Ridging die for damping package inner assembly of vehicle exhaust system

A technology of automobile exhaust system and internal components, which is applied in the direction of forming tools, manufacturing tools, feeding devices, etc., can solve problems such as abnormal noise of the muffler package, and achieve the effect of stable production size and convenient mold operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

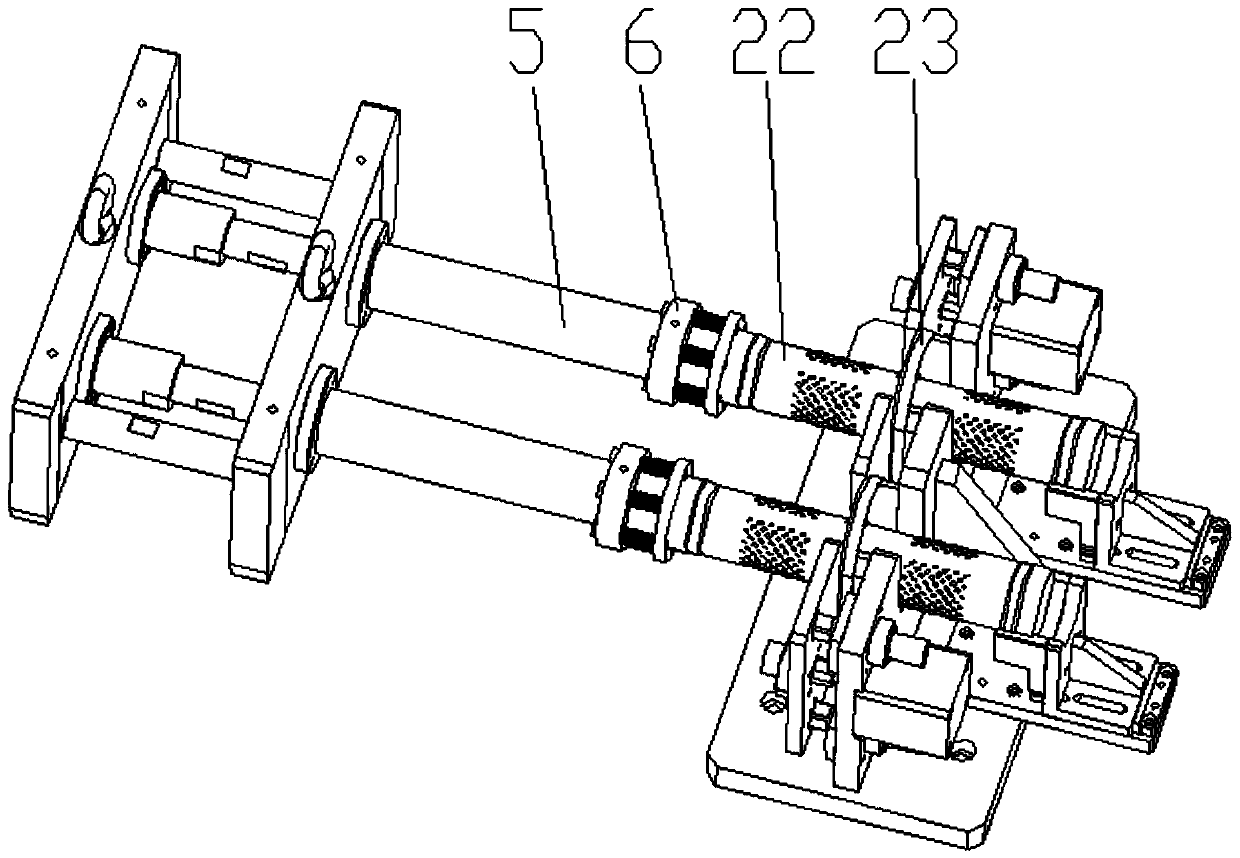

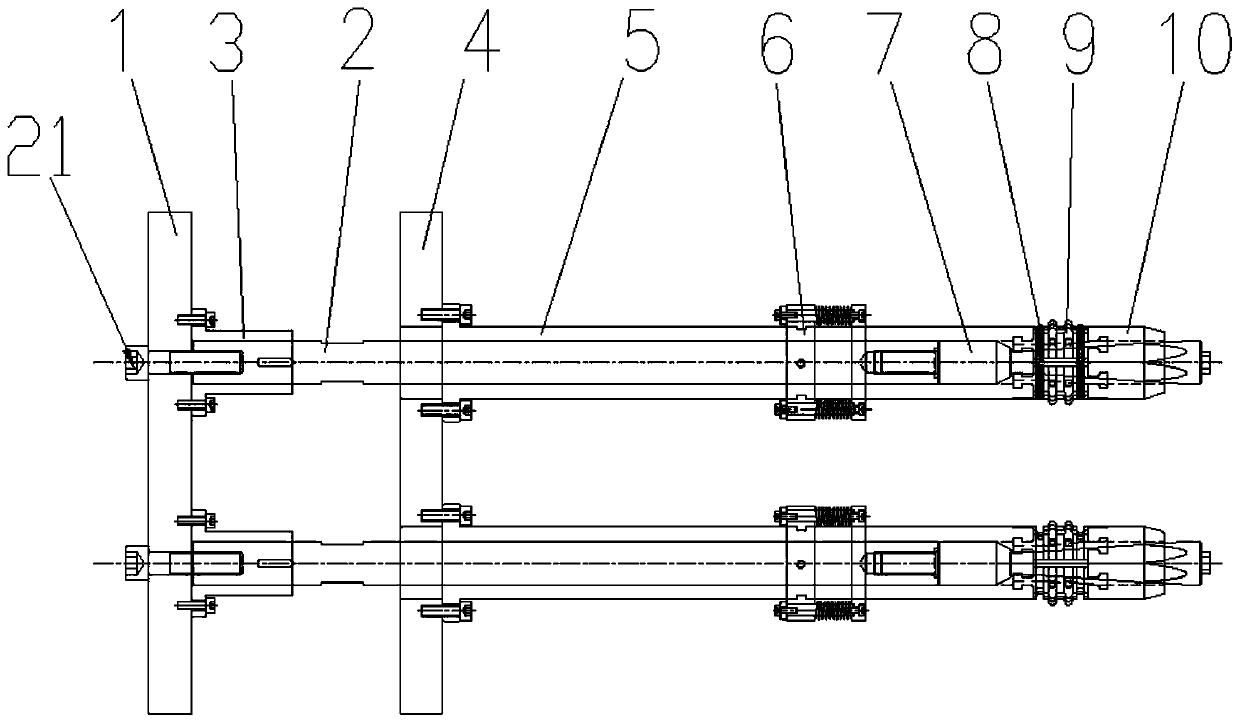

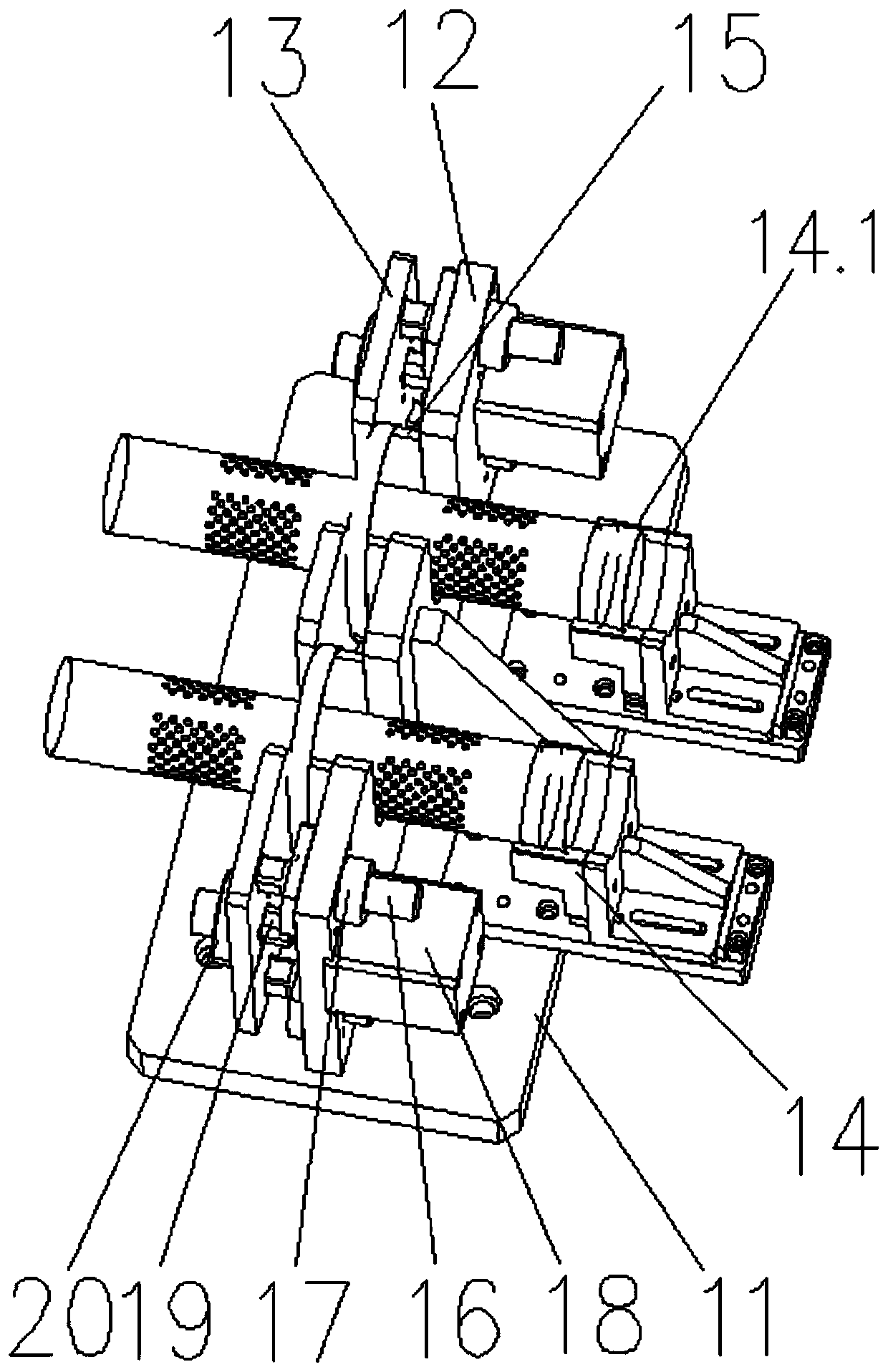

[0028] Such as Figure 1~Figure 5 As shown, a ridge mold of an automobile exhaust system muffler package inner component ridge mold in the embodiment is characterized in that it includes a ridge assembly and a clamping tool assembly, wherein the ridge assembly includes a ridge movable plate 1, a positioning ring 3, Tie rod 2, ridge fixing plate 4, overcoat rod 5, positioning mechanism 6, taper rod 7, locking mold 9, end chuck 10;

[0029] The ridge movable plate 1 and the ridge fixed plate 4 are arranged side by side;

[0030] A locating ring 3 is installed on one side of the ridge movable plate 1, and a pull rod 2 is installed in the center of the locating ring 3, and the end of the pull rod abuts against the ridge movable plate 1, and is locked on the ridge by a fixing member 21. On movable board 1;

[0031] The pull rod 2 is arranged through the ridge fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com