High-rigidity polypropylene composite without flow marks as well as preparation method of polypropylene composite

A technology of polypropylene and no flow marks, which is applied in the field of high-rigidity non-flow mark polypropylene composites and its preparation. , the effect of accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

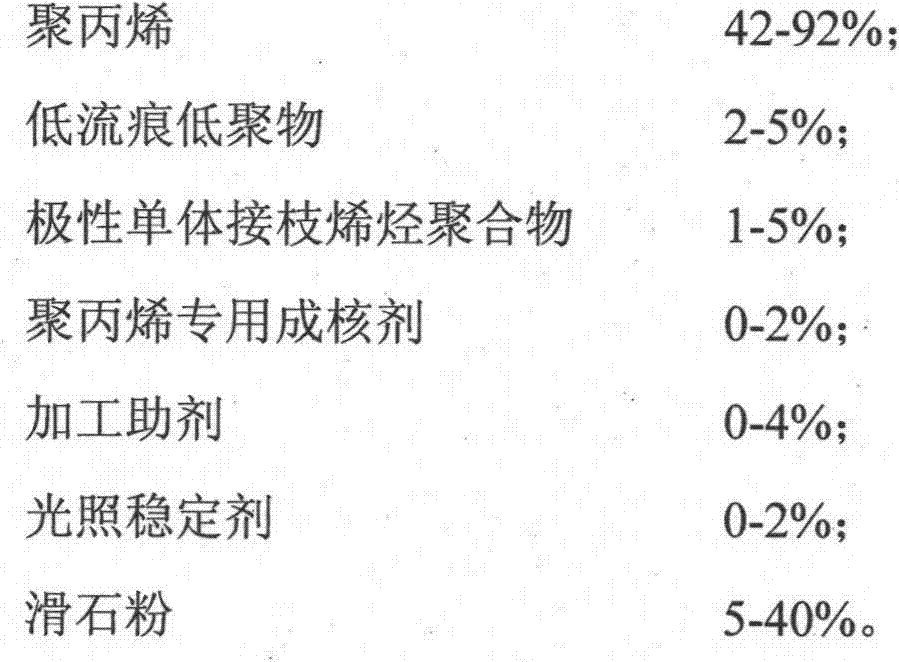

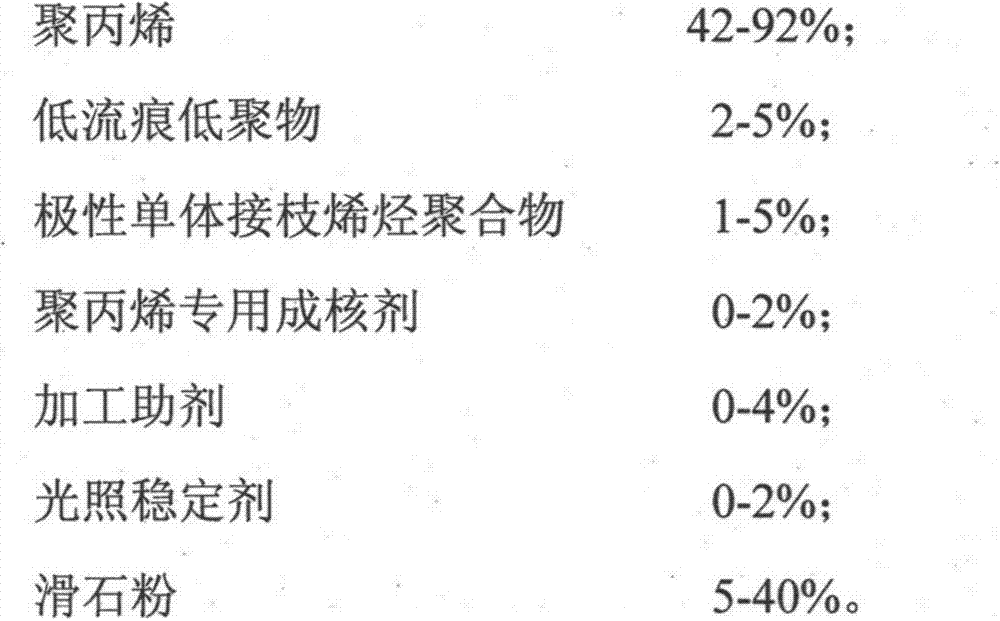

Method used

Image

Examples

Embodiment 1

[0021] 92 kg of polypropylene PP HP500N (CNOOC Shell), 1 kg of erucamide, 1 kg of acrylamide, 1 kg of LLDPE grafted with maleic anhydride graft Bondyram4108 in a twin-screw extruder with a length-to-diameter ratio of 40:1 Medium melt mixing and dispersion, 5 kg of 3000-mesh talc powder is fed into the twin-screw extruder from the side through a weight-loss weighing scale, and the temperature of each section of the extruder is set at 190-225 ° C, extruded and granulated, and finally the product is obtained.

[0022] Test its performance according to the corresponding standards, the list is as follows:

[0023] Table 1

[0024] performance

[0025] The uniformity of the surface gloss of the sample sheet is obviously improved by adding the low-flow mark substance, the appearance quality of the sample is improved, and the dispersibility of the filler and the compatibility with the resin are improved at the same time. Therefore, the bending modulus and bending strength o...

Embodiment 2

[0027] 75.5 kilograms of polypropylene PP T30S (Daqing Petrochemical Company), 0.5 kilograms of erucamide, 1.5 kilograms of ethylene bisstearamide, 1 kilogram of HDPE grafted maleic anhydride graft Bondyram5101, 0.2 kilograms of phenolic antioxidant 1010, 0.2 kg of phosphite antioxidant 168, 0.6 kg of processing aid EBS, and 0.5 kg of light stabilizer 770 were melt-mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and 20 kg of 3000-mesh talcum powder passed through the weight loss process. The type weighing scale is fed into the twin-screw extruder from the side, and the temperature of each section of the extruder is set at 190-225 ° C, extruded and granulated, and finally the product is obtained.

[0028] Test its performance according to the corresponding standards, the list is as follows:

[0029] Table 2

[0030] performance

[0031] By adding low-flow mark substances, the surface gloss of the final product is improved, and ap...

Embodiment 3

[0033] 62 kg of polypropylene PP YPJ-3860 (Yangzi Petrochemical), 1.5 kg of stearic acid amide, 2.5 kg of behenic acid amide, 0.5 kg of ethylene-octene copolymer maleic anhydride graft 493D, 0.5 kg of polypropylene Nuclear agent HPN-20E, 0.5 kg of phenolic antioxidant 1010, 0.5 kg of phosphite antioxidant 627A, 1 kg of processing aid calcium stearate, 1 kg of light stabilizer 944 in a 40:1 aspect ratio Melt, mix and disperse in the twin-screw extruder. 30 kg of 3000-mesh talc powder is fed into the twin-screw extruder from the side through a weight-loss weighing scale. Finally get the product.

[0034] Test its performance according to the corresponding standards, the list is as follows:

[0035] table 3

[0036] performance

[0037] By adding low-flow-mark substances and nucleating agents to eliminate the flow-mark appearance defects of the final sample, the appearance quality of the part is greatly improved. At the same time, the tensile strength, flexural stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com