Surface treatment method for highlight edge of aluminum alloy mobile phone shell

A mobile phone case and surface treatment technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, application, etc., can solve the problems of low product yield, inability to achieve, and the color boundary is not straight, achieving low cost and high production efficiency , The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

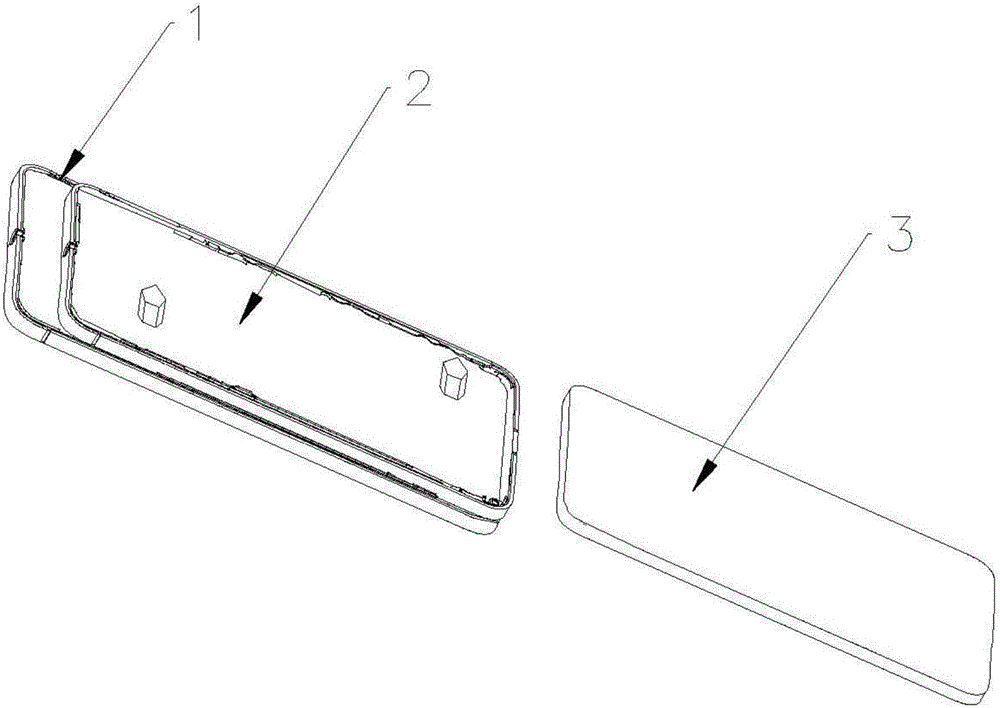

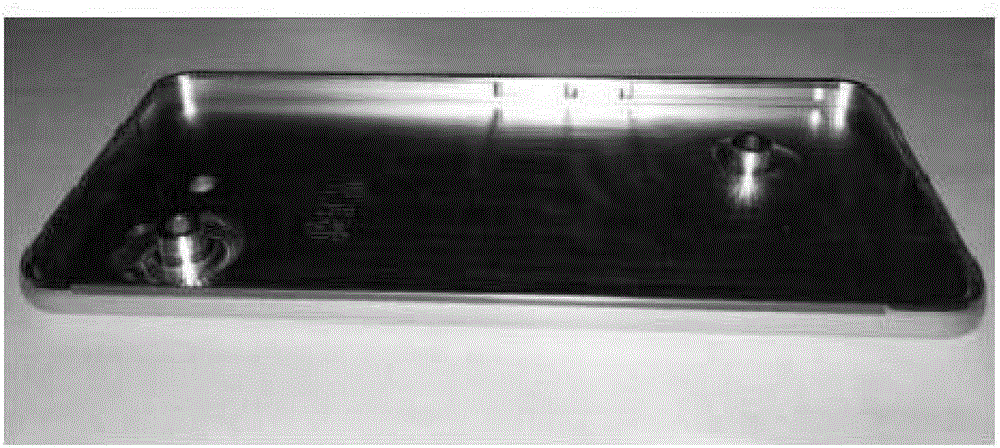

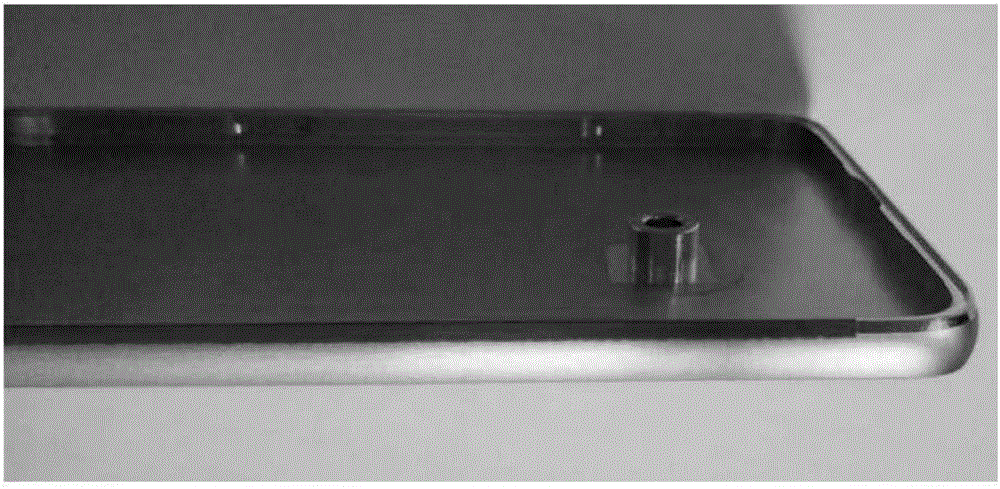

[0051] In this embodiment, a surface treatment method for the high-gloss edge of an aluminum alloy mobile phone casing 2 includes the following steps:

[0052] Step (1) Process the exterior and inner cavity of the aluminum alloy mobile phone case 2. The mobile phone case 2 includes a back cover and a frame; Perform CNC high-gloss processing on the frame to form a high-gloss edge. The frame includes a horizontal frame located at the upper and lower ends of the mobile phone case 2, a vertical frame located at the left and right sides of the mobile phone case 2, and a corner edge connecting the horizontal frame and the vertical frame. The vertical frame includes The upper frame edge and the lower frame edge away from the display screen; then degrease and clean the mobile phone shell 2;

[0053] Step (2) Cover the cover plate 3 of the shielding fixture above the inner cavity of the mobile phone case 2, then place the mobile phone case 2 in the protective case, clamp the protective...

Embodiment 2

[0075] In this embodiment, a surface treatment method for the high-gloss edge of an aluminum alloy mobile phone casing 2 includes the following steps:

[0076]Step (1) Process the exterior and inner cavity of the aluminum alloy mobile phone case 2. The mobile phone case 2 includes a back cover and a frame; Perform CNC high-gloss processing on the frame to form a high-gloss edge. The frame includes a horizontal frame located at the upper and lower ends of the mobile phone case 2, a vertical frame located at the left and right sides of the mobile phone case 2, and a corner edge connecting the horizontal frame and the vertical frame. The vertical frame includes The upper frame edge and the lower frame edge away from the display screen; then degrease and clean the mobile phone shell 2;

[0077] Step (2) Cover the cover plate 3 of the shielding fixture above the inner cavity of the mobile phone case 2, then place the mobile phone case 2 in the protective case, clamp the protective ...

Embodiment 3

[0099] In this embodiment, a surface treatment method for the high-gloss edge of an aluminum alloy mobile phone casing 2 includes the following steps:

[0100] Step (1) Process the exterior and inner cavity of the aluminum alloy mobile phone case 2. The mobile phone case 2 includes a back cover and a frame; Perform CNC high-gloss processing on the frame to form a high-gloss edge. The frame includes a horizontal frame located at the upper and lower ends of the mobile phone case 2, a vertical frame located at the left and right sides of the mobile phone case 2, and a corner edge connecting the horizontal frame and the vertical frame. The vertical frame includes The upper frame edge and the lower frame edge away from the display screen; then degrease and clean the mobile phone shell 2;

[0101] Step (2) Cover the cover plate 3 of the shielding fixture above the inner cavity of the mobile phone case 2, then place the mobile phone case 2 in the protective case, clamp the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com