Glass etching solution, high alumina-silica glass etching method and high alumina-silica glass with textures on surface

A high-alumina-silicate glass and etching solution technology, which is applied in the direction of surface etching composition, chemical instrument and method, telephone structure, etc., can solve the problem of poor etching effect of high-alumina-silicate glass and insufficient decoration of high-alumina-silicate glass surface pattern Satisfying aesthetic needs and other issues, achieving the effect of exquisite pattern, easy operation, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

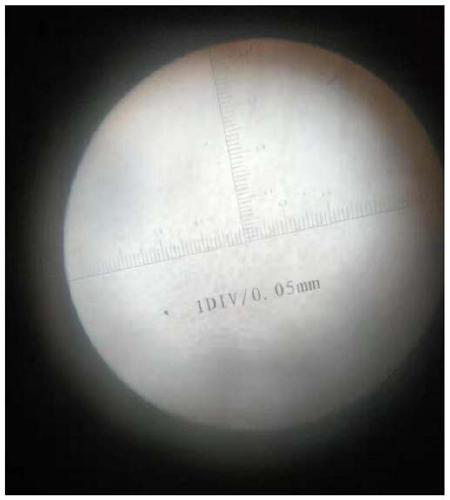

Image

Examples

Embodiment 1

[0027] ⑴. Prepare high-alumina-silicate glass snowflake effect special etching solution according to the following ratio (wt%): NH 4 F10.8%, NH 4 HF 2 21.5%, KHF 2 11.6%, HCL 5.8%, HNO 3 23.5%, KCL 3.8%, CuSO 4 1.7%, NaNO 3 3.5%, NaH 2 PO 4 3.8%, FeCL 3 2.2%, H 2 O 11.8%, fully stirred until the liquid is completely dissolved and transparent, that is, the glass etching solution is obtained.

[0028] ⑵. Cover and protect the side (tin side) of the original high-alumina silica glass that does not need to be etched with a sticky protective film.

[0029] (3) Clean the side of the original high-alumina-silicate glass that needs to be etched with deionized water, and put it into the etching solution in a wet state for immersion etching.

[0030] ⑷. Control the temperature of the etching solution at 20-25°C. Control etching time is 10-15 minutes.

[0031] (5) After reaching the etching time requirement, take out the etched glass from the etching solution in time, t...

Embodiment 2

[0033] (1) Carry out the preparation (wt%) of glass etchant according to the following ratio: NH 4 F 13.6%, NH 4 HF 2 16.5%, KHF 2 15.8%, HCL 7.6%, HNO 3 20.5%, KCL 4.6%, CuSO 4 2.8%, NaNO 3 8%, NaH 2 PO 4 3.0%, FeCL 3 2.7%, H 2 O 10.4%, fully stirred until the liquid is completely dissolved and transparent, that is, the special etching solution for high-alumina-silicate glass snowflake effect is prepared.

[0034] ⑵. Cover and protect the side (tin side) of the original high-alumina silica glass that does not need to be etched with a sticky protective film.

[0035] (3) Clean the side of the original high-alumina-silicate glass that needs to be etched with deionized water, and put it into the etching solution in a wet state for immersion etching.

[0036] ⑷. Control the temperature of the etching solution at 20-25°C. Control etching time is 10-15 minutes.

[0037] (5) After reaching the etching time requirement, take out the etched glass from the etching sol...

Embodiment 3

[0039] ⑴. Prepare high-alumina-silicate glass snowflake effect special etching solution according to the following ratio (wt%): NH 4 F15%, NH 4 HF 2 10%, KHF 2 8%, HCL 15%, HNO 3 15%, KCL 5%, CuSO 4 6%, NaNO 3 8%, NaH 2 PO 4 3%, FeCL 3 5%, H2 O 10%, fully stirred until the liquid is completely dissolved and transparent, that is, the special etching solution for snowflake effect of high-alumina silica glass is prepared.

[0040] (2) Cover and protect the side (tin side) of the high-alumina-silicate glass that does not need to be etched with a sticky protective film.

[0041] (3) Clean the side of the original high-alumina-silicate glass that needs to be etched with deionized water, and put it into the etching solution in a wet state for immersion etching.

[0042] ⑷. Control the temperature of the etching solution at 20-25°C. Control etching time is 10-15 minutes.

[0043] (5) After reaching the etching time requirement, take out the etched glass from the etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com