Patents

Literature

54results about How to "Consistent texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

New method for activating and recycling tyre waste rubber powder

InactiveCN101696285AUniform responseConsistent texturePlastic recyclingButadiene-styrene rubberEngineering

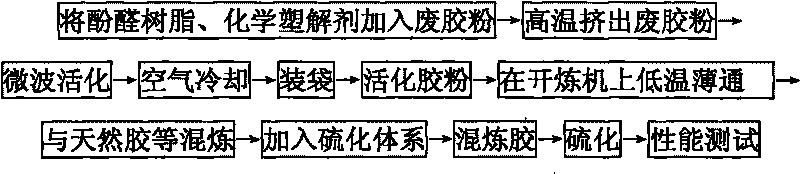

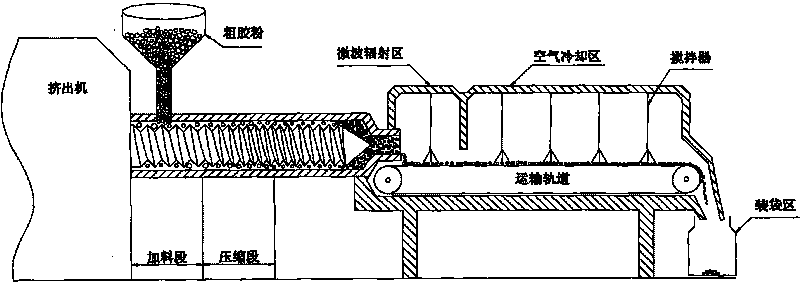

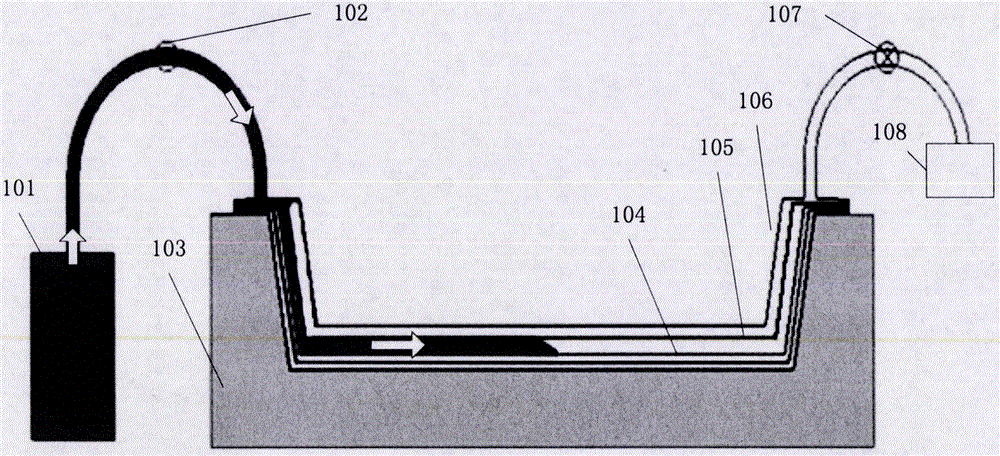

The invention discloses a new method for activating and recycling tyre waste rubber powder, which belongs to the technical field of recycling waste rubbers. The process comprises the following steps: adding a fixed quantity of modifying agent into the waste rubber powder; extruding the mixture by using a screw extruder; heating, drying and cracking the waste rubber powder in the extruding process to ensure that a large number of cross bonds in the waste rubber powder are fractured; cooling the extruded waste rubber powder after microwave radiation, then activating the waste rubber powder, and mixing the activated waste rubber powder with universal rubbers such as natural rubber, cis-butadiene rubber, styrene butadiene rubber and the like to prepare a gross rubber; and vulcanizing the gross rubber. Tests show that a sample and a product containing the activated rubber powder have excellent performances, and the process is simple, convenient and efficient and has outstanding economic benefits and social benefits.

Owner:XUZHOU COLLEGE OF INDAL TECH

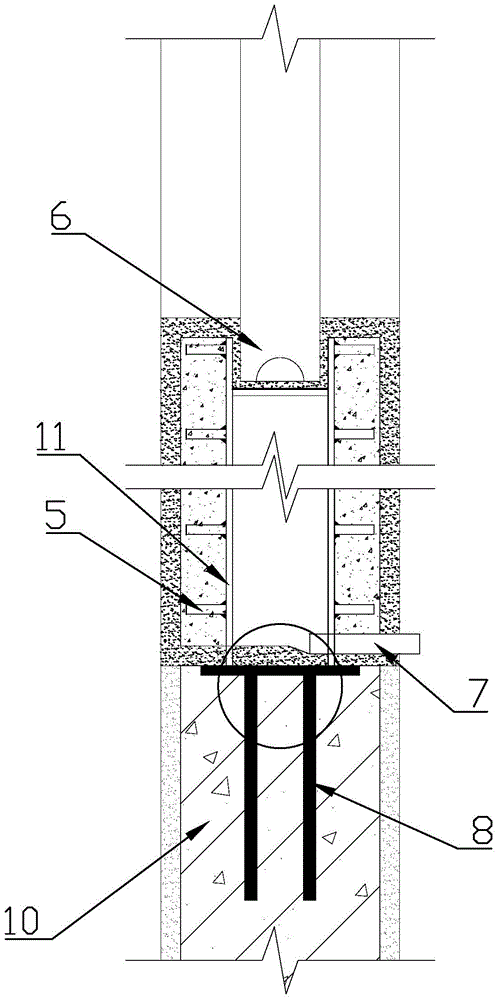

Production method for automatically producing true through-body tiles with imitated marble texture

ActiveCN107805073AAutomated production preparationEfficient productionClaywaresEngineeringMaterial distribution

The invention discloses a production method for automatically producing true through-body tiles with an imitated marble texture. The continuous, efficient and automatic production is realized throughpreliminary material distribution, secondary material distribution, molding, carrier marking and identification printing. The carrier marking and the identification printing are simultaneously adoptedto greatly guarantee the accuracy of the production of the through-body tiles; and two-stage material distribution is adopted to ensure that the texture effect of a body layer has multiple variations, is good and is same to the texture effect of a glazed layer.

Owner:GUANGDONG BOFFIN MECHANICAL & ELECTRICAL CO LTD

Surface treatment method of amorphous alloy

InactiveCN103993314AConsistent colorConsistent textureAnodisationSuperimposed coating processAluminum metalAluminium oxides

The invention relates to the technical field of amorphous alloy and in particular relates to a surface treatment method of amorphous alloy. The method comprises the following steps: 1, performing cold spraying, namely spraying an aluminum layer or an aluminum alloy layer to the surface of the amorphous alloy by adopting a cold spraying process to obtain a semi-finished product; 2, performing anodizing treatment, namely performing anodizing treatment on the aluminum layer or the aluminum alloy layer in the semi-finished product obtained in the step 1 to enable an aluminum oxide film to be formed on the surface the aluminum layer or the aluminum alloy layer to obtain a finished product. According to the method, the treated amorphous alloy product can be perfectly matched with an aluminum alloy product in appearance, and the appearance requirements of industrial design are met; moreover, compared with a PVD (physical vapor deposition) technology, the method has the characteristics that the appearance requirements can be well met on the basis of the advantage of low cost, and the application range of the amorphous alloy is greatly expanded.

Owner:WINTOP DONGGUAN INDAL TECH

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

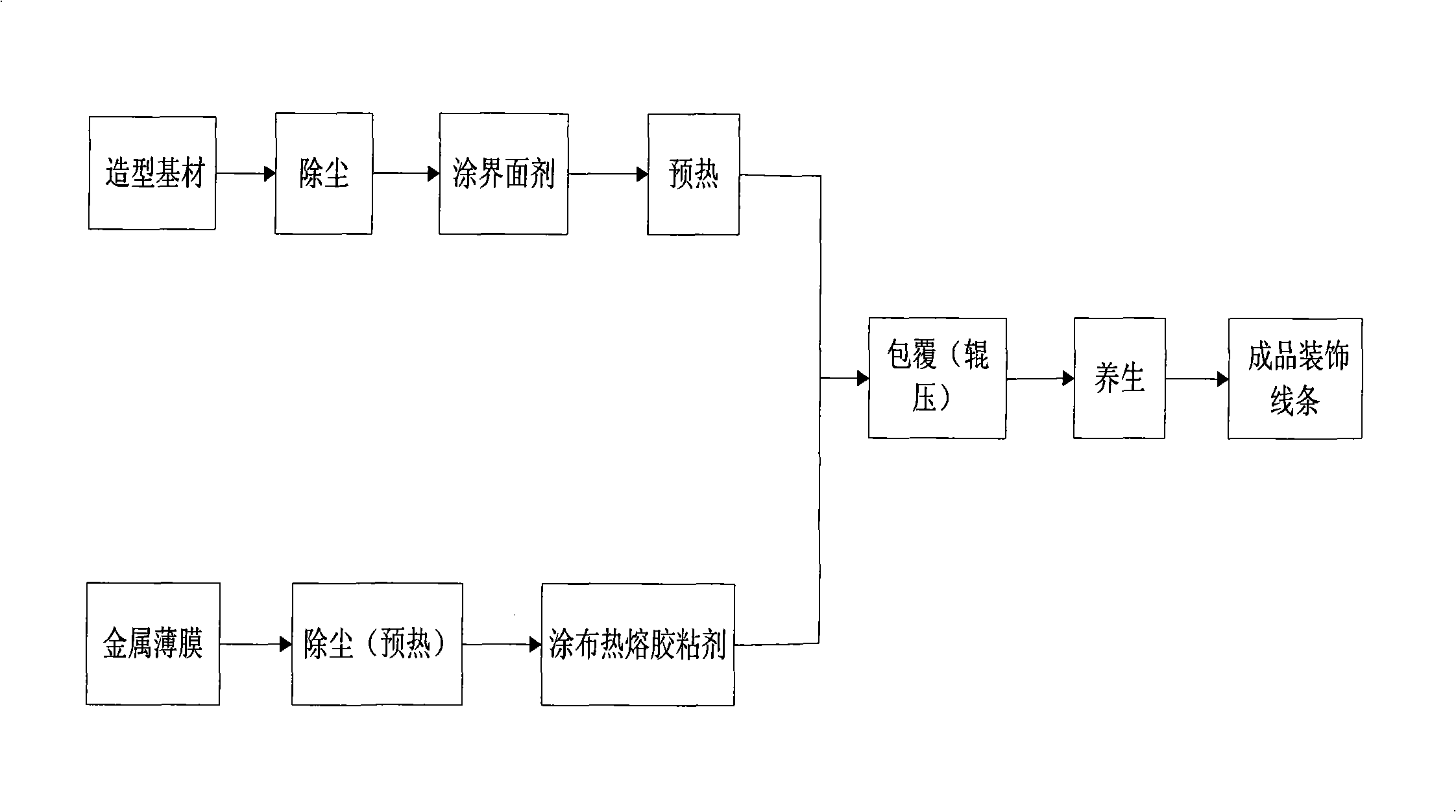

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

Copper plate card and preparation method thereof

ActiveCN102704321AQuality assuranceWith textureCoatings with pigmentsWater-repelling agents additionNatural resourceFolding endurance

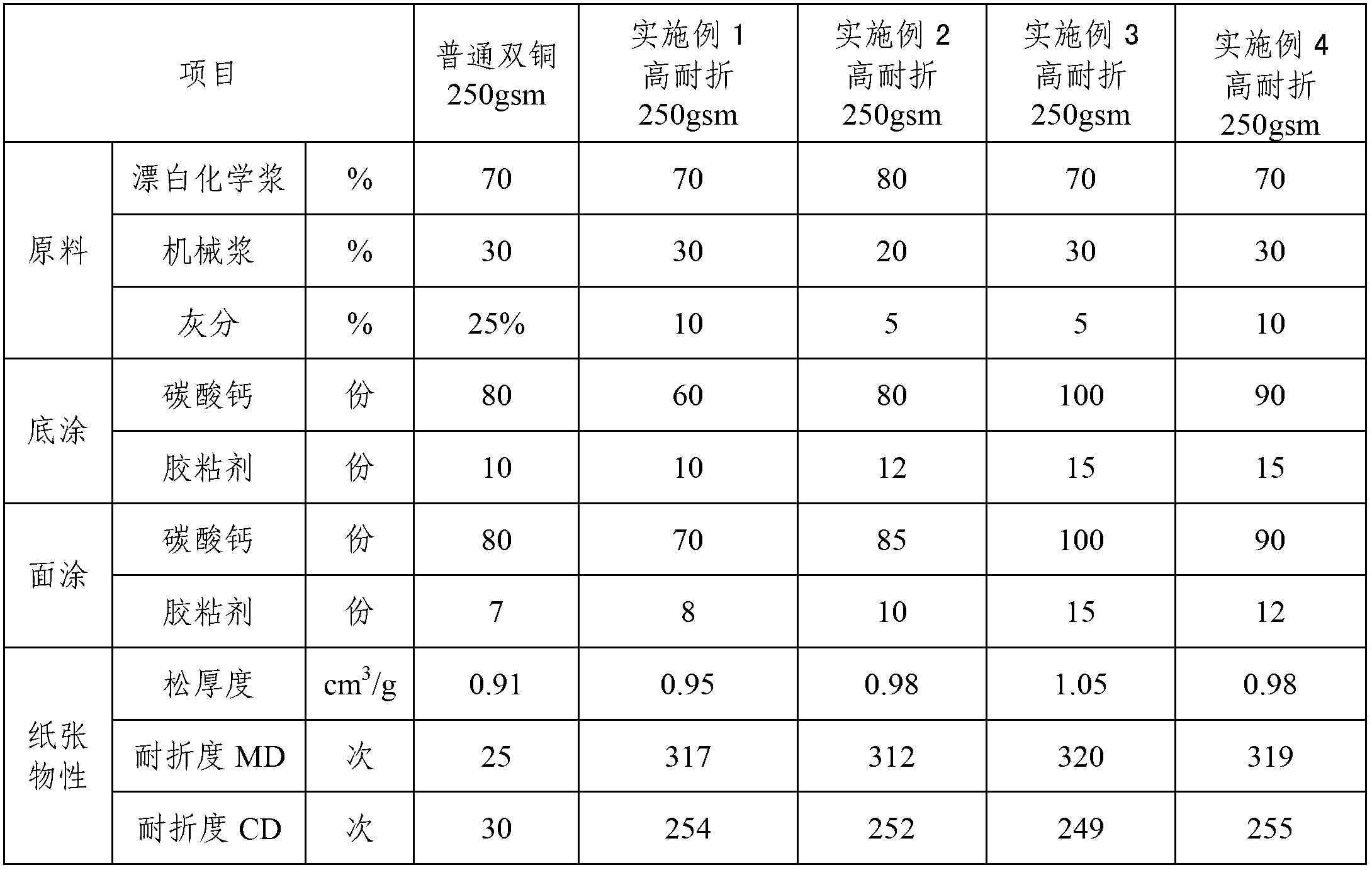

The invention provides a copper plate card, which comprises base paper, a ground coating and a surface coating, wherein the ground coating and the surface coating are coated on both sides of base paper in sequence; the preparation raw material for base paper comprises chemical pulp, mechanical pulp, wet-end chemicals, an inner sizing agent and a surface sizing agent, and the chemical pulp accounts for 20 to 80 parts by weight, and the mechanical pulp accounts for 10 to 30 parts by weight; the ground coating comprises pigment accounting for 60 to 100 parts by weight and an adhesive accounting for 10 to 17 parts by weight; and the surface coating comprises pigment accounting for 70 to 100 parts by weight and an adhesive accounting for 8 to 15 parts by weight. The invention also provides a preparation method of the copper plate card. The copper plate card and the preparation method select and use the mechanical pulp in a suitable proportion, reduce the utilization of the chemical pulp, save natural resources such as forest, water and the like, are beneficial to environmental protection, and ensure the quality; in addition, the bulk of the energy-saving environment-friendly copper plate card with high hard fold quality is controlled within 0.95 to 1.05cm<3> / g, the folding endurance of obtained paper is good, the coating quantity on the both sides are concordant approximately, the remaining effect of printing ink on the paper surface is excellent, and the color of ink is bright.

Owner:HAINAN JINHAI PULP & PAPER

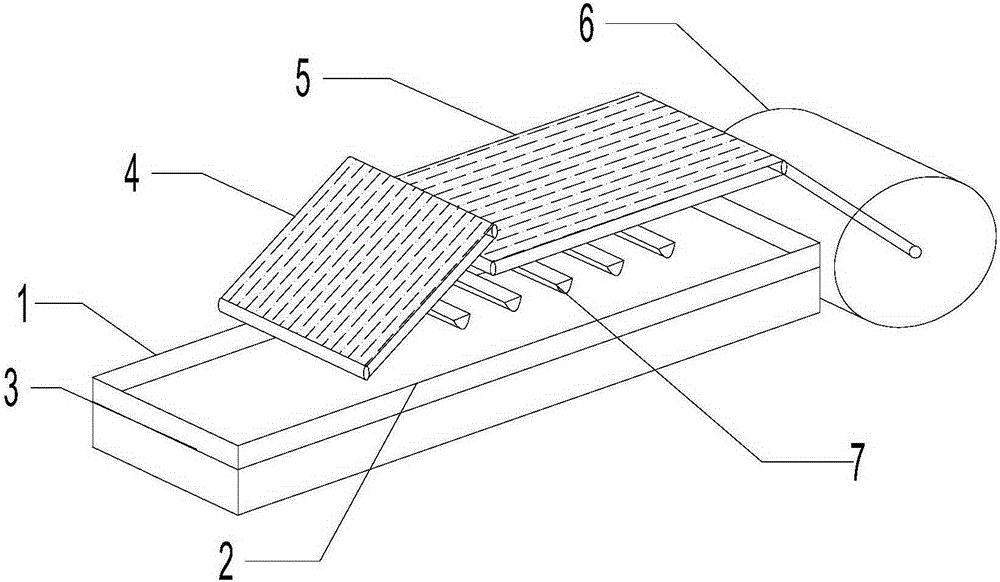

Novel micro powder intelligent multi-pipe distribution full-body ceramic tile and preparation method thereof

ActiveCN109927161AMeet the requirementsSuppression of forward and backward displacementCeramic shaping plantsFeeding arrangmentsMetallurgySlurry

The invention relates to a novel micro powder intelligent multi-pipe distribution full-body ceramic tile and a preparation method thereof. The preparation method includes the steps that basic slurry and color pulp are mixed, and color powder is made through spray drying; the color powder in different colors is delivered to a plurality of mixers to be stirred according to set proportions; the powder mixed in the mixers is discharged into a distributor through small distributing belts according to pre-set distributing procedures to be naturally piled to form a pattern, a wedge disc device with afreely controlled height is installed on the rear portion of the distributor, and backward displacement of the powder is restrained by adjusting the height distance from the wedge disc device to a large distributing belt; and the formed pattern powder is conveyed into a press mould frame, and compression moulding is conducted.

Owner:广东清远蒙娜丽莎建陶有限公司 +1

Nutrition-enriched recombinant translucent meat slices and preparation method thereof

The invention discloses nutrition-enriched recombinant translucent meat slices and a preparation method thereof. The translucent meat slices comprise the raw materials of meat stuffing, cane sugar, mixed powder of puffed peanut powder, puffed sesame powder and puffed tartary buckwheat flour or a pulp-powder mixture of mashed fruit and melon earthnut pulp and puffed tartary buckwheat flour, edible salt and food additives. The preparation method comprises the steps of mincing of meant, puffing, pulping, chopping, emulsifying, slicing of the quick-frozen meat and then curing, thus obtaining the recombinant translucent meat slices. The method is capable of preparing the translucent meat slices from the minced meat fully; tartary buckwheat, peanuts and semen sesami nigrum, or fruit and melon earthnut can be added into the meat slices as binding agent or seasoning materials, and the tartary buckwheat also covers meat taint, so that the prepared recombinant nutrition-enriched translucent meat slices are thicker in taste, and balanced and rich in nutrition; the preparation process is exquisite; and the types of products are varied to meet the requirements of different people. Besides, after being baked, the translucent meat slices are crisper, are more balanced in nutritional ingredient and do not generate harmful substances.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

Smokeless mirror face chemical polishing solution

The invention discloses a smokeless mirror face chemical polishing solution which is prepared from the following components in percentage by weight: 75-80% of phosphoric acid, 3-4% of sulfuric acid, 0.5-1% of a brightener, 0.8-1.2% of an oxidizing agent, 0.5-0.6% of a corrosion inhibitor, 0.1-0.3% of an accelerant, 0.05-0.07% of a catalyst and the balance of water. The smokeless mirror face chemical polishing solution in the polishing process does not generate any smoke, generates neither irritant nor potential toxic and harmful gas, and is free of environmental pollution. When the smokeless mirror face chemical polishing solution is used for polishing, the bright dipping speed is high, and the brightness value is nearly consistent with that of three-acid polishing. The smokeless mirror face chemical polishing solution is simple to operate, and in actual production, the relationship between temperature and time needs to be considered without considering other factors, so that the human cost of the manufacturer is lowered.

Owner:湖北安登环保科技有限公司

Metal powder coating and preparation process thereof

InactiveCN111218191ASimple preparation processIncrease productivityPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses a metal powder coating. The metal powder coating comprises, by weight, 30 parts of epoxy resin, 30 parts of polyester resin, 0.07 part of a wrinkling agent, 30 parts of a filler, 0.8 part of carbon black, 0.4 part of wax powder, base powder and a metallic pigment, wherein the ratio of the base powder to the metallic pigment is 1000:5. The invention also provides a preparation process of the metal powder coating. The preparation process of the metal powder coating is simple in flow, and effectively improves the production efficiency; and a molten material and the metallic pigment are mixed, so that the utilization rate of the metallic pigment is improved, the quality stability of the coating between batches is effectively ensured, and the textures of the wrinkle metal powder coating are consistent.

Owner:佛山市顺德区千之彩实业有限公司

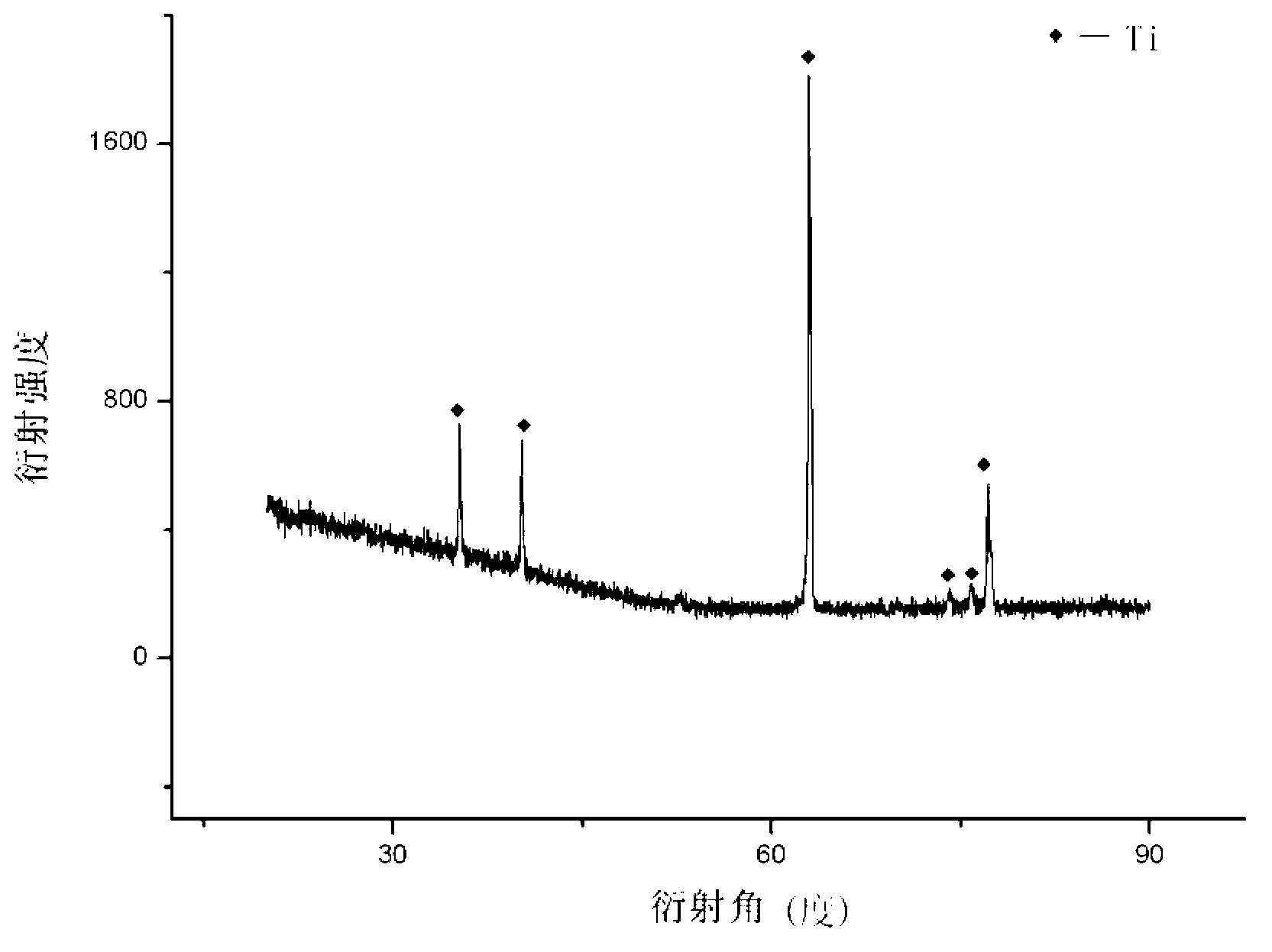

Method for preparing titanium metal coating on ceramic surface

The invention discloses a method for preparing a titanium metal coating on a ceramic surface. The method for preparing the titanium metal coating on the ceramic surface comprises the following steps of: firstly, placing ceramic the surface of which is treated into a quartz tube; then placing a mixture of titanium powder and iodine powder into a container, and placing the container into the quartz tube; then placing the quartz tube into a program control furnace, vacuumizing the program control furnace repeatedly, and introducing an inert gas, warming the program control furnace at the warming speed of 15-20 DEG C / min to 1030-1200 DEG C and carrying out heat preservation, and cooling, thereby obtaining the ceramic the surface of which is coated with the metal coating. The coating provided by the invention is high in purity, and has strong bonding force with base body ceramic, is uniform in distribution on the whole ceramic plane, can form a smooth deposition surface easily; and the device is simple, low in cost and simple to operate.

Owner:CHANGAN UNIV

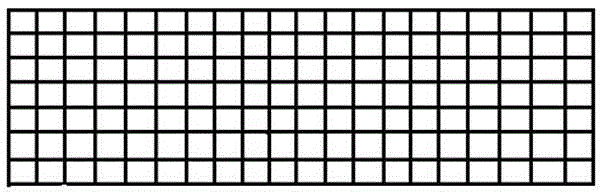

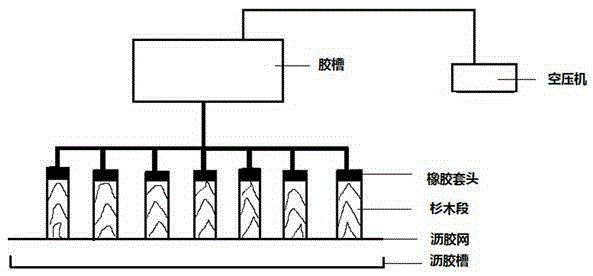

A processing method for making imitation cypress material from Chinese fir

InactiveCN104002345BHigh hardnessHigh densityWood treatment detailsPressure impregnationEngineeringWater soluble

The invention provides a processing method for manufacturing an imitated cupressus funebris material by utilizing Chinese fir. The processing method comprises a cutting technology for Chinese fir logs, a standing tree pressurization and perfusion technology, a non-defect curing technology for the Chinese fir logs infused with phenolic resin, a flat-sawn board lumber making technology of the cured Chinese fir logs and a repair technology, wherein the standing tree pressurization and perfusion technology comprises the following steps: fixing a homemade rubber sleeve to one end of the Chinese fir; connecting the other end of the rubber sleeve to an air compressor and pressurizing the inside of the rubber sleeve after adding the water-soluble phenolic resin in the other end of the rubber sleeve, wherein the water-soluble phenolic resin enters from one end of the Chinese fir log under the action of pressure and flows out from the other end of the Chinese fir log after penetrating through the overall Chinese fir, so that the aim of impregnating quickly is fulfilled. The imitated cupressus funebris material manufactured by the processing method has the characteristics that the wood is hard, the hardness is high, the density is high, the textures are consistent with that of cupressus funebris; moreover, the cedar resources are rich, the raw material source is wide, and the cost is low, so that the cost of the imitated cupressus funebris material is greatly reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

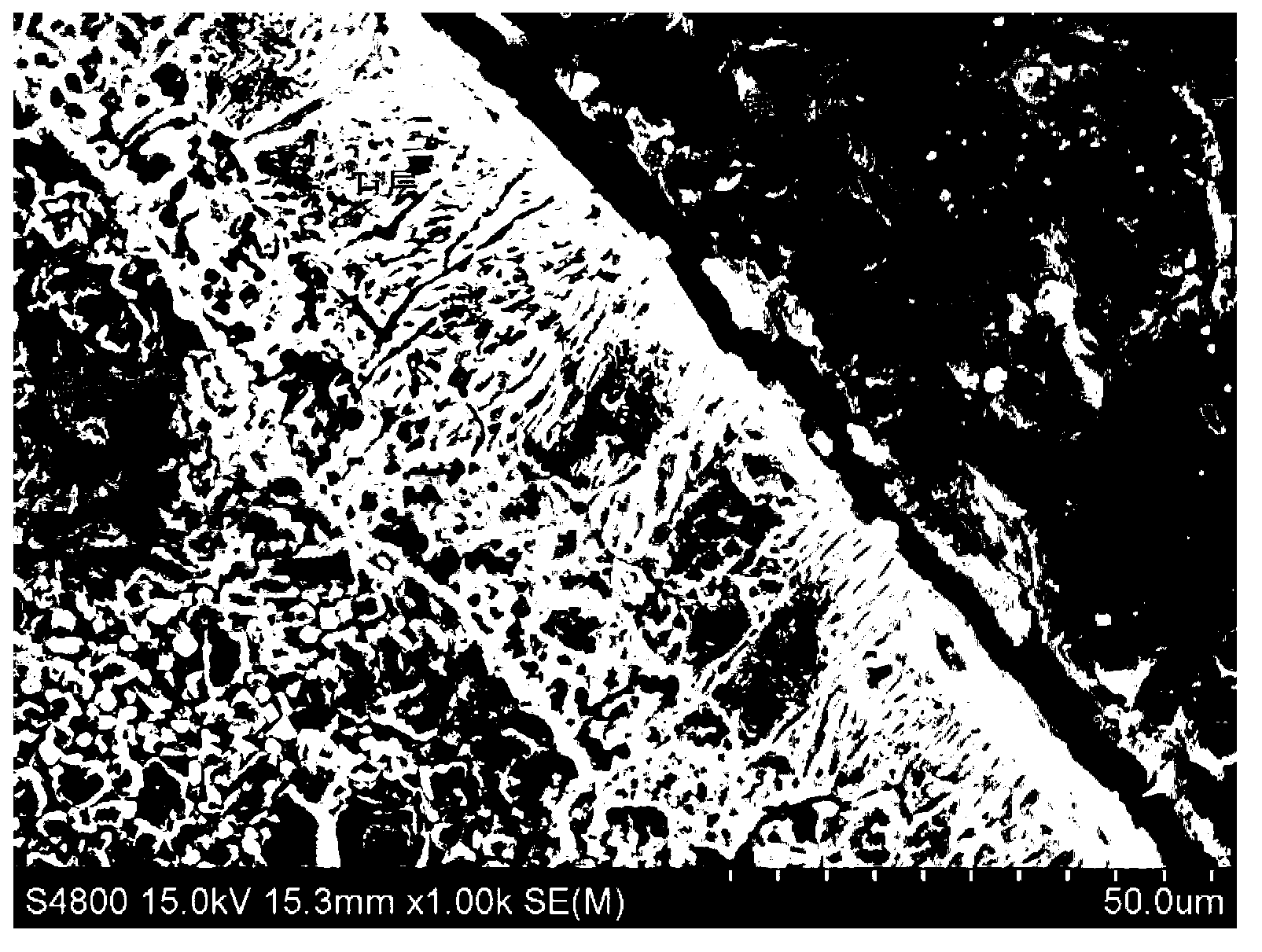

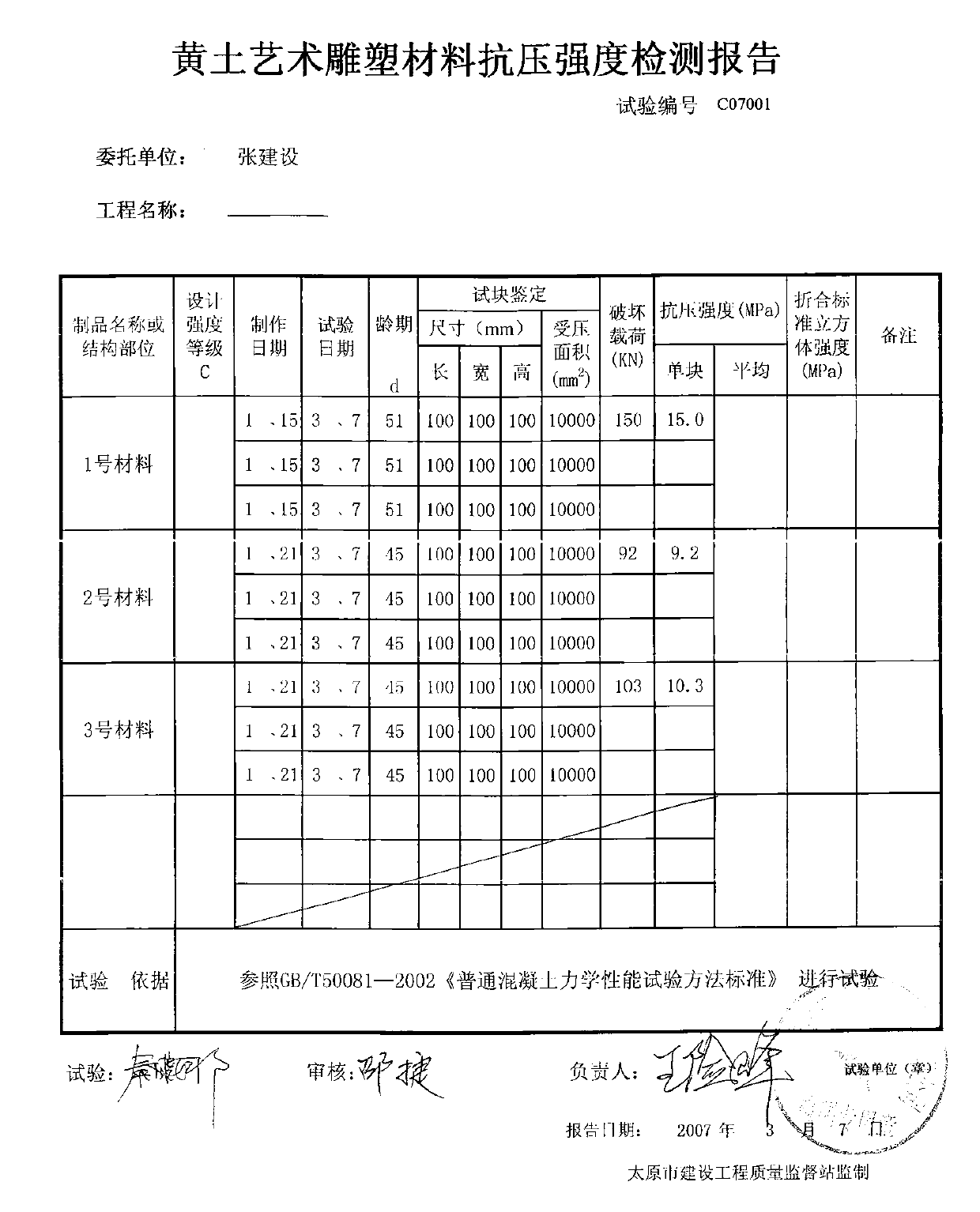

Sculpture material containing loess

The invention relates to a soil sculpture material, specifically to a sculpture material containing loess. The sculpture material is prepared from the following raw materials by weight: 100 parts of loess with a granularity of 90 to 150 meshes, 25 to 30 parts of magnesium oxide powder and a magnesium chloride solution with a Baume degree of 25 to 35, wherein a ratio of the total volume of the loess and the magnesium oxide powder to the volume of the magnesium chloride solution is 1: 0.28-0.32. The sculpture material containing loess provided by the invention has the advantages of fine texture, convenience in sculpturing, consistency of interior and exterior texture, no local loose and soft part in the center of the material, no cracking, no falling of dregs, no collapse, rain resistance, good up-rightness, small drying shrinkage, excellent low temperature resistance and flame resistance, compressive strength of more than 9 MPa, which is close to the hardness of No. 250 cement, low cost, easy operation and good practicality; and the sculpture material is applicable to manufacturing of outdoor large-scale sculpture works, soil sculptures, embossments and soil sculpture revetments and plays an active role in promotion of regional culture activities with Chinese characteristics.

Owner:ZHONGBEI UNIV

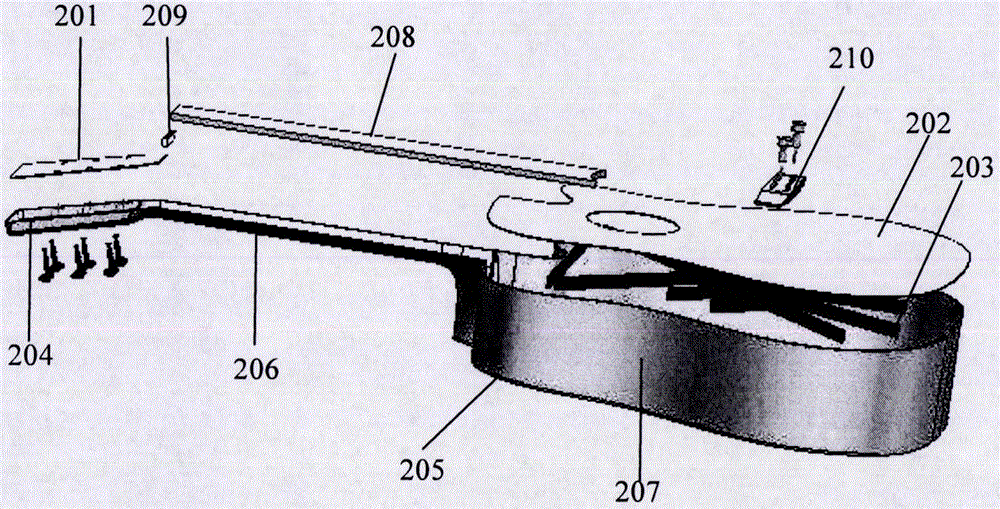

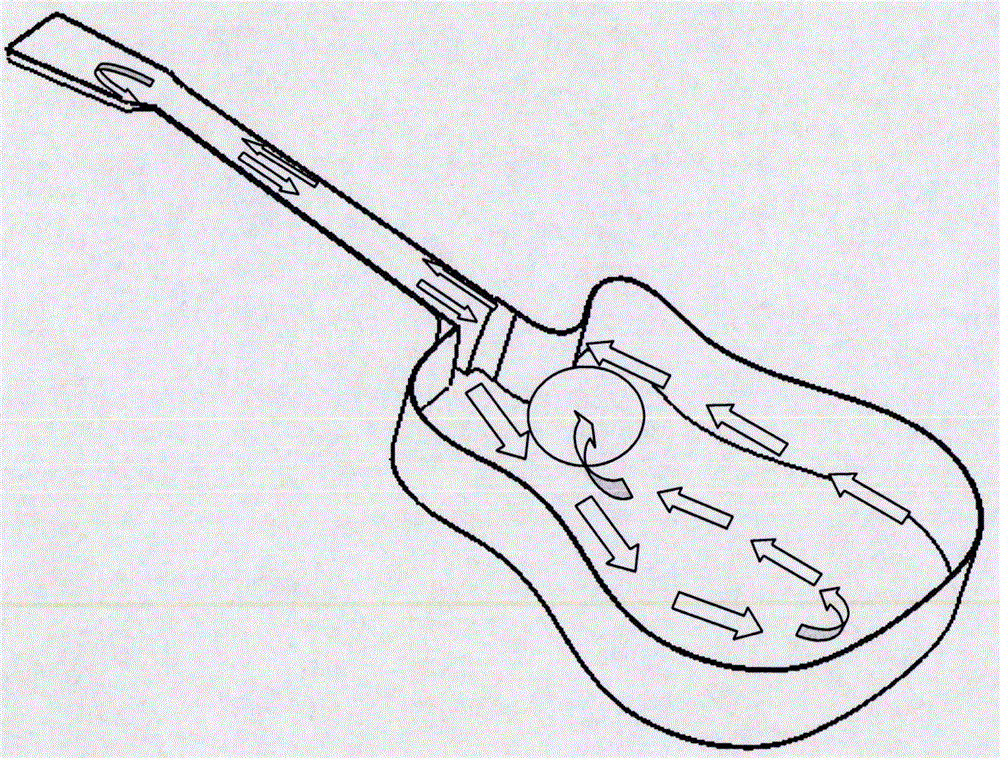

Carbon fiber guitar and making method thereof

The invention discloses a carbon fiber guitar and a making method thereof. The carbon fiber guitar comprises a carbon fiber guitar body, a carbon fiber sound beam, a carbon fiber panel and a carbon fiber guitar head cover board; the carbon fiber guitar body is formed by a guitar body, a guitar neck, side boards and a back board in an integrated mode, the carbon fiber sound beam adheres to the carbon fiber panel, and the carbon fiber panel adheres to the carbon fiber guitar body; the guitar head and the guitar neck are hollow thin-wall components and are each communicated with a resonating body formed by the side boards, the back board and the panel. The carbon fiber guitar is not affected by temperature and humidity, has good conductivity of panel vibration, and is easy to maintain, good in sound ductility, larger in sound volume, higher in resonance intensity, bold in sound and longer in fermata.

Owner:李焕强

Integral abrasion resistant anti-ageing comb-shaped carrier roller for belt conveyer

InactiveCN105858113AExcellent contact sports performanceImprove sealingRollersAdhesive beltEngineering

Owner:云南小龙潭矿务局有限责任公司机修分公司

Porcelain tile adopting micro-powder composite ink-jet positioning dry particle process and preparation method of porcelain tile

The invention discloses a porcelain tile adopting a micro-powder composite ink-jet positioning dry particle process and a preparation method of the porcelain tile. The preparation method comprises thefollowing steps: (1) carrying out fixed-point and fixed-position material distributing on a micro-powder surface material, and carrying out reverse beating and compression molding to prepare a micro-powder green brick with natural stone-like textures; (2) polishing and cutting the micro-powder green brick; (3) designing a decorative pattern, and printing the decorative pattern on the surface of the polished micro-powder green brick in an ink-jet mode; (4) printing a fixing agent on the surface of the green brick according to the decorative pattern, then applying dry particles, adhering the dry particles by utilizing the fixing agent, and removing the dry particles which are not fixed to form an effect that the dry particles exist on the decorative pattern; (5) applying wear-resistant matte transparent glaze to the surface of the green brick; and (6) firing the green brick coated with the wear-resistant matte transparent glaze to obtain the porcelain adopting the micro-powder compositeink-jet positioning dry particle process.

Owner:广东清远蒙娜丽莎建陶有限公司

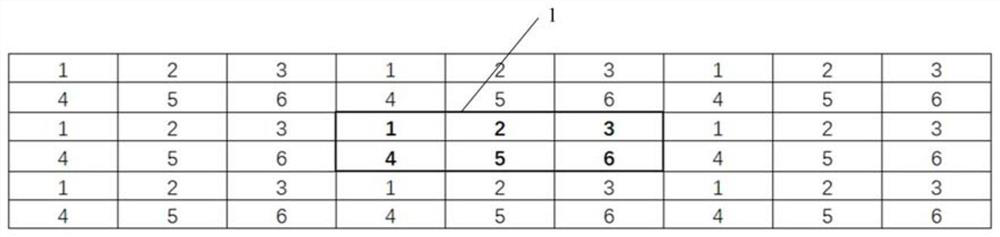

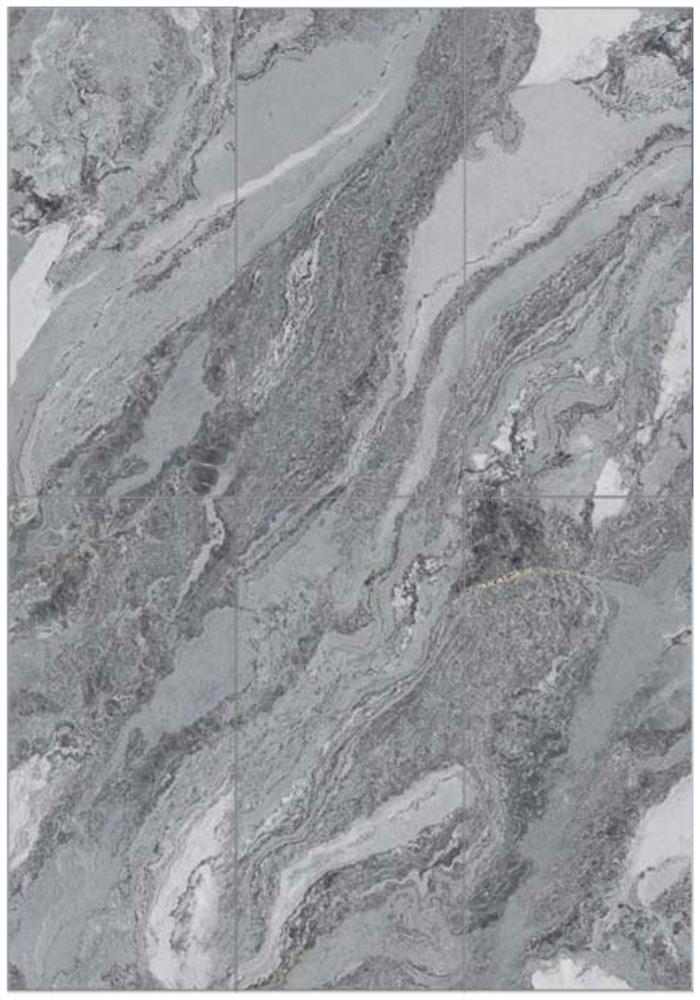

Production method of close-joint grain-connection super-wear-resistant diamond glaze marble ceramic tile and ceramic tile

InactiveCN112592159AConsistent textureControl deformationDuplicating/marking methodsPattern printingCeramic tilesMetallurgy

The invention discloses a production method of a close-joint grain-connection super-wear-resistant diamond glaze marble ceramic tile and ceramic tile, which comprises the following steps: acquiring acontinuous-grain image on a stone material, and segmenting the continuous-grain image into n design drawings; layering each design drawing according to different colors to obtain a plurality of printing drawings; obtaining a ceramic tile green body, and printing the ith design drawing on the ceramic tile green body by adopting an ink-jet printer; sequentially printing a plurality of printing patterns on the surface of the ceramic tile green body by adopting a screen printer; and then applying glaze, firing, edging and polishing to obtain a finished product of the non-limited-connection-grain close-joint super-wear-resistant diamond glaze paving brick. Correspondingly, the invention further discloses the ceramic tile. By implementing the method, the non-limited close-joint super-wear-resistant diamond glaze paving brick with the interlaced deviation within 0.3 mm can be obtained, the paving effect of the brick is more similar to that of natural marble, and the decorative effect is effectively improved.

Owner:佛山市大角鹿大理石瓷砖有限公司

Method for producing snack colored snapper fillets

InactiveCN103719939AEvenly bakedNo bone spursFood thermal treatmentFood dryingBiotechnologyFish Flavor

The invention relates to a method for producing snack colored snapper fillets. The method comprises the steps of selecting materials, segmenting, slicing, salting, carrying out heat-pump cold-air drying, carrying out light-wave and microwave balanced baking, carrying out vacuum packaging and sterilizing. The method comprises the following specific steps: removing the heads, internal organs, skin and fishbone of colored snappers, which serve as raw materials, segmenting to obtain fish flesh, segmenting to obtain small fillets, uniformly mixing the small fillets and a salting material, then, placing in a material bucket, and salting for 16-20 hours; placing the salted small fillets on a screen mesh, horizontally placing the screen mesh on a smoking vehicle, and pushing the vehicle into a storehouse for heat-pump cold-air drying; feeding the fillets subjected to cold-air drying in a box-type microwave oven, baking with the combination of microwaves and light waves, firstly baking with the light waves for 60 seconds, and then, simultaneously baking with the light waves and the microwaves for 150 seconds; finally, carrying out vacuum packaging and sterilizing, thereby obtaining the snack colored snapper fillets. The obtained snack colored snapper fillets are uniform in inside / outside baking, consistent in texture, rich in nutrition and strong in grilled fish flavor, are elastic, crispy and chewy and are free from fishbone.

Owner:湖南唐人神西式肉制品有限公司

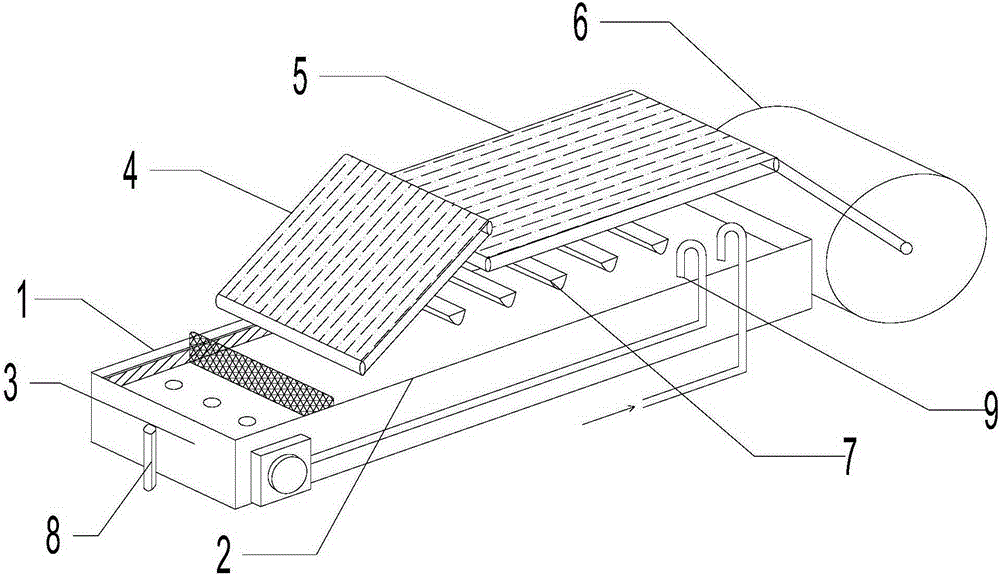

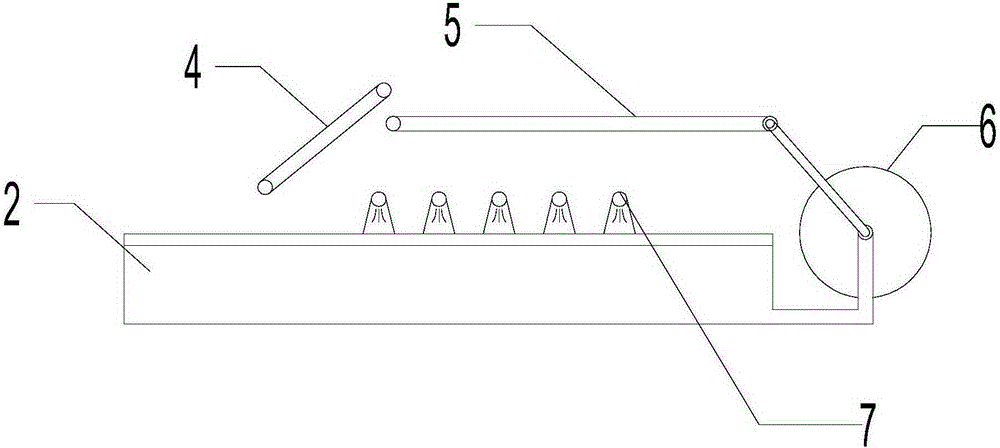

Automatic beancurd sheet production machine with blowing pipes

InactiveCN106689401AMake up timeMake up for the human factorCheese manufactureFood scienceEngineeringCirculating pump

The embodiments of the invention disclose an automatic beancurd sheet production machine with blowing pipes. The machine consists of a machine frame, a water tank, a milk tank, a soybean milk circulating pump, a cooling water tank, the blowing pipes, a beancurd sheet collecting drum and a conveying belt. According to the production machine capable of automatically producing beancurd sheets, disclosed by the embodiments of the invention, beancurd sheets formed in the milk tank can be picked continuously without stopping and waiting for beancurd sheet forming, can be air-dried through naturally absorbing residual heat of the milk tank on the conveying belt of the machine frame just like original manual operations and are cut and packaged, so that automatic continuous operation is achieved, the work efficiency of production is increased, the cost is reduced, the consistency of texture is guaranteed, and the defect that skilled workers need long-time training, and artificial factors are made up.

Owner:HONGXING ENTERPRISE CO LTD

Flavor stewed meat processing method

InactiveCN107668532AReduce internal energyReduce the temperatureMeat/fish preservation by freezing/coolingLow temperature curingEngineering

The invention discloses a flavor stewed meat processing method which includes the steps: curing meat for 1-1.5 hours at the temperature of 4-6 DEG C, and soaking the cured meat for 35-38 hours; performing breathing type massage in a vacuum massager; adding seasonings and water to boil; rapidly transferring the high-temperature cooked meat and soup into a vacuum cooling box, and performing vacuum cooling; draining and cooling the cooked meat, and performing vacuum packaging; storing the packaged meat at the temperature ranging from -2 DEG C to -3 DEG C. According to the method, cooling time canbe remarkably shortened, growth and reproduction of microorganisms are furthest restrained, sanitation and flavor of stewed meat are kept, expiration date of the stewed meat is prolonged, refrigerating temperature ranges from -2 DEG C to -3 DEG C, freshness and original flavor of stewed meat products are maintained, vacuum cooling of the stewed meat products and the soup is performed together, taste of the products is purer and stronger, the meat is cured at the lower temperature, curing liquid is not easily acetified and the like, original flavor is kept, cured meat is sufficiently massaged,textures of the stewed meat products are consistent, the flavor stewed meat is fresh and tender in texture, uniform in color and pure in taste.

Owner:邛崃市桑园宏吉果蔬种植专业合作社

Process for making knitted hat

The invention relates to a process for making a knitted hat. The making process comprises the following specific steps: (1) waxing, namely winding and waxing single yarns for 2-3 times, so that the yarns can be uniformly coated with the wax; (2) twisting, namely doubling and reversely twisting the waxed 2-4 strands of single yarns, and forming yarns with the twist of 110-120; (3) knitting, namely knitting by using a computer knitting machine of 12-14 needles, and reasonably performing jacquard weaving according to color selection after weaving; (4) sewing, namely sewing hat pieces by adopting polyester threads, and fixing the crown according to the requirements; (5) after-finishing, namely covering the sewed hat by a setting plate, pressing at the temperature of 90-120 DEG C, sucking steam to dry and setting the hat. The process disclosed by the invention has the advantages that according to the making process disclosed by the invention, the made knitted hat has the advantages of lightness and thinness, breathability and the like on the basis of heat insulation.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

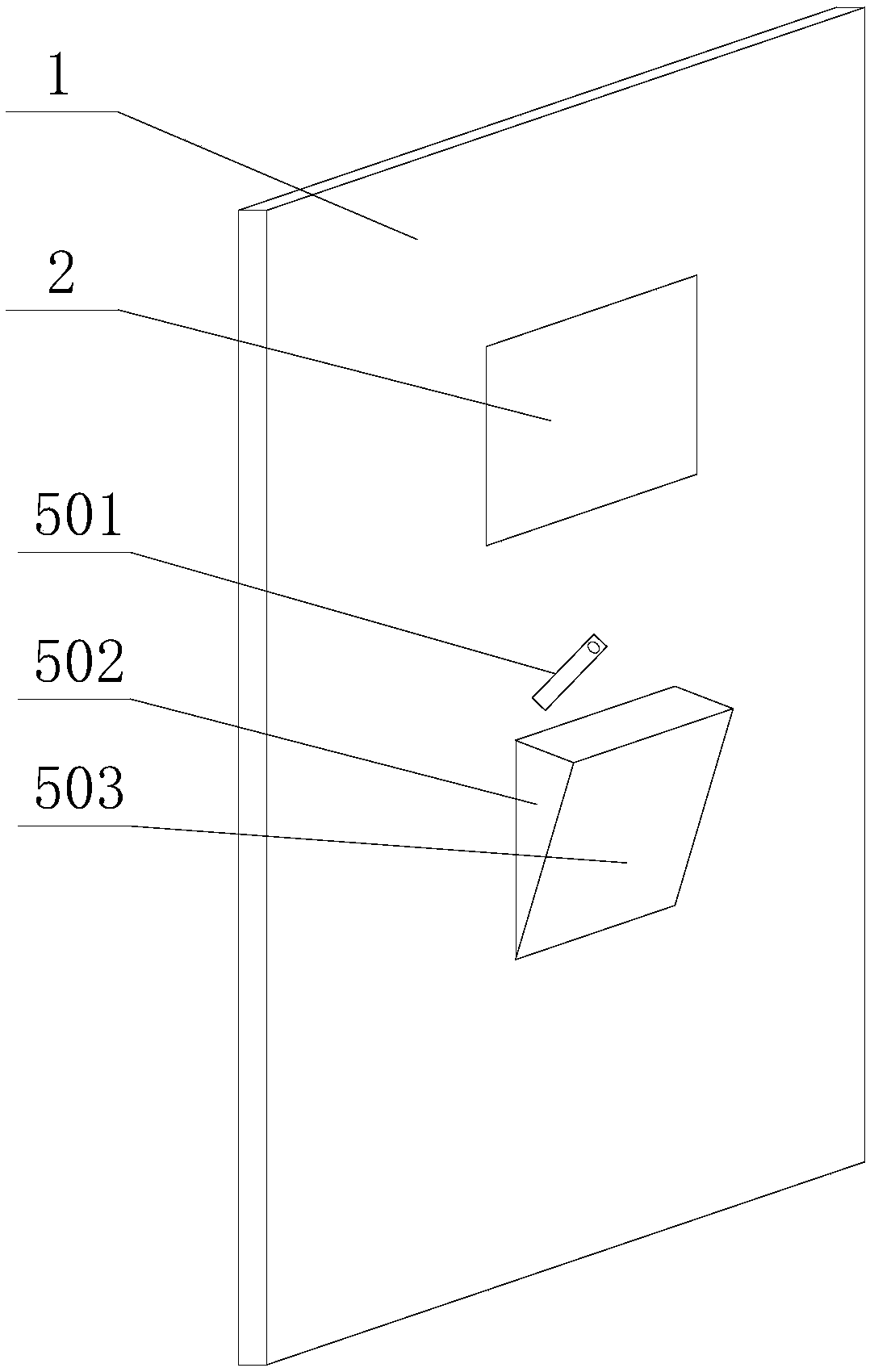

Novel bathroom door

InactiveCN108060875ANice appearanceConsistent textureFireproof doorsNoise insulation doors/windowsEngineeringElectrical and Electronics engineering

The invention relates to the technical field of bathroom doors, in particular to a novel bathroom door. The novel bathroom door comprises a door panel and a door frame, one side of the door panel is hinged to the door frame, and a handle is arranged on the door panel. The door panel comprise an aerogel layer, a foam metal layer and a wood plate layer. The foam metal layer is arranged between the aerogel layer and the wood plate layer. The purpose of the novel bathroom layer is to solve the problems that an existing bathroom door is poor in damp prevention and sound insulation effect.

Owner:广东横琴粤澳深度合作区华发七弦琴知识产权运营服务有限公司

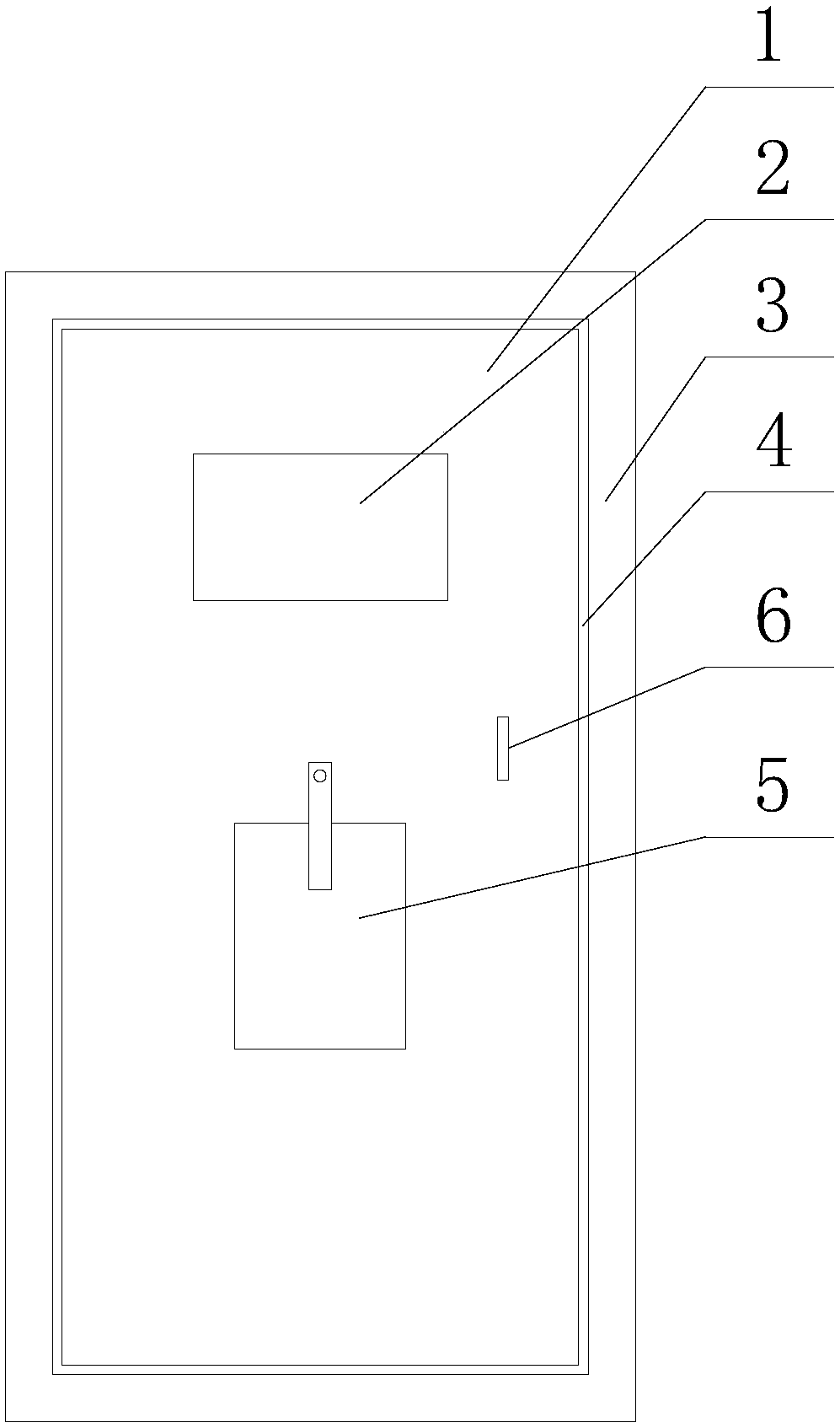

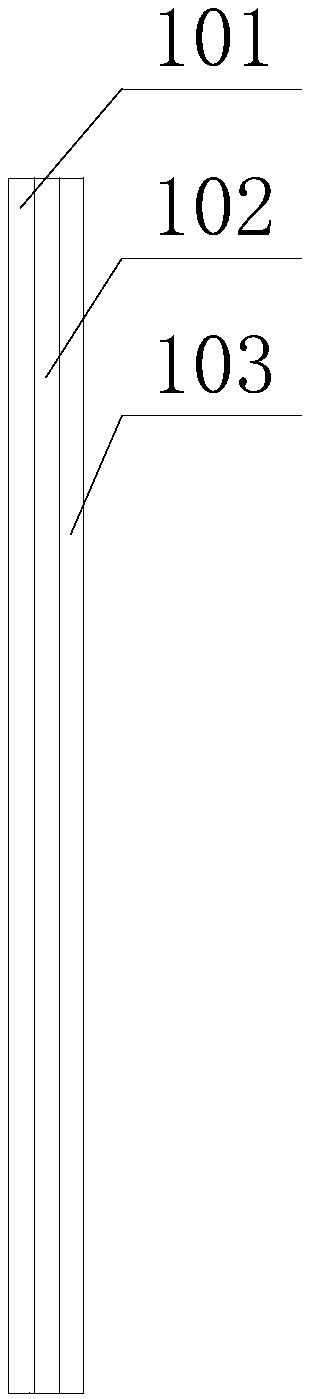

Manufacturing method of instrument warm box

Disclosed is a manufacturing method of an instrument warm box. Hot press molding is carried out on a sheet, and a main body of a box body and a main body of a box door are manufactured; the main body of the box body and the main body of the box door are put into corresponding foamed moulds respectively, and aluminum foil film layers are attached to the outer surfaces of core moulds of the foamed moulds; a foaming machine is used for manufacturing the box body with a warm layer and the box door with a warm layer through a polyurethane foaming technology, and then, the box body and the box door are assembled into a finished product; and the sheet is formed by sequentially arranging a C layer, a D layer and a C layer, wherein the C layers are short glass fiber reinforced unsaturated polyester resin composite material layers, and the D layer is a copper wire mesh layer with the wire diameter ranging from 0.3mm to 0.7mm.

Owner:吉林市吉化北方华丰仪表有限公司

Preparation technology of microcrystallized glass-ceramic composite plate as bench surface in kitchen or bathroom

The invention discloses a preparation technology of a microcrystallized glass-ceramic composite plate as a bench surface in a kitchen or a bathroom. The preparation technology comprises weighing 55-63% of SiO2, 5-7% of Al2O3, 15-16% of CaO, 3-6% of ZnO, 2-5% of Na2O, 4-5% of CaF2 and 1-3% of B2O3, mixing the materials to obtain a uniform mixture, putting the mixture into a high-alumina crucible, putting the high-alumina crucible into a silicon-molybdenum furnace, carrying out heating to a temperature of 1480 DEG C, carrying out thermal insulation for 2h to obtain melt glass, pouring the melt glass onto a preheated flat iron plate, pressing the glass liquid through the iron plate to obtain a thin sheet with the thickness of 3-5mm, putting the thin sheet into a furnace at a temperature of 620-630 DEG C, carrying out annealing for 0.5h, carrying out cooling, putting the thin glass sheet on a common vitrified brick, putting the vitrified brick with the thin glass sheet into a high temperature furnace, carrying out coring and crystallization so that the glass sheet is firmly bonded to the base and carrying out cooling. The preparation technology has less steps, a low cost and a high microcrystalline layer crystallization rate. The microcrystallized glass-ceramic composite plate does not produce granular sensation and has high bonding strength, high strength and high hardness.

Owner:李林君

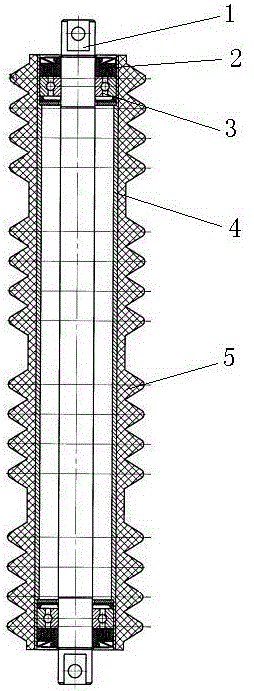

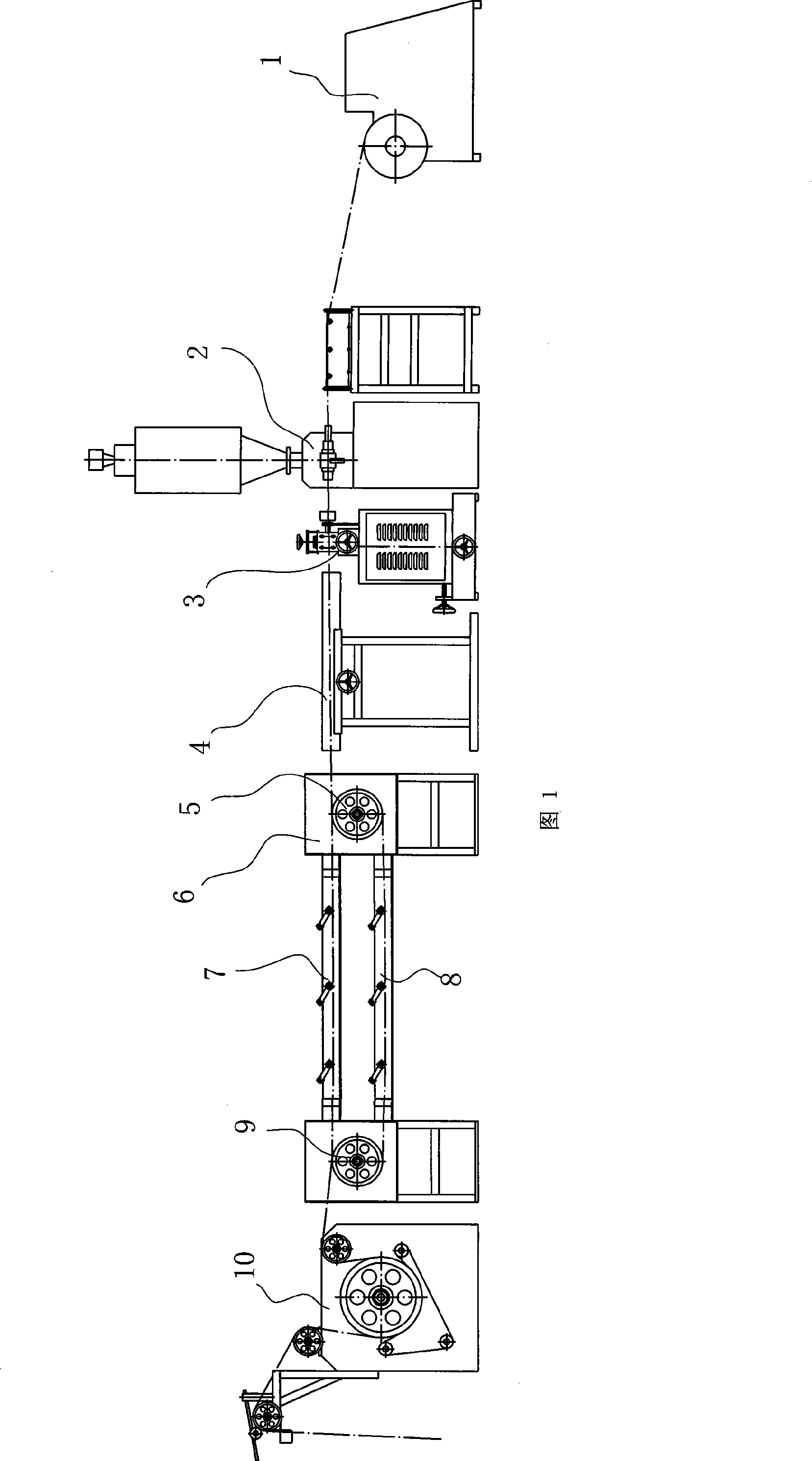

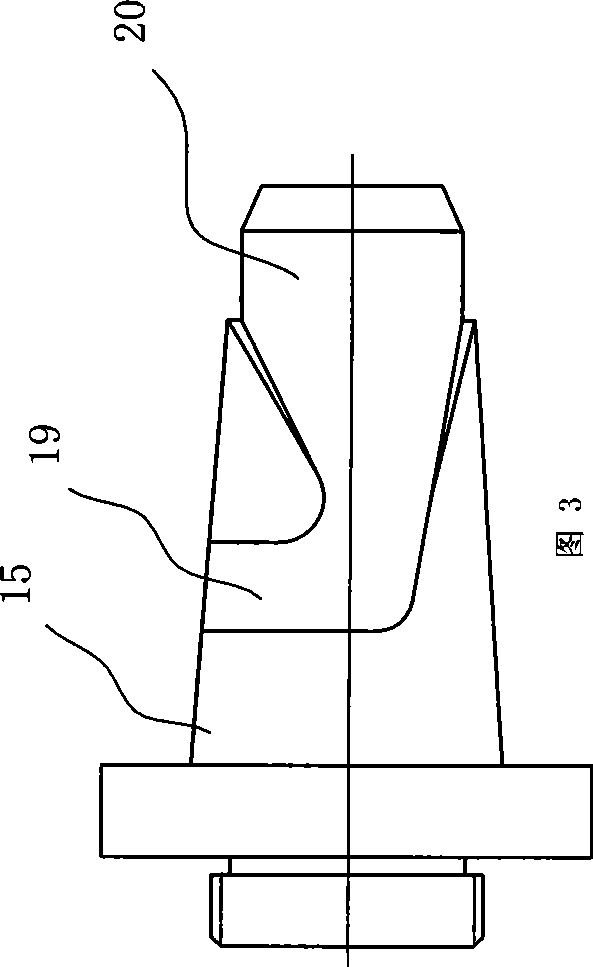

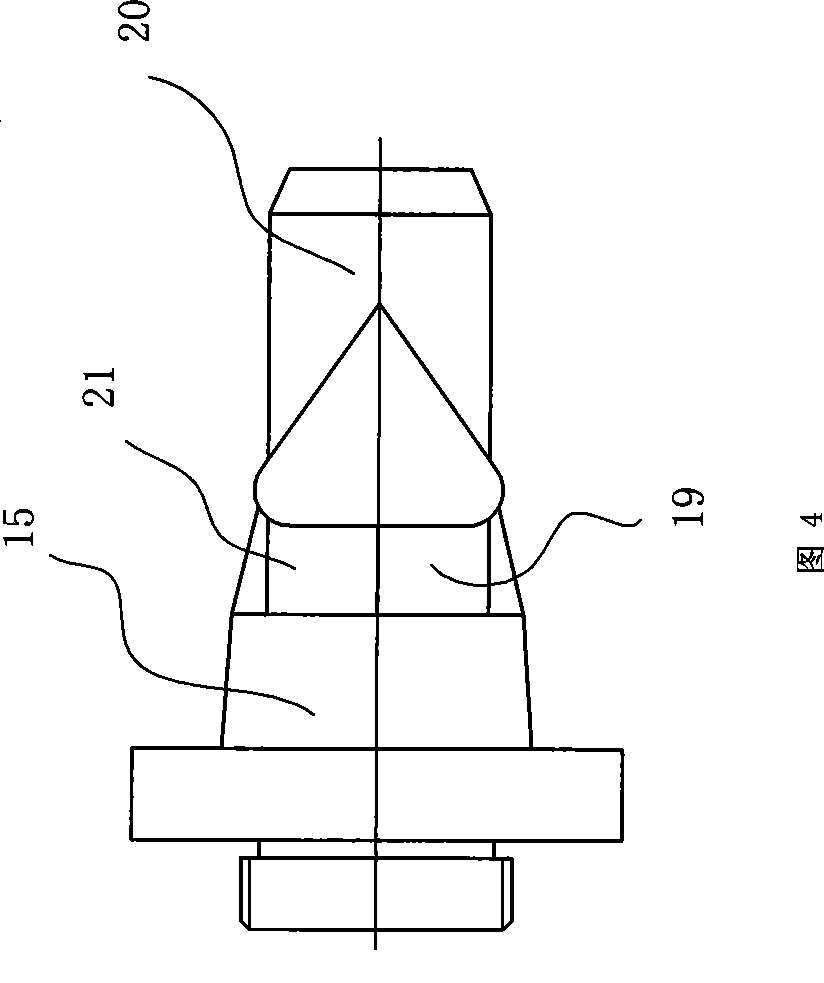

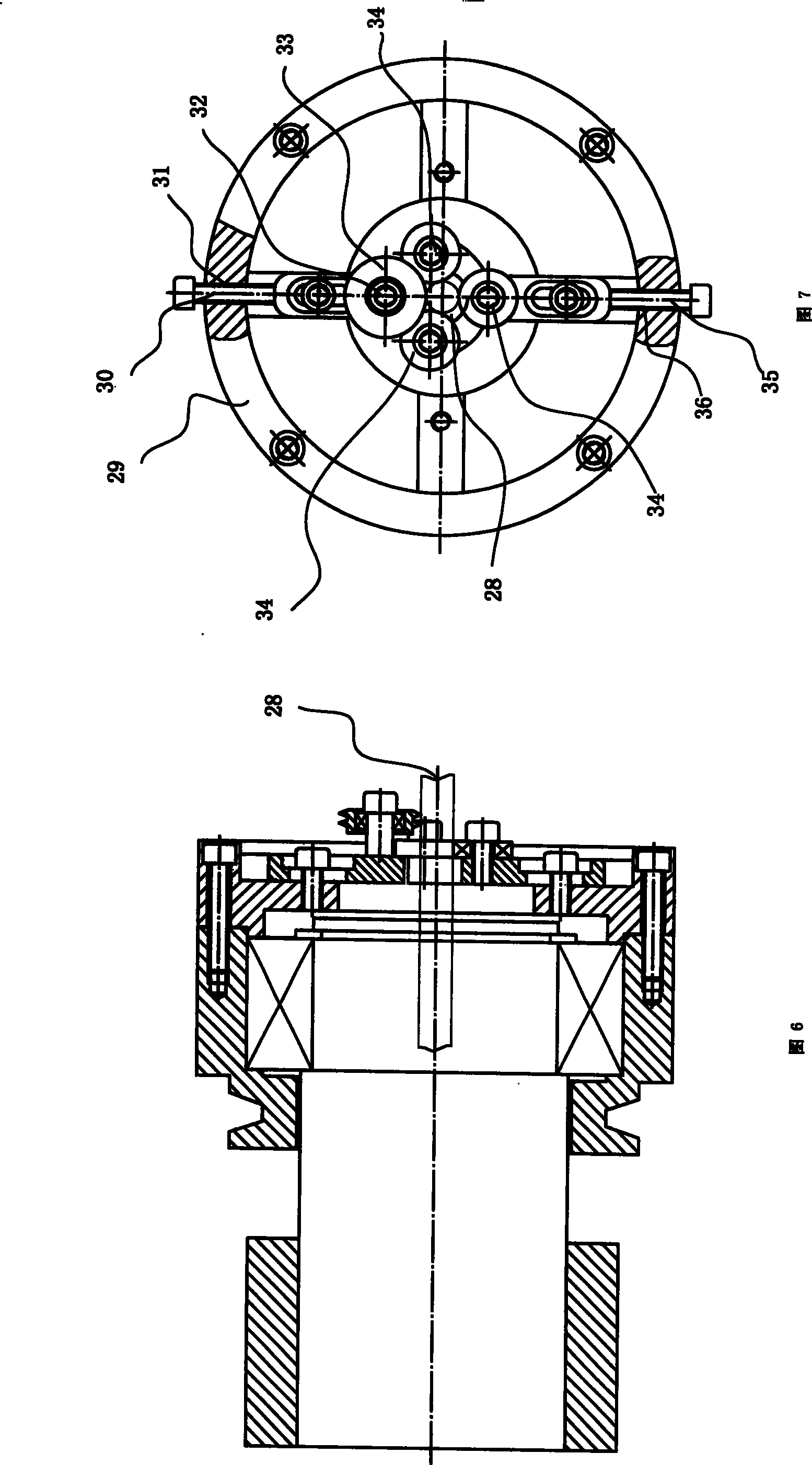

Manufacture equipment of rainbow tube

InactiveCN101398137ASolve the blockageSolve efficiency problemsPoint-like light sourceElectric lightingRainbowEngineering

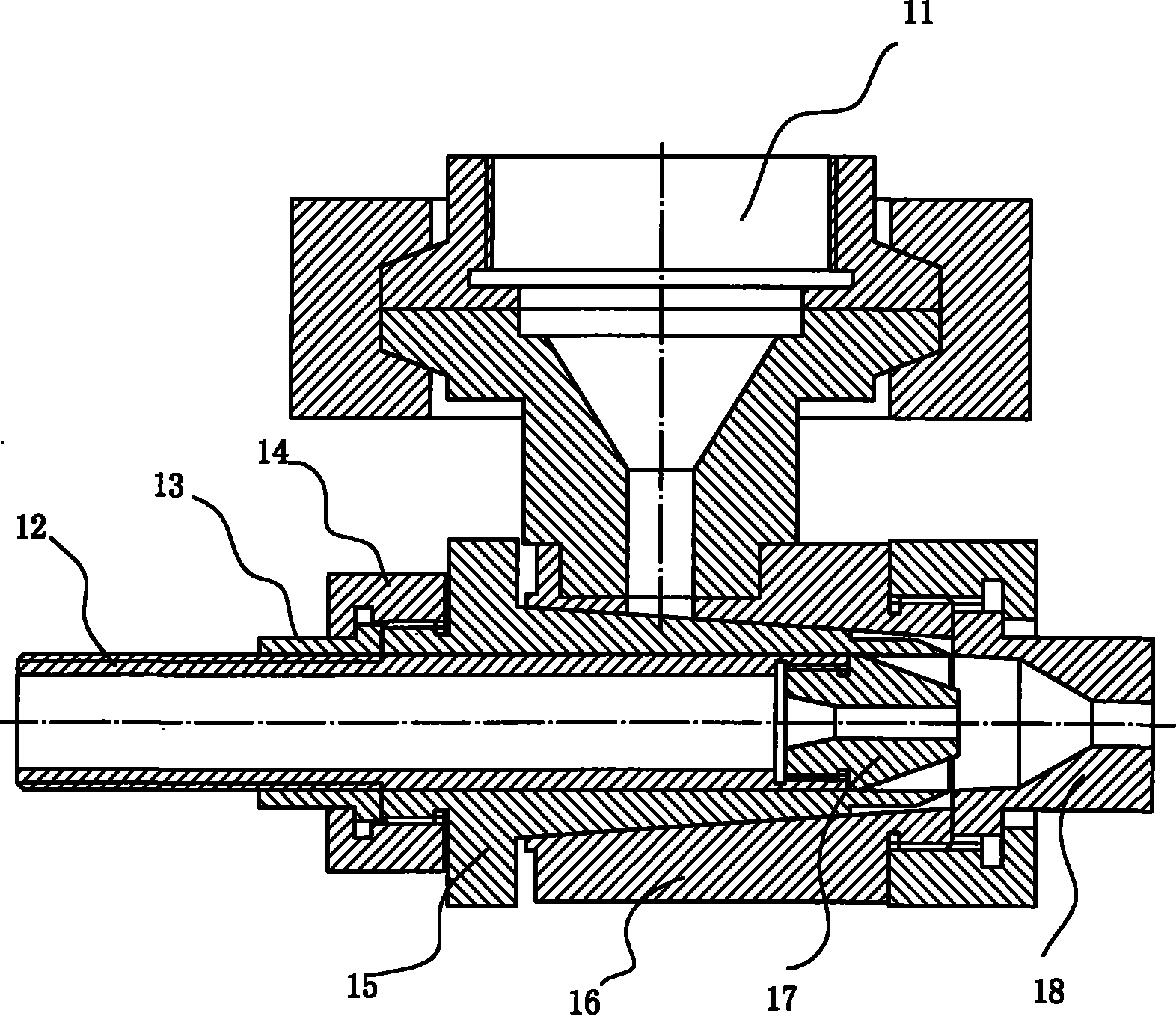

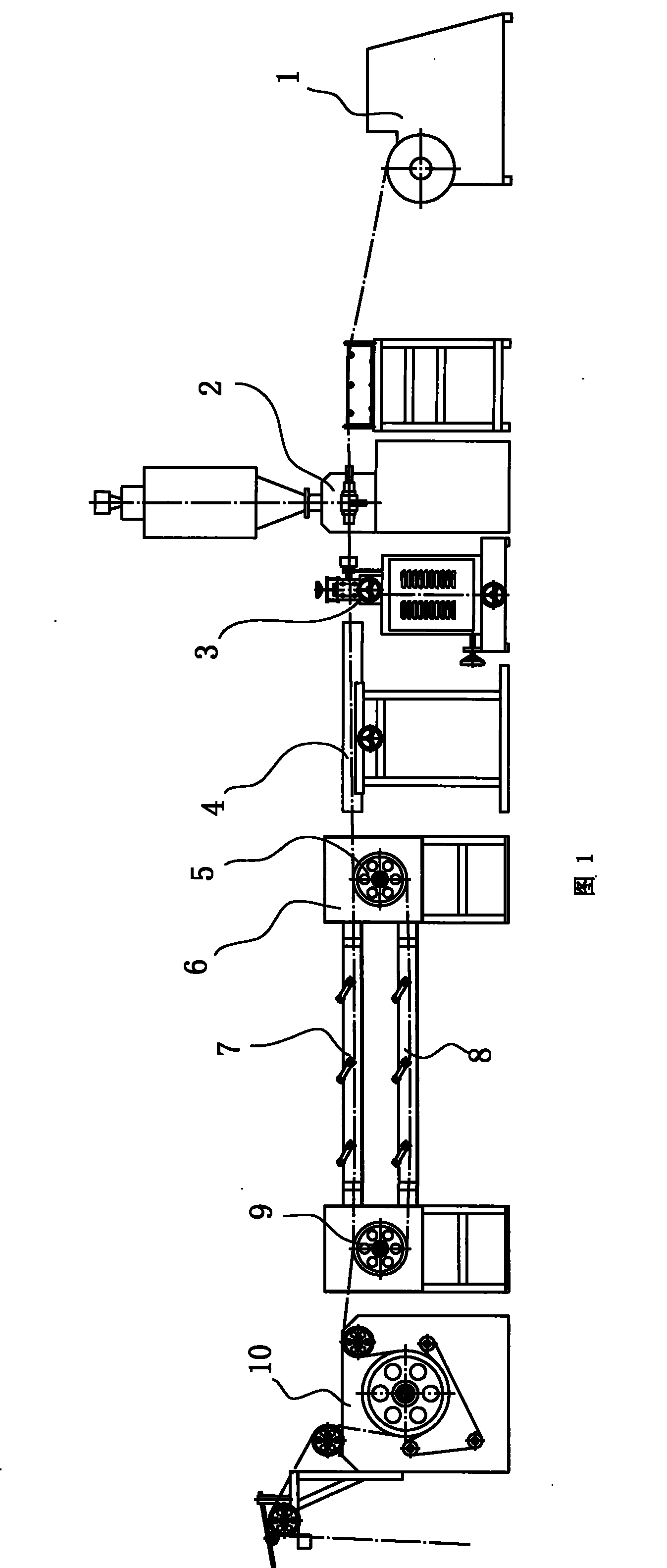

The invention discloses manufacturing equipment of a rainbow tube, which is primarily characterized in that: a die head comprises an aligning shaft (12), a die core (15), a die barrel (16), inner core positioning dies (17) and dies (18), wherein, the die core is sheathed on the aligning shaft and sheathed into the die barrel, the inner core positioning dies are installed on the die core detachably, the dies are installed on the core barrel detachably, the die barrel is connected and communicated with a feed barrel of an extruder through a discharge port, two diffluent channels (19 and 21) are arranged on the die core, an included angle is formed by the two diffluent channels, the entry ends of the two diffluent channels are connected and communicated with the feed barrel through a through hole and the discharge port on the die barrel, and the exit ends of the two diffluent channels are connected and communicated with the channels of the dies. The inner core and outer sheath of the rainbow tube can be completed together on a set of equipment only by changing the inner core positioning dies and dies with different calibers as the detachable inner core positioning dies and dies are adopted, furthermore, plastics are not easy to stack in the die head, thus being characterized by quick discharge and high production efficiency.

Owner:温州岳虹塑料机械有限公司

Production process of chest of drawers

The invention discloses a production process of a chest of drawers and relates to the field of furniture production. According to the production process of the chest of drawers, long connection and wide connection cutting is adopted, a raw material can be used more reasonably, it can be guaranteed that the color difference and the grains of a product are consistent, no large error is caused, a basis is provided for matched machining of a rear segment, and the production efficiency is improved.

Owner:安徽中至信家居有限公司

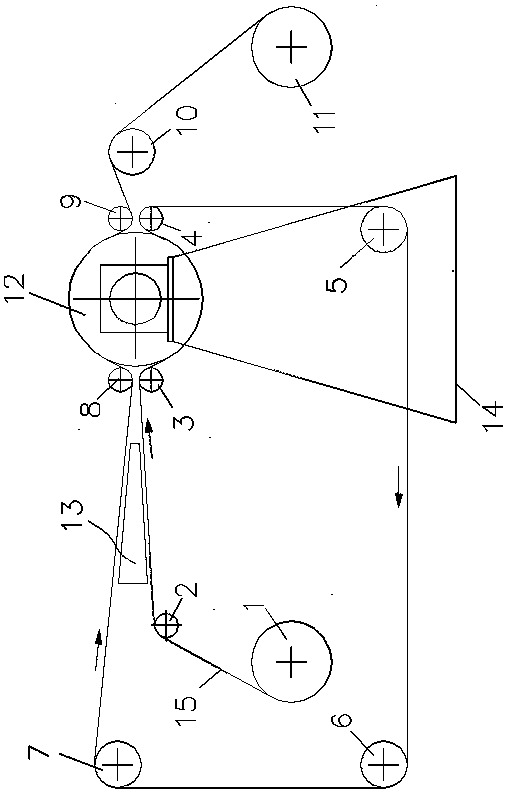

A double-sided texture machine for producing artificial leather

ActiveCN106245344BFew partsReduce manufacturing costTextiles and paperEngineeringMechanical engineering

The invention relates to a double-side pattern making machine for artificial leather production. The double-side pattern making machine comprises a negative-pressure pattern pressing roller, a feeding roller, a receiving roller, guide-in rollers, guide-out rollers, a heater, a frame, a transmission device for driving the rollers and a group of turning guide rollers. An artificial leather material on the feeding roller attaches to the lower half of the negative-pressure pattern pressing roller through a feeding guide roller, an A-side first guide-in roller and an A-side first guide-out roller so as to form patterns on the A side of the artificial leather material. The artificial leather material output by the A-side first guide-out roller enters a B-side first guide-in roller through the turning guide rollers to allow the artificial leather material to attach to the upper half of the negative-pressure pattern pressing roller in a negative pressure manner so as to form the patterns on the B side of the artificial leather material. The double-side pattern making machine has the advantages that the double-side pattern pressing of the artificial leather material is achieved by one negative-pressure pattern pressing roller, main parts are reduced evidently, production cost is lowered evidently, popularization is benefited, and the double-side pattern making machine is convenient to mount and maintain.

Owner:浙江利盛包装科技有限公司

A kind of preparation method of recreational colored sea bream fillets

InactiveCN103719939BConsistent textureFull of nutritionFood thermal treatmentFood dryingBiotechnologyFish Flavor

Owner:湖南唐人神西式肉制品有限公司

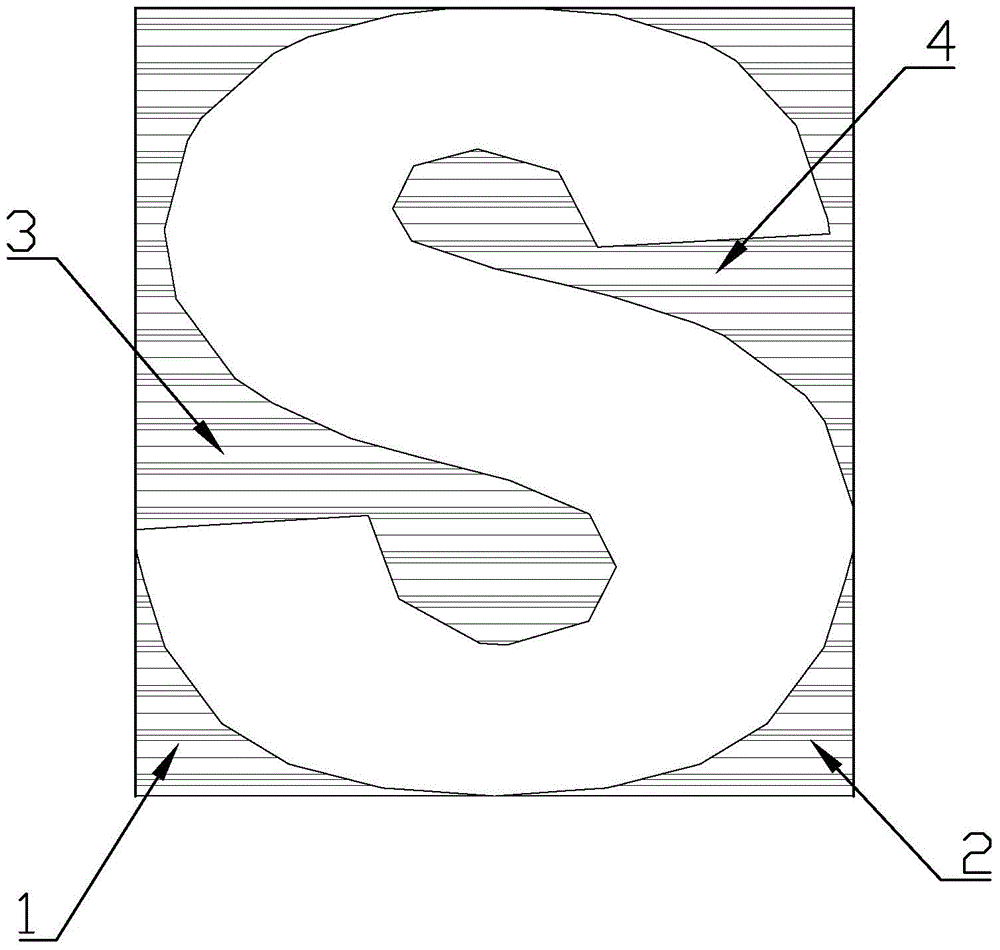

A construction method for large-scale hollowed-out characters on cast-in-situ concrete walls

ActiveCN103556822BRealize cast-in-place processConsistent colorWallsSpecial ornamental structuresMaterials scienceBuilding construction

The invention discloses a construction method of large hollowed-out characters of a cast-in-place concrete wall. The construction method of the large hollowed-out characters of the cast-in-place concrete wall achieves the cast-in-place process of the hollowed-out characters by arranging special-shaped steel die blocks in reserved holes of a cast concrete wall surface, positioning and arranging the special-shaped steel die blocks to be a needed hollowed-out character frame, welding and fixing iron sheet sealing dies along the side end surface of the hollowed-out character frame, sealing two outside surfaces of every special-shaped steel die block with timber formworks so that a closed casting space is formed among the timber formworks, the iron sheet sealing dies and the cast concrete wall surface, and casting concrete into the casting space through a feed opening. Plastering and construction of the facing of the wall surface are performed sequentially and synchronously on the cast concrete wall surface and a cast hollowed-out character region so that the uniformity of the color and the texture of the exterior facing can be guaranteed.

Owner:深圳市建工集团股份有限公司

Method for preparing yellow jade marrow by optimizing grey white jade marrow

The invention provides a method for preparing yellow jade marrow by optimizing grey jade marrow, and belongs to the technical field of gemstone processing. The method comprises the following steps of: heating and soaking a grey jade marrow raw material in an acid solution; taking out the grey jade marrow raw material and putting the same into a muffle furnace, heating the material at normal pressure and performing heat preservation; after finishing the treatment, naturally cooling the muffle furnace to room temperature; and obtaining yellow jade marrow. According to the method, a mode of carrying out thermal optimization treatment on the grey marrow in the ferric chloride and concentrated hydrochloric acid solution environment is adopted, on one hand, concentrated hydrochloric acid can inhibit ferric chloride from becoming ferric hydroxide and can also corrode impurities in the ferric chloride; and on the other hand, heating and soaking can accelerate the speed of iron ions entering the crystal, so that the jade marrow presents a more uniform yellow effect, and the yellow jade marrow with pure texture and uniform color is produced.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Manufacture equipment of rainbow tube

InactiveCN101398137BSolve the blockageSolve efficiency problemsPoint-like light sourceElectric lightingRainbowEngineering

The invention discloses manufacturing equipment of a rainbow tube, which is primarily characterized in that: a die head comprises an aligning shaft (12), a die core (15), a die barrel (16), inner core positioning dies (17) and dies (18), wherein, the die core is sheathed on the aligning shaft and sheathed into the die barrel, the inner core positioning dies are installed on the die core detachably, the dies are installed on the core barrel detachably, the die barrel is connected and communicated with a feed barrel of an extruder through a discharge port, two diffluent channels (19 and 21) arearranged on the die core, an included angle is formed by the two diffluent channels, the entry ends of the two diffluent channels are connected and communicated with the feed barrel through a throughhole and the discharge port on the die barrel, and the exit ends of the two diffluent channels are connected and communicated with the channels of the dies. The inner core and outer sheath of the rainbow tube can be completed together on a set of equipment only by changing the inner core positioning dies and dies with different calibers as the detachable inner core positioning dies and dies are adopted, furthermore, plastics are not easy to stack in the die head, thus being characterized by quick discharge and high production efficiency.

Owner:温州岳虹塑料机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com