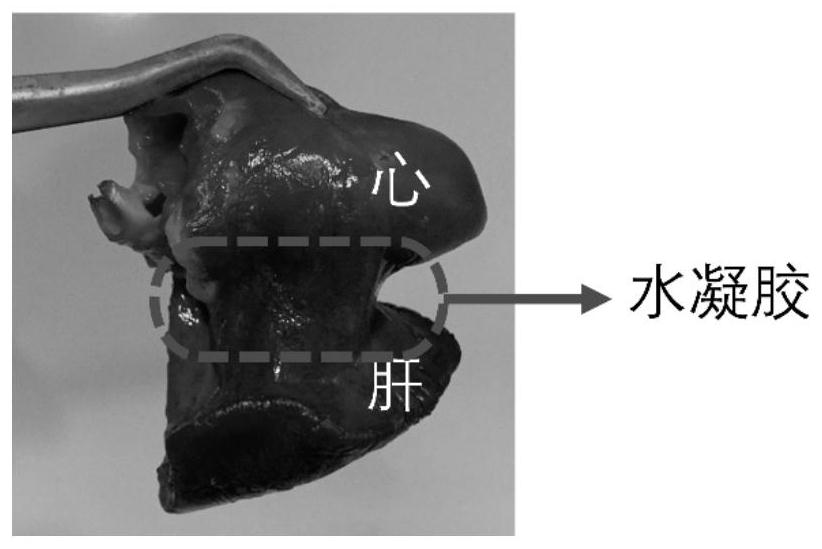

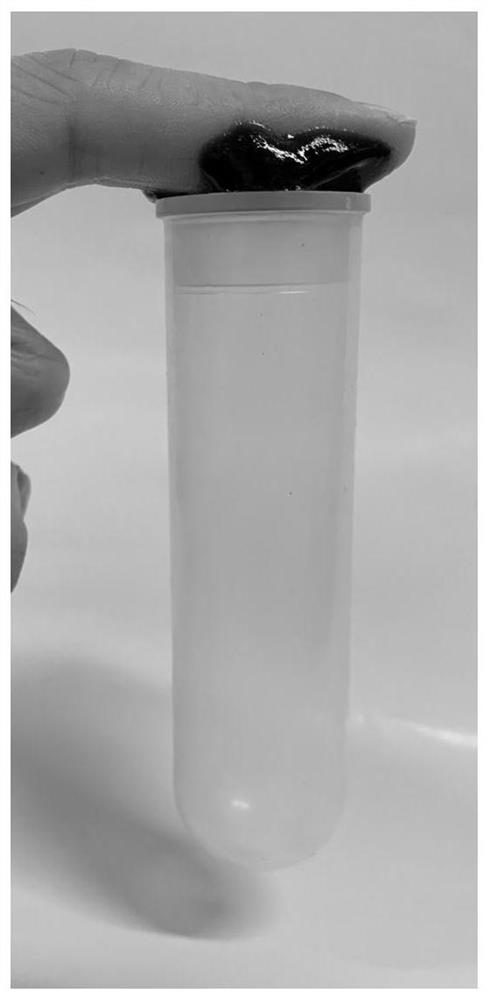

A hydrogel and responsive technology, applied in the field of preparation of multiple responsive self-healing and self-adhesive hydrogels, can solve the problems of poor mechanical properties of hydrogels, lack of tissue adhesion and cell affinity, etc. , to achieve the effect of simple preparation method, wide application potential and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At room temperature, take 36.9 g of bacterial cellulose suspension with a mass fraction of 8.13 mg / g (about 0.3 g of bacterial cellulose), disperse it into 30 mL of tris buffer with a pH value of 8.5, and then add 0.2 g Tannic acid, stir evenly, after the prepolymerization reaction for 6 hours, add 0.2 g of cystamine dihydrochloride to continue the reaction for 1.5 hours to obtain the bacterial cellulose suspension coated with tannic acid, and successfully introduce disulfide bonds, and the suspension Centrifuge and wash for later use.

[0026] Add 5g of polyvinyl alcohol into 45mL of deionized water and heat to 95°C, stir for 2 hours until the polyvinyl alcohol is completely dissolved, add the centrifuge obtained in the previous step into the polyvinyl alcohol solution and continue to stir evenly, then add 5mL of the concentration to 0.04g / Add 1 mL of borax solution dropwise at a rate of 1 mL / min, stir for 20 min, and then naturally cool to room temperature to obtain ...

Embodiment 2

[0030] At room temperature, take 36.9 g of bacterial cellulose suspension with a mass fraction of 8.13 mg / g (about 0.3 g of bacterial cellulose), disperse it into 30 mL of tris buffer with a pH value of 8.5, and then add 0.5 g Tannic acid, stir evenly, after the prepolymerization reaction for 6 hours, add 0.2 g of cystamine dihydrochloride to continue the reaction for 1.5 hours to obtain the bacterial cellulose suspension coated with tannic acid, and successfully introduce disulfide bonds, and the suspension Centrifuge and wash for later use.

[0031] Add 5g of polyvinyl alcohol into 45mL of deionized water and heat to 95°C, stir for 2 hours until the polyvinyl alcohol is completely dissolved, add the centrifuge obtained in the previous step into the polyvinyl alcohol solution and continue to stir evenly, then add 5mL of the concentration to 0.04g / Add 1 mL of borax solution dropwise at a rate of 1 mL / min, stir for 20 min, and then naturally cool to room temperature to obtain ...

Embodiment 3

[0034] At room temperature, take 36.9 g of bacterial cellulose suspension with a mass fraction of 8.13 mg / g (approximately containing 0.3 g of bacterial cellulose), disperse it into 30 mL of tris buffer with a pH value of 8.5, and then add 0.8 g Tannic acid, stir evenly, after the prepolymerization reaction for 6 hours, add 0.2 g of cystamine dihydrochloride to continue the reaction for 1.5 hours to obtain the bacterial cellulose suspension coated with tannic acid, and successfully introduce disulfide bonds, and the suspension Centrifuge and wash for later use.

[0035] Add 5g of polyvinyl alcohol into 45mL of deionized water and heat to 95°C, stir for 2 hours until the polyvinyl alcohol is completely dissolved, add the centrifuge obtained in the previous step into the polyvinyl alcohol solution and continue to stir evenly, then add 5mL of the concentration to 0.04g / Add 1 mL of borax solution dropwise at a rate of 1 mL / min, stir for 20 min, and then naturally cool to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com