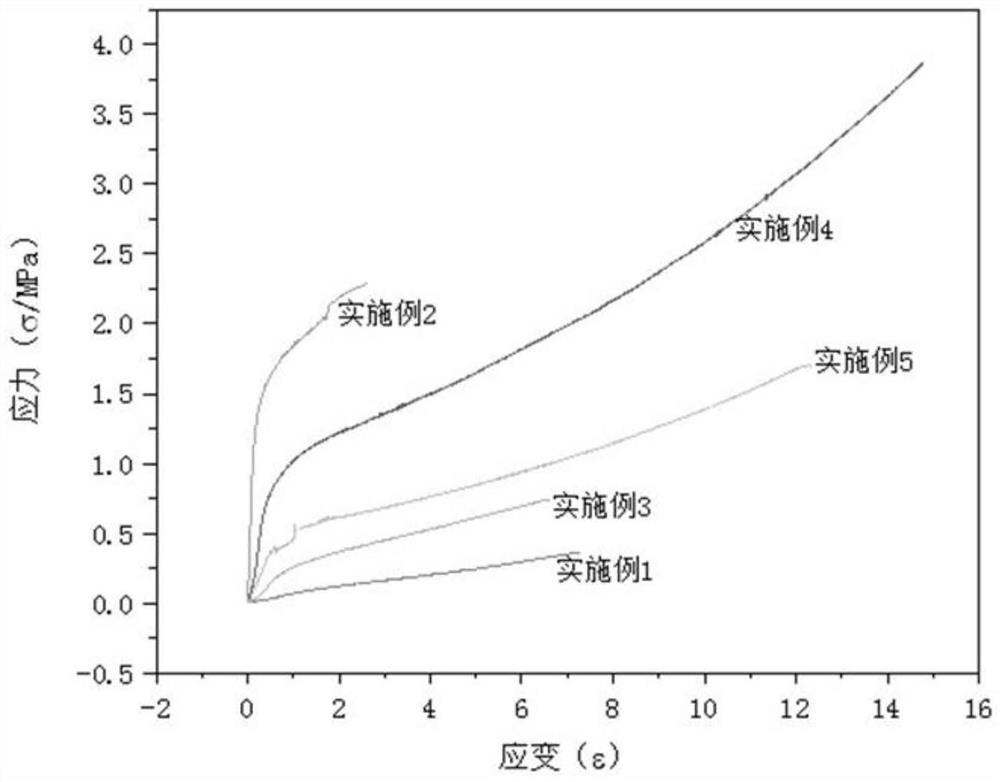

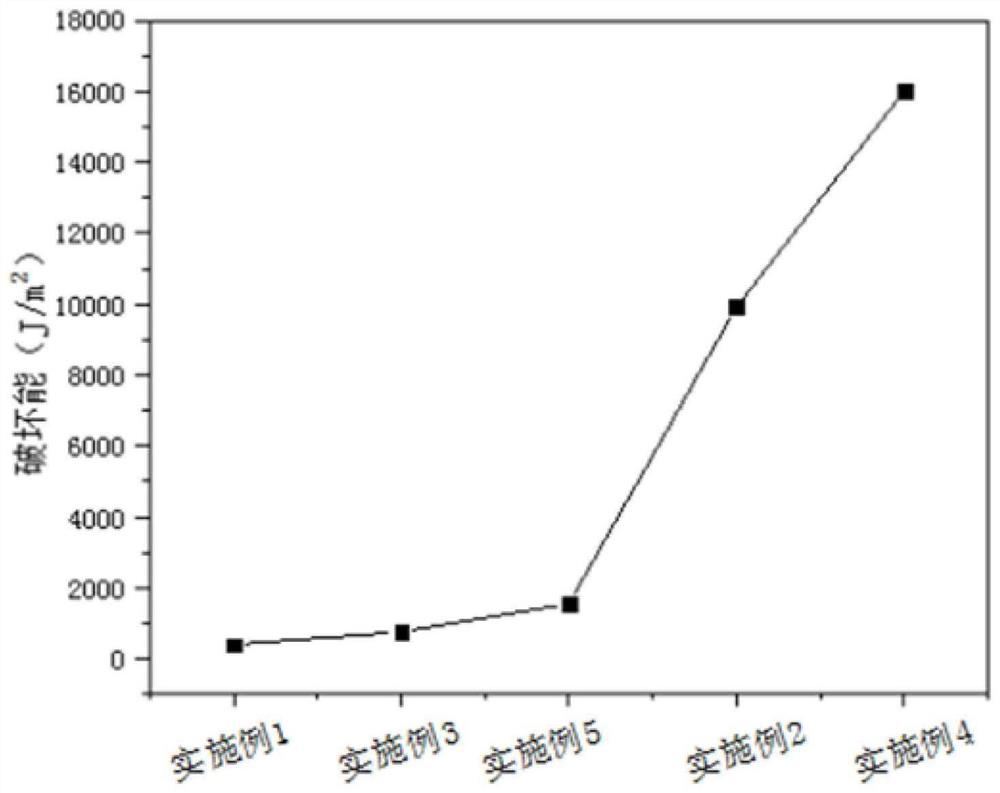

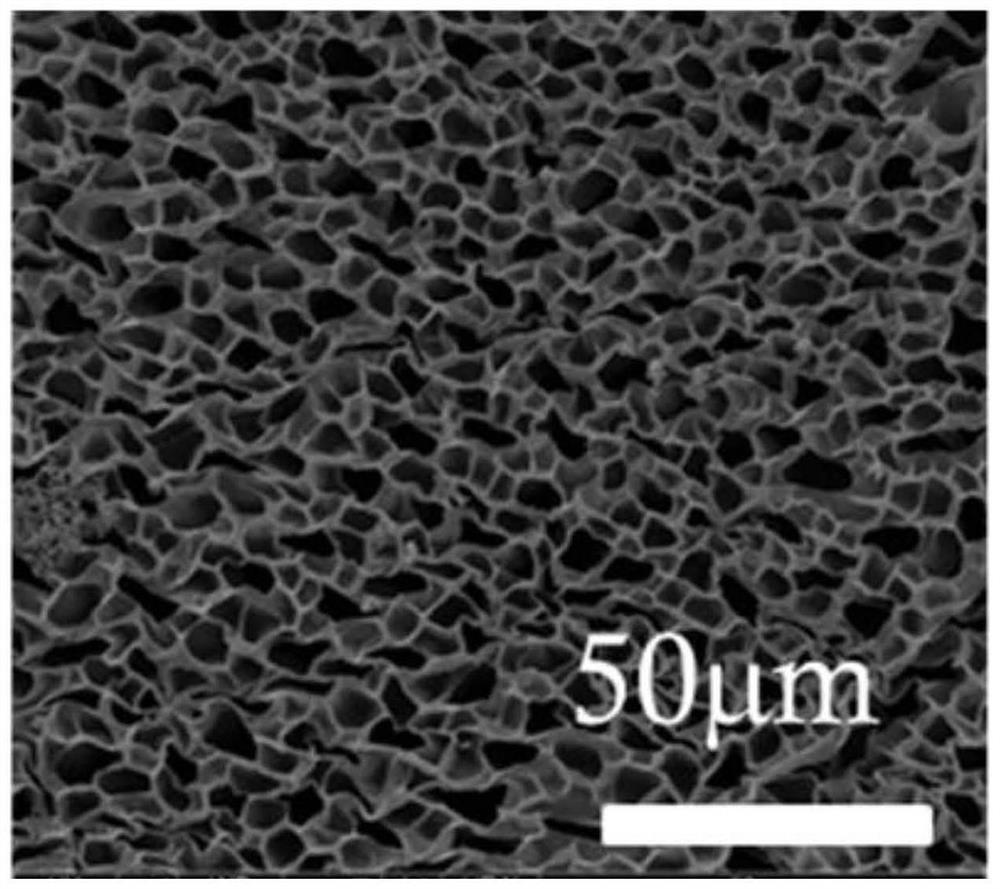

A preparation method of high-strength lignin hydrogel with adjustable mechanical properties

A lignin and high-strength technology, applied in the field of preparation of high-strength lignin hydrogel, can solve the problems of poor mechanical strength and achieve the effect of overcoming poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of a high-strength lignin hydrogel with adjustable mechanical properties of the present invention is specifically implemented according to the following steps:

[0048] Step 1, adding n-isopropylacrylamide into N,N-dimethylformamide, mixing evenly, then adding hydrogen peroxide, fully stirring to dissolve completely, and obtaining a polymer monomer solution;

[0049] Among them, the mass ratio of n-isopropylacrylamide, N,N-dimethylformamide and hydrogen peroxide is 10:1:0.001;

[0050] Step 2, the polymer monomer solution that obtains after step 1 is in N 2 The reaction is carried out in an atmosphere; the reaction temperature is 50°C-80°C, and the reaction time is 2h-4h; that is, free radical polymerization is carried out to obtain a long-chain polymer solution, and then the long-chain polymer solution is evaporated to dryness at a temperature of 25°C , to obtain polymer solids;

[0051] Step 3, adding alkali lignin to N,N-dimethylformamide to ...

Embodiment 2

[0056] The preparation method of a high-strength lignin hydrogel with adjustable mechanical properties of the present invention is specifically implemented according to the following steps:

[0057] Step 1, add methacrylic acid to N,N-dimethylformamide, mix well, then add ammonium persulfate, sulfate lignin and polyethylene glycol diglycidyl ether, stir well to dissolve completely , to obtain a polymer monomer solution;

[0058] Among them, the mass ratio of methacrylic acid, N,N-dimethylformamide, ammonium persulfate, sulfate lignin and polyethylene glycol diglycidyl ether is 10:10:0.002:1:0.1;

[0059] Step 2, the polymer monomer solution that obtains after step 1 is in N 2 The reaction is carried out in an atmosphere; the reaction temperature is 60°C, and the reaction time is 2.5h; that is, free radical polymerization (photoinitiated polymerization, thermally induced polymerization, redox polymerization) is carried out to obtain a long-chain polymer solution, and then the ...

Embodiment 3

[0065] The preparation method of a high-strength lignin hydrogel with adjustable mechanical properties of the present invention is specifically implemented according to the following steps:

[0066] Step 1, add dimethacrylic acid to N,N-dimethylacetamide, mix well, then add potassium persulfate, enzymatic lignin and N-hydroxysuccinimide, stir well to dissolve completely , to obtain a polymer monomer solution;

[0067] Among them, the mass ratio of dimethacrylic acid, N,N-dimethylacetamide, potassium persulfate, enzymatic lignin and N-hydroxysuccinimide is 10:50:0.005:2:0.2;

[0068] Step 2, the polymer monomer solution that obtains after step 1 is in N 2 The reaction was carried out in an atmosphere; the reaction temperature was 80°C, and the reaction time was 4 hours; that is, free radical polymerization (light-induced polymerization, heat-induced polymerization, redox polymerization) was carried out to obtain a long-chain polymer solution, and then the long-chain polymer so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com