Porcelain tile adopting micro-powder composite ink-jet positioning dry particle process and preparation method of porcelain tile

A technology of micropowder bricks and porcelain bricks, applied in the field of architectural ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

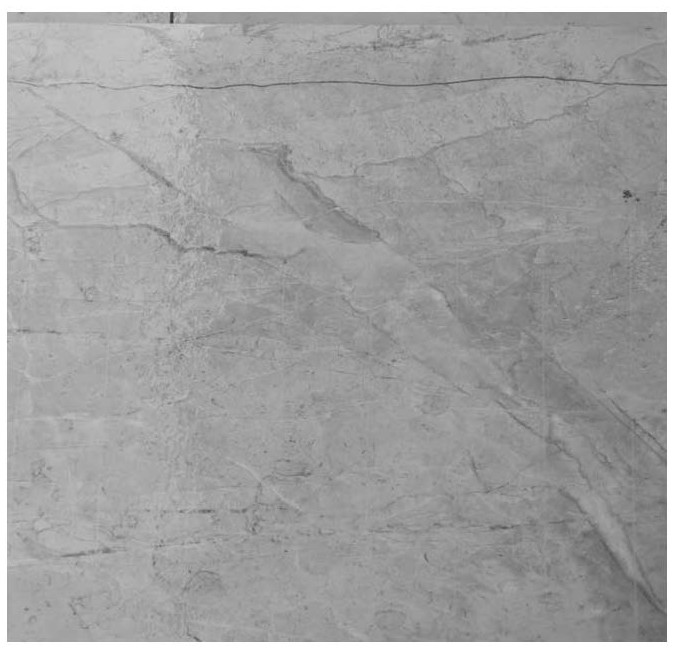

Image

Examples

Embodiment 1

[0049] Step 1. The micro-powder fabric is wet-mixed to make the corresponding powder. After grinding, the intelligent fabric system realizes the fixed point and positioning of the fabric, and the press is reversed and pressed to form a three-dimensional pattern similar to the natural imitation stone texture. Micro-powder fabrics include high-temperature fabrics and low-temperature fabrics, wherein the mass ratio of high-temperature fabrics to low-temperature fabrics is 55:45-65:35. The chemical composition of the high-temperature fabric includes: by mass percentage: SiO 2 70.4%, Al 2 o 3 18.5%, Fe 2 o 3 0.4%, TiO 2 0.2%, CaO0.5%, MgO0.3%, K 2 O 2.5%, Na 2 O 3.0%, loss on ignition 4.2%. The chemical composition of the low-temperature fabric includes: by mass percentage, SiO 2 70.6%, Al 2 o 3 18.2%, Fe 2 o 3 0.3%, TiO 2 0.15%, CaO 0.5%, MgO 0.3%, K 2 O 2.8%, Na 2 O 3.5%, loss on ignition 3.65%.

[0050] Step 2. After the adobe is dried, use the polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com