Patents

Literature

261results about How to "Meet appearance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

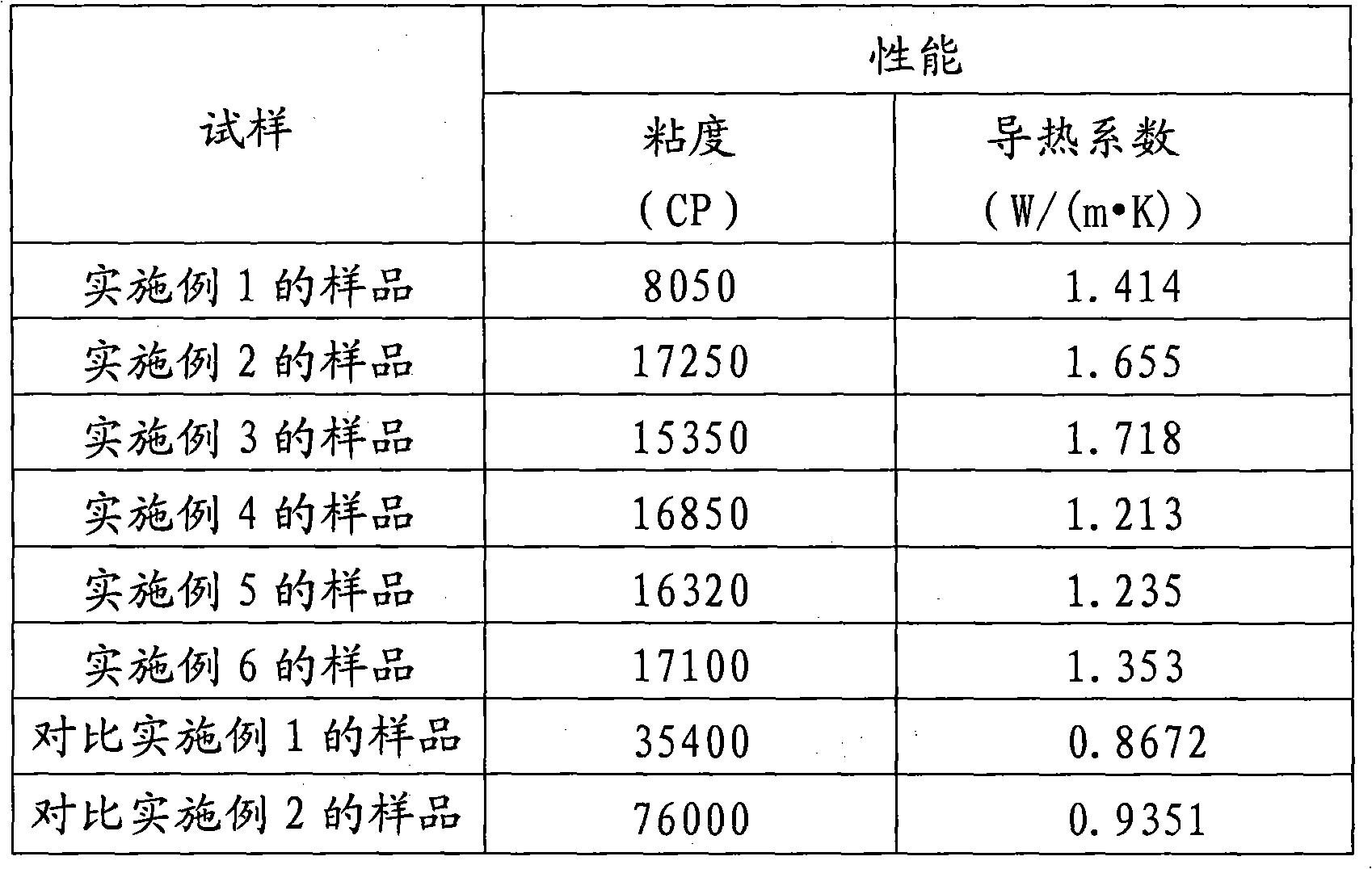

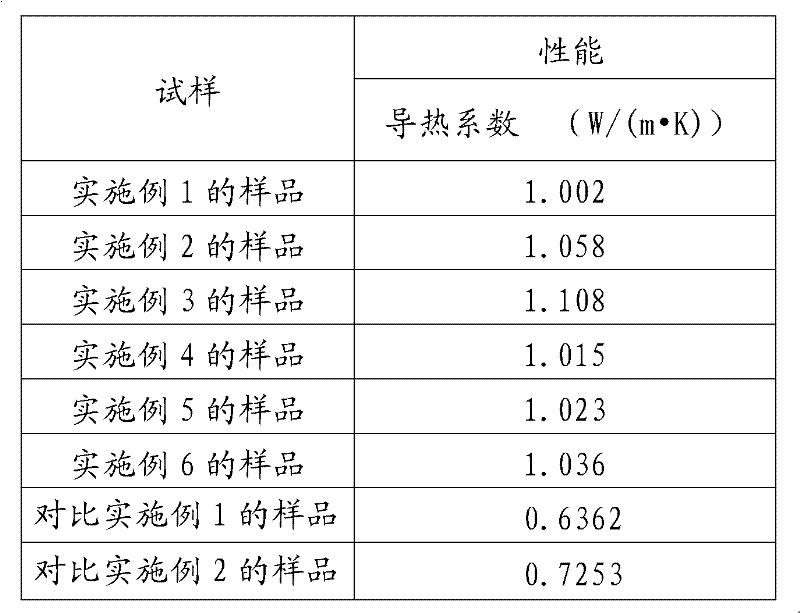

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

Method for preparing silicate nano-clay/urea resin composite adhesive

ActiveCN101818036AGood dispersionHigh reactivityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveDeep processing

The invention provides a method for preparing a silicate nano-clay / urea resin composite adhesive, and belongs to the field of deep processing of non-metallic mine and high polymer materials. The technical scheme of the method comprises the following steps of: first, performing surface activating treatment on the silicate clay; then, inorganically and organically modifying the nano-clay by using soluble silicate solution and a silane coupling agent respectively; and finally, adding the modified nano-clay in a process of synthesizing the urea resin so as to prepare the silicate nano-clay / urea resin composite adhesive. The raw materials of the composite adhesive have rich sources and low price; and the method has a simple process, can effectively reduce the free formaldehyde content of the urea resin, and simultaneously improve the mechanical performance of the urea resin.

Owner:溧阳常大技术转移中心有限公司

Flame retardant high-heat-conductivity epoxy resin electronic adhesive glue

InactiveCN102533192AImprove thermal conductivityDisperse quicklyNon-macromolecular adhesive additivesEpoxynovolac adhesivesHalogenAdhesive glue

The invention relates to flame retardant high-heat-conductivity epoxy resin electronic adhesive glue, which is formed by mixing ingredients A with amine curing agents according to the weight ratio of 100:(5-12), wherein the ingredients A comprises the following ingredients in parts by weight: 50 to 60 parts of spherical alumina powder, 20 to 30 parts of flame retardant fillings, 10 to 20 parts of epoxy resin, 1.5 to 2.5 parts of reactive diluents, 2 to 3 parts of halogen-free liquid flame retardants, 2 to 3 parts of toughening agents, 0.2 to 0.8 parts of thixotropic agents and 0.1 to 0.5 parts of coupling agents. According to the adhesive glue provided by the invention, the adhesive glue filled by the spherical alumina has higher condensate heat conductivity when being compared with the adhesive glue filled by the non-spherical alumina, and the heat accumulation of heating devices can be fast dispersed.

Owner:YANTAI DARBOND TECH

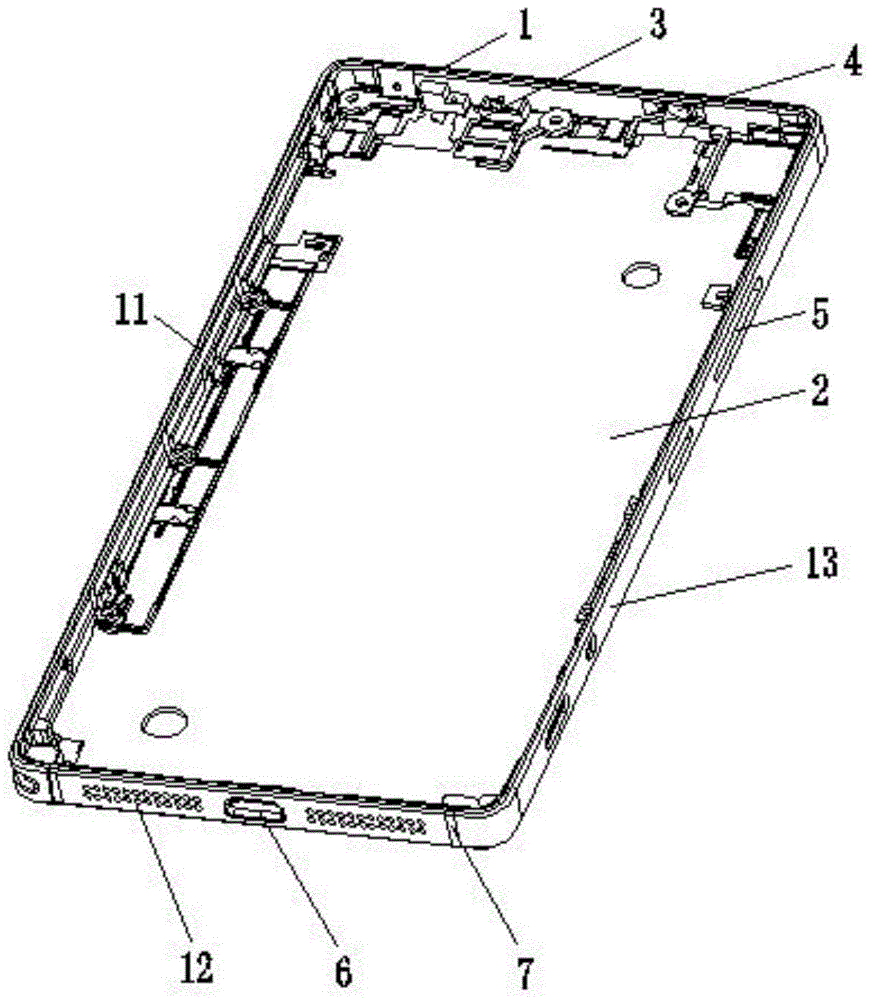

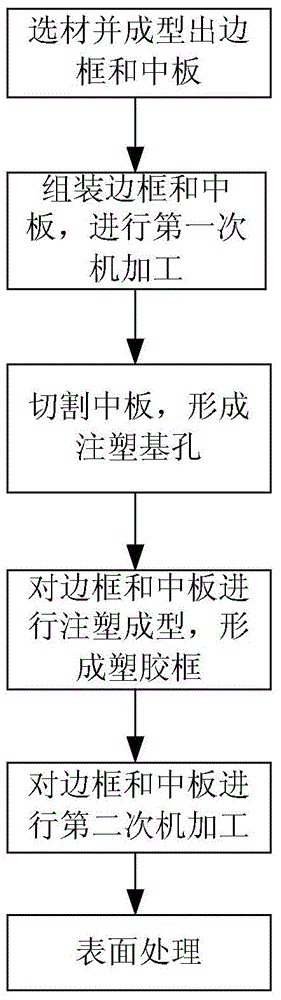

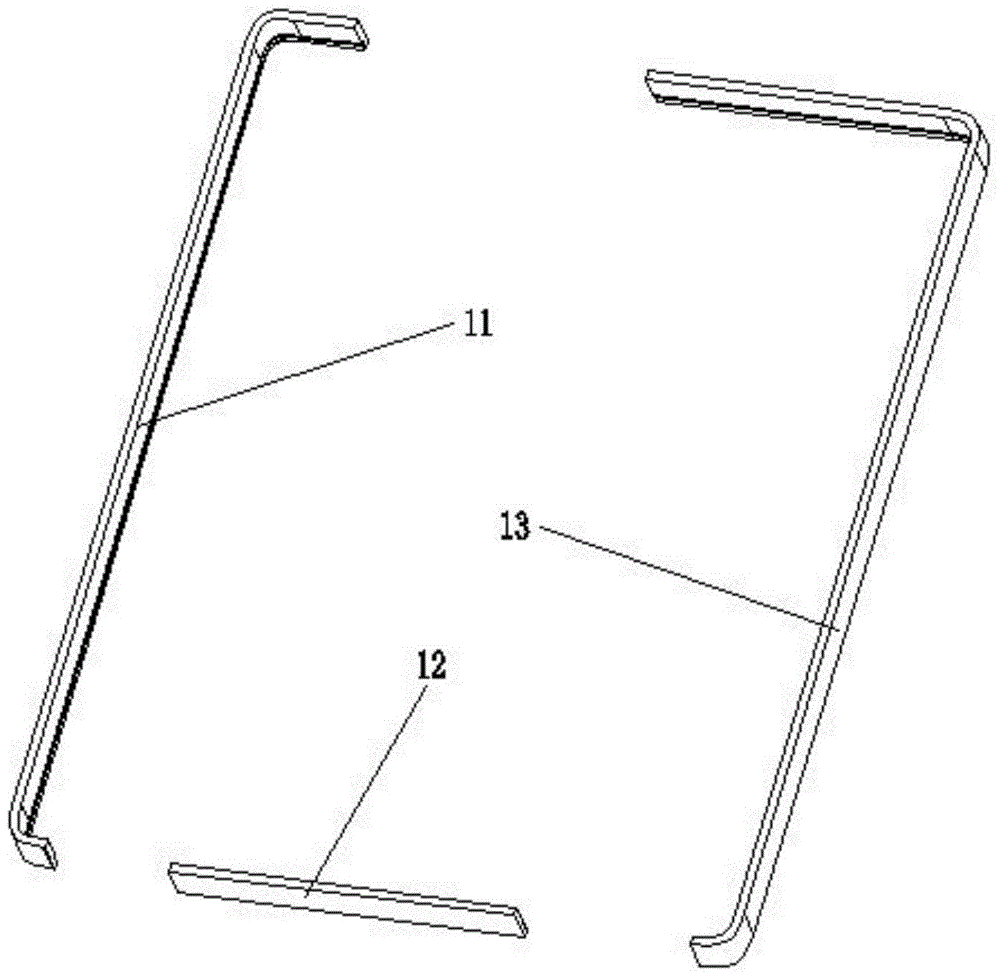

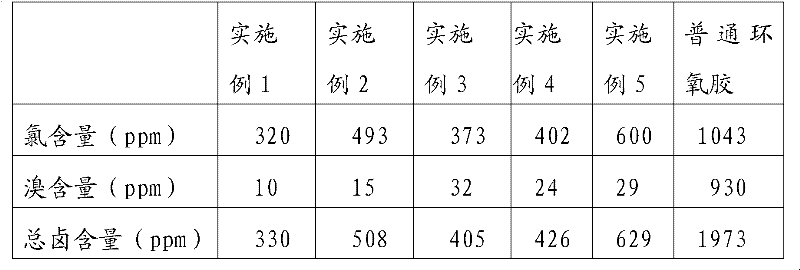

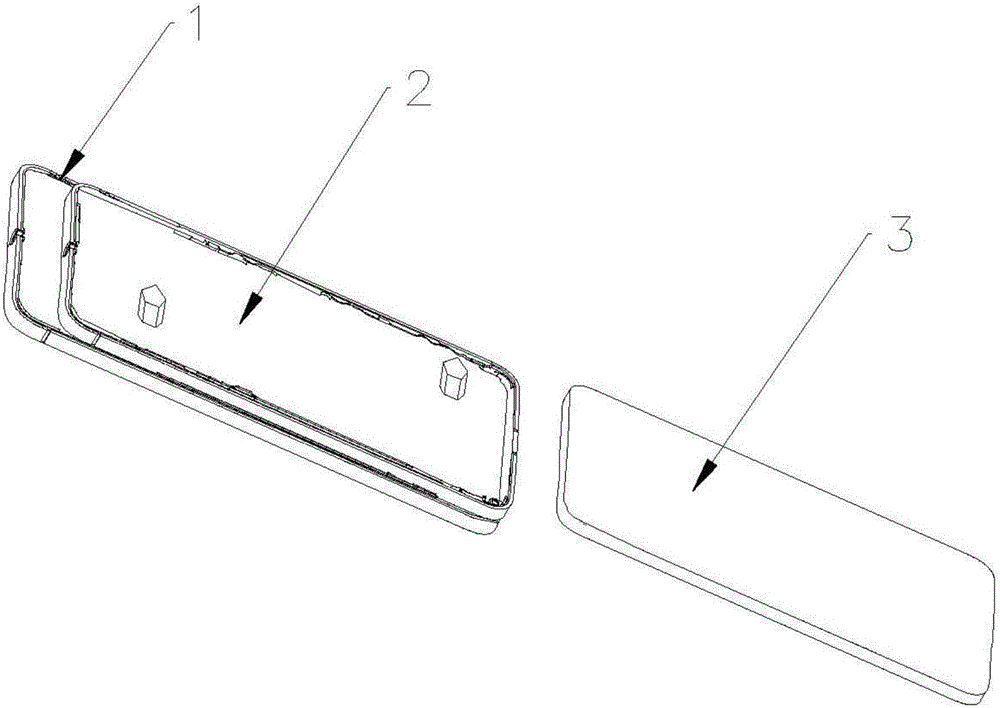

Mobile product middle frame and processing technology

InactiveCN104968178AReduce processSimple structureRack/frame constructionStructural engineeringInjection moulding

The invention discloses a mobile product middle frame. The mobile product middle frame comprises a side frame and a middle plate fixedly arranged in the side frame. A plastic frame is arranged on the middle plate. The plastic frame is formed at the joint of the middle plate and the side frame through injection molding. An earphone hole, a button hole and a USB hole are arranged in the side frame. The invention also provides a processing method for the mobile product middle frame. The method is used for forming the above mobile product middle frame. The side frame is formed from aluminum alloy sections through bending, the middle plate is formed from an aluminum sheet material through impact molding, then the plastic frame is formed from plastics through injection molding, machine processing working procedures are reduced effectively, the processing cost is lowered, the middle frame finished product has characteristics of simple structure and high intensity. Through a plurality of surface treatments, the middle frame is beautiful and fashionable, and appearance requirements of consumers can be met well.

Owner:AOJIE HARDWARE JIANGSU

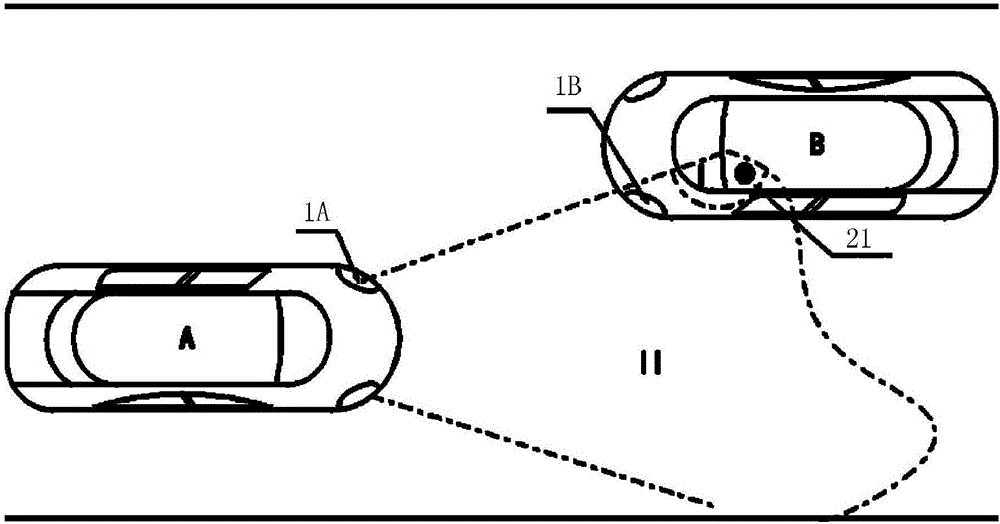

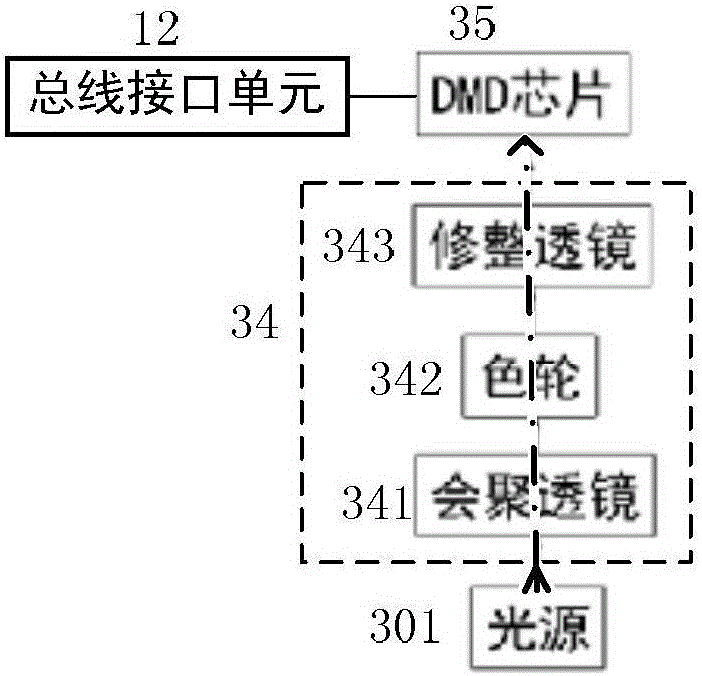

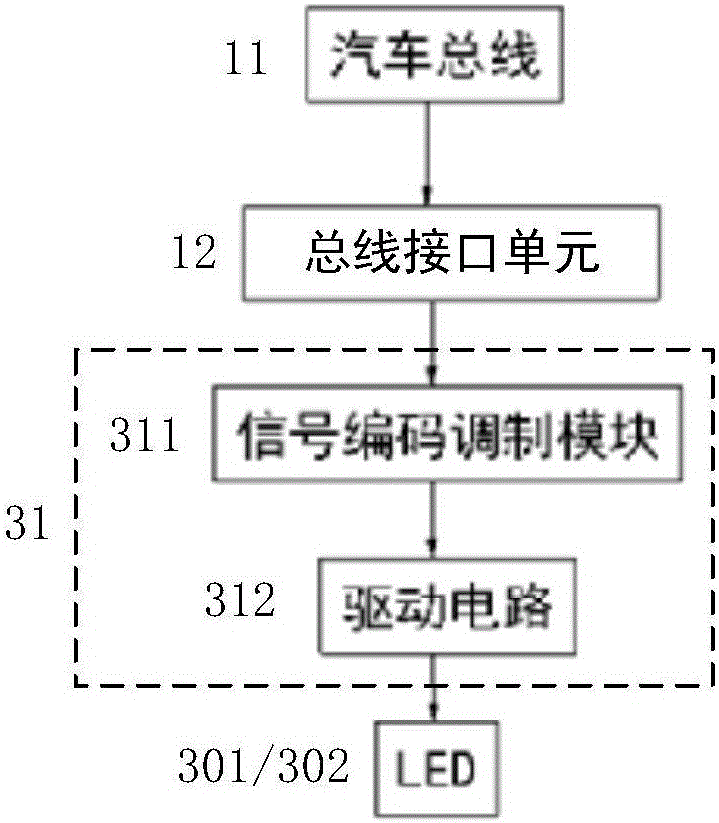

LiFi-and-DLP-based automotive illumination system and vehicle illumination signal device hereof

ActiveCN106043104APrevent affecting driving safetyRealize information interactionVehicle headlampsElectrical apparatusTraffic accidentEngineering

The invention relates to function features or parts of a vehicle illumination signal device or system, provides an LiFi-and-DLP-based automotive illumination system and a vehicle illumination signal device hereof. An LED main light source is used as a sending light source of a light fidelity (LiFi) sending assembly to send driving data of a vehicle out. A built-in LiFi receiving assembly is used for receiving a light signal sent by an opposite-side vehicle; decoding is carried out to obtain driving data of the opposite-side vehicle; and the data are transmitted to a vehicle bus. A digital light processing (DLP) projection system based on a DMD chip is used for providing projection illumination; according to the driving data, obtained by the LiFi receiving assembly, of the opposite-side vehicle, a projection illumination area is controlled; and a phenomenon that driving security is affected by dazzling light caused by a headlamp can be avoided by adjusting a projection area of light projected to an opposite-side driver position, so that information interaction between vehicles in a vehicle light signal reaching range is realized. A driving state of an adjacent vehicle is estimated and thus early warning of a vehicle collision accident is realized, thereby reducing the probability of a traffic accident effectively.

Owner:HASCO VISION TECHNOLOGY CO LTD

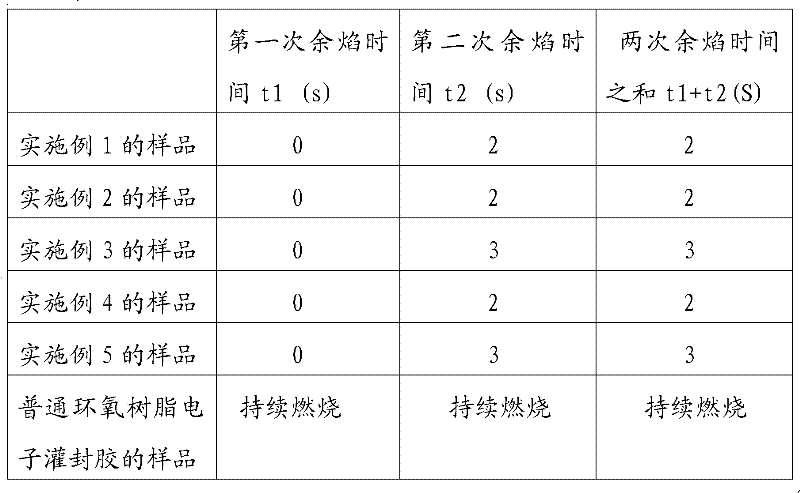

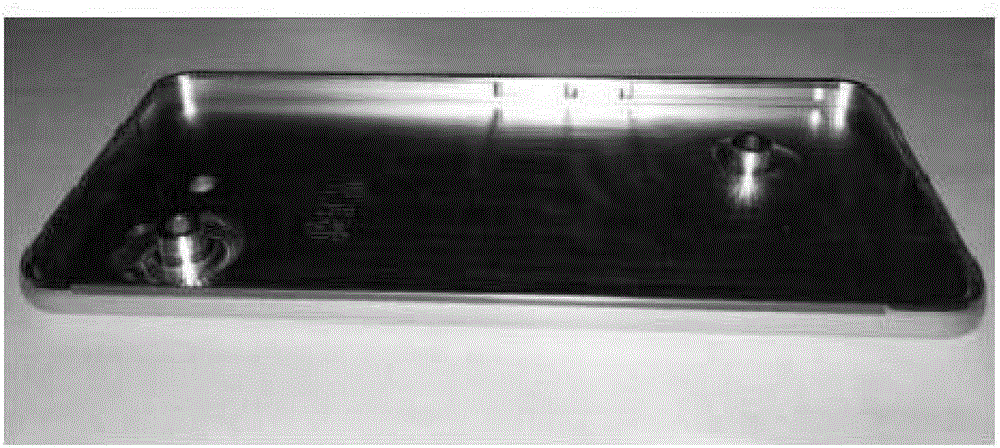

Halogen-free flame-retardant epoxy resin electronic pouring sealant

InactiveCN102516914ASatisfy Halogen Free RequirementsImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesEpoxyHalogen

The invention relates to a halogen-free flame-retardant epoxy resin electronic pouring sealant which is formed by mixing an A component and an amine curing agent according to the weight ratio of 100:4-13, wherein the A component comprises the following raw materials in parts by weight: 30-40 parts of halogen-free epoxy resin, 40-65 parts of flame-retardant fillers, 2-7 parts of halogen-free active diluting agents, 2-7 parts of halogen-free liquid flame retardants, 1-5 parts of toughening agents, 0.1-0.5 part of coupling agent and 0.1-0.5 part of pigment. The invention has the beneficial effects that the pouring sealant is free from halogen and satisfies the halogen-free requirements; the flame retardance is independent of a halogen-added flame retardant, so that the environment friendliness is achieved; the fame retardant ability is strong and can achieve the grade UL94-V0; and with the adoption of a double-component system, not only can the room-temperature curing be achieved, but also the thermal curing can be achieved, so that the operation is covneneint.

Owner:YANTAI DARBOND TECH

Surface treatment method for highlight edge of aluminum alloy mobile phone shell

ActiveCN106400083ANot easy to fadeImprove yieldSurface reaction electrolytic coatingInksSand blastingPrinting ink

The invention belongs to the technical field of aluminum alloy surface treatment, and particularly relates to a surface treatment method for the highlight edge of an aluminum alloy mobile phone shell. The surface treatment method comprises the following steps of machining of the counter and an inner cavity of the aluminum alloy mobile phone shell, CNC highlight treatment carried out on a frame after surface polishing, surface alkaline washing, surface sand blasting and first-time anodic oxidation, oil removal and cleaning, spraying of printing ink after shielding of the mobile phone shell, printing ink baking, ultraviolet exposure treatment, developing treatment, baking, UV radiation for curing printing ink, second-time anodic oxidation treatment, printing ink removal and third-time anodic oxidation treatment. After the highlight edge of the aluminum alloy mobile phone shell is subjected to three times of anodic oxidation treatment, the portion, close to a display screen, of a longitudinal frame of the mobile phone shell has the same color as the display screen, a frame-free visual sense is formed, the straightness of a color junction edge in second-time anodic oxidation and third-time anodic oxidation is ensured by the adoption of a three-dimensional exposure mode, the production yield reaches up to 90% or above, the cost is low, and production efficiency is high.

Owner:淮北暴风工业设计有限公司

High-heat-conductivity epoxy resin electronic binding glue

InactiveCN102127382AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesEpoxynovolac adhesivesReactive diluentThermal expansion

The invention relates to a high-heat-conductivity epoxy resin electronic binding glue. The invention is characterized in that the high-heat-conductivity epoxy resin electronic binding glue is prepared by mixing 100 parts by weight of a component A and 5-12 parts by weight of an amine curing agent; and the component A is prepared from the following raw materials in parts by weight: 70-85 parts of spherical aluminum oxide powder, 10-20 parts of epoxy resin, 2-3.5 parts of reactive diluent, 2.5-5 parts of toughener, 0.2-1 part of thixotropic agent and 0.1-0.5 part of coupling agent. The spherical aluminum oxide of the binding glue provided by the invention has higher filling volume than non-spherical aluminum oxide, and high heat conductivity for solids, and can quickly dissipate heat accumulated in the heating components; the filler with high filling volume can lower the thermal expansion coefficient and volume shrinkage, and thus, the binding glue is very suitable for binding electronic components; and the price of the spherical aluminum oxide is lower than that of boron nitride (BN) or aluminium nitride (ALN), and thus, the binding glue provided by the invention has the advantage of low cost.

Owner:YANTAI DARBOND TECH

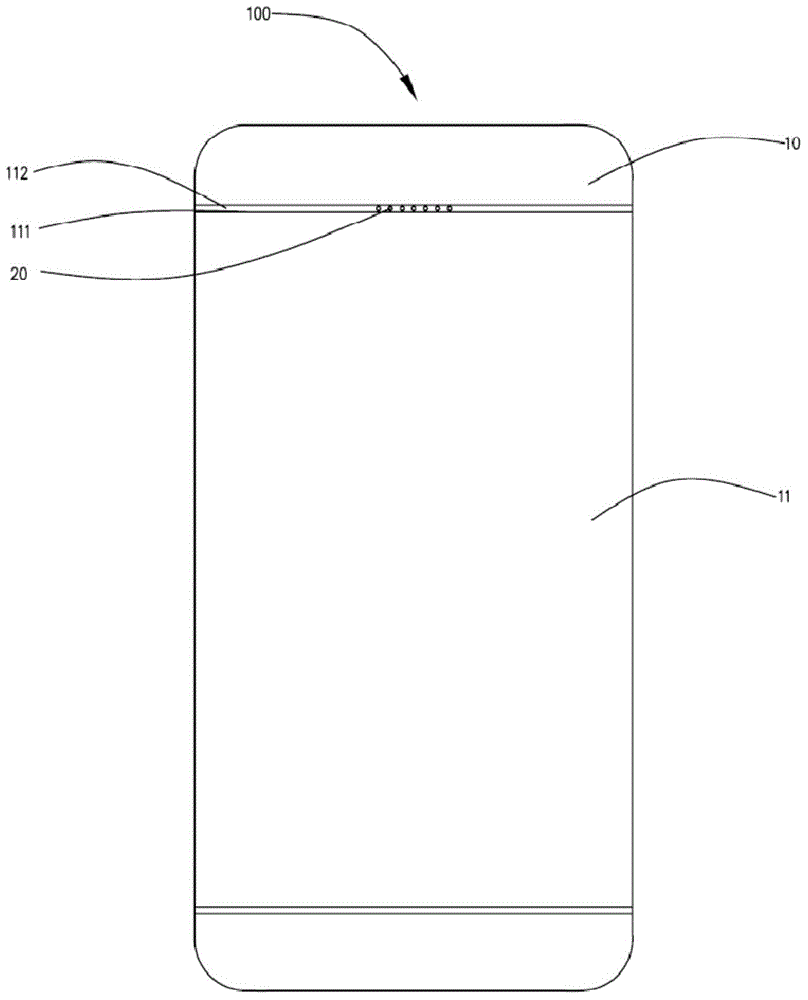

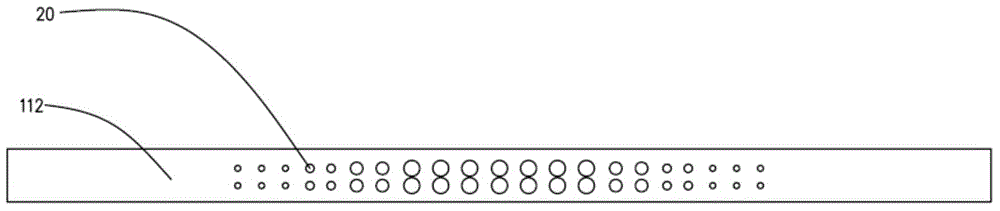

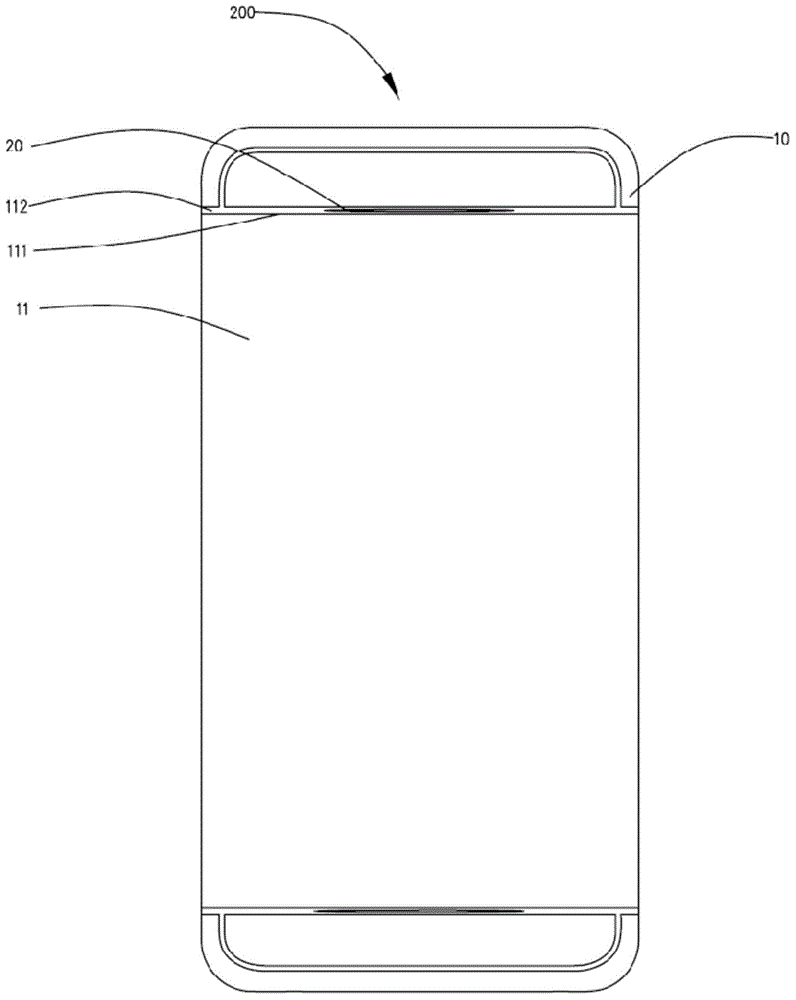

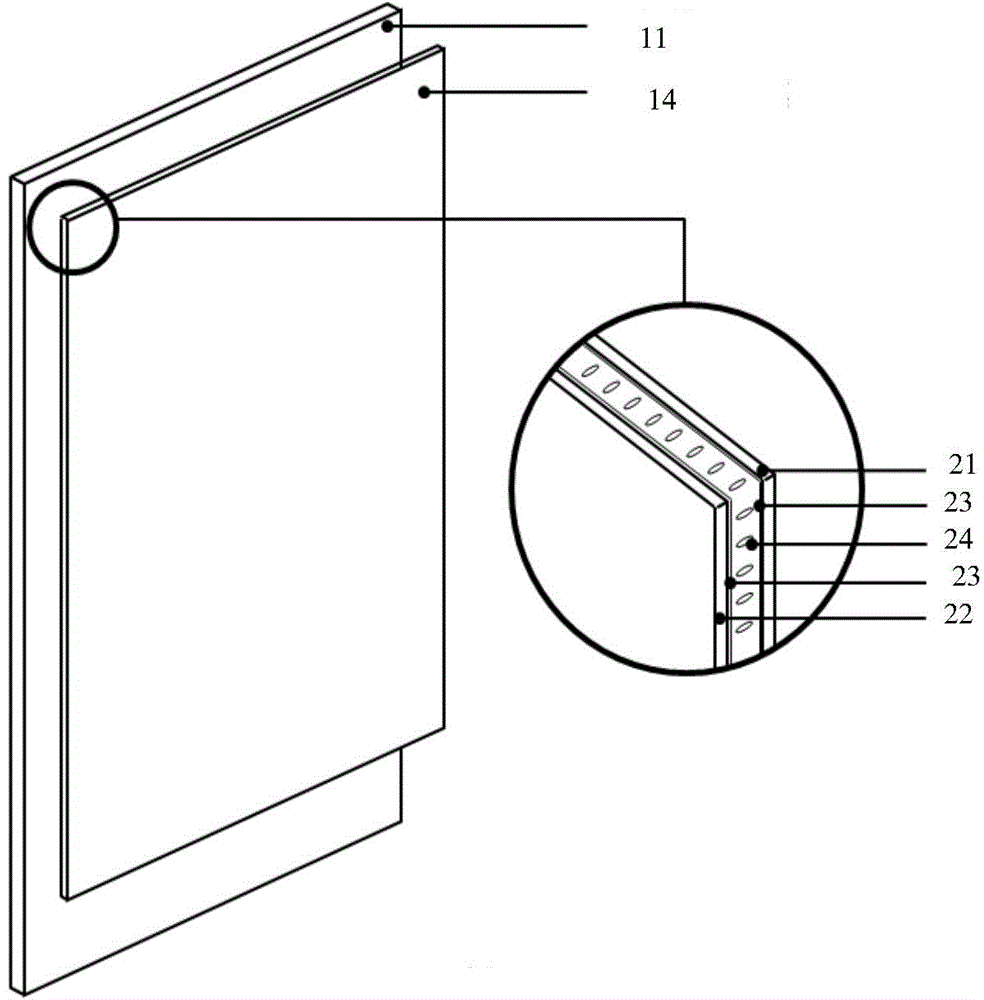

Housing and terminal adopting same

InactiveCN104580585ARich textureLess obtrusiveTelephone set constructionsMobile phoneElectrical and Electronics engineering

The invention discloses a housing which comprises a housing body, wherein a gap is formed in the housing body and is filled with an injection material; the injection material is a transparent material or a semitransparent material. According to the housing provided by the invention, the gap is filled with the injection material, and the injection material is the transparent material or semitransparent material, so that the texture of the housing is richer, the towering effect brought by the fact that the housing of a mobile phone is filled with plastic is alleviated, and appearance requirements of people for the housing of the mobile phone are met. In addition, the invention further provides a terminal adopting the housing.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

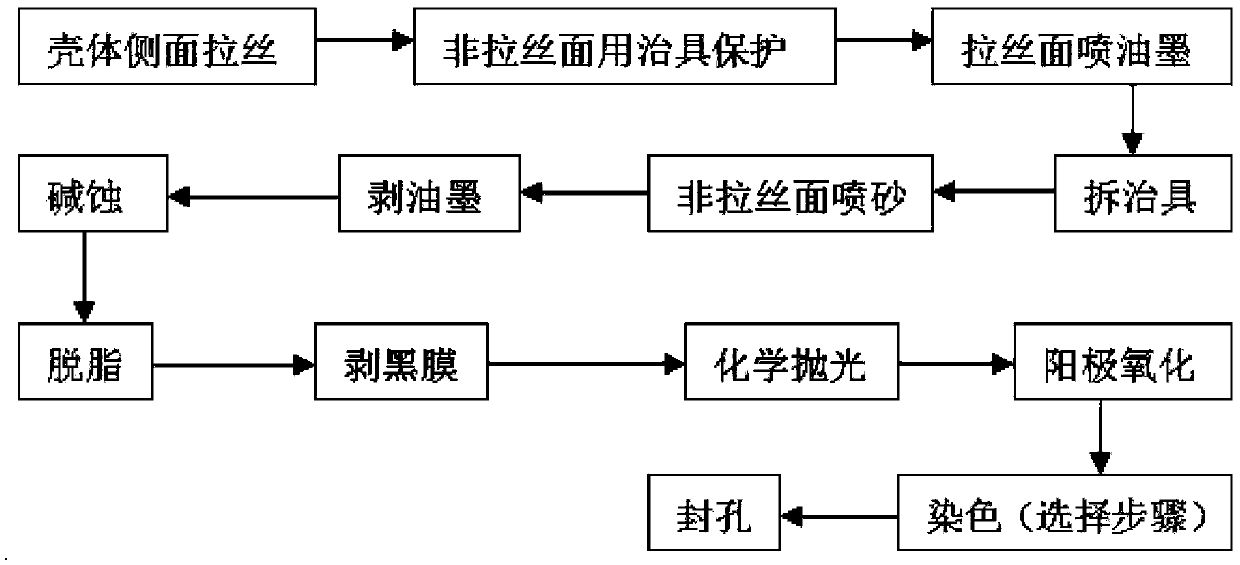

Surface treatment method of aluminum alloy shell

ActiveCN105364637AVariety of surface appearanceMeet appearance requirementsAnodisationAbrasion apparatusSand blastingAnodic oxidation

The invention provides a surface treatment method of an aluminum alloy shell, the surface treatment method comprises the following steps that S1, wire drawing is carried out on the side face of the aluminum alloy shell, and a wire-drawn surface is obtained; S2, sand blasting is carried out on the non-wire-drawn surface of the aluminum alloy shell; S3, anodic oxidation treatment is carried out on the whole aluminum alloy shell obtained after wire drawing and sand blasting, and an oxidation film layer is formed; and S4, hole sealing treatment is carried out on the aluminum alloy shell obtained after anodic oxidation treatment, and the aluminum alloy shell obtained after side face wire drawing and non-wire-drawn surface sand blasting is obtained. According to the surface treatment method of the aluminum alloy shell, the appearance of the aluminum alloy shell is rich and diverse.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

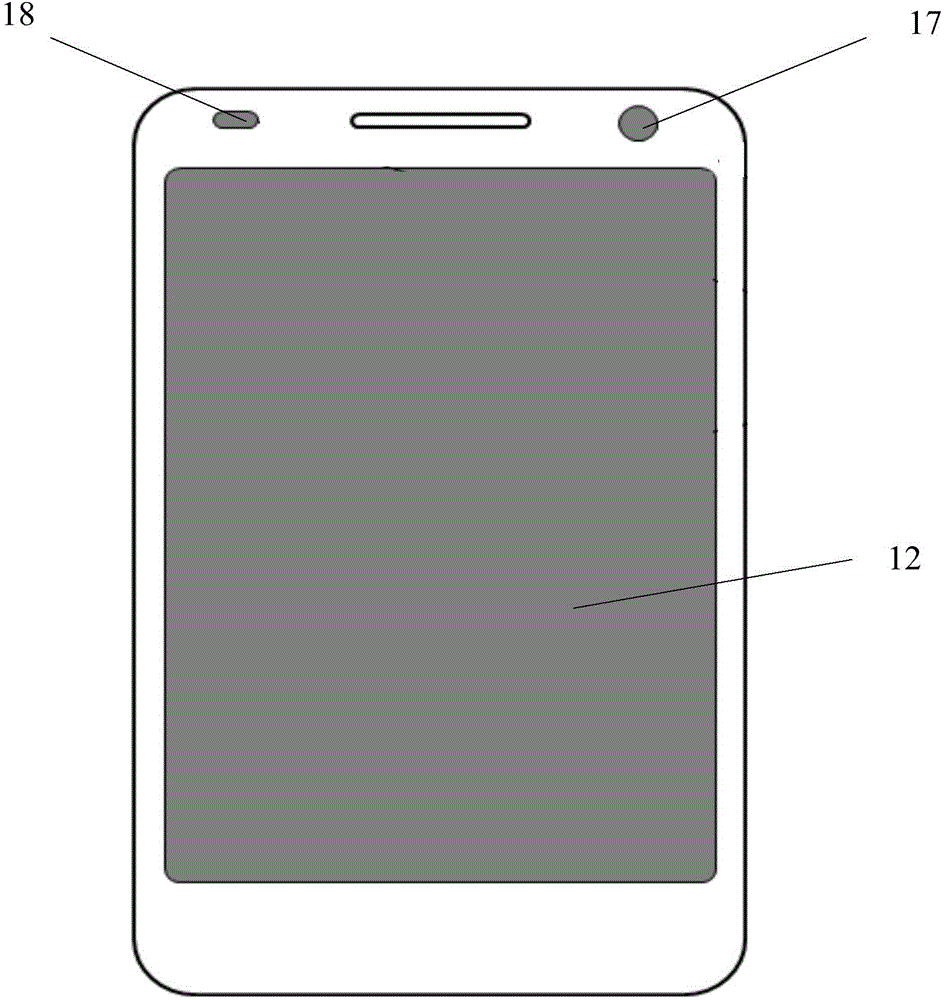

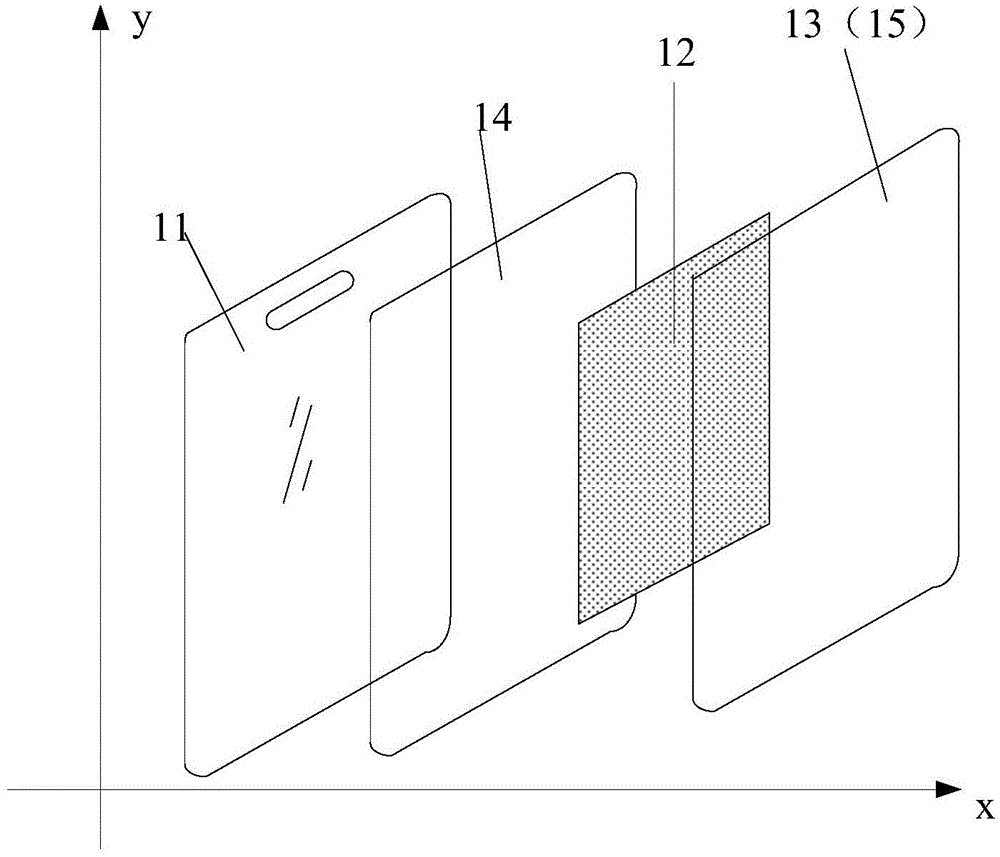

Terminal with variable color

ActiveCN104428740AMeet appearance requirementsImprove visual experienceStatic indicating devicesSubstation equipmentLiquid crystalEngineering

The invention provides a terminal with a variable color. The terminal comprises a touch screen,a display screen, a circuit board and a liquid crystal light-dimming film, wherein the touch screen is placed over the display screen; the circuit board is arranged under the display screen and formed by a driving circuit; the liquid crystal light-dimming film is mounted on the touch screen; the driving circuit applies control voltage to the crystal light-dimming film; when an amplitude of the control voltage is no less than a preset threshold value, the crystal light-dimming film is transparent; when the mplitude of the control voltage is no more than the preset threshold value, the crystal light-dimming film is non-transparent; and the color of the crystal light-dimming film at the transparent state is different from the color of the display screen.When the display screen is at the idle state, the display screen displays a different contour from a color of a present display screen in the prior art, so requirements for terminal contour by users are met and user visual experience effect is enhanced.

Owner:HONOR DEVICE CO LTD

Surface treatment method of amorphous alloy

InactiveCN103993314AConsistent colorConsistent textureAnodisationSuperimposed coating processAluminum metalAluminium oxides

The invention relates to the technical field of amorphous alloy and in particular relates to a surface treatment method of amorphous alloy. The method comprises the following steps: 1, performing cold spraying, namely spraying an aluminum layer or an aluminum alloy layer to the surface of the amorphous alloy by adopting a cold spraying process to obtain a semi-finished product; 2, performing anodizing treatment, namely performing anodizing treatment on the aluminum layer or the aluminum alloy layer in the semi-finished product obtained in the step 1 to enable an aluminum oxide film to be formed on the surface the aluminum layer or the aluminum alloy layer to obtain a finished product. According to the method, the treated amorphous alloy product can be perfectly matched with an aluminum alloy product in appearance, and the appearance requirements of industrial design are met; moreover, compared with a PVD (physical vapor deposition) technology, the method has the characteristics that the appearance requirements can be well met on the basis of the advantage of low cost, and the application range of the amorphous alloy is greatly expanded.

Owner:WINTOP DONGGUAN INDAL TECH

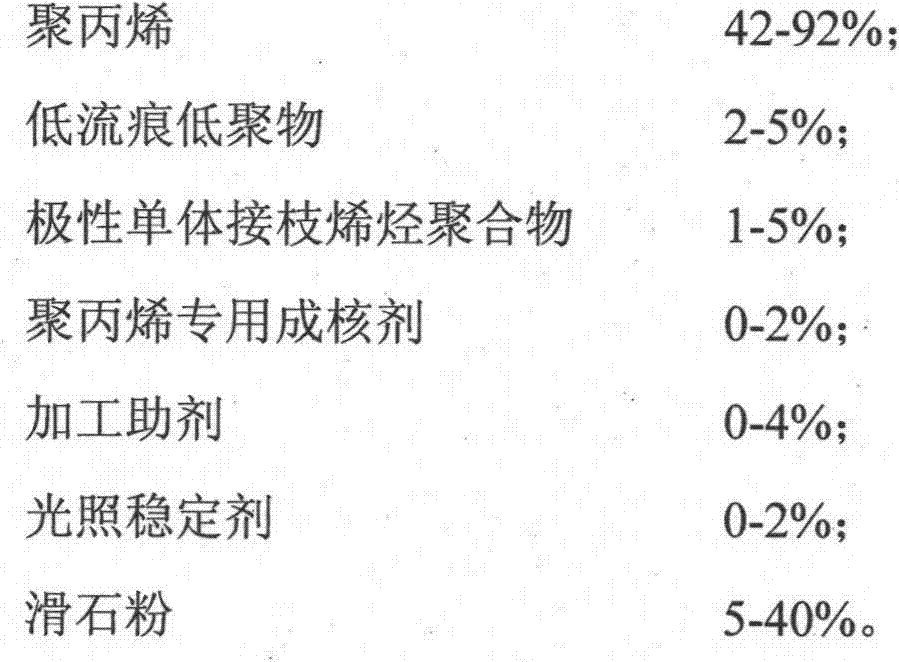

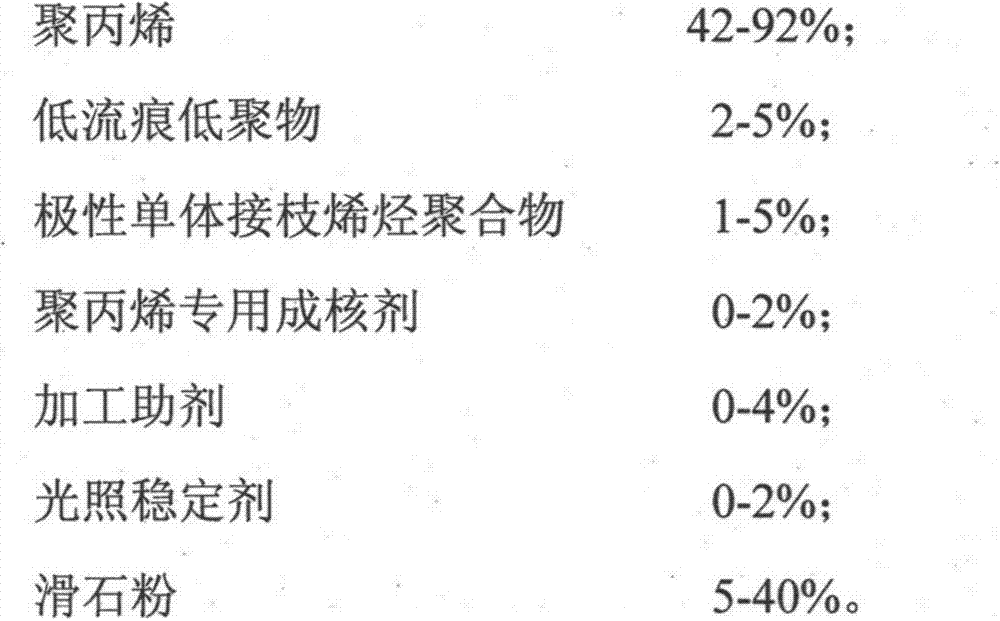

High-rigidity polypropylene composite without flow marks as well as preparation method of polypropylene composite

The invention discloses a polypropylene composite for a fender as well as a preparation method of the polypropylene composite. The polypropylene composite is prepared from 42-92wt% of polypropylene, 2-5wt% of an oligomer with few flow marks, 1-5wt% of a polar monomer graft olefin polymer, 0-2wt% of a special nucleating agent for polypropylene, 0-4wt% of a processing aid, 0-2wt% of a light stabilizer and 5-40wt% of talcum powder. The preparation method comprises the following steps: melting, mixing and dispersing the polypropylene, the oligomer with few flow marks, the polar monomer graft olefin polymer, the special nucleating agent for polypropylene, the processing aid and the light stabilizer in a double-screw extruder; feeding the talcum powder into the double-screw extruder from one side by an agravic metering balance; and extruding and granulating, thereby finally obtaining the product, namely the polypropylene composite. The polypropylene composite has the characteristics of high rigidity, high gloss and no flow marks and meets the requirements of large-sized polypropylene parts on appearance, and polypropylene injection molded parts have no flow marks.

Owner:SHANGHAI KINGFA SCI & TECH

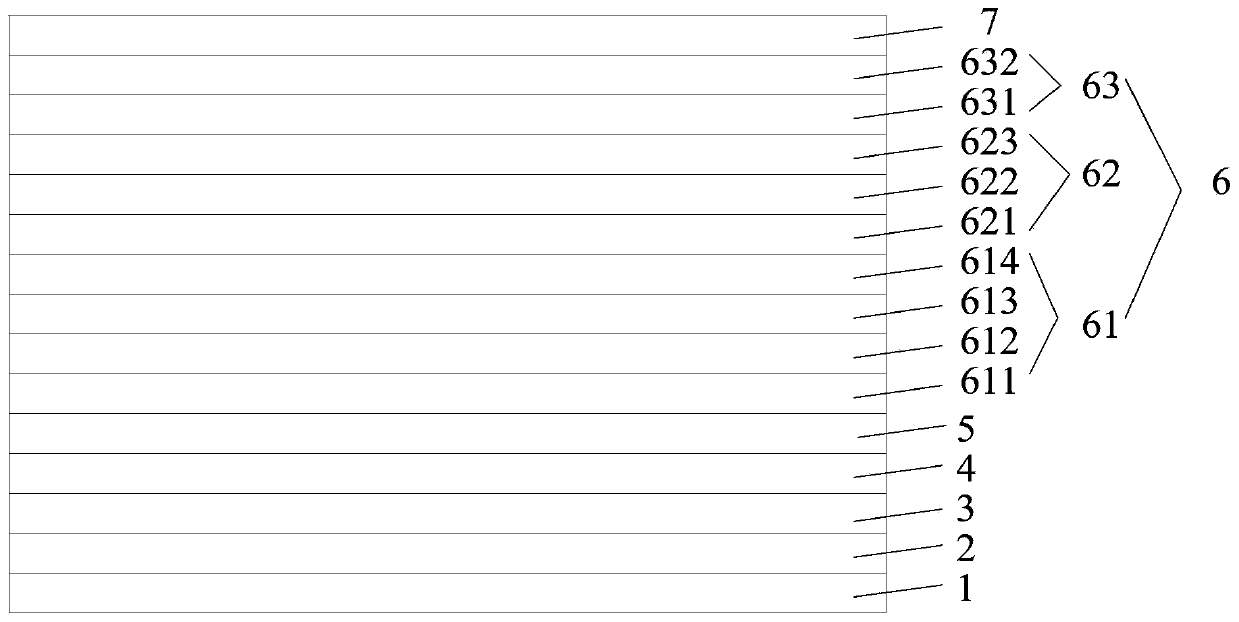

Solar cell for all-black crystalline silicon photovoltaic module and preparation method of solar cell

PendingCN111106186AEliminate unevennessLow refractive indexFinal product manufacturePhotovoltaic energy generationSilver electrodeRefractive index

The invention discloses a solar cell for an all-black crystalline silicon photovoltaic module and a preparation method of the solar cell. A front composite film is prepared by adopting tubular PECVD equipment and comprises a SiNx: Hy layer, a SiOxNy layer and a SiOx layer. The SiNx:Hy layer is connected with the n-type doped layer, and the SiOx layer is connected with a front silver electrode. TheSiNx: Hy layer is composed of 3 to 4 SiNx: Hy layers with different refractive indexes and thicknesses. The SiOxNy layer is composed of 2 to 3 SiOxNy layers with different refractive indexes and thicknesses. The SiOx layer is composed of 1 to 2 SiOx layers with different refractive indexes and thicknesses. By the adoption of the method, the requirement of the all-black crystalline silicon photovoltaic module can be completely met; the appearance color difference of the black module is remarkably eliminated; and the method can be applied to a traditional white backboard photovoltaic module.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

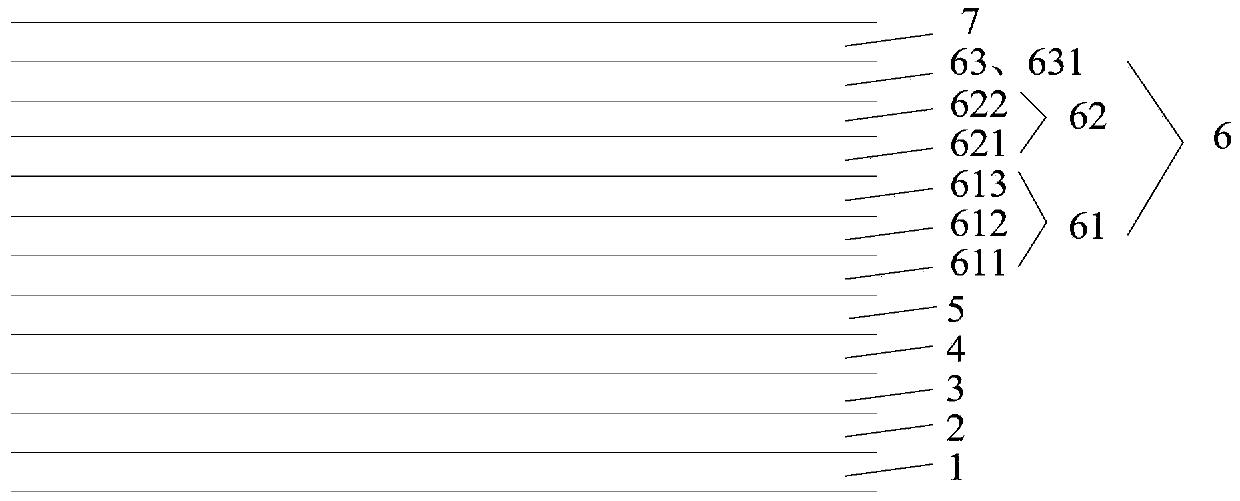

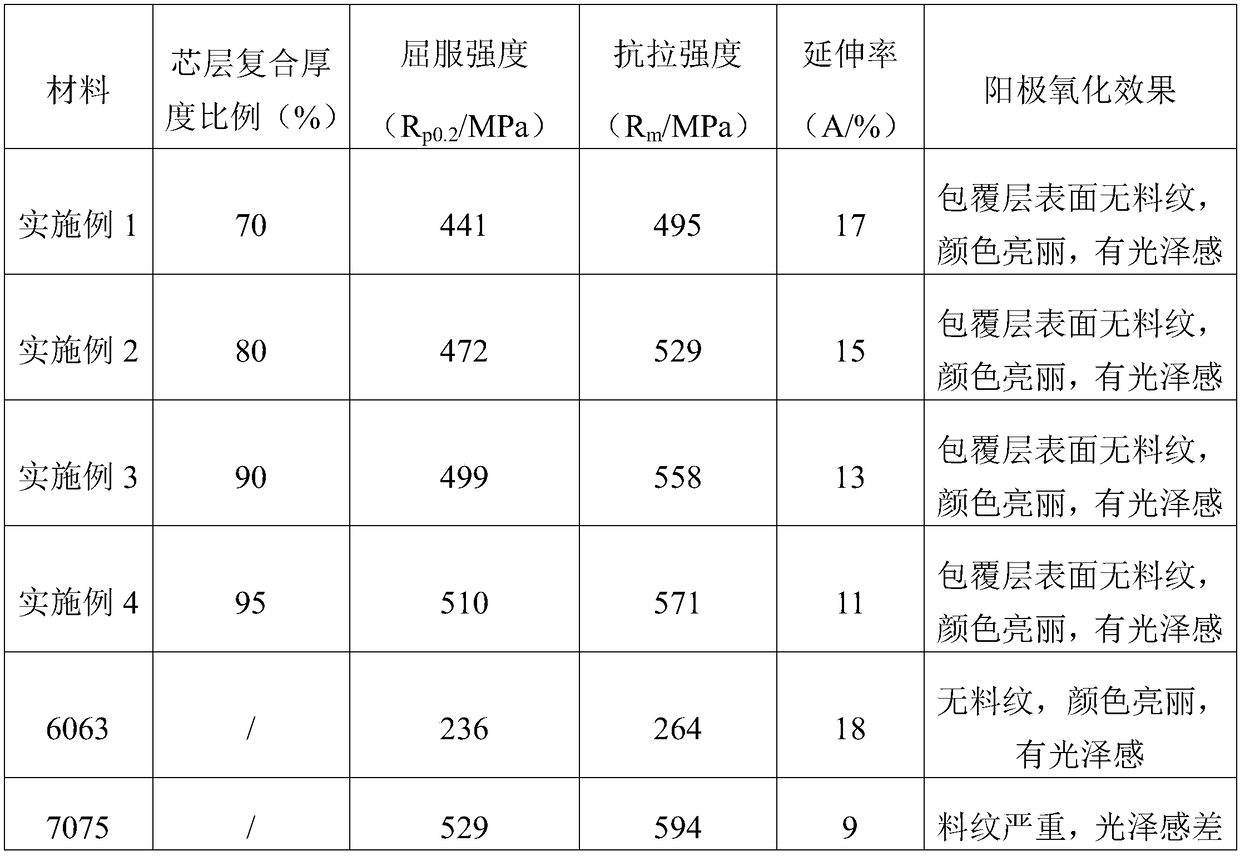

Preparation method of 6xxx/7xxx aluminum alloy composite

The invention discloses a 6xxx / 7xxx aluminum alloy composite. The 6xxx / 7xxx aluminum alloy composite comprises a core layer alloy and a coating layer alloy. A preparation method of the 6xxx / 7xxx aluminum alloy composite comprises the steps that (1) preparation of the core layer alloy and the coating layer alloy plates is carried out; (2) surface treatment is carried out; (3) welding fixing is carried out; (4) preheating and hot rolling are carried out; (5) a cutting plate is transversely cut; (6) solution hardening is carried out; (7) stretching is carried out; (8) aging is carried out; and (9) saw cutting is carried out, and thus the finished 6xxx / 7xxx aluminum alloy composite is obtained. The 6xxx / 7xxx aluminum alloy composite is prepared by a rolling complex mode, and technologies of the solution hardening and the aging are limited at the same time, so that the 6xxx / 7xxx aluminum alloy composite obtains high strength, has the characteristic of an excellent anodic oxidation effect, can meet the requirement of a high-end electronic product on the appearance and strength, is an ideal material for manufacturing an appearance piece of the electronic product and has very high utilization potentiality.

Owner:广西南南铝加工有限公司

Process for producing concentrated sea-buckthorn clear juice

The invention discloses a process for producing concentrated sea-buckthorn clear juice, which comprises the following steps of: crushing and squeezing the mature sea-buckthorn, adding water into the obtained juice, and fully stirring the juice to obtain primary turbid juice; sterilizing the primary turbid juice for 5 minutes at the high temperature of between 100 and 110 DEG C, cooling the sterilized juice to between 65 and 70 DEG C, separating the juice to obtain sea-buckthorn juice by using a centrifugal machine, then adding amylase, pectase and pear juice enzyme into the sea-buckthorn juice, and digesting the mixture at the constant temperature of between 50 and 55 DEG C to obtain secondary turbid juice; separating the supernate from the secondary turbid juice by centrifugation to obtain the sea-buckthorn clear juice; and filtering the sea-buckthorn clear juice to be clear by using a filter membrane, and concentrating the sea-buckthorn clear juice under vacuum to obtain the concentrated sea-buckthorn clear juice. The conditions adopted in the process are mild, pectin and starch which affect the clear juice are removed by combining ordered heating and cooling and enzymolysis, and the conditions of the whole process keep the nutrient components in the sea-buckthorn as much as possible and furthest reserve juice color and flavor.

Owner:合德堂食品工业(泾阳)有限公司

Production technique of concentrated clear persimmon juice

The invention discloses a production technique of concentrated clear persimmon juice. When being used for producing persimmon juice, the technique can concentratedly consume the raw material in a short time in the harvesting time of persimmon fruit, thereby enhancing economic value of persimmon. Orderly heating and cooling in combination with enzymolysis are used for removing pectin and starch which affect the clear juice, and the clear and bright juice is obtained through centrifugal separation. The low-temperature distillation is used for concentration in the concentration stage, thereby controlling the conditions in the whole technical process and maintaining the nutritional ingredients in fruit to the maximum, and the color and flavor of the fruit juice are maintained to the maximum.

Owner:合德堂食品工业(泾阳)有限公司

Quasi-monocrystalline silicon etching method

InactiveCN102306681AGood appearance consistencyAvoid the shortcomings of large color differenceFinal product manufactureSemiconductor devicesAcid etchingAlkaline etching

The invention relates to the solar energy cell production technology method field, concretely relating to a quasi-monocrystalline silicon etching method which comprises an alkaline etching operation on a quasi-monocrystalline silicon which mainly is (100) crystal grain and an acid etching operation on the quasi-monocrystalline silicon. Compared with simple acid etching, according to the invention, photoelectric conversion efficiency of a quasi-monocrystalline cell is obviously raised, a shiny phenomenon of part etching face caused by adopting simple alkaline etching can be obviously eliminated, and a whole process can be accurately adjusted according to an area the (100) crystal grain occupies. The quasi-monocrystalline silicon etching method has the characteristics of a fully controllable processing process, a good integral etching effect, qualified appearance and simple technology, and is suitable for quasi-monocrystalline silicon large scale production.

Owner:浙江向日葵大健康科技股份有限公司

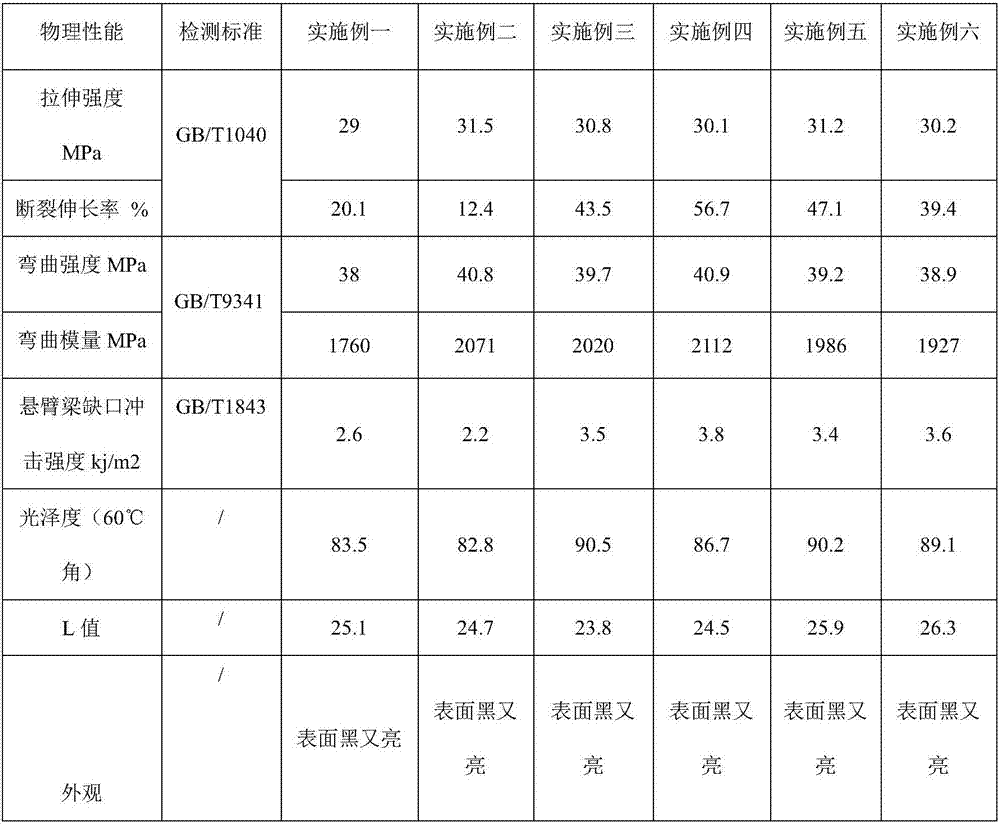

High light, high black and high impact polypropylene special material and preparation method thereof

The invention provides a high light, high black and high impact polypropylene special material and a preparation method thereof. The high light, high black and high impact polypropylene special material is composed of the following raw materials by weight: 80-90 parts of polypropylene resin, 10-20 parts of mineral filler, 0.1-0.5 part of a nucleating agent, 0.2-0.5 part of a dispersant, 0.2-0.4 part of an antioxidant, 1-4 parts of black masterbatch, and 0-1 part of other assistants. The high light, high black and high impact polypropylene special material provided by the invention adopts a special mixing process and preparation method, enhances the crystallinity of polypropylene material, and improves the dispersion of mineral filler. At the same time, because of high gloss, the composite material can replace ABS materials, reduce materials, and also meet the regulation (EC) No.1935 / 2004 of EU on food contact materials. The material can be used in kitchen appliance shells, endow the kitchen appliance surfaces with high gloss and high light, and improve the product appearances.

Owner:ORINKO NEW MATERIAL CO LTD

Pattern coating glass and preparation method thereof

ActiveCN102976624AWith arbitrary pattern selection featureApplicable to different needsMachiningMetal

The invention discloses a pattern coating glass and a preparation method thereof, and belongs to the technical field of glasses. The pattern coating glass is characterized in that coating layers are covered on partial surface of the glass, and patterns formed by the coating layers are arranged as arrays. The preparation method comprises the process routes of cutting, edging, coating colored glaze, coating, tempering and carrying out combined machining. The coating glass has the characteristic that the patterns can be selected at random, so that different demands can be met; and the coating glass can be used in a form of single glass and also can be processed into hollow sandwich composite glasses. LOW-E coating can be carried out based on pattern coating, thus the low radiation performance is brought to the glass as well as higher metal gloss, and the requirement on appearance in special environments is met.

Owner:TIANJIN SYP ENG GLASS CO LTD

Friction-resistant aluminum alloy hub spinning process

The invention discloses a friction-resistant aluminum alloy hub spinning process. Main procedures of the process comprise the steps of melting, casting pre-forming, homogenizing treatment, heating spinning, pre-heat treatment, shot blasting, spinning, heat treatment, shot blasting, machining and coating. Heat-spinning plastic deformation can make up superfine loosening defects, so that mechanical performance of a hub is improved; and the casting spinning new technology greatly improves the overall strength and corrosion resistance of a wheel, the machining allowance is greatly reduced, the service life of the wheel is significantly prolonged, safety of the wheel is significantly improved, vehicle weight reducing and oil saving are facilitated, and the wheel production cost is decreased.

Owner:BENGBU FUWOTE WHEEL MFG TECH

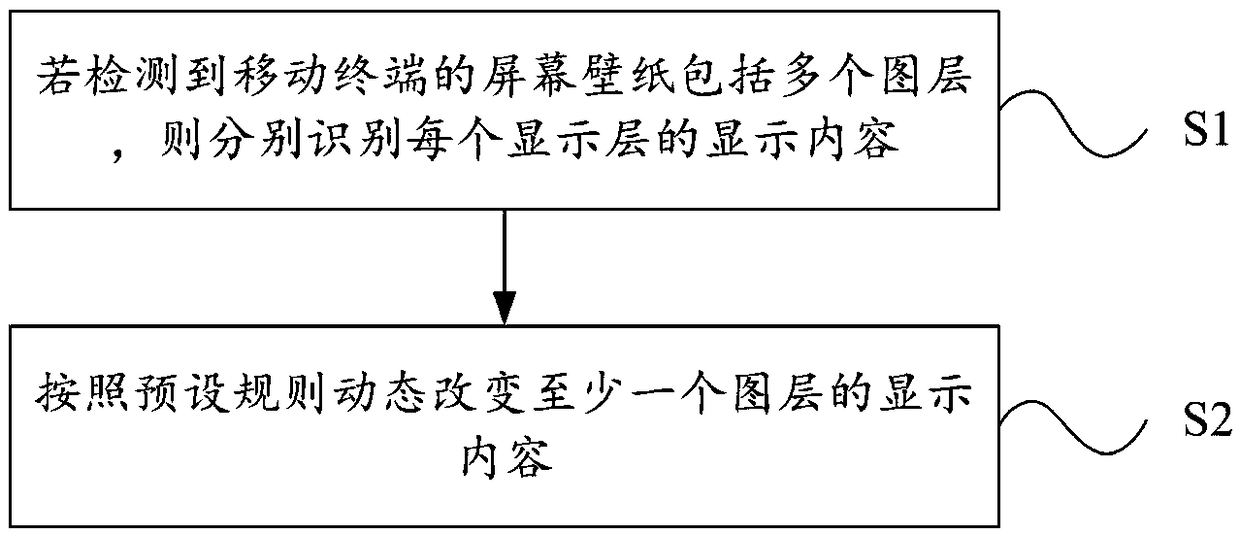

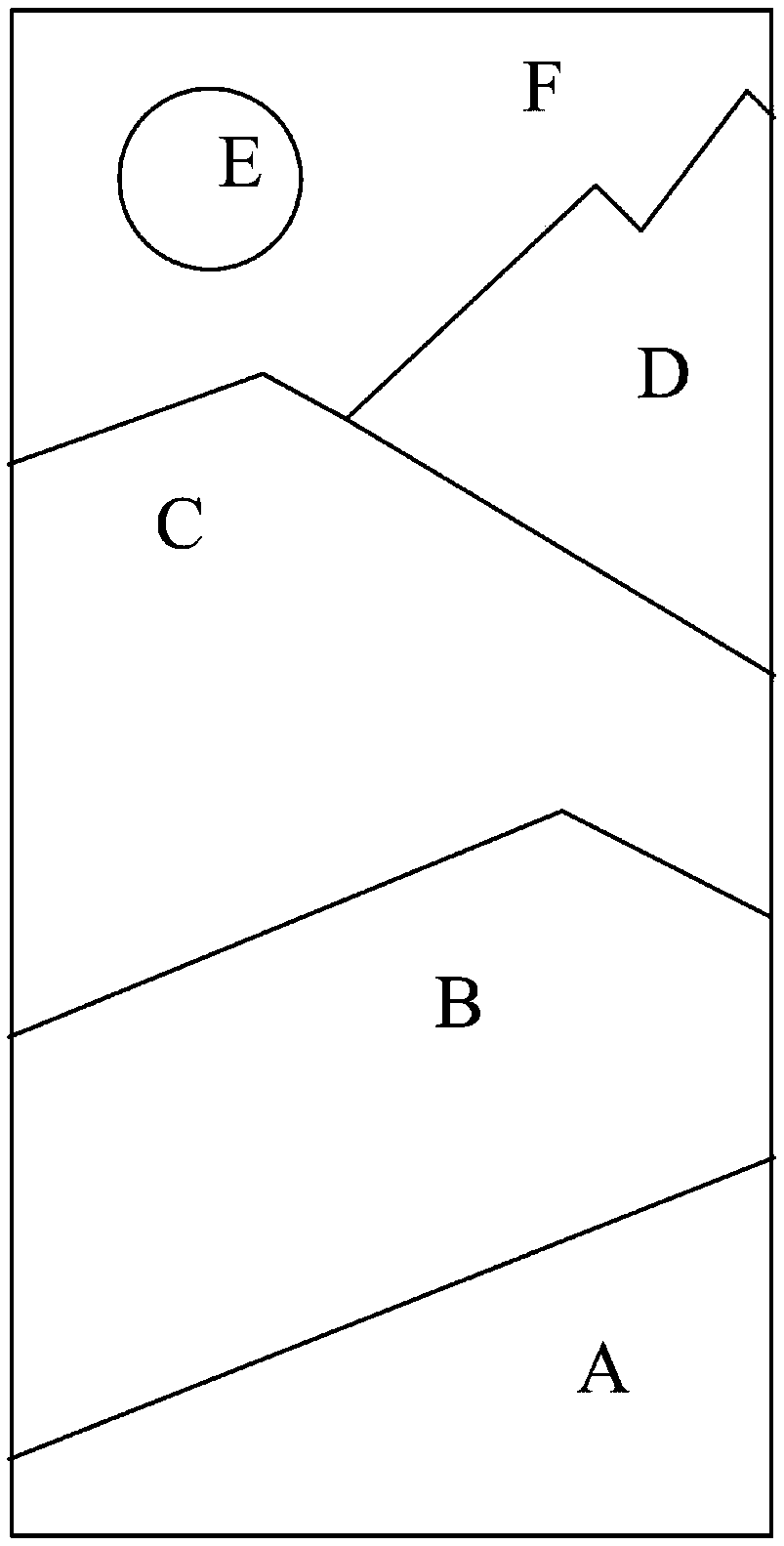

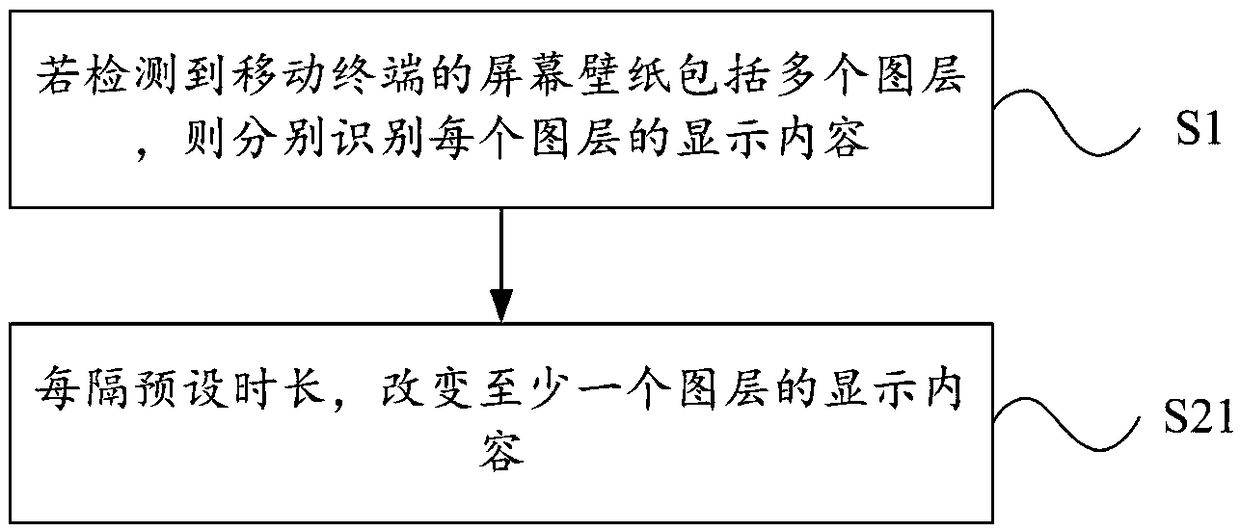

Screen wallpaper display method and mobile terminal

InactiveCN109117239AMeet appearance requirementsVarious forms of changeExecution for user interfacesComputer terminalComputer engineering

The embodiment of the invention provides a screen wallpaper display method and a mobile terminal, which relate to the technical field of communication, so as to solve the problems of single display color, content and the like of plane static wallpaper and lack of interest. The screen wallpaper display method comprises the following steps: if detecting that the screen wallpaper of the mobile terminal includes a plurality of picture layers, identifying the display contents of each picture layer; if detecting that the screen wallpaper of the mobile terminal includes a plurality of picture layers,identifying the display contents of each picture layer. The display contents of at least one of the layers are dynamically changed according to a preset rule. The screen wallpaper display method in the embodiment of the invention is applied to a mobile terminal.

Owner:VIVO MOBILE COMM CO LTD

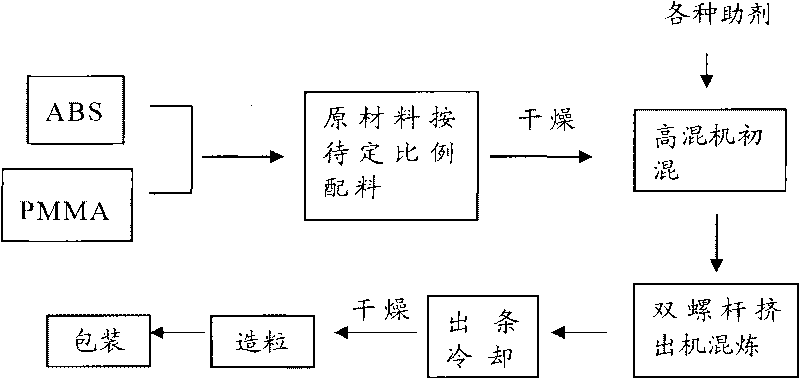

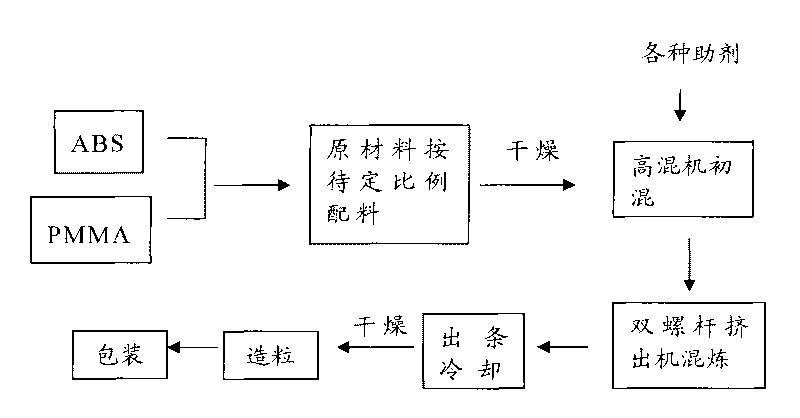

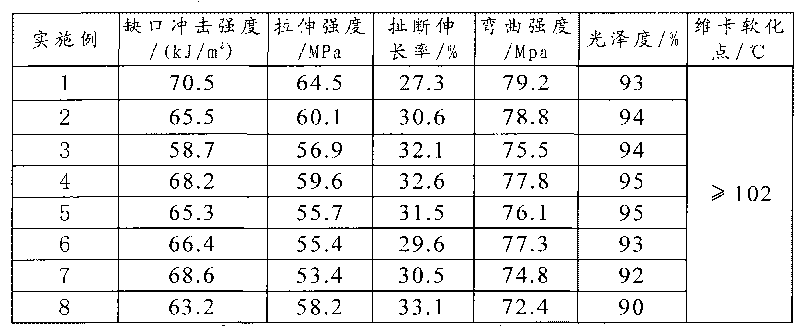

PMMA/ABS (polymethyl methacrylate/acrylonitrile butadiene styrene) composite material and manufacturing method

The invention provides a PMMA / ABS (polymethyl methacrylate / acrylonitrile butadiene styrene) composite material and a manufacturing method, which can solve the problems of poor thermal resistance, scraping resistance and high surface gloss and insufficiency in complex product molding requirements existing in the prior art. In the technical scheme, the composite material comprises the following components in parts by weight: 40-58 parts of ABS, 30-45 parts of polymethylmethacrylate, 5-12 parts of styrene-acrylonitrile, 0.1-0.3 part of antioxidant, 0.05-0.1 part of auxiliary antioxidant and 1.0-1.5 parts of lubricant. Through specific compound formulation, the invention ensures a PMMA / ABS alloy material has excellent thermal property, scraping resistance and high surface gloss and meets the molding requirements for the complex products, and improves processing property of materials.

Owner:QINGDAO GON TECHNOLOGY CO LTD

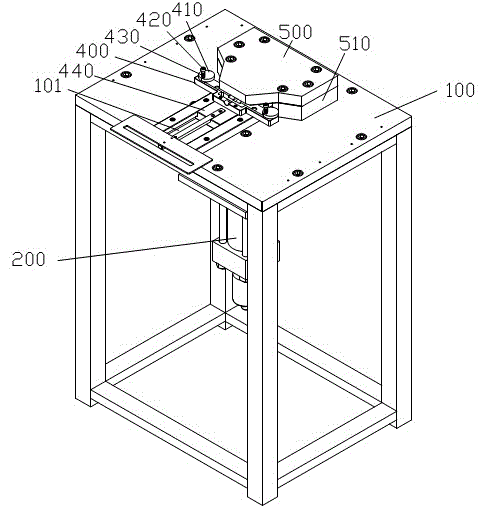

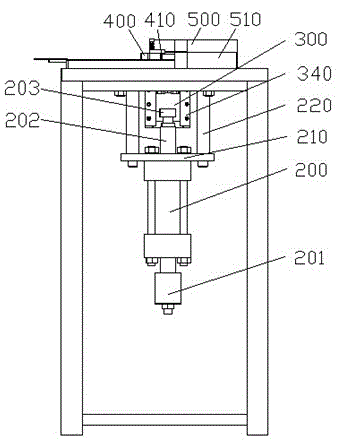

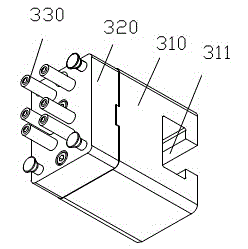

Inverted punching and riveting machine and riveting method thereof

The invention discloses an inverted punching and riveting machine and a riveting method thereof. The punching and riveting machine comprises a worktable, a fixture, a punch and an oil cylinder, the punch consists of one or more than one punch needles, an upper die and a lower die, the punch and the oil cylinder are arranged on the lower side of the worktable in an inverted manner, a top plate, a slider and a sensing device with a magnet and a check block are disposed on the upper side of the worktable, the slider is used for mounting the fixture and is limited by the sensing device with the magnet and the check block, a pre-tightening device for tightening the fixture in advance is arranged on the punch, the oil cylinder is fixedly connected with the lower die, the punch needles penetrate through the upper die, and the lower end surface of each punch needle is abutted onto the lower die. The punch and the oil cylinder are arranged on the lower side of the worktable in the inverted manner, accordingly, the structure of the punching and riveting machine is compact and small, spaces are saved, the gravity center of the punching and riveting machine is low, a plurality of rivets can be simultaneously placed on workpieces to be riveted in advance and are punched to deform by the aid of the punch needles at one step, machining efficiency is greatly improved, and the rivets are impacted in a closed area and are quite safe.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

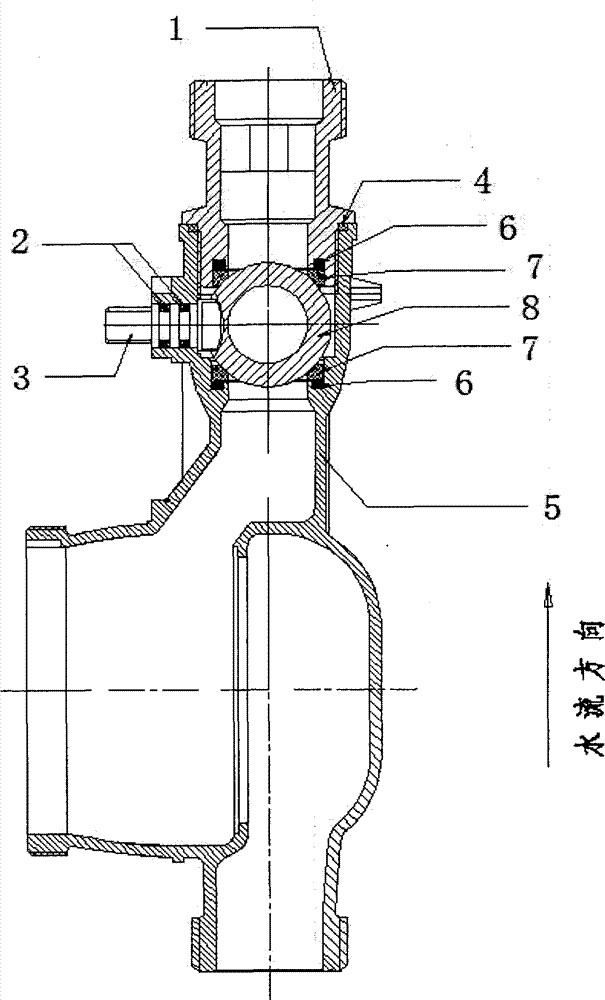

Hot forging pressing process water meter copper shell and manufacturing method thereof

The invention relates to a hot forging pressing process water meter copper shell and a manufacturing method thereof. The manufacturing method comprises the following steps: S1, feeding a copper bar which has the diameter Pi of 60-75 MM, and weighs 1,600-1,900 g; S2, rapidly heating the copper bar obtained in the S1 through combustion heater equipment to be 700-800 DEG C; S3, putting the copper bar obtained in the S2 in stamping equipment to be subjected to hot forging stamping forming with a special water meter copper shell mold; S4, cutting edges of the copper shell blank obtained in the S3; S5, inspecting the edge-cut copper shell obtained in the S4 to obtain the needed hot forging pressing process water meter copper shell. The quantity of waste gas generated in the hot forging pressing process water meter copper shell blank forming process is smaller than that of waste gas generated in casting process, so that the environment protection is efficiently improved; the sealing performance of the shell wall in forging pressing of the hot forging pressing process water meter copper shell blank is improved, no small air holes are formed in the shell wall, a process of secondary infiltration for controlling the small air holes is eliminated, and the scrappage caused by the small air holes is reduced.

Owner:宁波宁水仪表有限公司

Aluminum alloy hub hot-spinning technology for improving overall strength of wheel

InactiveCN107150209AReasonable shapeReasonable performanceMetal-working apparatusUltimate tensile strengthMechanical property

Aluminum alloy wheel hot spinning process to improve the overall strength of the wheel. The main process of the process is melting-casting pre-forming-homogenization treatment-heating spinning-preheating treatment-shot peening-spinning-heat treatment-shot peening-machine Plus‑coating. The plastic deformation of hot spinning can bridge the fine loose defects, thereby improving the mechanical properties of the wheel hub. The new casting and spinning process greatly improves the overall strength and corrosion resistance of the wheel, while the machining allowance is greatly reduced, and the service life and safety of the wheel are improved. Significantly improved, which is conducive to vehicle weight reduction and fuel saving, and the production cost of wheels is reduced.

Owner:ANHUI HENGXING WHEEL

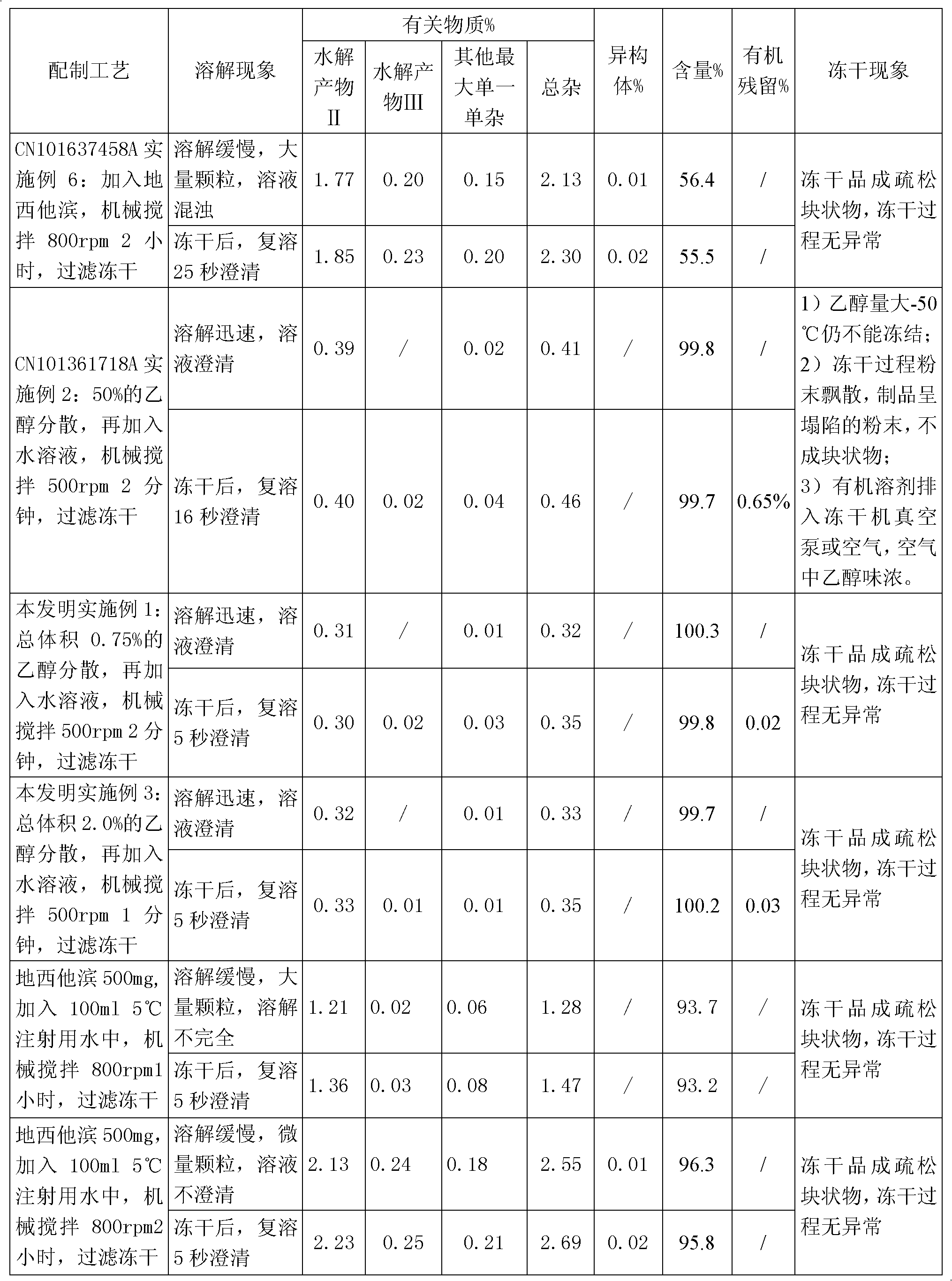

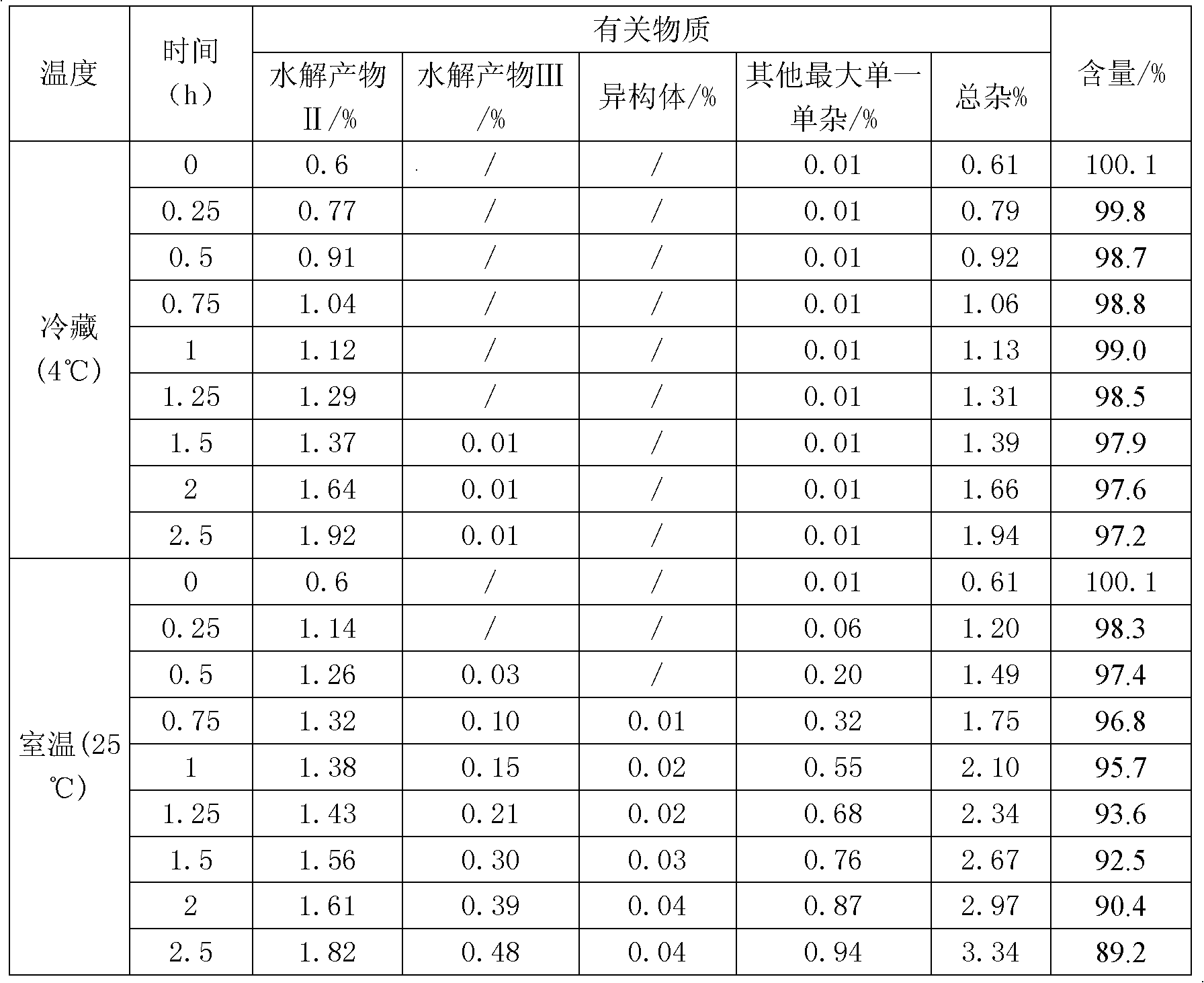

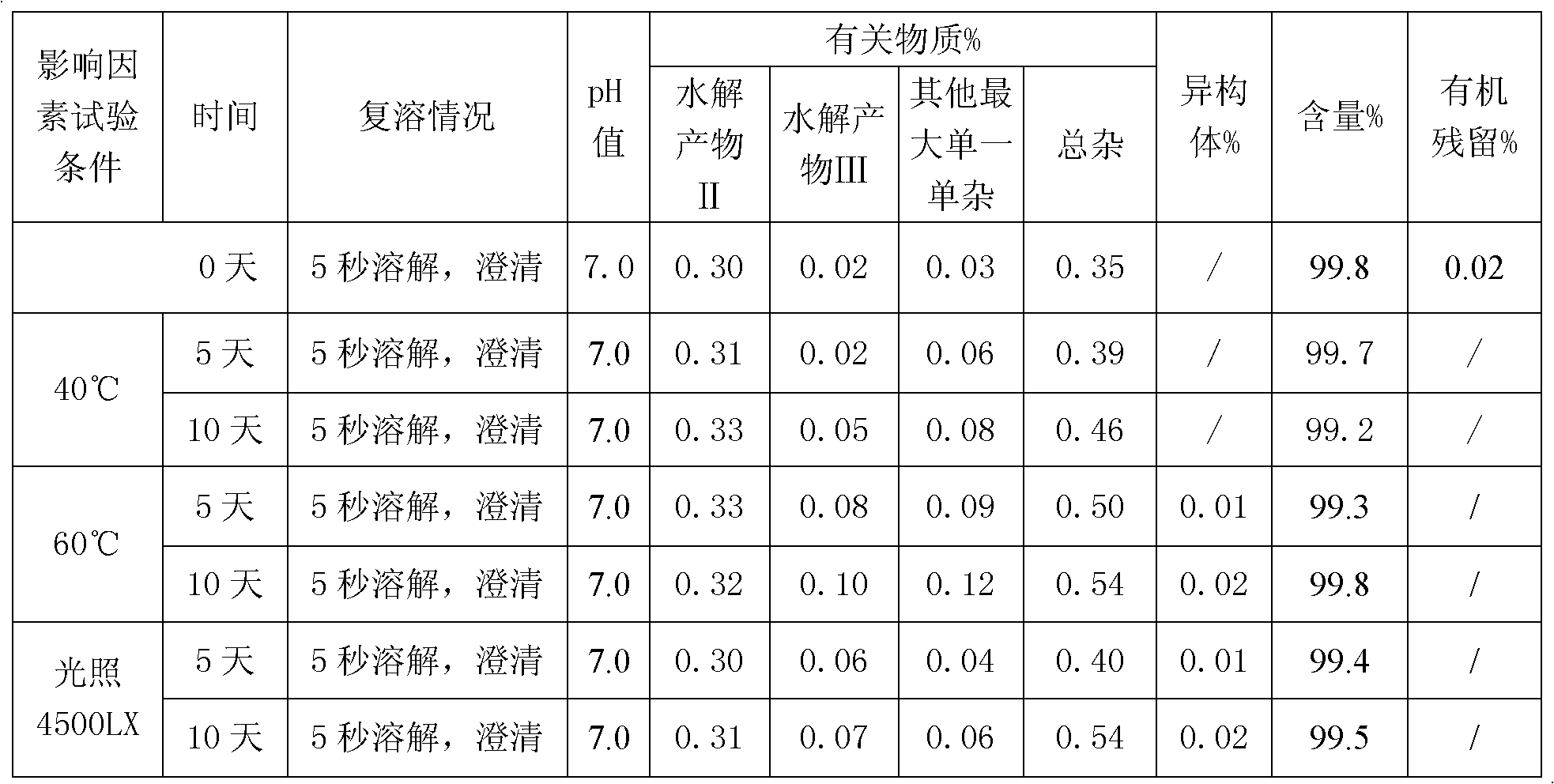

Decitabine freeze-dried preparation and preparation method thereof

ActiveCN102319222AFast dissolutionReduce usageOrganic active ingredientsPowder deliveryChemistryFreeze dry

The invention provides a Decitabine freeze-dried preparation and a preparation method thereof. The solution before being subject to freeze-drying process comprises Decitabine, organic solvent, pH regulator, and water for injection. The preparation method comprises the following steps: uniformly dispersing Decitabine in the organic solvent, putting the mixture in a 0-10 DEG C solution of water forinjection dissolving the pH regulator to dissolve Decitabine completely, so as to let the organic solvent account for 0.3-4.0 % of the total volume of the final mixture; then filtering, degerming, carrying out split charging in glass bottles, carrying out freeze drying to remove the organic solvent and the water for injection, so as to obtain the Decitabine freeze-dried preparation for clinical use. According to the invention, in the freeze-dried preparation, the content of the organic solvent residues is less than 0.8%, the preparation process is simple and convenient, the production steps are easy to control, the pollution to production equipment and environment caused by the organic solvent is reduced, and the product quality is guaranteed.

Owner:QILU PHARMA HAINAN

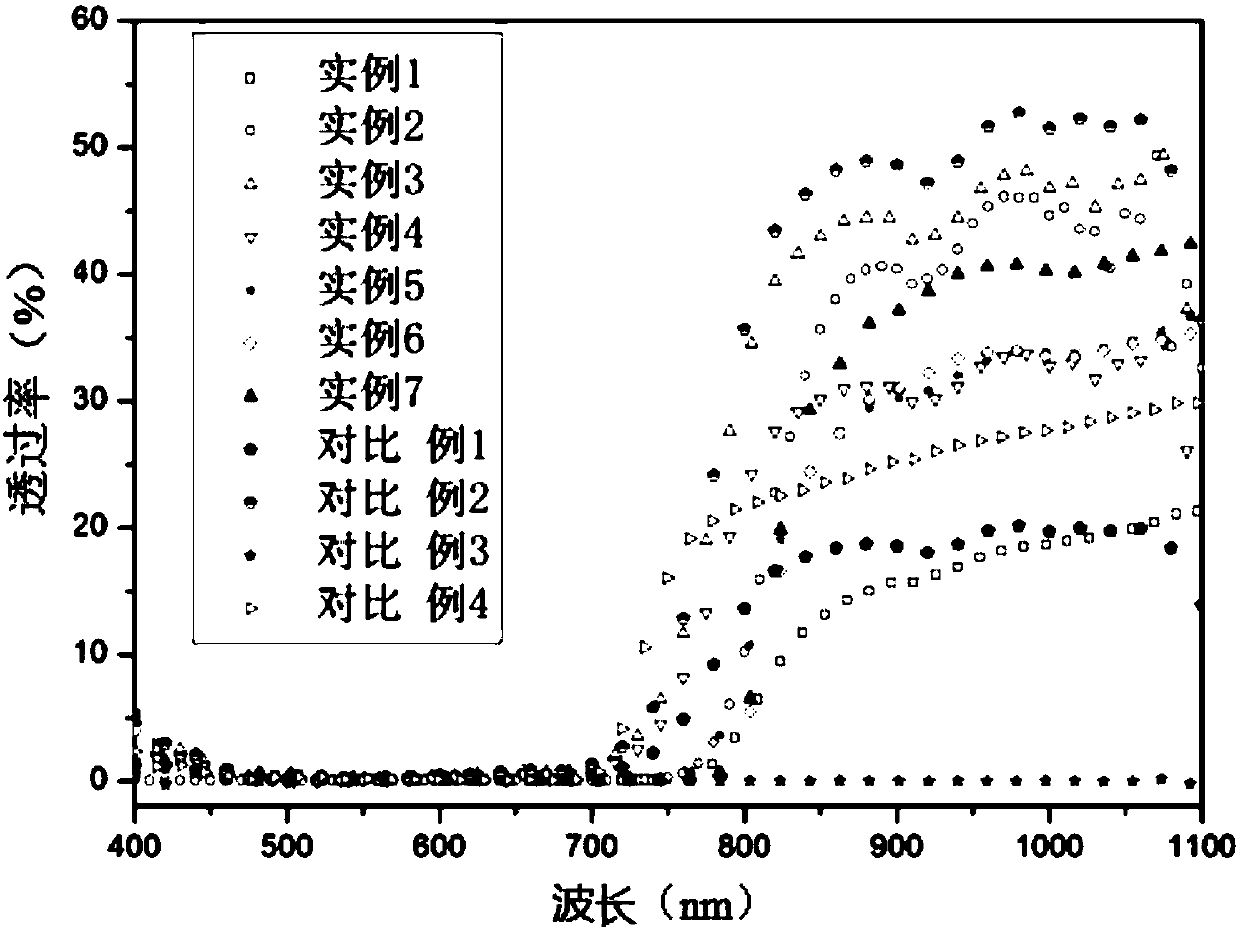

Modified plastic for laser welding and preparation method thereof

The invention provides modified plastic for laser welding. The modified plastic is prepared in the way that a perylene-series black toner is added into a base material through which laser can penetrate, the perylene-series black toner accounts for 0.05-5% of the modified plastic according to mass percent, and laser can penetrate the modified plastic at 800-1,100 nm. The invention further providesa preparation method of the modified plastic for laser welding. The invention provides the modified plastic, which is high in laser transmittivity, easy to dye, low in mobility and good in weather fastness and can meet the requirements on performance and appearance in case of long-time exposure, and application of the laser welding technology to the field of automobile interior and exterior trimming is greatly expanded.

Owner:YANFENG PLASTIC OMNIUM AUTOMOTIVE EXTERIOR SYST

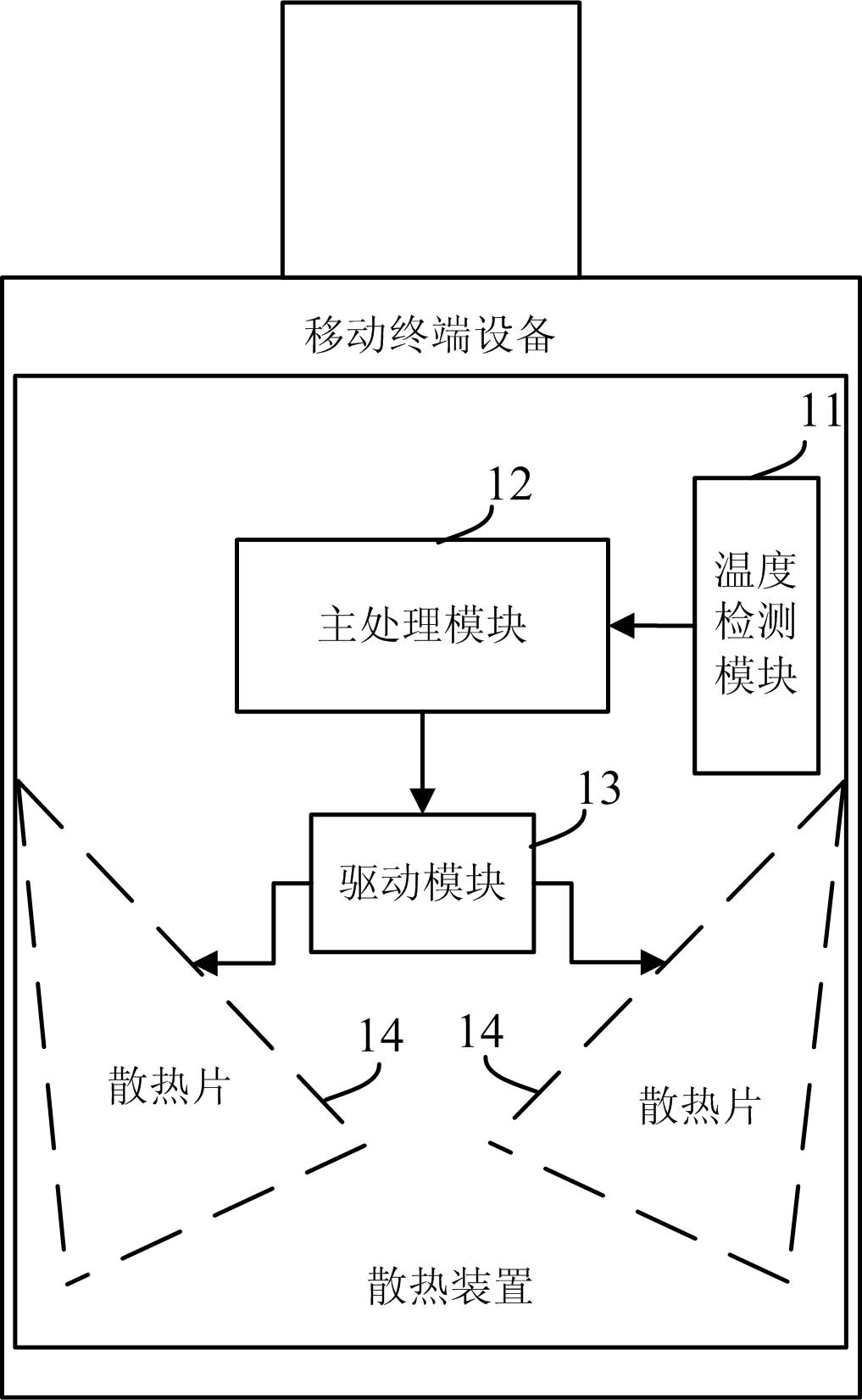

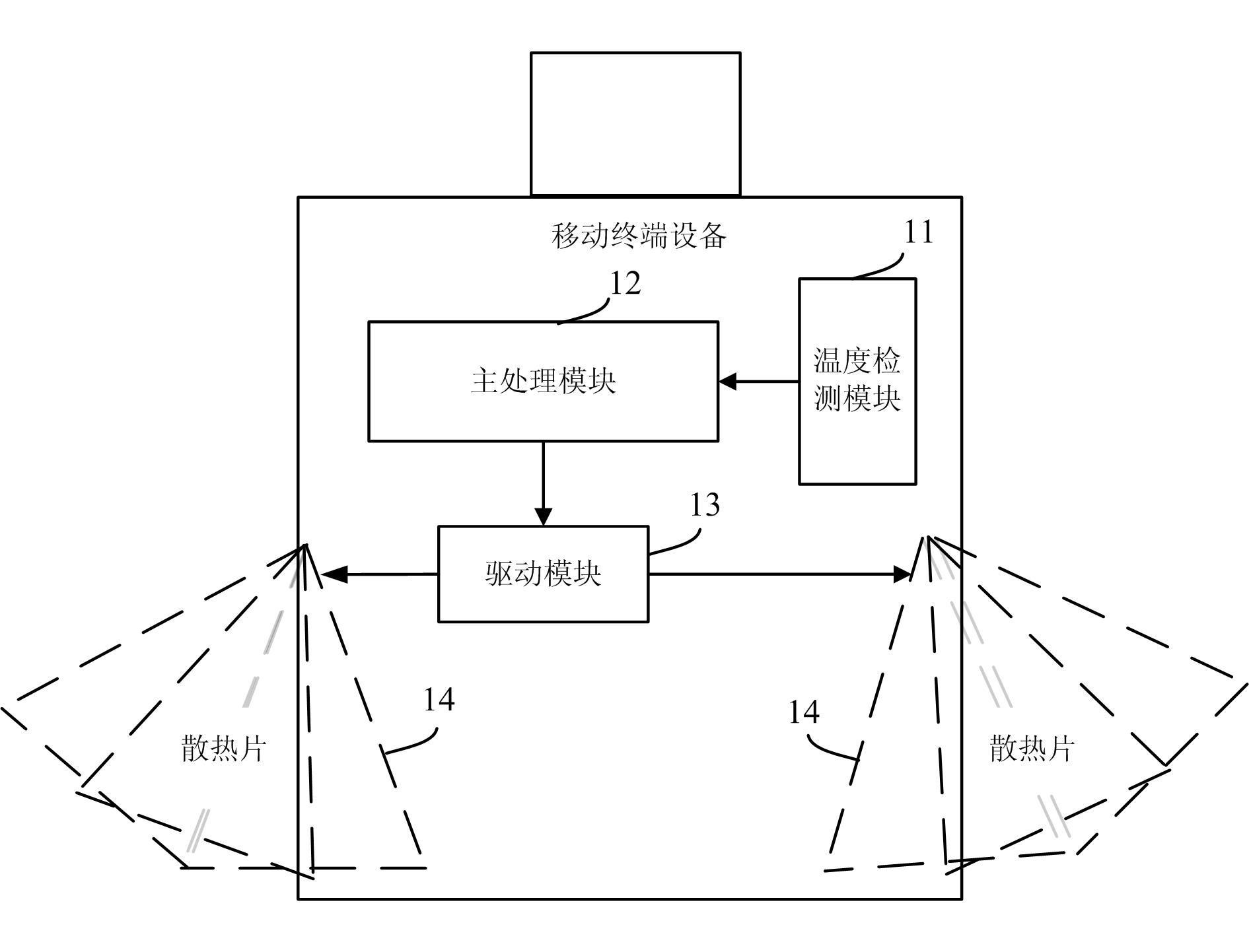

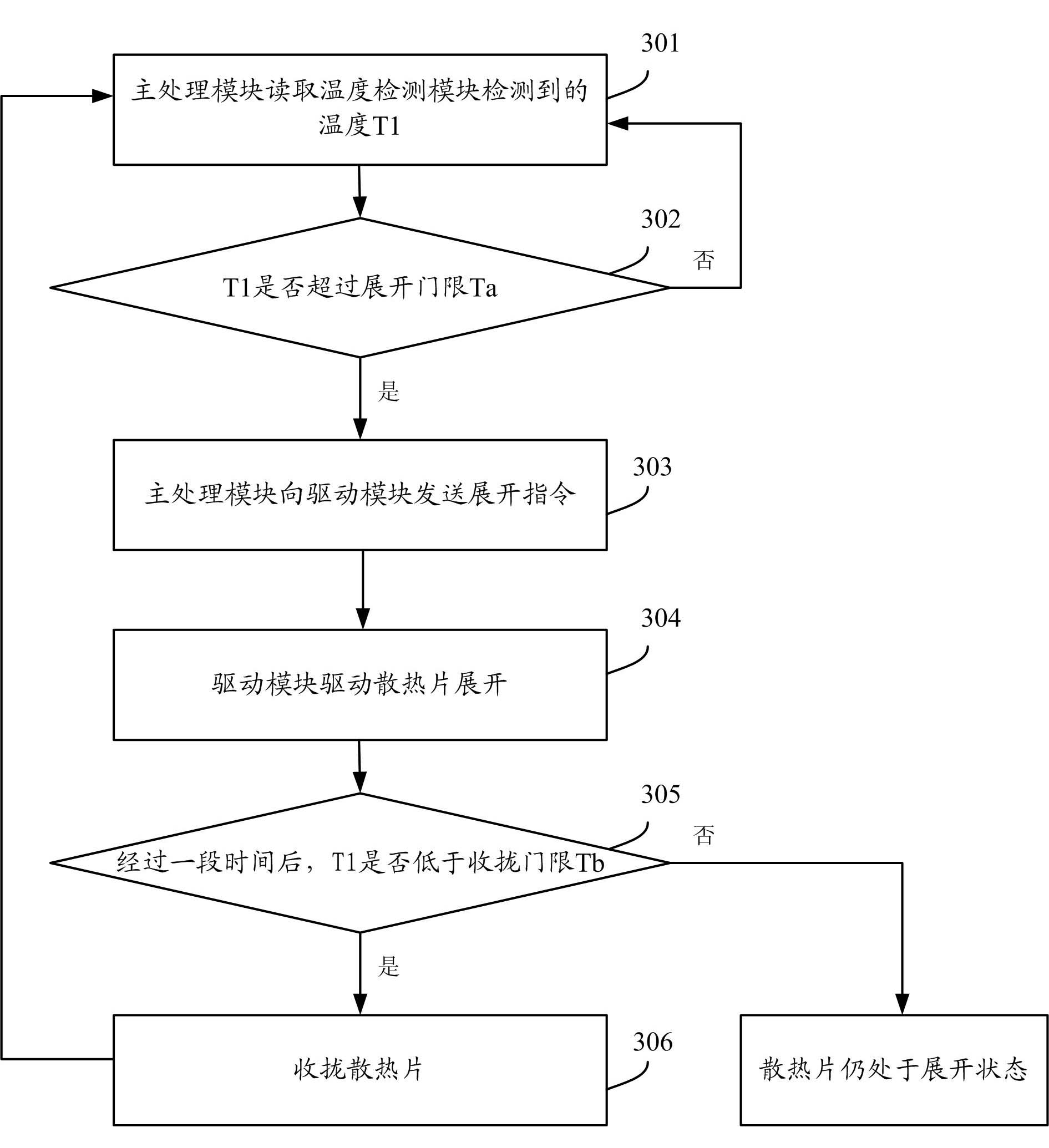

Heat radiating method and device

ActiveCN102105040AMeet appearance requirementsMeet volume requirementsCooling/ventilation/heating modificationsTerminal equipmentEngineering

The invention provides a heat radiating method and device, wherein the heat radiating method comprises the following steps of: detecting a temperature of a terminal device in real time; and driving a telescopic heat radiating fin to extend towards the outside of the terminal device according to the temperature and an unfolding condition. The heat radiating method and device not only meet the requirements on the terminal for the appearance and the volume, but also realize good heat radiation.

Owner:ZTE CORP

Spinning flange ring and forming technology thereof

ActiveCN105889744AImprove mechanical propertiesNo crackInternal combustion piston enginesConstructions elementsPunchingEngineering

The invention belongs to the technical field of automobile accessories, and particularly relates to a spinning flange ring and a forming technology thereof. The spinning flange ring comprises a flange ring body and a central inner hole. The inner wall of the flange ring body is of a groove structure. The ring body with the outer wall smoothly protruding surrounds the central inner hole. The spinning flange ring is manufactured through the first step of feeding, the second step of punching, the third step of inclination pressing, the fourth step of spinning forming, the fifth step of punching, the sixth step of inner circle turning, and the seventh step of outer circle turning and small hole drilling. The flange ring is manufactured through the spinning technology, the shape of a blank is preprocessed, part of the outer edge of the blank is pressed down, positioning is achieved through the central hole, and no cracks or wrinkles can appear in the spinning process; meanwhile, by means of the spinning technology, the product is good in plastic performance and longer in service life.

Owner:ZHEJIANG DONGXING AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com