New method for activating and recycling tyre waste rubber powder

A technology of tire waste rubber and a new method, which is applied in the field of activation and reuse of tire waste rubber powder and waste tire tread rubber powder, can solve problems such as complicated process, achieve accurate process, less production investment, and mainly The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further illustrate the scheme and effect of the present invention below in conjunction with embodiment.

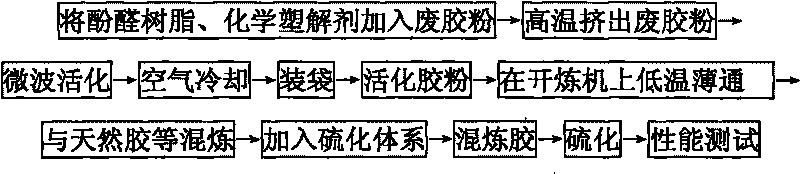

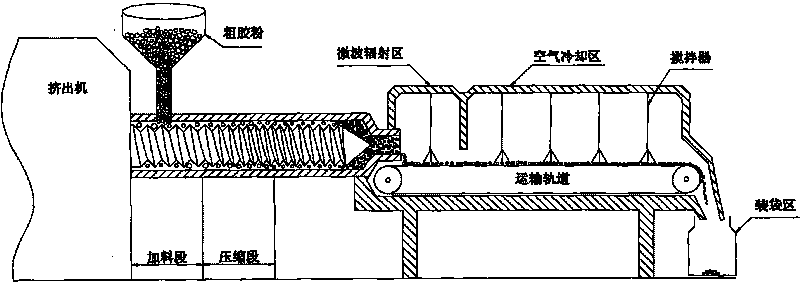

[0029] Such as figure 1 with figure 2 As shown, 25.0kg of waste rubber tire tread rubber powder with a particle size of 30 meshes was added to 3.0kg of compatibilizer phenolic resin and 0.2kg of chemical peptizer 2,2-benzamidophenyl disulfide, and then extruded by a screw Extrusion machine (XJ-250) for extrusion. After the waste rubber powder is extruded, it enters into the microwave radiation device while stirring, and is activated by microwave radiation. The radiation microwave frequency of the microwave device is 2450Hz, the power is 800W, and the irradiation time is 2min. The waste rubber powder activated by microwave radiation is air-cooled, and cooled for 10 minutes while stirring at 0-10°C. Thinly pass the activated waste rubber powder about 10 times on the low-temperature open mill (XK-160), and the roller distance is 0.5-1.0mm. Then, the activated rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com