Sculpture material containing loess

A loess and sculpture technology, applied in the field of earth carving materials, can solve the problems of easily damaged carving knives, not delicate texture, poor water resistance, etc., and achieve the effect of good erection, delicate texture and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

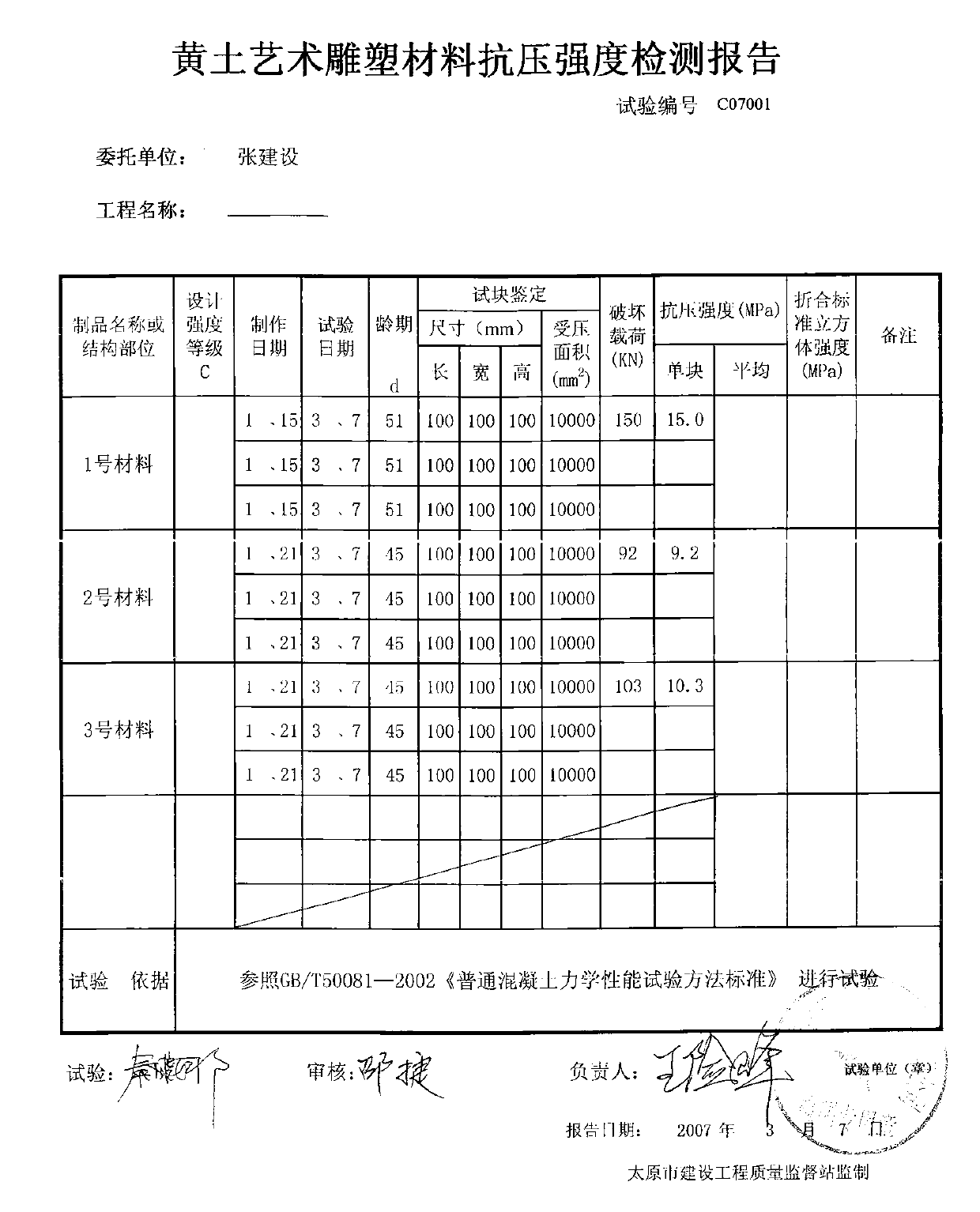

[0017] Embodiment 1: every part is 1kg

[0018] The preparation process of the sculpture material containing loess is as follows:

[0019] (1) Stir 100kg of cinnamon soil with a particle size of 90 meshes in Taiyuan, Shanxi and 25kg of magnesium oxide powder evenly to obtain a mixed dry powder, and then spray the mixed dry powder with a magnesium chloride solution with a Baume degree of 35, and stir while spraying. The mixture is obtained, and the volume ratio of the mixed dry powder and the magnesium chloride solution is 1:0.28;

[0020] (2) Place the mixture in a 100×100×100mm mold at 20°C, compact it, remove the mold, and obtain a loess-colored sculpture material.

[0021] Do the compressive strength MPa value test, up to 15.0; put it in the water basin test, it will not melt or decompose, and the uprightness is good; test it with a sculpture knife, the texture is fine, the texture is consistent inside and outside, and there is no partial softness in the middle; hollow o...

Embodiment 2

[0022] Embodiment 2: every part is 1kg

[0023] The preparation process of the sculpture material containing loess is as follows:

[0024] (1) 100kg of loess soil with a particle size of 120 mesh in Changzhi, Shanxi, and 30kg of magnesium oxide powder were mixed evenly to obtain a mixed dry powder, which was then sprayed on the mixed dry powder with a magnesium chloride solution with a Baume degree of 25, and stirred while spraying, to obtain Mixture, the volume ratio of mixed dry powder and magnesium chloride solution is 1:0.3;

[0025] (2) Place the mixture in a 100×100×100mm mold at 30°C, compact it, remove the mold, and obtain sculpture materials.

[0026] Do the compressive strength MPa value test, up to 9.2; put it in the water basin test, it will not melt or decompose, and the uprightness is good; test it with a sculpture knife, the texture is fine, the texture is consistent inside and outside, and there is no partial softness in the middle; hollow out Experiment wi...

Embodiment 3

[0027] Embodiment 3: every part is 1kg

[0028] The preparation process of the sculpture material containing loess is as follows:

[0029] (1) 100kg of chestnut cinnamon soil with a particle size of 150 mesh in Shanxi Luliang area and 28kg of magnesium oxide powder are mixed evenly to obtain a mixed dry powder, and then sprayed on the mixed dry powder with a magnesium chloride solution with a Baume degree of 30, and stir while spraying , to obtain the mixture, the volume ratio of the mixed dry powder and the magnesium chloride solution is 1: 0.32;

[0030] (2) Place the mixture in a 100×100×100mm mold at 5°C, compact it, remove the mold, and obtain sculpture materials.

[0031] Do the compressive strength MPa value test, up to 10.3; put it in the water basin test, it will not melt or decompose, and the uprightness is good; test it with a sculpture knife, the texture is fine, the texture is consistent inside and outside, and there is no partial softness in the middle; hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com