Patents

Literature

102results about How to "No slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

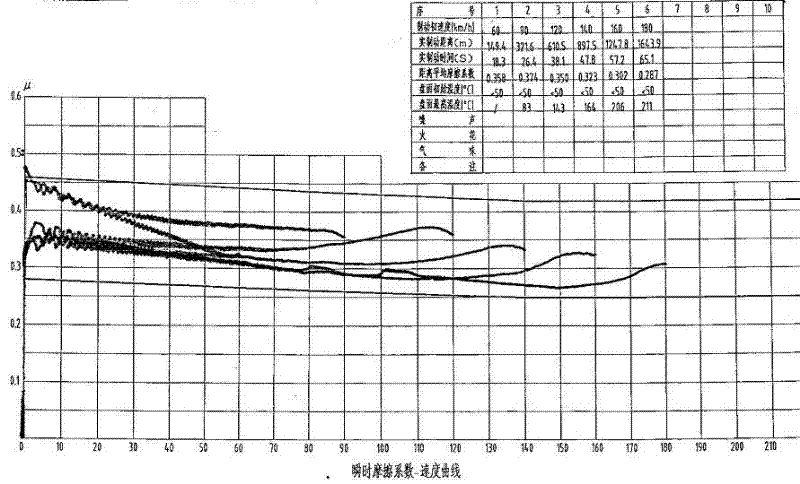

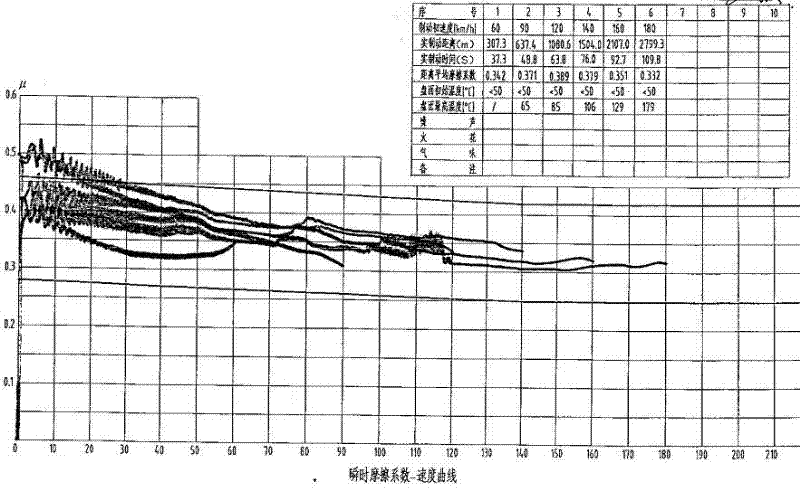

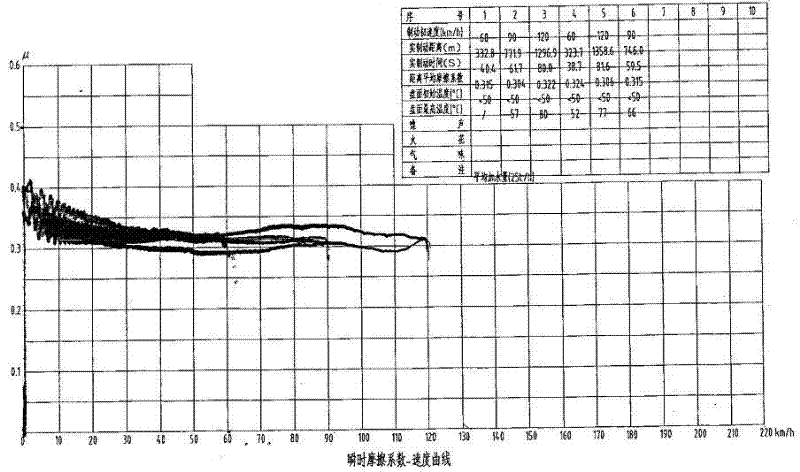

Hybrid fiber reinforced friction material for train braking and preparation method thereof

InactiveCN102191015AImprove toughnessImprove yieldOther chemical processesFriction liningFreight trainsAdhesive

The invention belongs to the technical field of materials, and particularly relates to a hybrid fiber reinforced friction material for train braking and a preparation method thereof. In the invention, a composite modified phenolic resin is used as an adhesive, and hybrid fibers, including carbon fiber, metal fiber, inorganic mineral fiber and the like, are used as the reinforcing fibers. Compared with the prior art, the invention improves the contour machining property of the organic synthetic brake, and the yield of the material is high; the brake has stable frictional property at different braking speeds, does not has obvious degradation of frictional property at high speed, and does not have the phenomena of shedding and cracking on the working surface after the braking test. The friction material provided by the invention can be widely used for manufacturing brake pads, brakes, brake shoes and the like in braking systems of passenger and freight trains, municipal rail transportation, subways and the like.

Owner:FUDAN UNIV

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

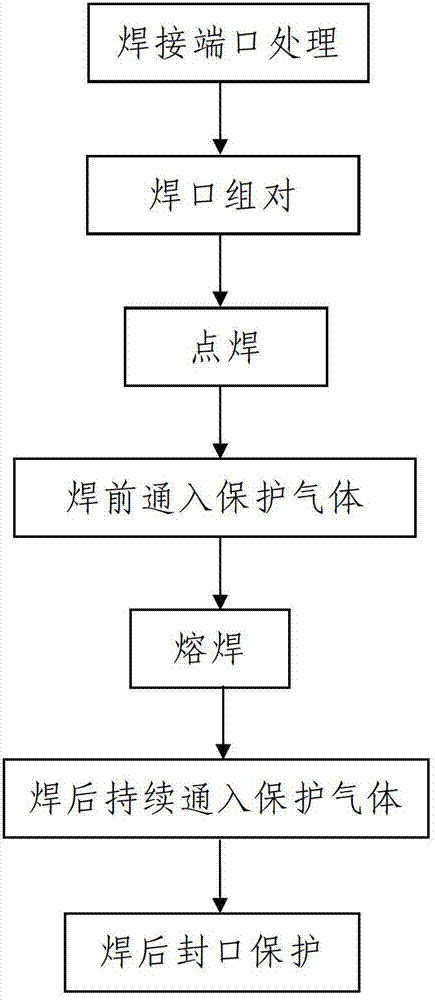

Automatic traceless fusion welding technology of thin-wall stainless steel clean pipeline

The invention discloses an automatic traceless fusion welding technology of a thin-wall stainless steel clean pipeline. The technology comprises the following steps of: step 1, treating a welding port: milling pipe end welding surfaces of two welded pipeline segments into planes; step 2: assembling welded junctions; step 3: carrying out point welding; step 4: carrying out fusion welding: carrying out fusion welding on the two pipeline segments by adopting an argon tungsten-arc welding machine, wherein the fusion welding process comprises the following steps of: introducing a protective gas before welding, welding the two welded pipeline segments by adopting the argon tungsten-arc welding machine, and introducing argon continuously during the welding process and introducing a protective gas continuously after welding; and step 5: sealing and protecting after welding. The automatic traceless fusion welding technology of the thin-wall stainless steel clean pipeline provided by the invention is reasonable in design, is simple and convenient to operate, is convenient to achieve, has a good pipeline cleanness control effect, is high in welding quality, and can effectively solve the problems of high labor intensity, low efficiency, high production cost, severe welding junction oxidation, poor formation inside and outside a welding line, difficulty in controlling cleanness in pipelines, poor cleanness control effect and the like in an existing welding method.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Zirconium mullite sagger

The invention provides a zirconium mullite sagger which comprises the following raw materials: natural mullite, tabular corundum, zircon sand, alpha-alumina micro powder, silicon dioxide micro powder, kaolin and a binding agent, wherein the natural mullite consists of mullite granules of which the particle size is within 0.5-1 mm and mullite powder granules of which the particle size is smaller than 0.5 mm; the mass ratio of the mullite granules to the mullite powder granules is (3-4):(6-8); the tabular corundum consists of tabular corundum granules of which the particle size is within 0.1-0.5 mm and tabular corundum powder granules of which the particle size is smaller than 0.1 mm; the mass ratio of the tabular corundum granules to the tabular corundum powder granules is (4-5):(3-4); the particle size of the zircon sand is less than 0.1 mm. The zirconium mullite sagger has the advantages of corrosion resistance and freedom of falling residues, the materials are small in heat capacity and thermal expansion, and the circulation use number is large.

Owner:浙江立鑫高温耐火材料有限公司

Method for smelting nitrogenous Co-Cr-Mo alloy for surgical implanting through electroslag remelting furnace

The invention belongs to the field of metallurgy and relates to a method for smelting nitrogenous Co-Cr-Mo alloy for surgical implanting through an electroslag remelting furnace. The method comprises the following steps: I, preparing an electrode and slag charge, welding a Co-Cr-Mo alloy stun rod and an artificial electrode together, and using a slag charge feeder to add the slag charge to be remelted; II, closing the furnace and filling nitrogen continuously for 2 minutes and then stopping nitrogen supply, and starting a cooling circulation system; III, arcing and slugging, and adopting a power, current, voltage and slag resistance comprehensive control method; IV, after slag charge adding, supplying nitrogen continuously; V, after the finish of an arcing period, starting a melting period, adopting a melting speed and slag swing control method, and stabilizing the melting speed to be 5kg / min; VI, adopting a stepped power reduction method during a hot top sealing process; and VII, cooling and demoulding inside the furnace. The Co-Cr-Mo alloy remelted by adopting the method is excellent in ESR ingot segregation control, N element is evenly distributed, the burning loss is less than 5 percent, the content of sulphur is lower than 10 ppm, and the ingot surface is free from the defect of slag troughs.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

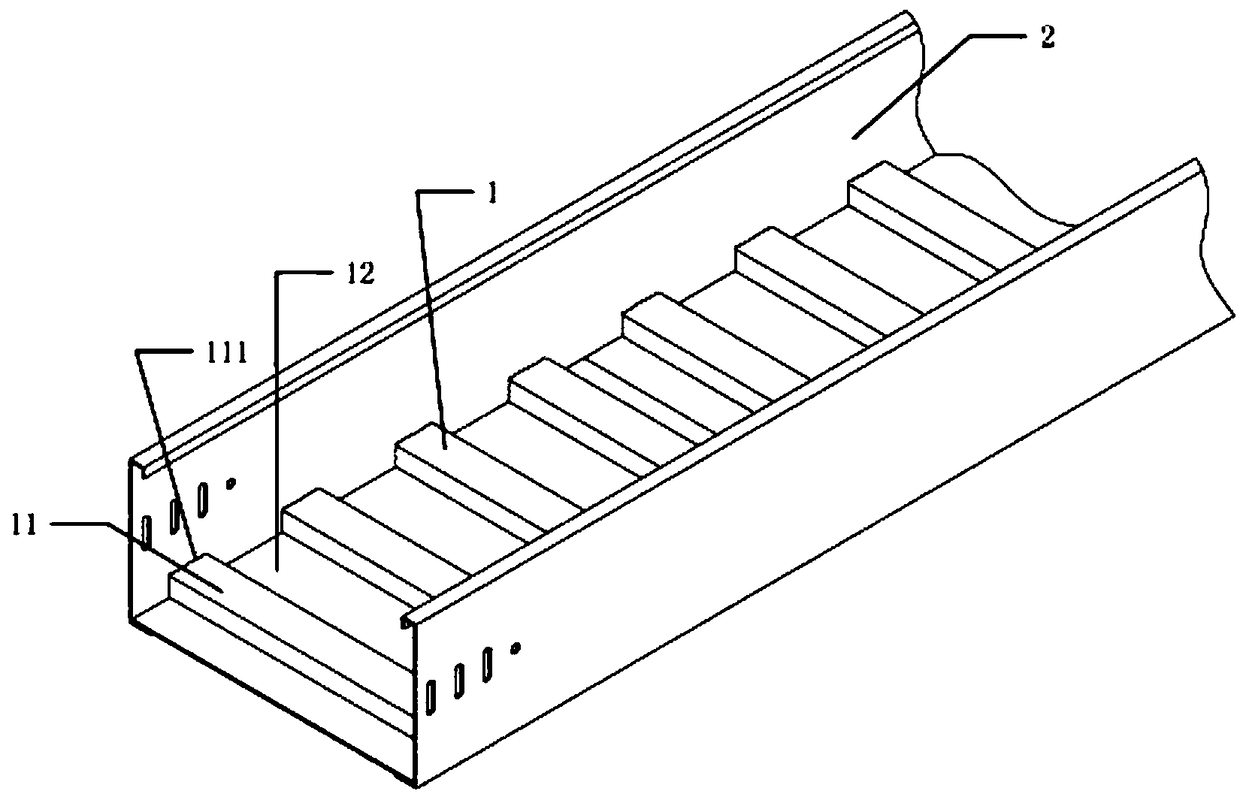

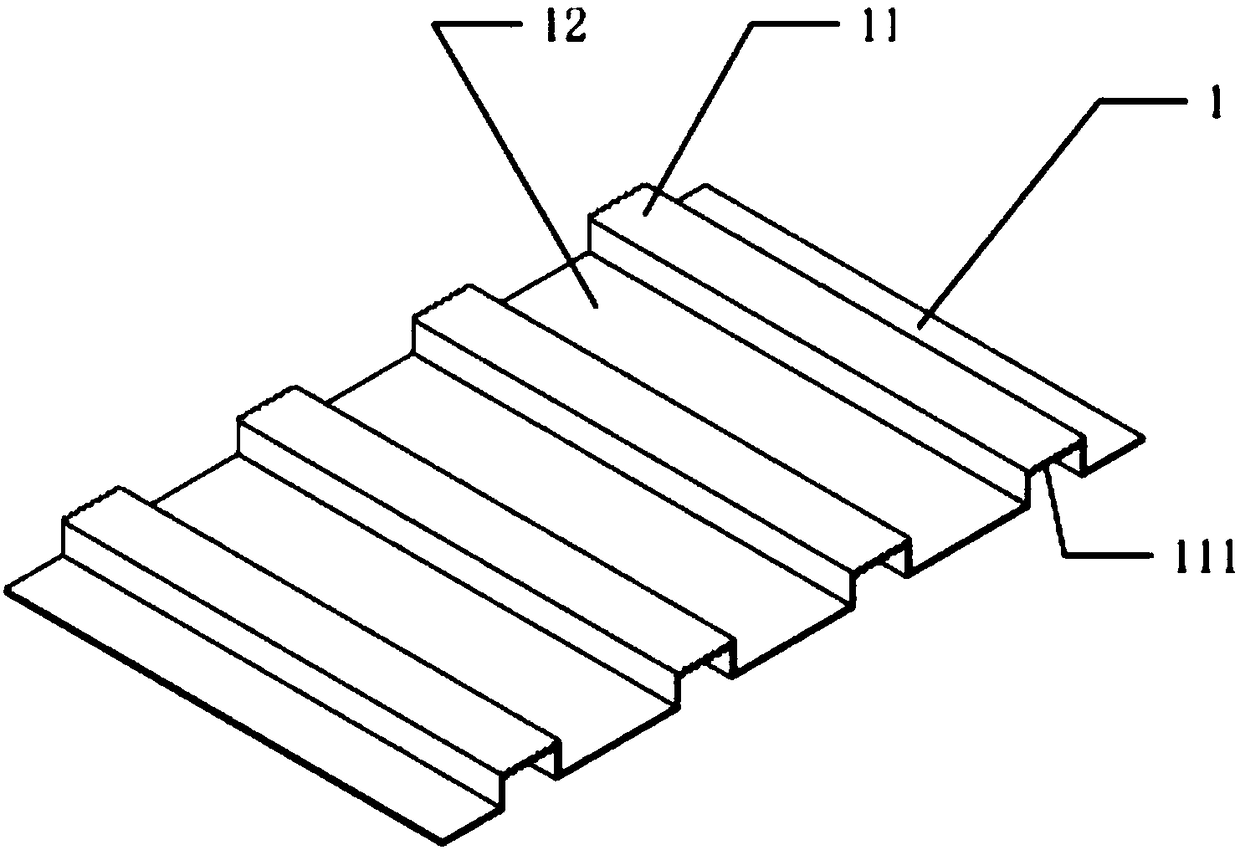

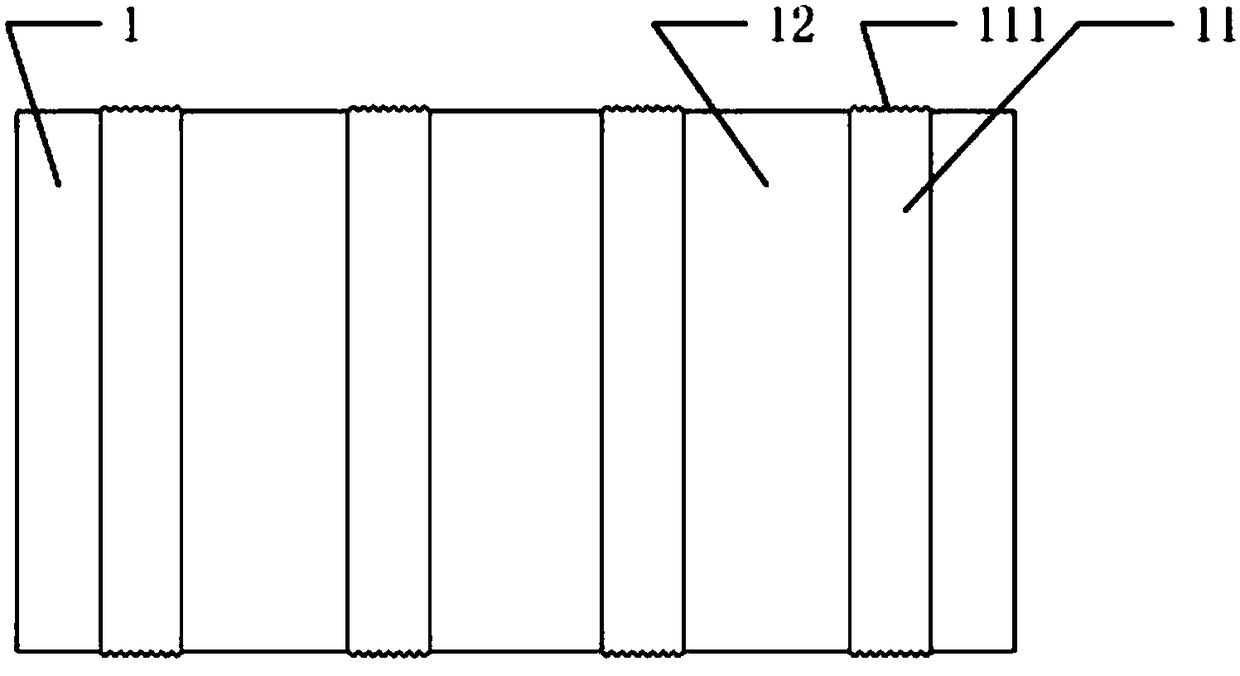

Corrugated tray bridge adopting toothed multi-pole T-type joint projection welding

PendingCN108599047ASolve corrosionSolve quality problemsElectrical apparatusEngineeringSurface processing

The invention discloses a corrugated tray bridge adopting toothed multi-pole T-type joint projection welding. The corrugated tray bridge comprises a bottom plate (1), bottom plate protrusions (11), bottom plate protruding end face teeth (111), bottom plate grooves (12) and side plates (2); the bottom plate protrusions (11) and the bottom plate grooves (12) are constantly arranged at intervals to form the bottom plate (1) in a corrugated shape, two edges of the bottom plate protrusions (11) are provided with multiple protruding points to form the bottom plate protruding end face teeth (111), and the bottom plate protruding end face teeth (111) on two sides of the bottom plate (1) are welded to thee side plates (2) of the bridge to form the corrugated tray bridge. According to the corrugatedtray bridge, the achievement of the production process of the projection welding of the bottom plate and the side plates of a light and enhanced tray cable bridge is ensured, the difficult problem ofthe protection of welding thin plates through gas of a light enhanced bridge is solved, the difficult problem that the anti-corrosion performance and appearance quality need to be restored though surface processing after hot dip galvanized steel plates and stainless steel plates are welded is solved, and the pollution in surface processing procedures is avoided.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

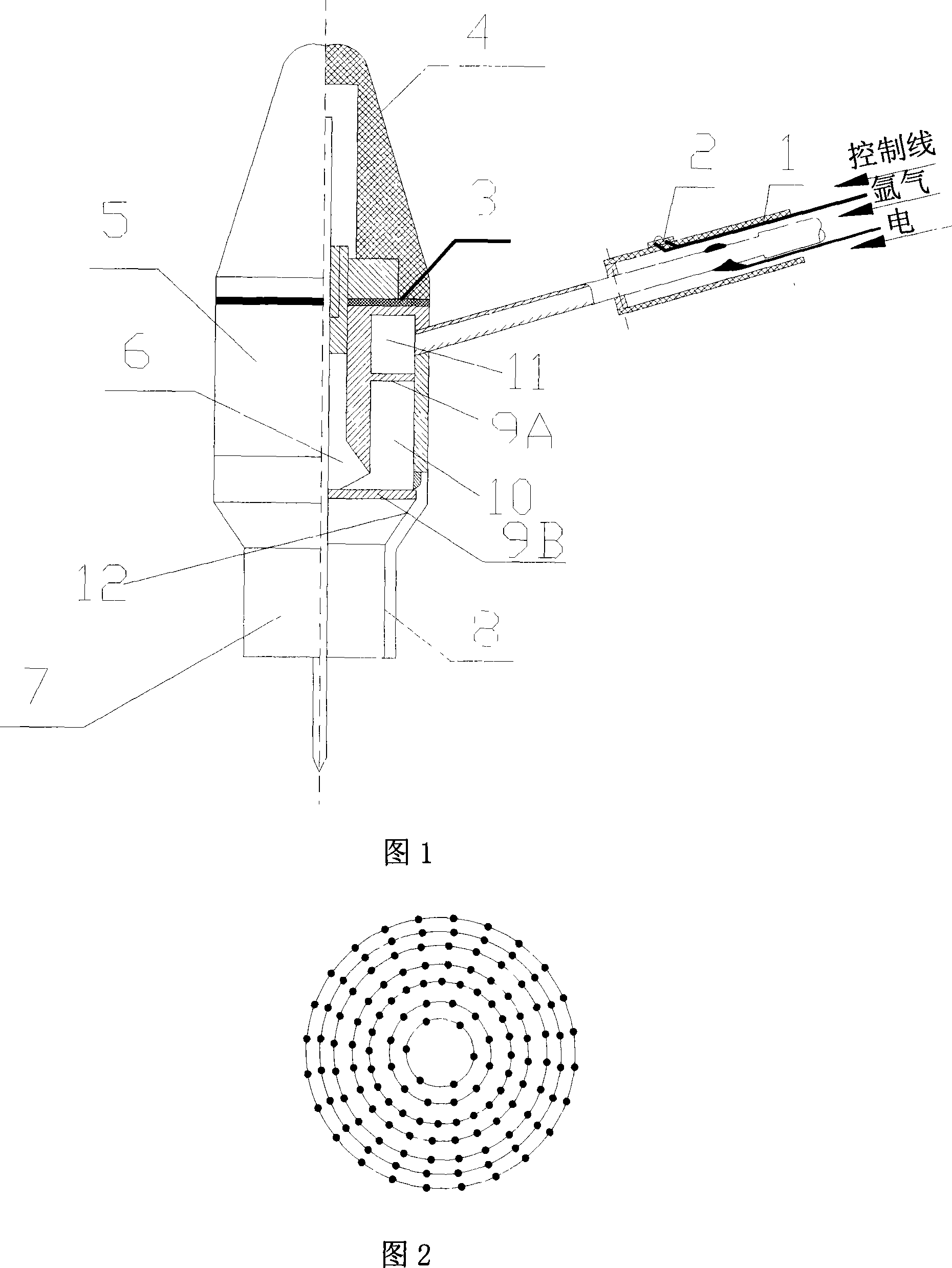

Cold air type argon-arc welding gun

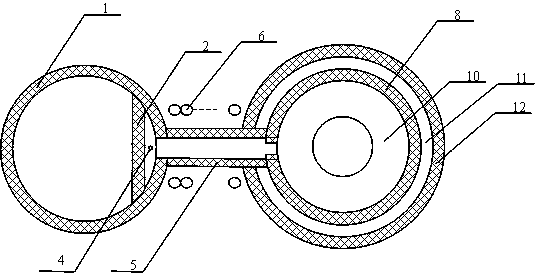

InactiveCN101085489AEffective isolationAvoid isolationElectrode supporting devicesCold airHeat-affected zone

The invention relates to the argon cold air arc welding machine. It has top and down air chamber through the screen current and connected to the nozzle, and separated by rigid air lens with intersected through holes. The air lens is divided into top and down air chambers, forming effective isolation air multi layer post screening the current. It forms multi layer protective layer current. It has concentrated electric arc temperature, small thermal input, quick speed, and less thermal influence. It solves existing technical issues, avoids the location limitation of vacuum argon filling welding equipment. It realizes welding under natural conditions.

Owner:郭光耀

Cement foaming insulation board, preparation method and application thereof

The invention relates to a cement foaming insulation board, a preparation method and application thereof; the cement foaming insulation board is prepared by adopting the steps of: uniformly mixing 4-6 parts by weight of acidic cement, 0.15-1.6 parts by weight of hydrogen peroxide by adding proper dosage of water, adding 1-3 parts by weight of curing agent in a mould, and uniformly stirring and curing, wherein the total forming duration is less than 25 min. According to the cement foaming insulation board provided by the invention, a fireproof and environmental-friendly material is used as a raw material of a building insulation board, so that the material has the advantages of small mass, sound insulation, environmental protection, high toughness, non-deformation, non-slag dropping and long service life; the curing agent is adopted in the preparation process to reinforce the adhesion effect and improve the integral strength and hardness of the board, and the board is firmer; and the cement foaming insulation board can be applied on outer walls, interior walls and partition walls of buildings.

Owner:天津得全集成房屋有限公司

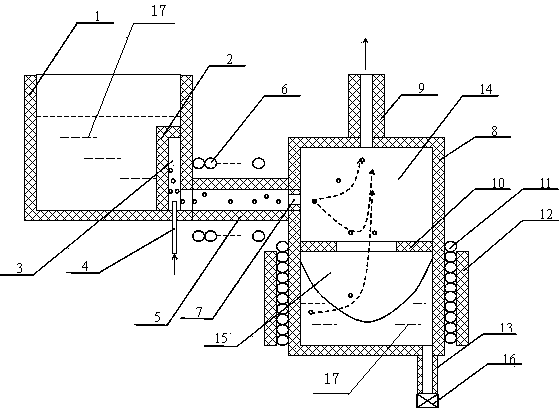

System for removing hydrogen in molten aluminum

The invention discloses a system for removing hydrogen in molten aluminum. The system comprises a molten aluminum tank, a communication tube and a double-cavity type degassing tank, wherein the molten aluminum tank is communicated with the double-cavity type degassing tank by the communication tube; the double-cavity type degassing tank comprises a vacuum cavity and a molten aluminum cavity, wherein a partition plate is arranged between the vacuum cavity and the molten aluminum cavity; a through hole is formed in the middle part of the partition plate; the vacuum cavity is arranged above the molten aluminum cavity; an electromagnetic oscillating coil is arranged outside the molten aluminum cavity; a rotary drive coil is arranged outside the electromagnetic oscillating coil; a liquor taking tube is arranged on the lower part of the molten aluminum cavity; a valve is arranged on the lower part of the liquid taking tube; a gas pumping tube is arranged on the upper part of the vacuum cavity; a gas filling cavity enclosed by a ceramic filter plate and the inner wall of the molten aluminum tank is arranged inside the molten aluminum tank; a gas filling tube is arranged below the gas filling cavity; one end of the gas filling tube extends into the gas filling cavity; the other end of the gas filling tube is arranged outside the gas filling cavity. The system disclosed by the invention adopts the double-cavity type degassing tank, and integrates the technologies, such as electromagnetic driving, ultrasonic-vibration degassing, inert gas removing, spraying and degassing, degassing by centrifugal force, and vacuum degassing, so that the optimal degassing effect is achieved.

Owner:STATE GRID CORP OF CHINA +2

Scrub resistant diatom ooze coating

InactiveCN105645861AGood water resistance and friction resistanceExtended service lifeCalcium carbonateTitanium oxide

The invention relates to a scrub resistant diatom ooze coating. Raw materials of an existing diatom ooze coating are many, processing and selling costs are high, and coated walls are easy to stain and fall off, easily drop powder, is not resistant to scrubbing and has short service life. By the use of diatomite, sierozem, heavy calcium carbonate powder, white cement, HPMC, redispersible latex powder, titanium oxide and sodium chloride, the coating is manufactured with advantages as follows: raw materials are few; energy is saved and the environment is protected; operation is easy; processing method is simple; cost is low; water resistance is strong; the coating is scrub resistant; no powder drops; durability is good; and the coating is non-toxic and odourless, and has strong covering power, soft color and good decorative effect.

Owner:重庆发顺化工有限责任公司

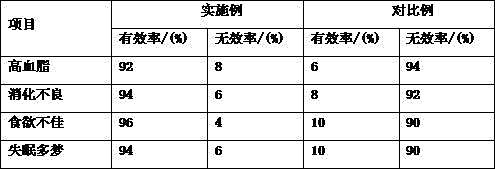

Blueberry water chestnut bread with gardenia aroma

InactiveCN106720034AUniform colorNo burnt white phenomenonDough treatmentBakery productsWater ChestnutsTherapeutic effect

The invention belongs to the technical field of food processing, in particular to a blueberry water chestnut bread with gardenia aroma. The blueberry water chestnut bread with the gardenia aroma is prepared by the following raw materials: water chestnut powder, fresh gardenias, blueberries, linden honey, coconut oil, yeast powder, fresh pear skins, fresh orange peels, fresh locust flowers, cynarin, zeaxanthin, gynostemma pentaphyllum extract, schisandra chinensis extract. The blueberry water chestnut bread with the gardenia aroma is light purple and uniform and consistent in color and luster without burned white phenomenons . The blueberry water chestnut bread with the gardenia aroma is complete and full without defects and cracks, and the surface is clean and smooth without black bubbles and spots. The blueberry water chestnut bread with the gardenia aroma is fine and elastic with uniform air holes and clear textures, and breadcrumbs don't drop. The blueberry water chestnut bread with the gardenia aroma tastes delicious with slight sweetness and sour and is soft and not tooth-sticky and tooth-cracking. The baked bread with a gardenia aroma and a blueberry aroma has an aromatic and harmonious flavor. The blueberry water chestnut bread with the gardenia aroma has a significant therapeutic effect for patients suffering from high blood lipids, indigestion, poor appetite, and insomnia and dreaminess.

Owner:蒋金刚

Instant corn noodle

InactiveCN104824556ADelicate tasteTaste effectFood freezingMulti-step food processesPowder mixtureCold store

The invention discloses an instant corn noodle. The instant corn noodle is prepared from corn keratin endosperm powder and corn farinaceous endosperm powder, and is prepared through the following steps: uniformly mixing the corn keratin endosperm powder with the corn farinaceous endosperm powder according to a ratio of 1:1, adding salt accounting for 0.6% of the weight of the above obtained powder mixture and normal temperature drinking water accounting for 30-35% of the weight of the powder mixture, fully stirring to obtain a wet powder mixture, putting the wet powder mixture in a spiral puffing machine, carrying out puffing extrusion to form cooked noodles, sending the cooked noodles to a regulating chamber, regulating, packaging the regulated noodles by a food stage plastic bag, rapidly sending the bag to a quick freeze chamber, quickly freezing, and moving to a cold store for storage in order to obtain the finished instant corn noodle. The instant corn noodle can be directly eaten after direct boiling without immersion, and has the advantages of good boiling fastness, no soup turbidity after long time boiling, good elasticity, no fracture, smoothness in mouth, and fine mouthfeel.

Owner:辽宁曙光食品有限公司

Obstruction and explosion suppression material aluminum foil of oil tank for gas station

The invention discloses an obstruction and explosion suppression material aluminum foil of an oil tank for a gas station. The aluminum foil comprises the following components in percentage by weight: 0.4 to 0.8 percent of Si, 0.5 to 0.9 percent of Fe, 0.05 to 0.2 percent of Cu, 1.0 to 1.5 percent of Mn, 0.05 to 0.15 percent of Zn, 0.02 to 0.04 percent of Mg and the balance of Al. The aluminum foil has relatively high flexibility and tensile strength; the obstruction and explosion suppression material, which is used for preparing the aluminum foil, of the oil tank for the gas station has relatively appropriate softness and hardness; and residues and powder are prevented from falling and an oiling machine is prevented from being blocked when the aluminum foil is used.

Owner:茂名市亚泰铝合金抑爆材料有限公司

Organic planting method for bayberries

InactiveCN103703951AGlossy colorHigh oil contentBio-organic fraction processingOrganic fertiliser preparationSocial benefitsContinuous use

The invention relates to a planting method for bayberries, in particular to an organic planting method for bayberries. Along with development of modern agricultural production, a woodland ecosystem is damaged by pollution caused by continuous using of chemical substances such as chemical fertilizers, pesticides and hormone, and an agricultural environment is damaged, the quality of a product is reduced, the selling price of the product is reduced, and the income of forest workers is reduced. Organic bayberry products are produced by using an organic bayberry planting production technology, the problems existing in production of the bayberries are solved, high yield, stable yield and high quality on production of the bayberries are guaranteed, the balance of an agroecological system is maintained, the purposes of developing agricultural economy and protecting an agricultural environment are achieved, and the economical benefit and the social benefit are high.

Owner:YULIN YIXING AGRI TECH DEV GENERAL

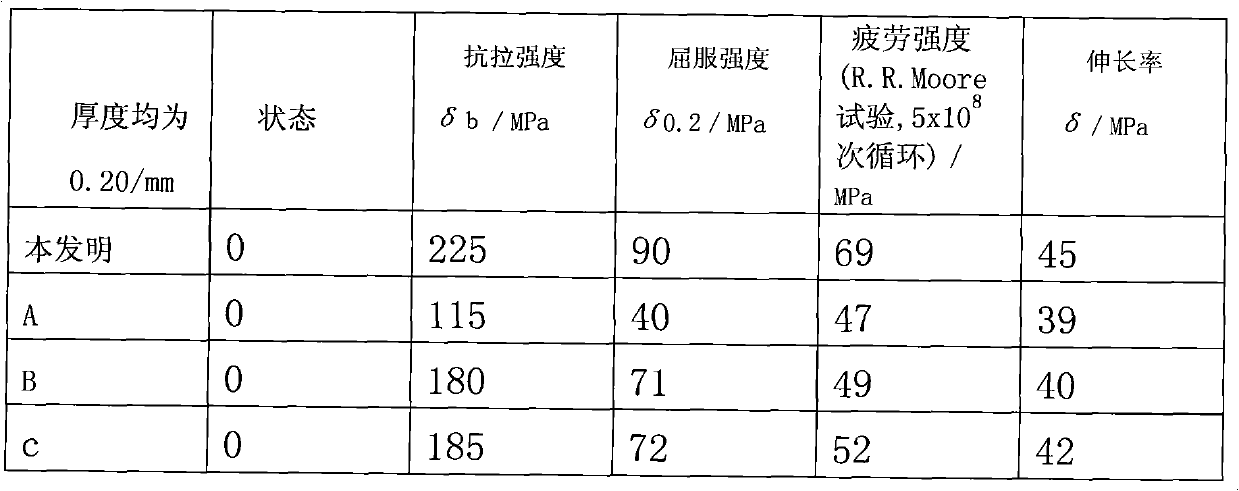

Explosion-suppressing material and preparation method thereof

InactiveCN102634703AImprove extrusion resistanceGood anti-collapseFire rescueBoring toolsChemical compositionPerformance index

The invention belongs to a preparation method of an explosion-suppressing material. The explosion-suppressing material comprises the following chemical compositions by weight percent: 0.3-0.5 percent of Si, 0.1-0.3 percent of Fe, 0.15-0.25 percent of Cu, 1.0-1.5 percent of Mn, 1.0-1.5 percent of Mg, 0.1-0.3 percent of Zn, 0.15-0.25 percent of Ti, 0.03-0.06 percent of La, 0.05-0.09 percent of Ce and the balance Al. A grain structure of the explosion-suppressing material is refined by adopting a repeated heating forging and pressing method. The explosion-suppressing material provided by the invention has excellent extrusion resistance, collapse prevention, zero dreg-falling and high-strength explosion-suppressing property. The performance indexes of the explosion-suppressing material, such as strength, plasticity, fracture toughness and fatigue resistance, are greatly increased according to the preparation method; the technology is simple and is easily performed; and the service life of the explosion-suppressing material is prolonged.

Owner:王季庄

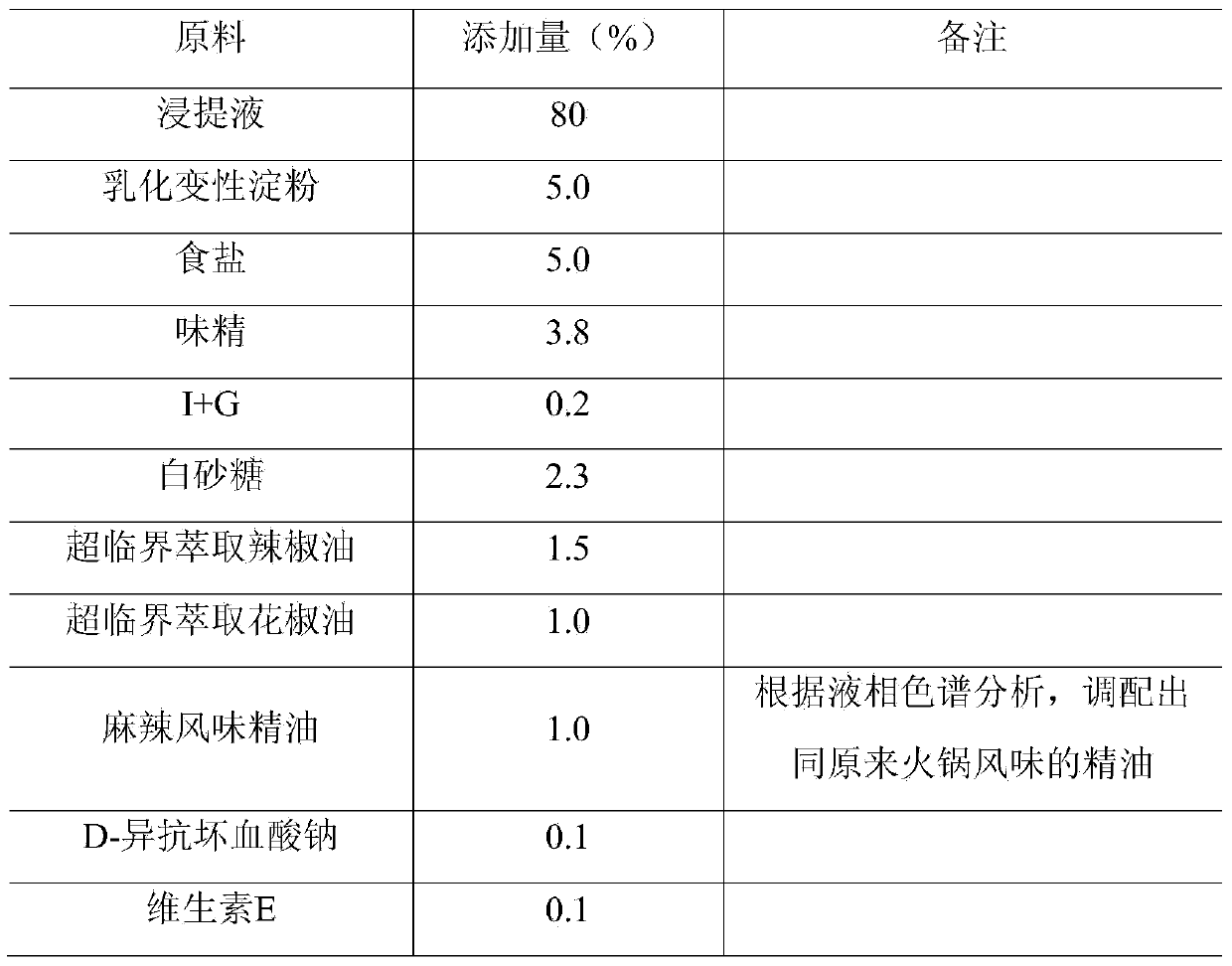

Preparation method of emulsified hotpot seasoning

ActiveCN103621967ADoes not affect consumptionImprove refreshingFood ingredient functionsFood preparationAdditive ingredientColloid

The invention provides a preparation method of an emulsified hotpot seasoning, and belongs to the technical field of preparation methods of hotpot seasonings. The preparation method comprises the steps: crushing commercially available hotpot seasoning, feeding separated material residue into a digestion tank, digesting for 20-30min, and then crushing by using a ball grinding mill; pumping crushed materials and a digestion solution of the crushed materials into a double-effect concentrator for concentrating, wherein the content of dry materials in concentrated feed liquid is 50-60 percent; and adding the obtained concentrated digestion solution in an emulsifying tank, adding an auxiliary material and an emulsifying agent for emulsifying, grinding by using a colloid mill after the emulsification is completed, and carrying out heat preservation within 60-80 DEG C in the whole process. The emulsified hotpot seasoning prepared by adopting the preparation method uses a conventional hotpot seasoning as a raw material, the hotpot seasoning is crushed by using a crusher, a colloid mill and other devices, and then the emulsified hotpot seasoning is prepared by using an emulsifying technology and by adding partial ingredients. The emulsifying hotpot seasoning is treated by using the technology, on the basis of no change of an original flavor of products, the flavor of the products is enhanced.

Owner:BEIJING NEW SPICY WAY RESTAURANT MANAGEMENT

Environment-friendly degradable child colored oiled crayon and preparation method thereof

The invention provides an environment-friendly degradable child colored oiled crayon. The colored oiled crayon comprises the following components the content of which is in mass fraction: 0.3-12% of chromogenic reagent, 6-15% of color-developing agent, 35-53% of emulsifying wax, 15-20% of polyethylene glycol, 12-25% of stearic acid, and 2-15% of talcum powder. The child colored oiled crayon disclosed by the invention overcomes the shortcoming that the existing child crayon is difficult to erase, and has the advantages that after writing, color can be removed by wiping with water, and no trace is left. The colored oiled crayon is dust-pollution-free, environment-friendly, non-toxic and innocuous, and can be not only used as a child crayon, but also used to write on a whiteboard for teaching. The production process is simple and mass production of the crayon is easy to realize.

Owner:浙江奥乐奥新材料科技有限公司

Soldering flux for lead-tin soldering of shaft tips of instrument

InactiveCN101890587AStrong moistureUniform coatingWelding/cutting media/materialsSoldering mediaPhosphoric acidAlloy

The invention relates to a soldering flux for lead-tin soldering of shaft tips of an instrument, and aims to solve the problem that the conventional shaft tips (anti-seismic abrasion-resistant alloy tool steel) of the instrument cannot be subjected to the lead-tin soldering. The soldering flux consists of rosin, phosphoric acid and alcohol, wherein moderately strong phosphoric acid is used as an antioxidant; the rosin is acidic at a high temperature so as to enhance the effect of an anti-oxidation film; meanwhile, the rosin can reduce surface tension and increase soldering fluidity, is favorable for soldering and wetting weldments, has anti-oxidation effect and floats on the surface of the soldering flux after being molten to form an isolating layer, so that the solder side is prevented from being oxidized; and the alcohol can enhance the fluidity of the soldering flux, make the soldering flux uniformly coated, dissolve a lubricant for cleaning the solder side, and enhance the humidity of the soldering flux so as to fulfill the aim of the lead-tin soldering. The soldering flux can be used for the lead-tin soldering of the shaft tips of the instrument, and can also be used for the lead-tin soldering of other metals such as stainless steel and the like; meanwhile, the soldering flux has the advantages of convenient preparation, low cost and easy popularization.

Owner:BEIJING TIAN YOU SCI EQUIP & TECH

Rhizoma coptidis piece processing and comprehensive utilizing method

The invention belongs to the technical field of traditional Chinese medicine processing and particularly relates to a rhizoma coptidis piece processing method. Mainly a new choice is provided for rhizoma coptidis piece processing. The method includes the following steps of harvesting, crude cleansing, dewatering, refined cleansing, slicing, drying and screening, and rhizoma coptidis decoction pieces are obtained, and leftovers obtained during cutting of the rhizoma coptidis pieces are comprehensively utilized. The method can be used for processing rhizoma coptidis pieces and rhizoma coptidis on the producing area, the method is high in industrialization degree, energy is saved, and the content of total alkaloids in the obtained rhizoma coptidis decoction pieces is higher than that of total alkaloids in rhizoma coptidis decoction pieces obtained through a traditional method by 10% or above.

Owner:SOUTHWEST UNIVERSITY

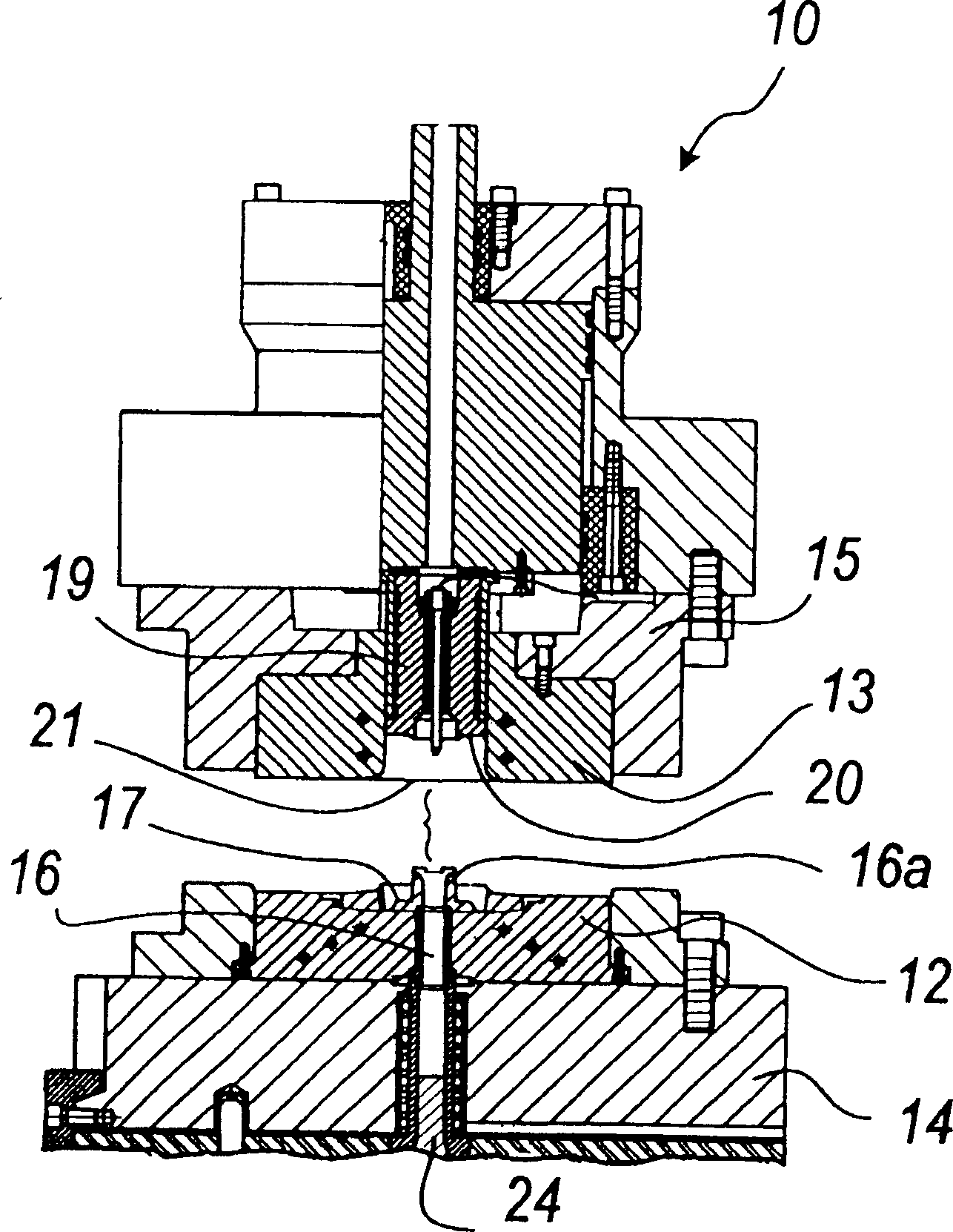

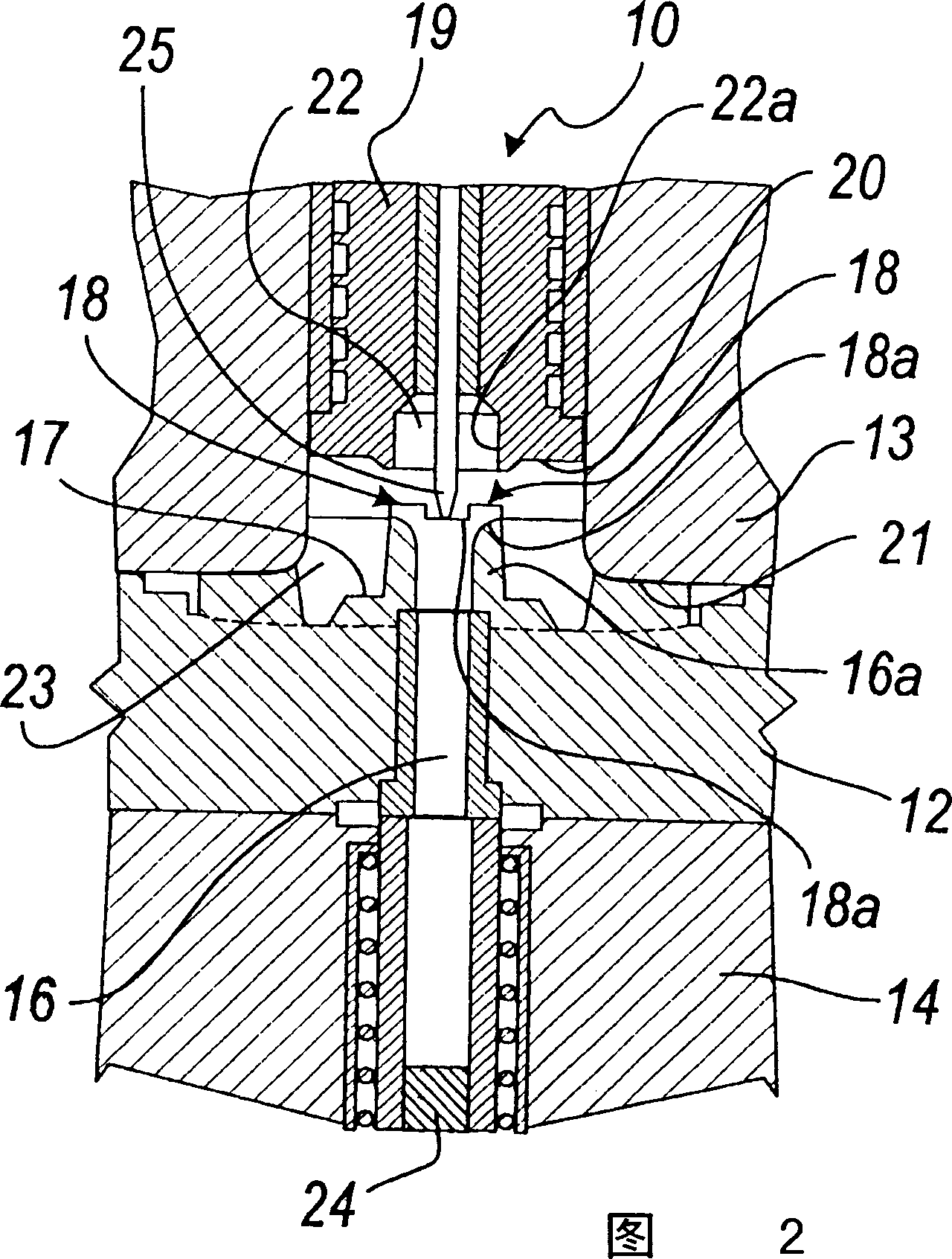

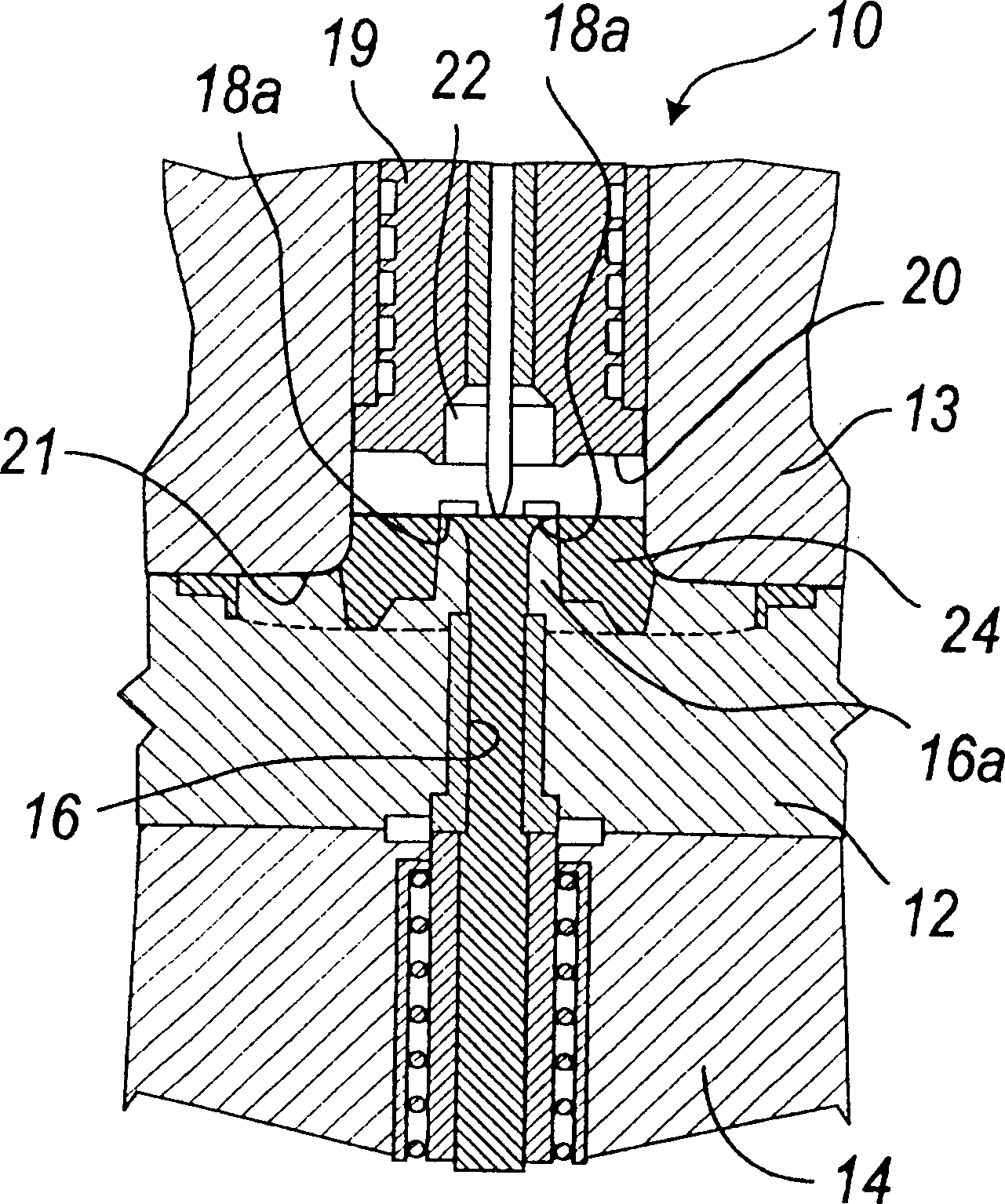

Apparatus for manufacturing articles made of light alloys and the like, and method performed by the apparatus

InactiveCN1863627ACompact structureNo slagCasting parameters measurement/indication devicesLiquid metalMetal

An apparatus and method for manufacturing articles made of aluminum, aluminum alloys, light alloys and the like, the apparatus comprising a lower die section (12) and at least one upper die section (13), associated with corresponding press platens (14, 15) for closure determining shape of the cast article, a vertically elongated duct (16) for introducing liquid metal, a to pressurized furnace that leads into the lower die section (13) that forms at least one lower impression (17) with at least one concave portion for introducing liquid metal through at least one corresponding inlet (18) formed at the upper portion of the duct (16), a male plug (19) associated with the upper die section, and movable with respect thereto.

Owner:BBS RIVA

Obstruction and explosion suppression material aluminum foil of oil tank for gas station

Owner:茂名市亚泰铝合金抑爆材料有限公司

Explosion suppression material

The invention relates to an explosion suppression material. The explosion suppression material comprises the following chemical components in percentage by weight: 0.05-0.1% of Si, 0.03-0.035% of Cu, 1.0-1.1% of Mn, 1.0-1.1% of Mg, 0.2-0.3% of Cr, 0.05-0.08% of Ti, 0.08-0.12% of Fe, 0.08-0.1% of Zn and the balancing amount of Al. The explosion suppression material has an excellent corrosion-resistant property and is high ductility; in addition, the explosion suppression material is relatively high in strength and can completely meet the needs.

Owner:BEIJING PHOENIX TECH CO LTD

Tea flavor moon cake and preparation method thereof

The invention discloses a tea flavor moon cake which comprises moon cake skin and moon cake filling, wherein the moon cake skin comprises water dough and oil dough; the water dough is prepared from the following raw materials in parts by weight: 10-15 parts of wheat flour, 3-4 parts of water and 2-3 parts of rapeseed oil; the oil dough is prepared from the following raw materials in parts by weight: 10-15 parts of wheat flour and 5-7 parts of lard oil; the moon cake filling is prepared from the following raw materials in parts by weight: 3-3.5 parts of steamed dough, 3-4 parts of peanuts, 2-3 parts of walnuts, 5-6 parts of sesames, 2-3 parts of white sugar, 0.4-0.6 part of lard oil, 1-2 parts of dried tangerine or orange peel and 10-12 parts of tea leaves; a part refers to the weight of 0.5kg. The invention further discloses a method for preparing the tea flavor moon cake. The tea flavor moon cake is natural and healthy in food materials and does not have any preservative or additive; by carefully choosing and reasonably mixing the various raw materials, the nutritional ingredients of the various raw materials are remained to the greatest degree, and oily feel brought by the lard oil is neutralized by using the tea leaves salted by the dried tangerine or orange peel and sugar.

Owner:姚金龙

Fluorescent pencil lead

The invention discloses a fluorescent pencil lead, which comprises, by weight part, 10-15 parts of clay, 40-50 parts of graphite, 10-15 parts of pigment powder, 2-4 parts of sodium carboxymethylcellulose, 8-12 parts of a colourant, 5-10 parts of an adhesive, and 10-20 parts of photoinduced energy storage noctilucent powder. The written handwriting emits fluorescence in the dark. The manufactured pencil lead writes smoothly, is not prone to generate slag, is high in adhesive force, and is not likely to be broken.

Owner:RUGAO CHANGJIANG SCI & TECHCAL IND CO LTD

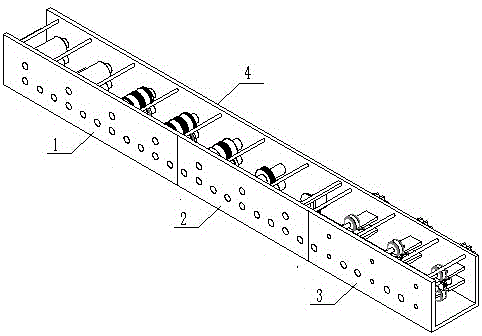

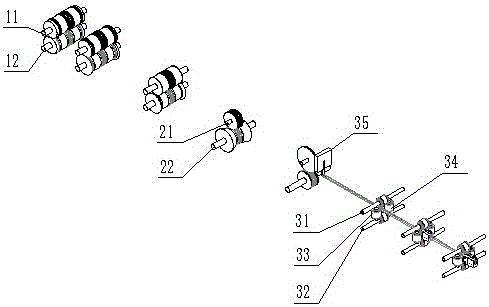

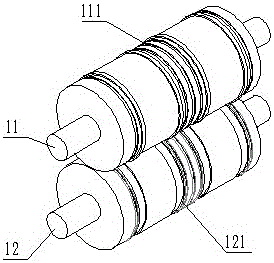

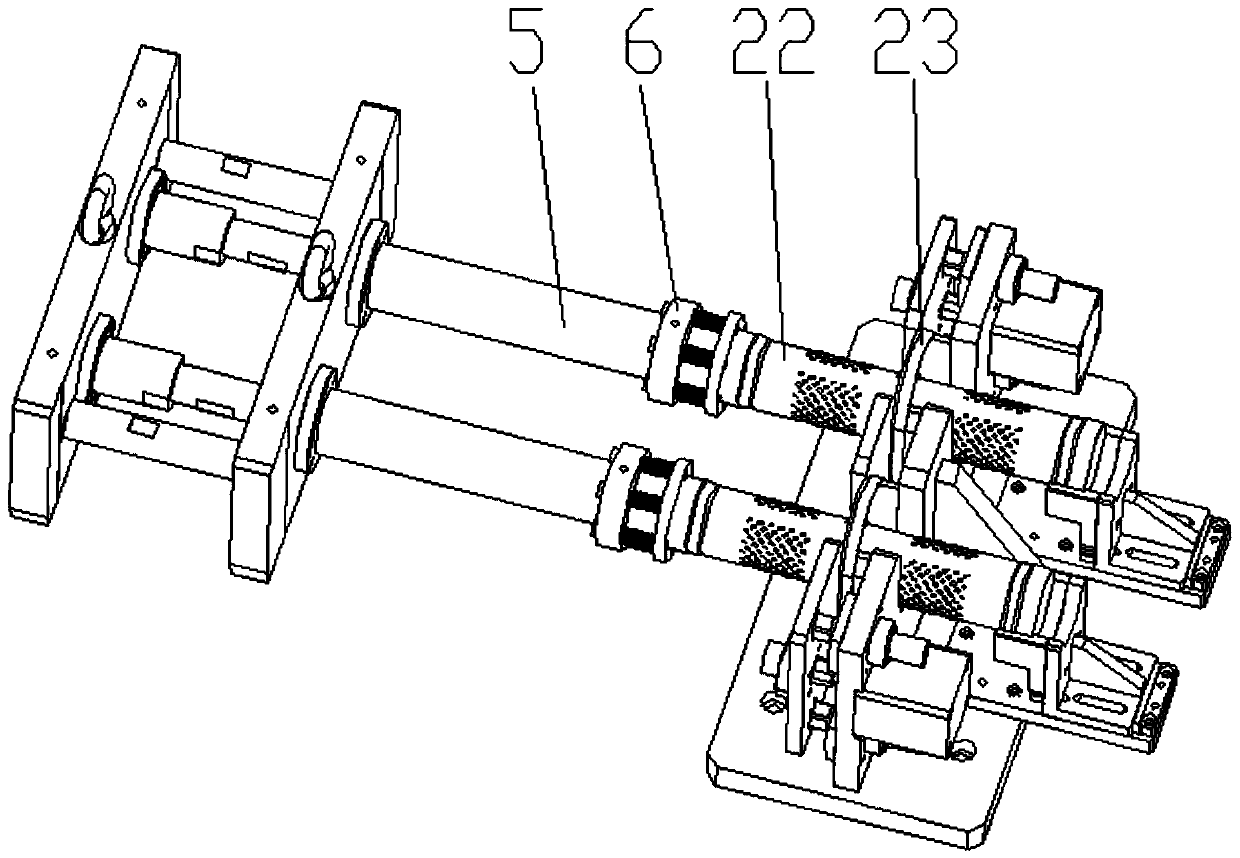

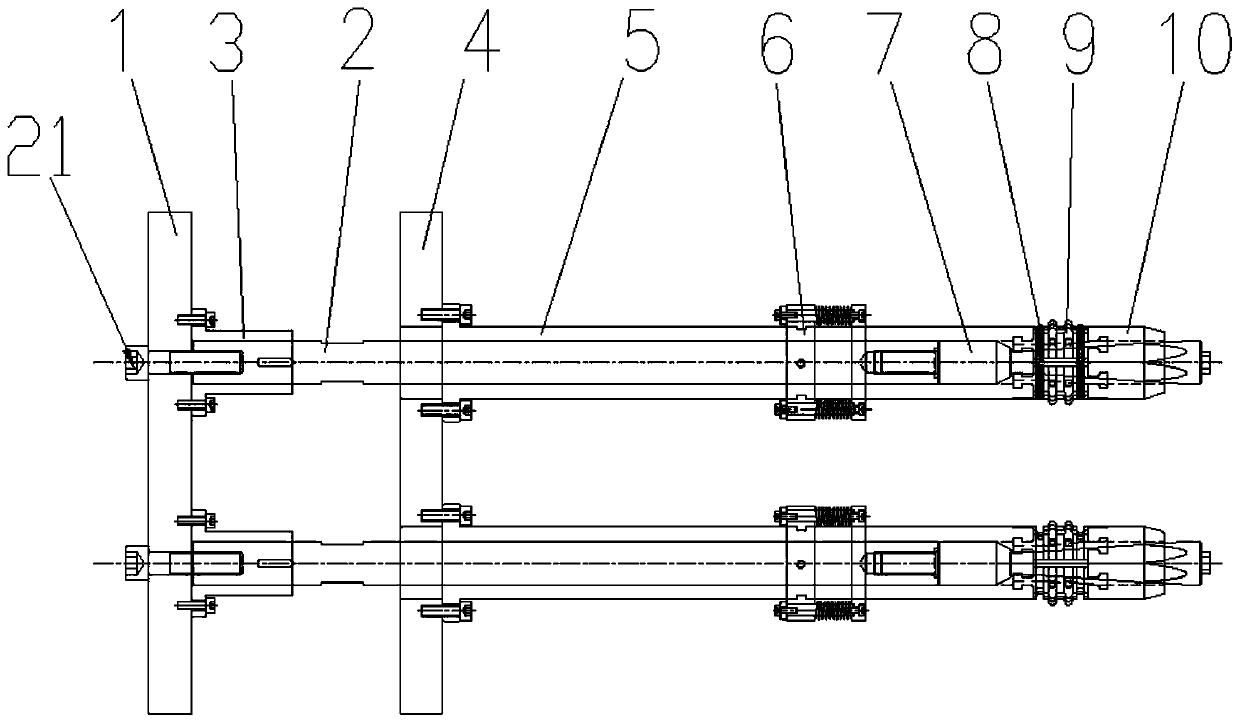

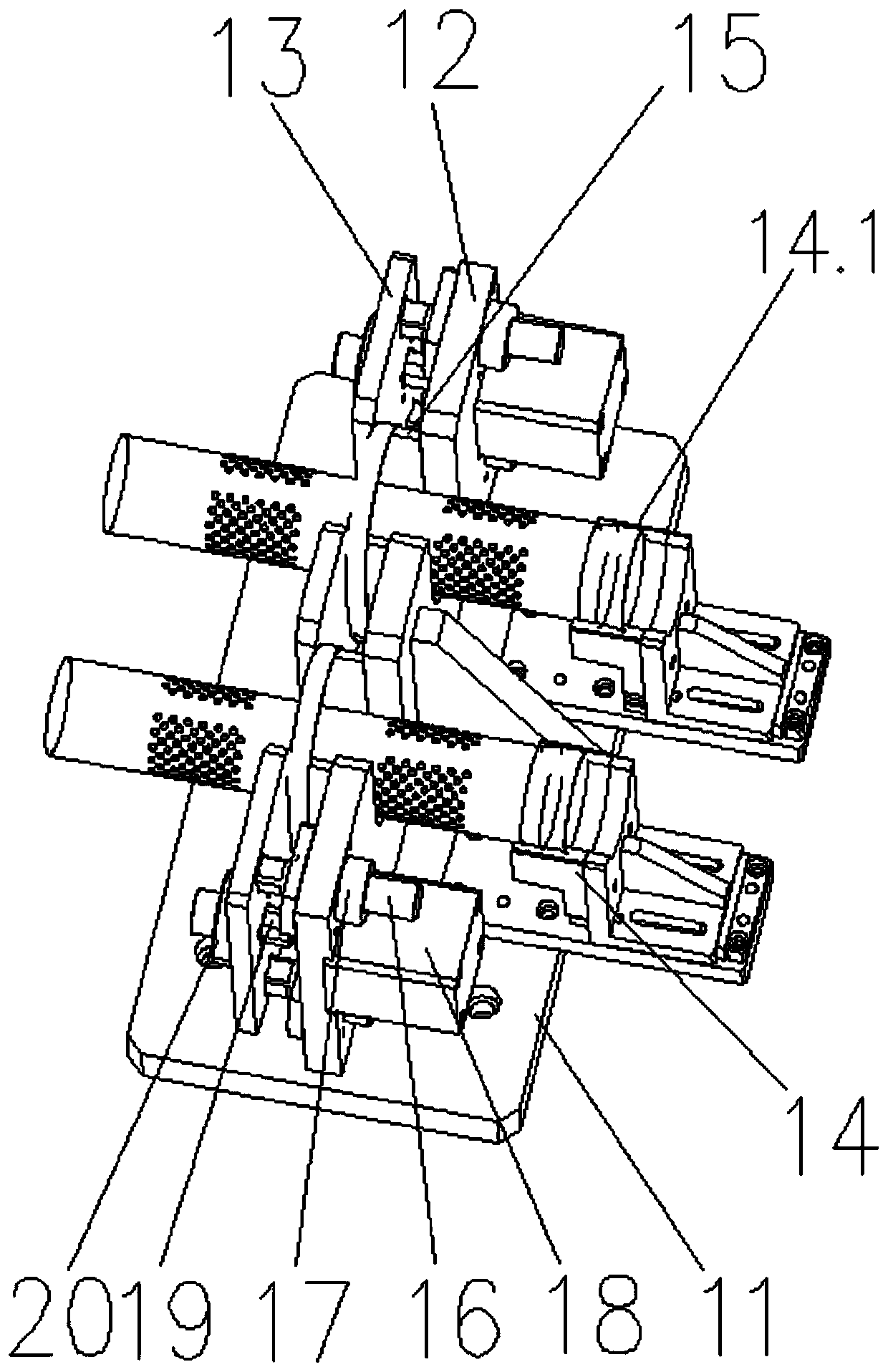

Sectional material forming device

A profile forming device, which includes an indentation section, a gathering section and a forming section fixed on a frame in sequence, the indentation section is composed of an upper creasing roller and a lower creasing roller, and the gathering section is composed of an upper gathering roller and a lower gathering roller The forming section is composed of forming upper roller, forming lower roller, forming left roller, forming right roller and pressing device, and the steel belt is located between the upper and lower rollers of the creasing section, gathering section and forming section. It has the characteristics of simple structure, no welding equipment, low cost, good forming effect and high production efficiency.

Owner:HUBEI MEILI PROTECTING FACILITY TECH

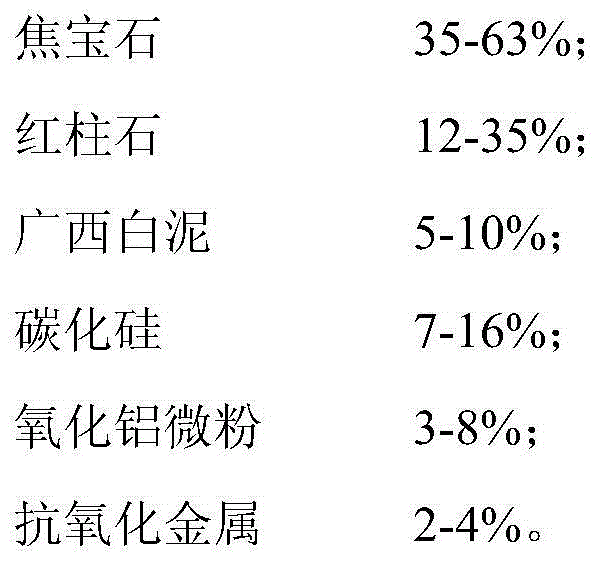

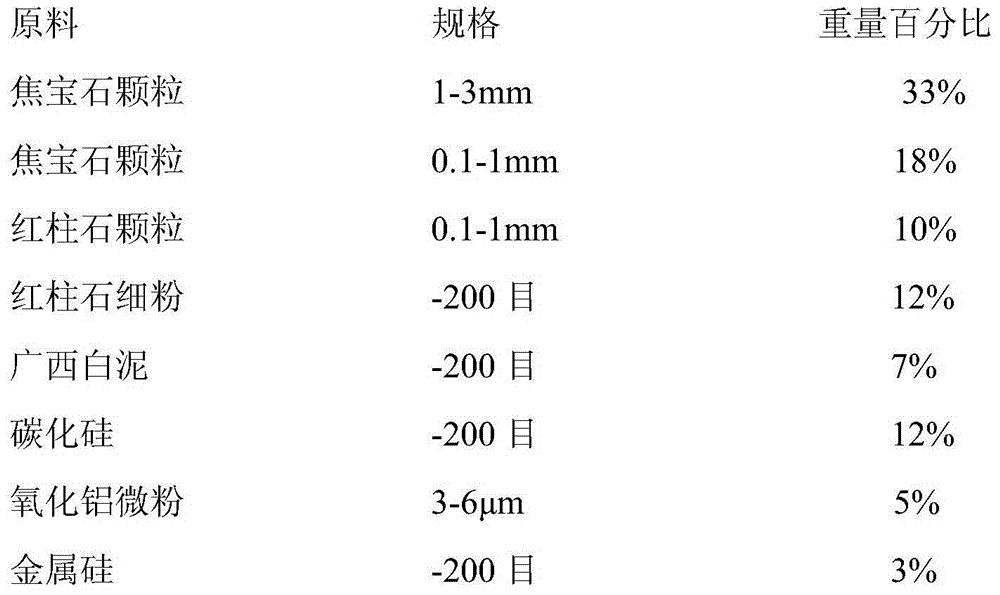

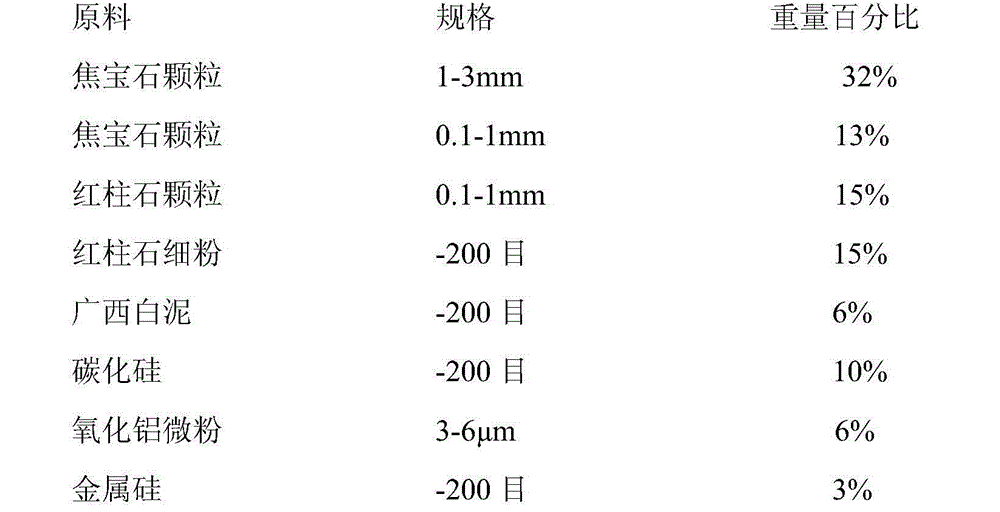

Refractory material used for ladle and preparation method of refractory material

The invention belongs to the technical field of refractory materials, and particularly relates to a refractory material used for a ladle and a preparation method of the refractory material. The refractory material is prepared from the following materials in percentage by weight: 35-63% of flint clay, 12-35% of andalusite, 5-10% of Guangxi white mud, 7-16% of silicon carbide, 3-8% of alumina micro powder and 2-4% of anti-oxidant metal. The refractory material has the characteristics of good size stability, peelingresistance, anti-corrosion, no adhering slag and good thermal insulation. The preparation method is simple in process and easy to conduct.

Owner:山东硒拓新材料科技有限公司

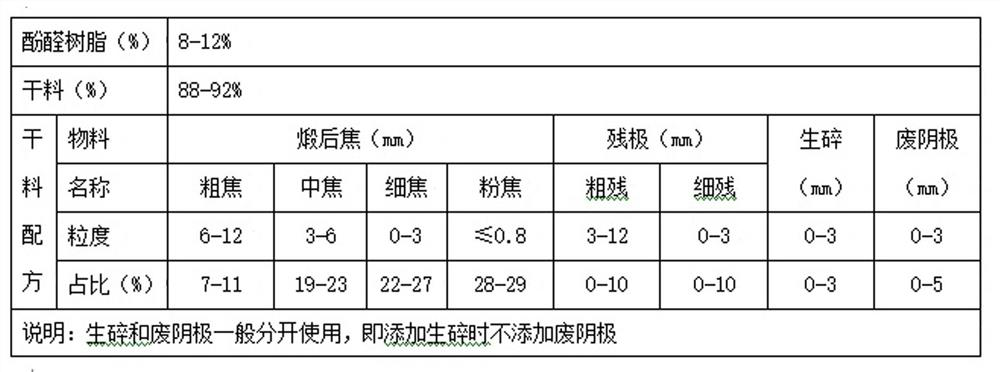

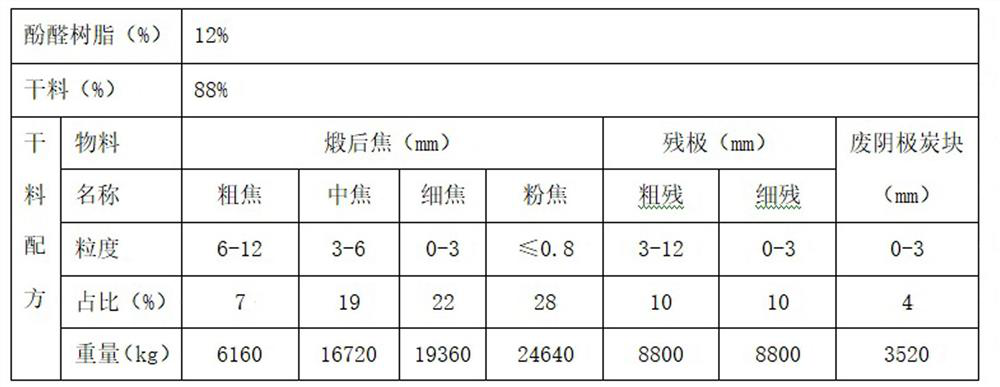

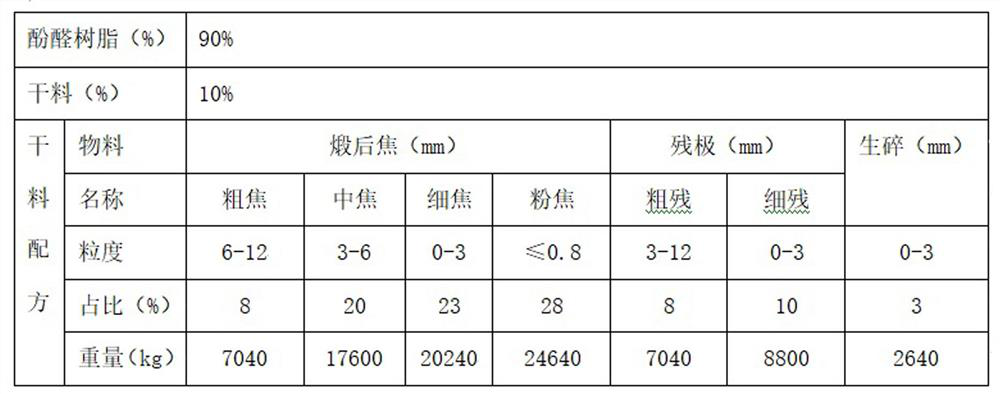

Production method of novel environment-friendly anode carbon block

The invention discloses a production method of a novel environment-friendly anode carbon block. The production method comprises the following steps of: respectively crushing and screening 88-92 parts of a dry material and 8-12 parts of phenolic resin; mixing and kneading the dry material for 20-25 minutes, adding phenolic resin, mixing and kneading for 20-25 minutes to obtain a paste material, uniformly putting the paste material into a mold in a vibration molding machine, performing compression molding by using a hydraulic machine, demolding and cooling to form a primary green anode carbon block; feeding the primary green anode carbon block obtained after demolding into a tunnel type electric heating kiln, and heating for 2-3 hours at the temperature of 150-200 DEG C to obtain a green anode carbon block; then putting the green anode carbon block into a roasting furnace for roasting, and raising the temperature of a flame path in the roasting furnace to 200 DEG C from the normal temperature at a heating rate of 3-4 DEG C / H; raising the temperature to 1100 DEG C from 200 DEG C at a heating rate of 8-10 DEG C / H; and keeping the temperature at 1100 DEG C for 48 hours to enable the anode temperature to uniformly reach 950-1000 DEG C, thereby obtaining a mature anode carbon block. The method is environment-friendly and low in use cost.

Owner:河南中孚铝业有限公司

Fresh keeping tablets for grapes

InactiveCN105076372AInhibition of growth and reproductionEffective antiseptic preservationFruit and vegetables preservationSide effectMagnesium stearate

The invention discloses fresh keeping tablets for grapes. The fresh keeping tablets are prepared from the following raw materials in percentage by weight: 60-70% of a fresh keeping agent, 2-4% of a Chinese herbal medicine antibacterial agent, 10-20% of a slow-release agent, and 1-2% of magnesium stearate, wherein the Chinese herbal medicine antibacterial agent is selected from but not limited to one or several kinds of celery seeds, dill seeds, alpine yarrow herb, hyssopus officinalis and camomile; the slow-release agent is selected from starch and / or microcrystalline cellulose; the fresh keeping tablets are prepared through the following steps: crushing the raw materials, screening the crushed materials, feeding the screened materials through calculation, mixing the fed materials, preparing wet granules, baking the wet granules, enabling the baked granules to be made into whole granules, totally mixing the whole granules, and tabletting the mixed granules, wherein the weight of each fresh keeping tablet is 0.7-0.8g. The fresh keeping tablets for the grapes provided by the embodiment of the invention have the advantages that in the storage and transportation process, the grapes stored with the fresh keeping tablets are high in fresh keeping degree, and the fresh keeping tablets take effect quickly, are convenient, simple and safe, and are free from any side effects. The grapes can maintain the original color and the original flavor for a long term.

Owner:XINJIANG AILIYATE BIOTECH CO LTD

Ridging die for damping package inner assembly of vehicle exhaust system

PendingCN110666043AEasy to operateDimensional stability in productionShaping toolsMetal-working feeding devicesPipe fittingClassical mechanics

The invention relates to a ridging die for a damping package inner assembly of a vehicle exhaust system. The ridging die comprises a ridging assembly and a clamping tool assembly, wherein the ridgingassembly comprises a ridging movable plate, positioning rings, pull rods, a ridging fixed plate, outer sleeve rods, positioning mechanisms, cone rods, clamping and locking die bodies and end clampingheads, and the clamping tool assembly comprises a tool base plate, tool fixed plates, tool movable plates, pipe fitting positioning blocks, profiling plates, guide pillars, guide sleeves, oil cylinders, oil cylinder connecting rods and floating joint bases. By means of the ridging die, part of metal of a damping pipe is stretched and deformed, and the inner assembly assembling process of fixing two parts of a clapboard and the damping pipe is achieved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Indoor landscape wall or gallery painted with viable moss on wall surface

InactiveCN110754315AEasy to keep tidyDoes not rotCovering/liningsSelf-acting watering devicesLiving roomCement board

The invention discloses an indoor landscape wall or gallery painted with viable moss on the wall surface. According to the indoor landscape wall or gallery, a modified alkali-reducing cement board isused as a moss attaching substrate, superabsorbent fibers are used as water-supply moisturizing materials, and single or multiple moss cut stem composites, resistant to shade and drought and capable of normally growing on an alkaline substrate, are selected. An effective soft decoration approach is provided for indoor space walls of subway passages and platforms, large comprehensive indoor plazas,offices, living rooms and the like, so as to reduce threats to human health, which are caused by excessive formaldehyde, radioactive radiation and the like generated in prevalent hard decoration of such places, and accordingly, the indoor environment is purified and beautified. The indoor landscape wall or gallery has the advantages that indoor three-dimensional greening conditions are met, the technical factors that existing three-dimensional moss greening technologies are not suitable for indoor spaces and especially not suitable for wall greening in living rooms are eliminated, the moss isplanted on the cement board directly, rot, odor, poison and peeling are avoided, simple management is achieved, an effective approach is provided for improvement of indoor soft decoration and indoorenvironment as well as protection of physical and psychological health of citizens, and the indoor landscape wall or gallery has a broad application prospect.

Owner:武汉长江绿色工程科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com