Inverted punching and riveting machine and riveting method thereof

A technology of punching riveting machine and inverted type, which is applied in the field of improvement of inverted type punching riveting machine and its riveting method, which can solve the problems of affecting riveting quality, increasing labor intensity, and easy dislocation of riveting holes, etc., so as to simplify the structure and reduce labor intensity , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

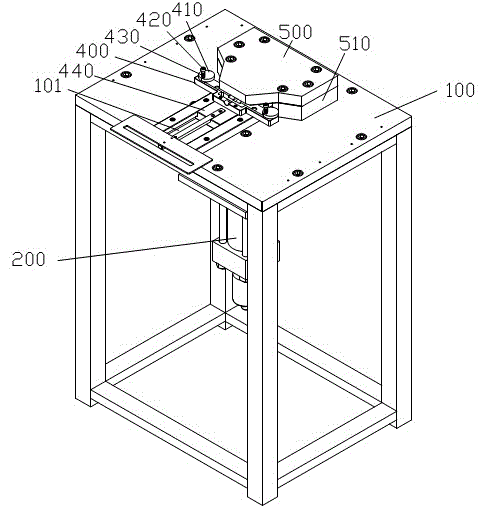

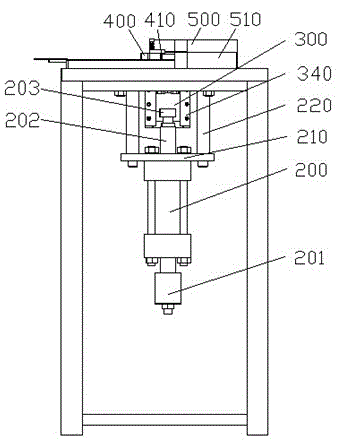

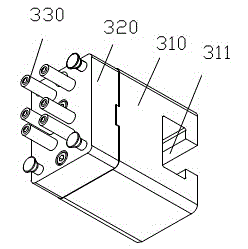

[0038] The invention discloses an inverted riveting machine. The inverted riveting machine is used to punch the bottom of the rivet of a workpiece to be riveted. Under the action of the punching force, the bottom of the rivet is deformed to form an undercut, thereby The workpieces to be riveted are riveted together. see figure 1 and figure 2 As shown, the punching riveting machine includes a workbench 100, a fixture 400 arranged on the workbench 100 for fixing the workpiece to be riveted, a punch 300 and an oil cylinder 200 arranged upside down on the workbench 100; The stamping force required by factors such as the quantity, structure, material and stamping deformation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com