Waterproof and anti-icing fly ash/pvc composite board and its preparation method and application

A composite board and fly ash technology, applied in applications, other household appliances, flat products, etc., can solve the problems of cracking strength of composite materials, limited waterproof and anti-icing performance of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a method for preparing a waterproof and anti-icing fly ash / PVC composite plate, comprising the following steps:

[0046] S1, sieve the fly ash, and then dry the sieved fly ash at 90-110°C for 15-45 minutes to obtain the dried fly ash, which is designated as fly ash I;

[0047] S2, adding the dried coal ash into a nitric acid solution with a concentration of 25 to 35 wt %, performing acidification treatment, then suction filtration, water washing and post-drying treatment to obtain acidified coal ash, which is denoted as pulverized coal Gray II;

[0048] S3, according to a predetermined mass ratio, modify the acidified fly ash with a silane coupling agent at 25-35° C. for 15-45 minutes and then dry it to obtain the fly ash modified by the silane coupling agent. It is fly ash III;

[0049] S4, mix the fly ash modified by the silane coupling agent, resin PVC, plasticizer, Ca-Zn stabilizer, and stearic acid according to the predetermined addition ra...

Embodiment 1

[0059] Embodiment 1 of the present invention provides a method for preparing a waterproof and anti-icing fly ash / PVC composite sheet, comprising the following steps:

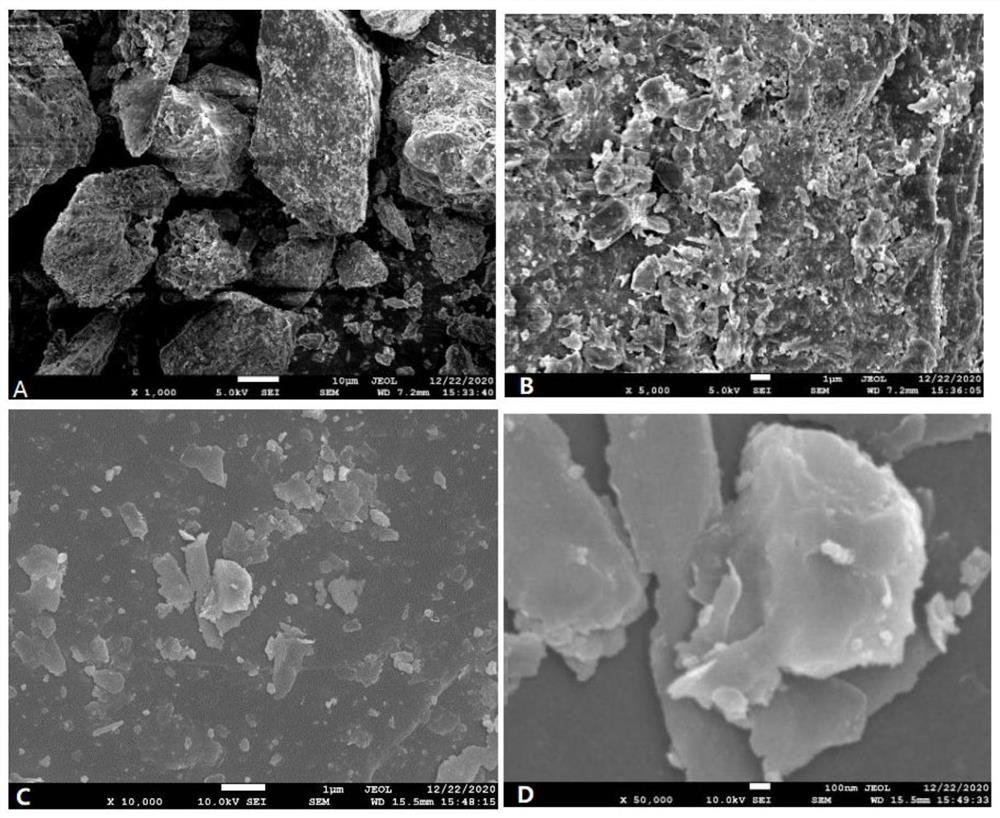

[0060] S1, sieve the fly ash with a 180-mesh sieve, and then dry the sieved fly ash at 100°C for 30 minutes to obtain the dried fly ash, which is designated as fly ash I (such as figure 1 shown);

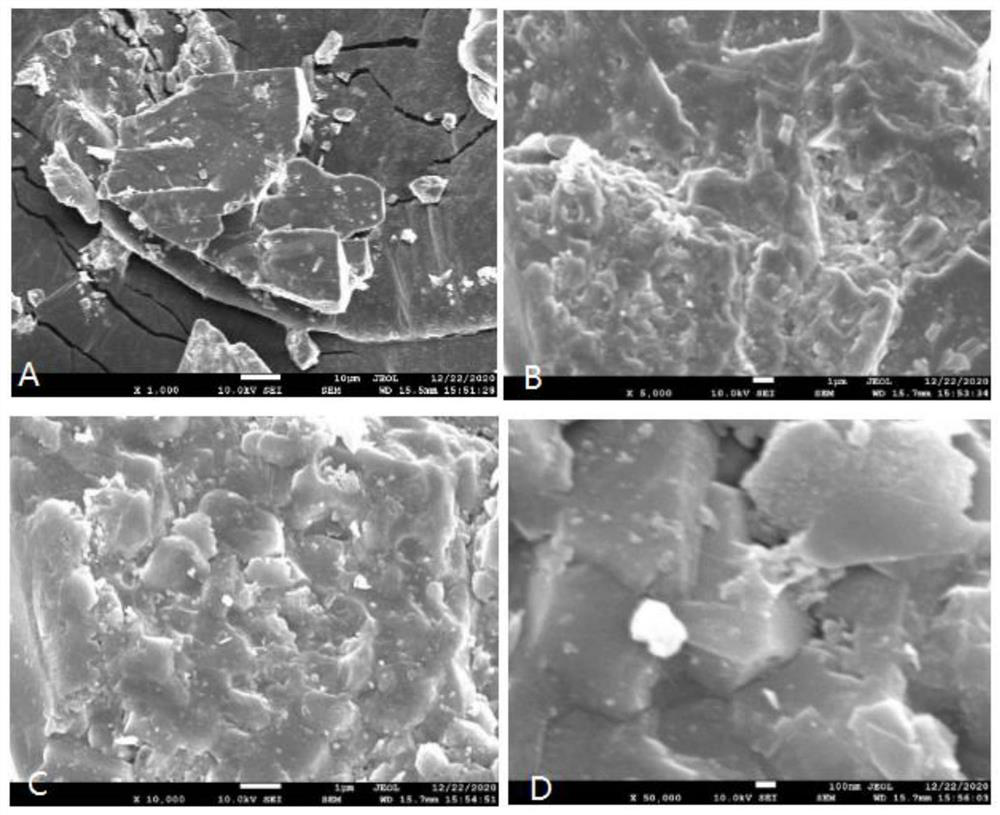

[0061] S2, adding the dried fly ash into a nitric acid solution with a concentration of 30wt%, performing acidification treatment, acidifying at 30°C for 30 minutes, and then performing suction filtration, washing with water and drying to obtain acidified fly ash , recorded as fly ash II (such as figure 2 shown);

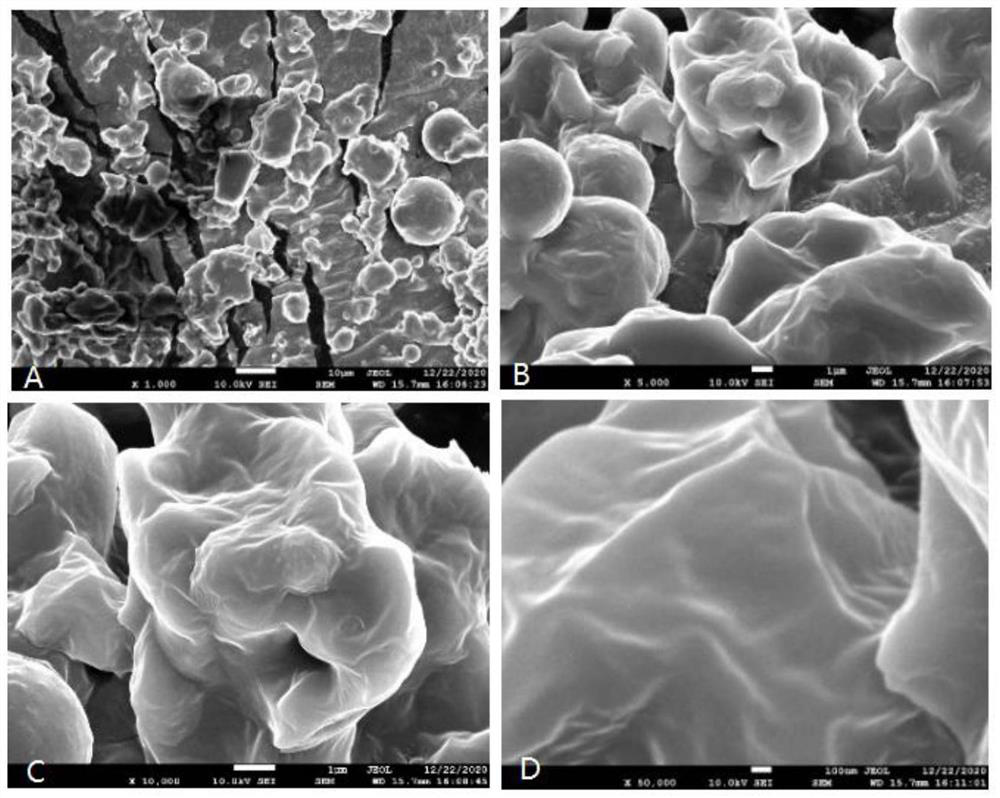

[0062] S3, the acidified fly ash is modified with a silane coupling agent at 30°C for 30 minutes and then dried to obtain the fly ash modified by the silane coupling agent, which is denoted as fly ash III (such as image 3 and Figure 4 shown); wherein, the mass ratio of the acidified fly ash and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com