Pattern coating glass and preparation method thereof

A coating glass and pattern technology, which is applied in the field of pattern coating glass and its preparation, achieves the effects of low radiation performance, expanded application field and good metallic luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

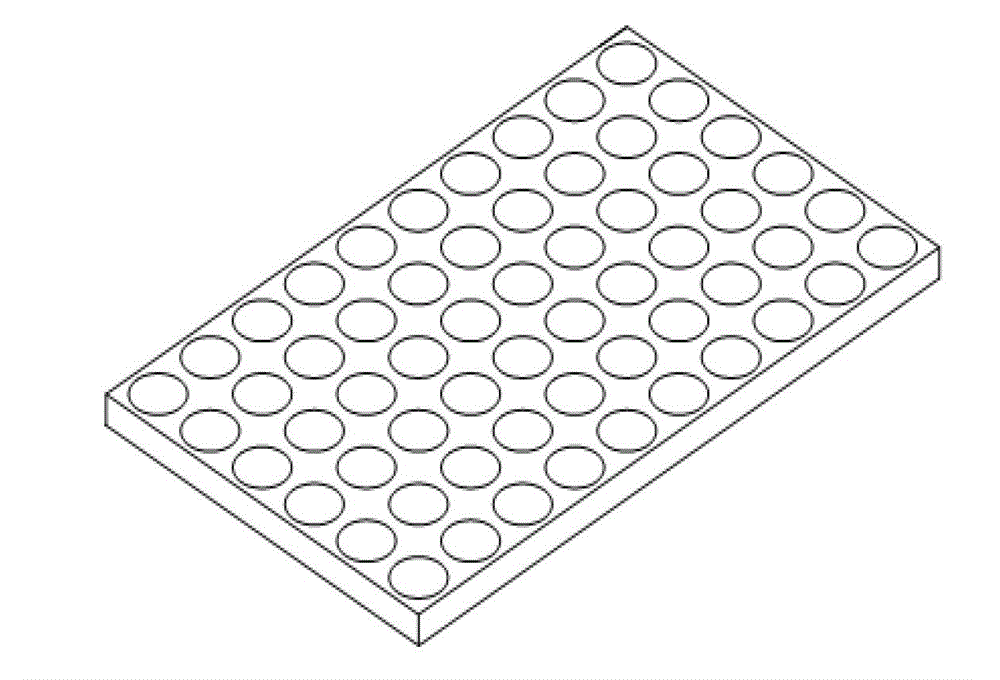

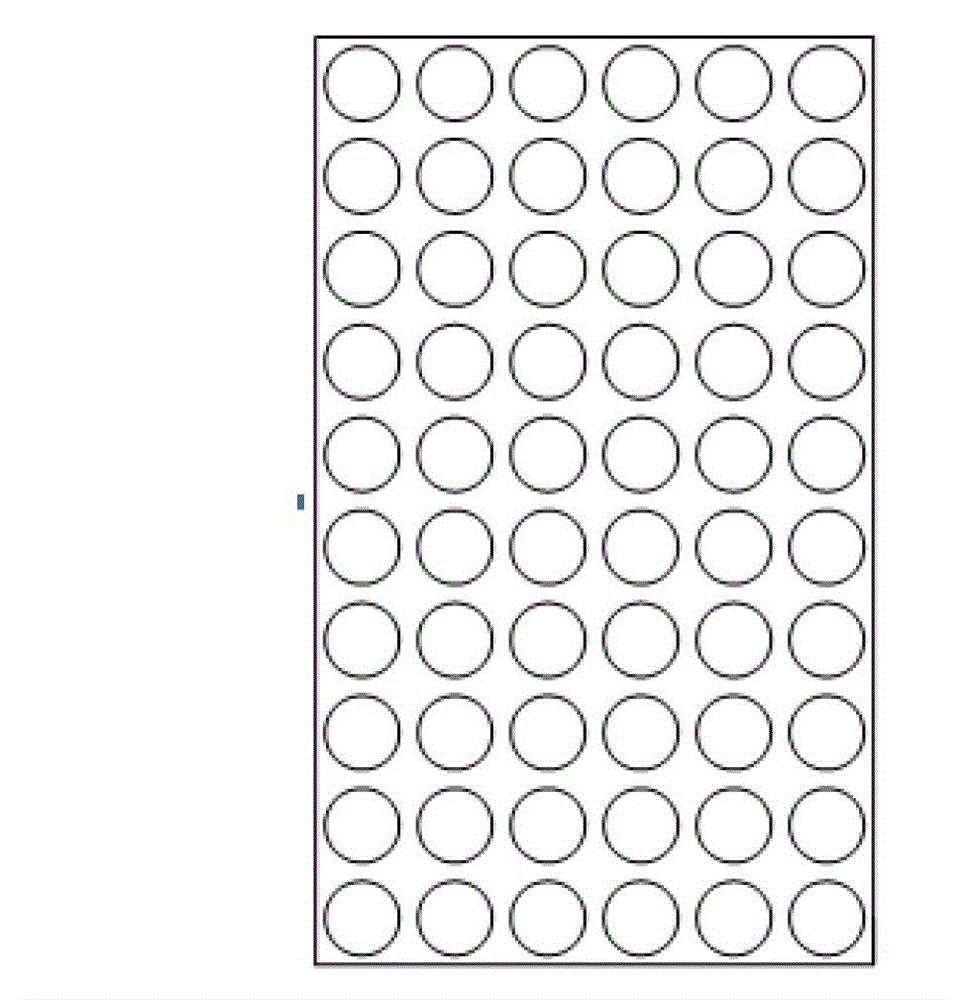

[0029] A pattern coated glass, the glass surface is partially covered with a coating layer, and the patterns formed by the coating layer are arranged in an array.

[0030] The pattern is circular, such as figure 1 shown.

[0031] The coating film layer is an anti-oxidation film layer, and the material is SnO 2 or SiN X .

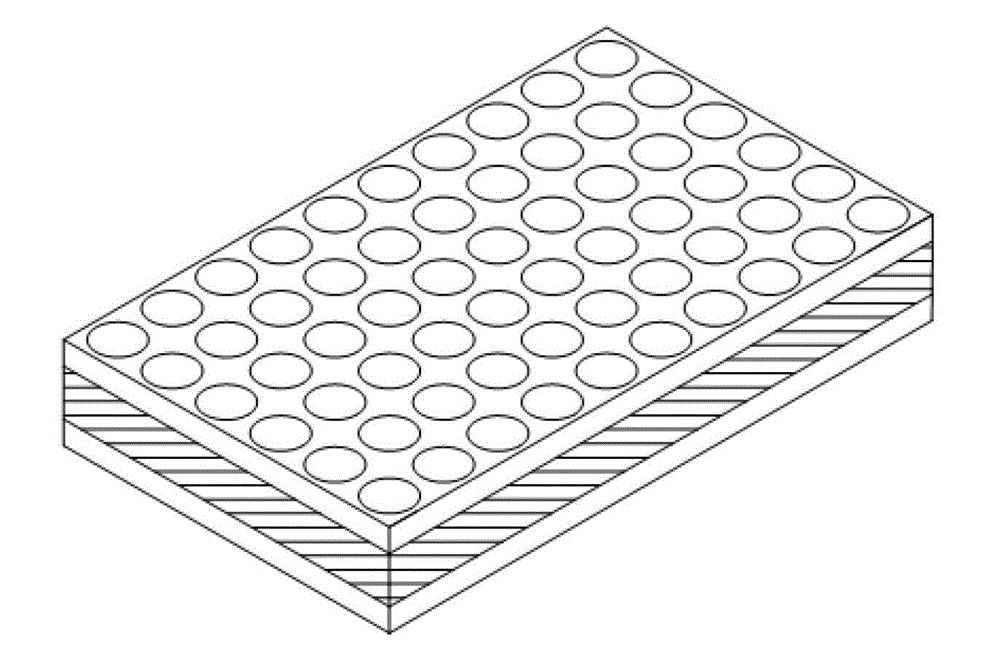

[0032] The coated glass is single-layer glass (such as figure 1 , 2 shown), composite laminated glass (such as Figure 5 , 6 shown) or insulating glass (such as image 3 , 4 shown).

[0033] The specific embodiment of this invention is as follows:

[0034] 1. According to the graphic and glass size, and the required pattern, make the required screen for screen printing. Purchase black organic glaze (glaze number RAL5010), black organic glaze has better heat absorption effect and helps to burn completely when heated.

[0035] 2. Process the glass and cut it into the size and shape required by the project.

[0036] 3. The edge can be finely polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com