PMMA/ABS (polymethyl methacrylate/acrylonitrile butadiene styrene) composite material and manufacturing method

A composite material and anti-oxidant technology, applied in the field of plastic materials, can solve the problems of insufficient molding requirements of complex products with high surface gloss, poor heat resistance, etc., and achieve good mechanical properties, scratch resistance, and good heat resistance , the effect of good processing fluidity

Inactive Publication Date: 2010-06-16

QINGDAO GON TECHNOLOGY CO LTD

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The invention provides a PMMA / ABS composite material and a manufacturing method, which can solve the problems of poor heat resistance, scratch resistance, high surface gloss and insufficient molding requirements of complex products in the prior art.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

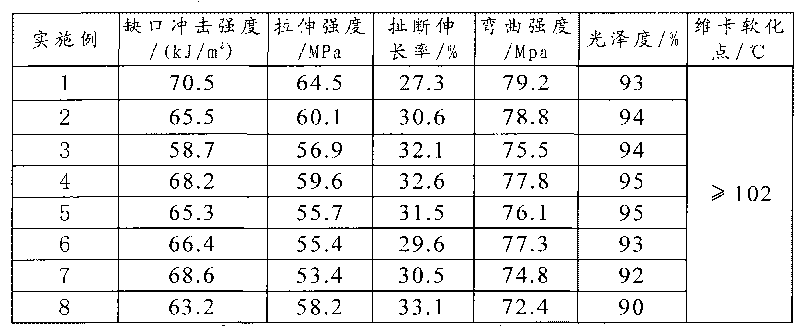

[0030] 58 parts of ABS, 30 parts of PMMA, 12 parts of SAN, 0.2 parts of antioxidant 1010, 0.05 parts of DLTP, 1.2 parts of zinc stearate.

Embodiment 2

[0032] 53 parts of ABS, 35 parts of PMMA, 12 parts of SAN, 0.2 parts of antioxidant 1010, 0.05 parts of DLTP, 1.2 parts of zinc stearate.

Embodiment 3

[0034] 48 parts of ABS, 40 parts of PMMA, 12 parts of SAN, 0.2 parts of antioxidant 1010, 0.05 parts of DLTP, 1.2 parts of zinc stearate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Login to View More

Abstract

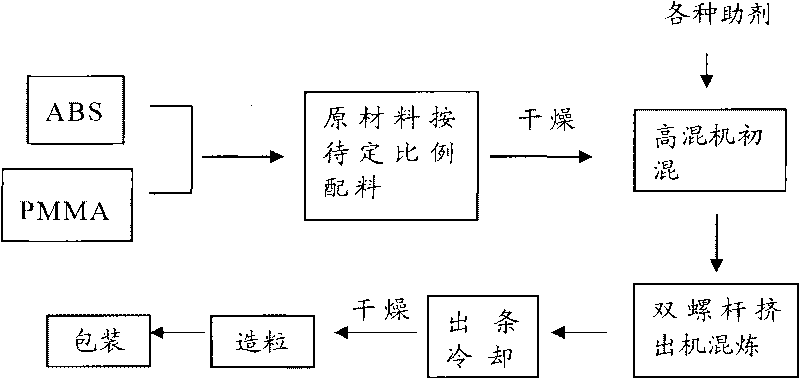

The invention provides a PMMA / ABS (polymethyl methacrylate / acrylonitrile butadiene styrene) composite material and a manufacturing method, which can solve the problems of poor thermal resistance, scraping resistance and high surface gloss and insufficiency in complex product molding requirements existing in the prior art. In the technical scheme, the composite material comprises the following components in parts by weight: 40-58 parts of ABS, 30-45 parts of polymethylmethacrylate, 5-12 parts of styrene-acrylonitrile, 0.1-0.3 part of antioxidant, 0.05-0.1 part of auxiliary antioxidant and 1.0-1.5 parts of lubricant. Through specific compound formulation, the invention ensures a PMMA / ABS alloy material has excellent thermal property, scraping resistance and high surface gloss and meets the molding requirements for the complex products, and improves processing property of materials.

Description

technical field [0001] The invention relates to plastic materials, in particular to a PMMA / ABS composite material and a manufacturing method. Background technique [0002] With the development of the national economy and the improvement of people's quality of life, the requirements for the appearance of home appliances are getting higher and higher. Many home appliance manufacturers, especially TV manufacturers, are constantly pursuing the personalized appearance of their products, which has become one of the main means for suppliers to attract consumers' attention. In recent years, especially the black and bright, colorful pearlescent design is the most eye-catching. Among them, the body shell made of high-gloss spray-free "black and bright" resin has a black and bright appearance, which is full of aesthetic feeling and good visual effect. The characteristic of this material is that injection molding products do not need to be sprayed, which not only improves production e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L55/02C08L33/12C08L25/12C08K5/134C08K5/098C08K5/372

Inventor 王爱国陈广龙王龙

Owner QINGDAO GON TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com