A double-sided texture machine for producing artificial leather

A kind of artificial leather and double-sided technology, which is applied in the direction of textiles and papermaking, can solve the problems of high production cost, low production efficiency, large structure volume, etc., and achieve the effect of reduced production cost, small footprint and completely consistent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

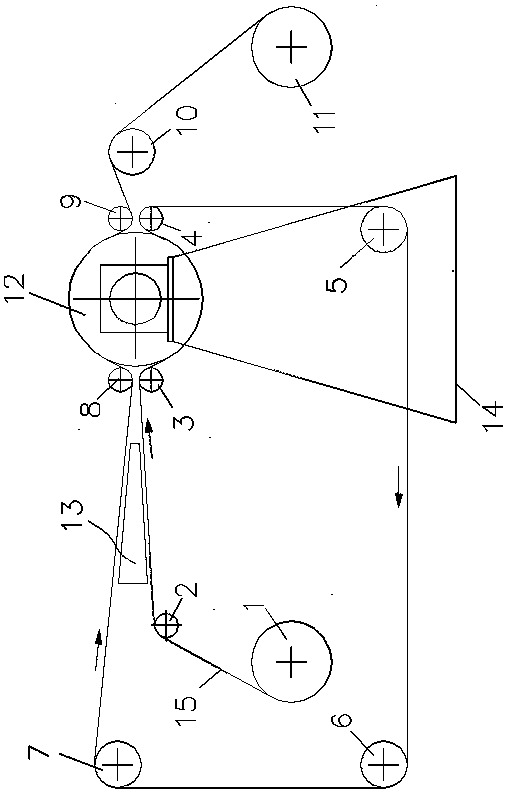

[0019] like figure 1 Shown, the present invention comprises: negative pressure embossing roll 12, feeding roll 1, receiving roll 11, lead-in roll, lead-out roll, guide roll, heater 13, frame 14, the transmission of each roll transmission of traction and a The group turns over the lead-in rollers. In order to make the schematic diagram clearer, the frame of the present invention only shows a part, and other parts are omitted. In fact, each roller is connected to the frame through bushings or bearings, and the frame is a fixed integral structure. The negative pressure embossing roller 12 is only provided with one, and one side of the lower half of the negative pressure embossing roller is provided with the first lead-in roller 3 of the artificial leather A surface, and the other side is provided with the first lead-out roller 4 of the A surface , one side of the first lead-in roller on the A side is provided with a feed roller, and the artificial leather material 15 on the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com