Patents

Literature

173results about How to "Eliminate abnormal noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

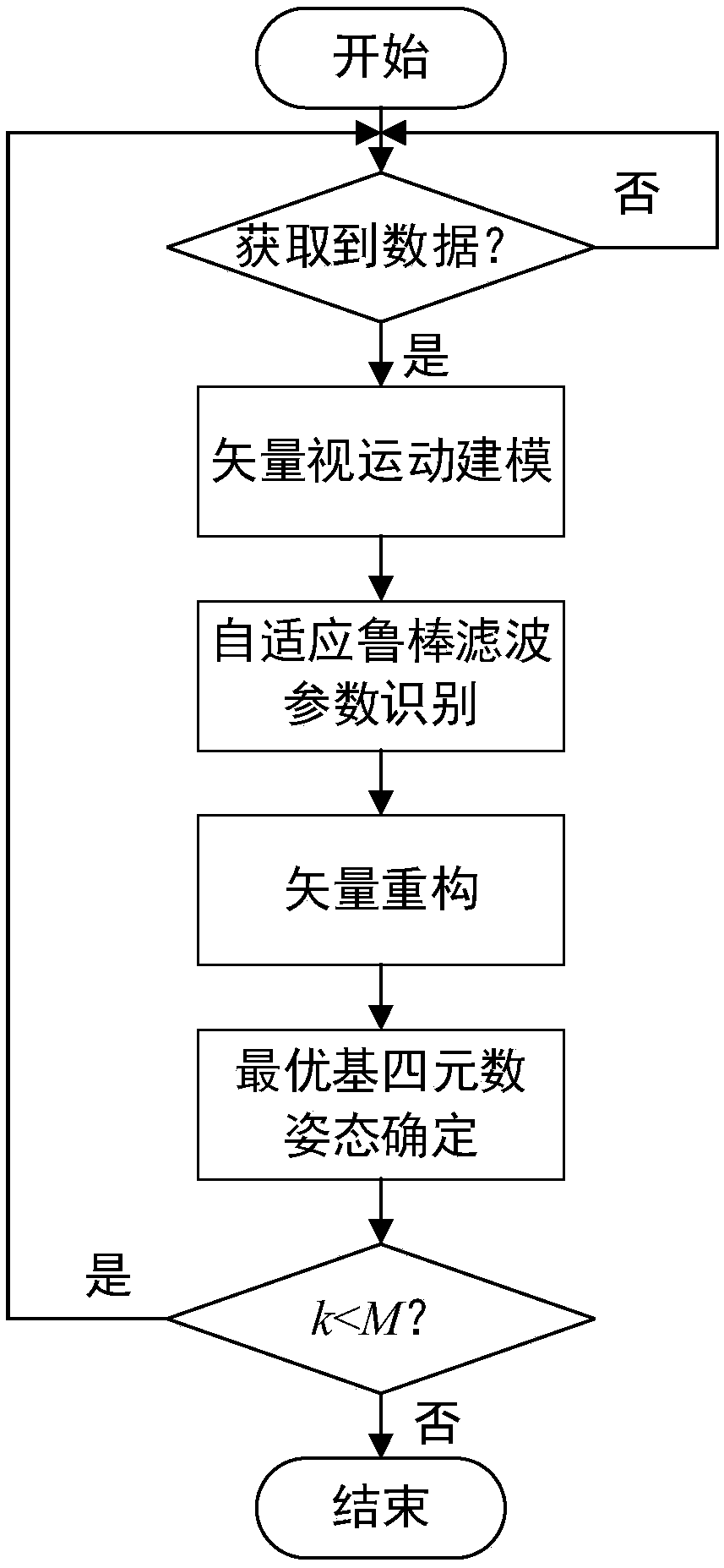

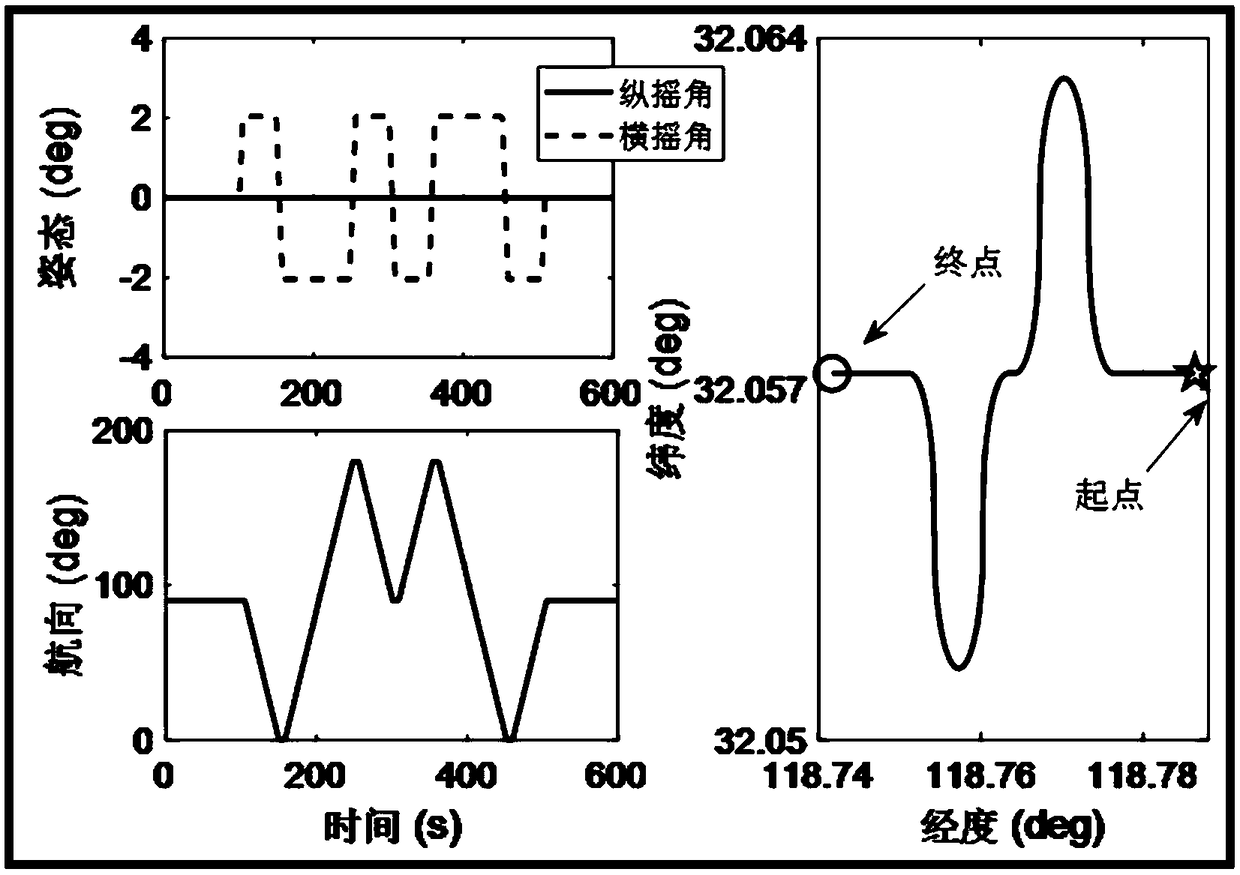

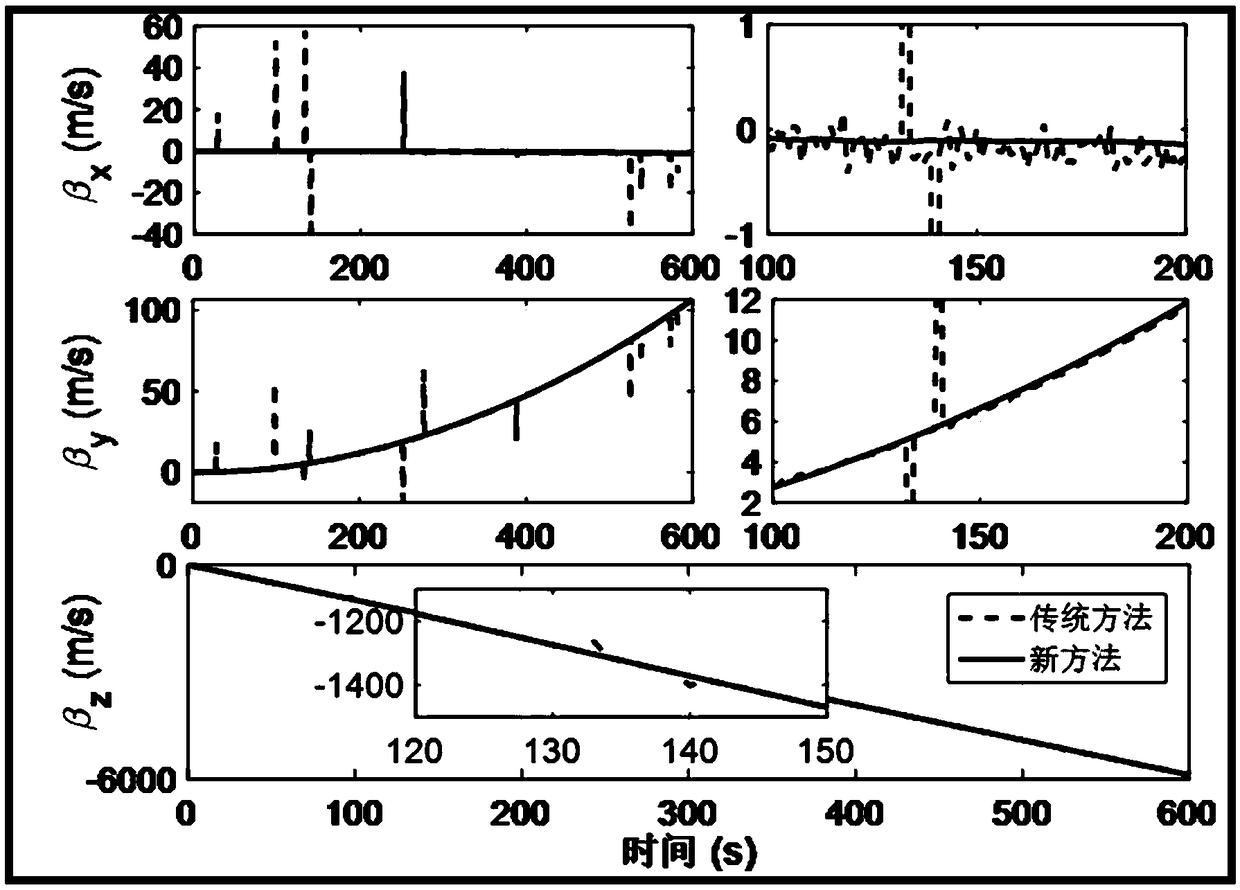

DVL-assisted (Doppler velocity log-assisted) SINS (strap-down inertial navigation system) robust on-moving initial alignment method

ActiveCN109141475ARealize Quantitative RepresentationReduce the influence of abnormal noiseMeasurement devicesReal-time dataQuaternion

The invention discloses a DVL-assisted SINS robust on-moving initial alignment method. The DVL-assisted SINS robust on-moving initial alignment method comprises the following steps of step (1), acquiring real-time sensor data; step (2), establishing a vector apparent motion parameter equation; step (3), on the basis of establishing the vector apparent motion parameter equation, estimating a parameter matrix through adaptive robust Kalman filtering; step (4), establishing reconfiguration vectors based on estimated parameters; step (5), through an optimal base quaternion attitude determining method, computing the error angle between a determined attitude and a real attitude; step (6), setting an initial alignment moment as M and a real-time data acquiring moment as k, if k=M, outputting an initial alignment result and completing an initial alignment process, and if k<M, determining that the initial alignment process is not completed, and repeating the above steps of (1) to (5) until theinitial alignment process is completed. The DVL-assisted SINS robust on-moving initial alignment method solves the problems of poor alignment precision and divergent alignment processes when system measured noise is abnormal.

Owner:北京唯实深蓝科技有限公司

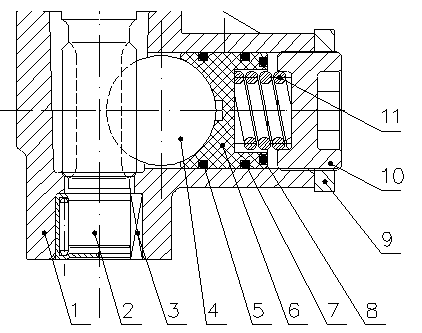

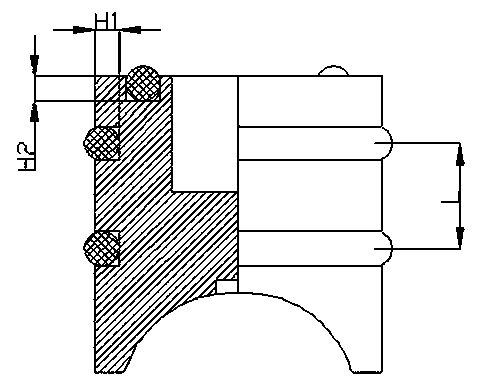

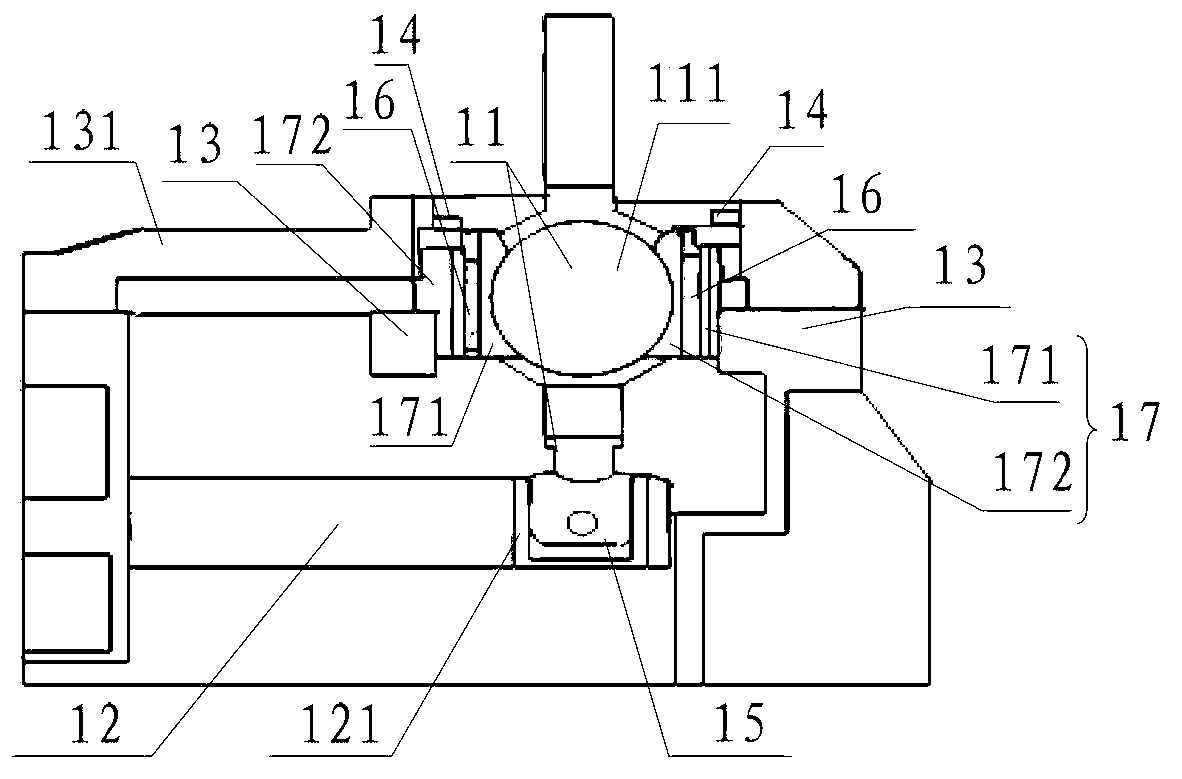

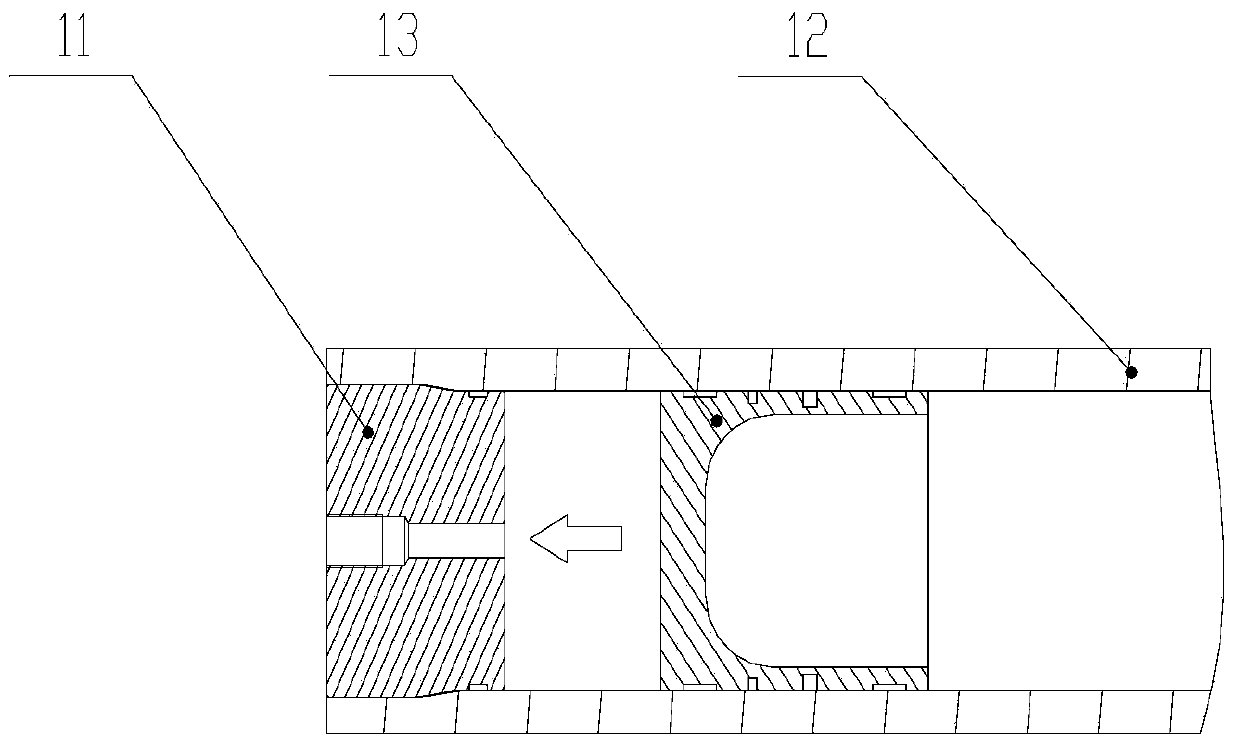

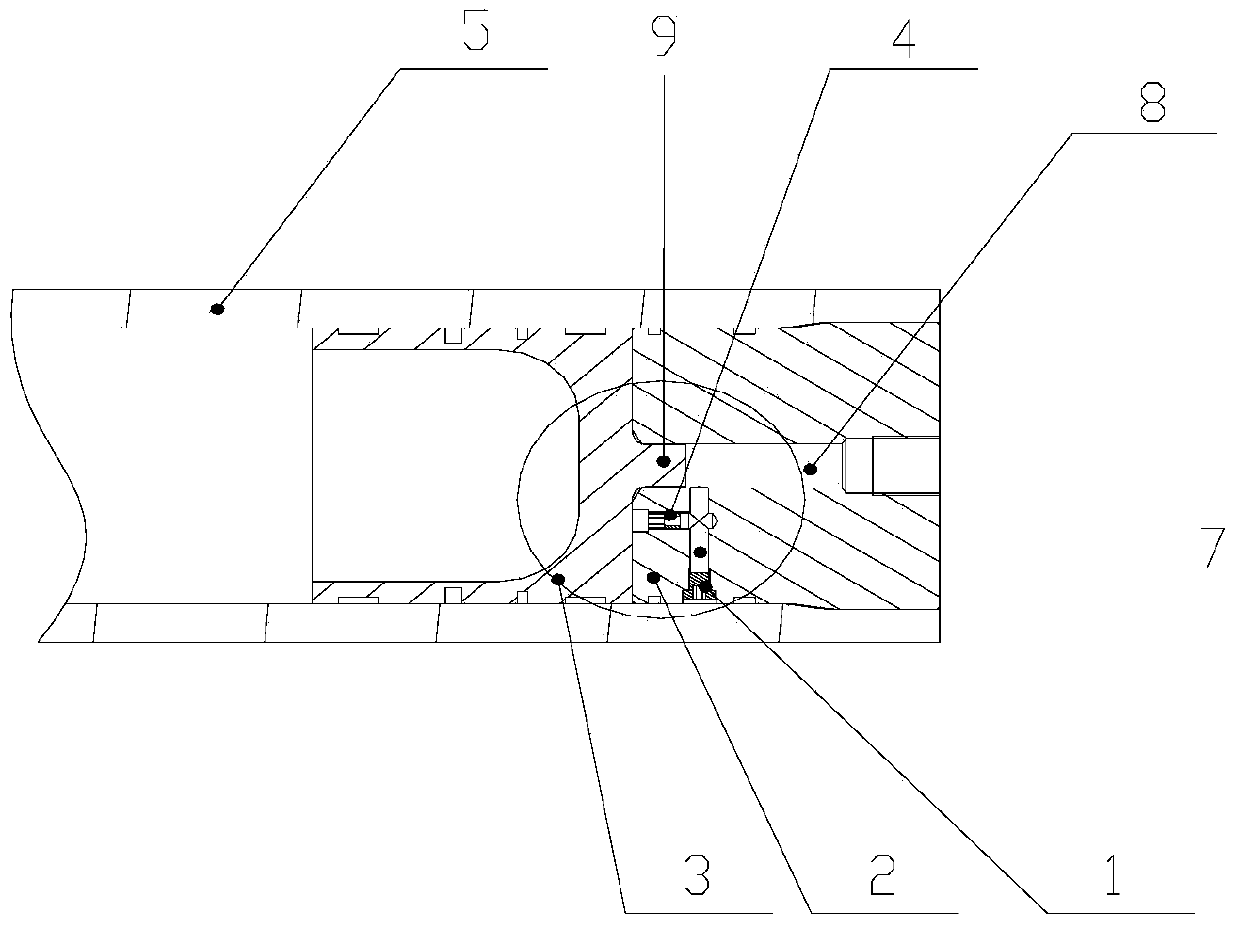

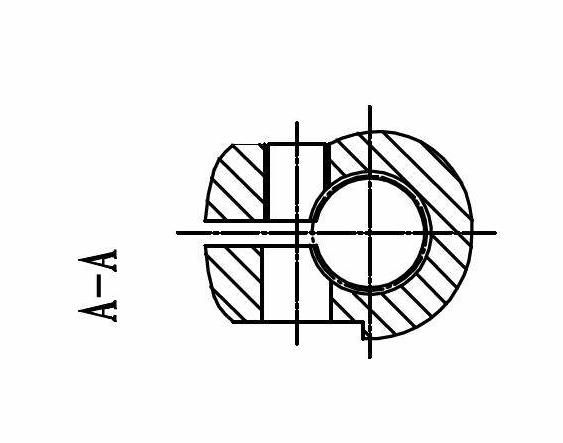

Abnormal sound prevention structure of automobile mechanical steering gear

The invention relates to the field of mechanical steering gears of automobile steering systems, and provides an abnormal sound prevention structure of an automobile mechanical steering gear. The abnormal sound prevention structure comprises a steering gear body shell, a small gear shaft, a gear shaft fixing bearing, a gear rack, a clearance adjusting and locking nut and a clearance adjusting nut, the small gear shaft is fixedly arranged in the steering gear body shell through the gear shaft fixing bearing, the outer side of the gear rack is pressed by one end of a gear rack supporting press block, the clearance adjusting nut is screwed on the steering gear body shell and compresses a spring, the other end of the spring is compressed bythe other end of the gear rack supporting press block, two annular grooves are formed in the circumferential face, matched with the steering gear body shell, of the gear rack supporting press block, and are provided with an O-shaped rubber ring I and an O-shaped rubber ring II respectively, the end face, opposite to the clearance adjusting nut, of the gear rack supporting press block, is provided with a third annular groove, and an O-shaped rubber ring III is arranged in the third annular groove. Through the abnormal sound prevention structure, performance requirements for the automobile steering systems can be met, and abnormal sounds of a traditional mechanical steering gear can be reduced or even removedcompletely.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

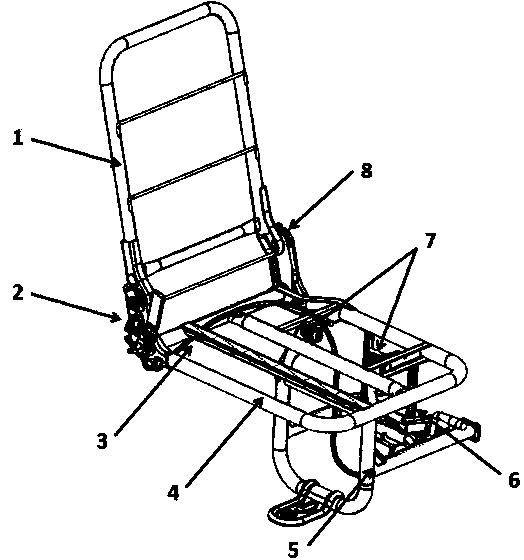

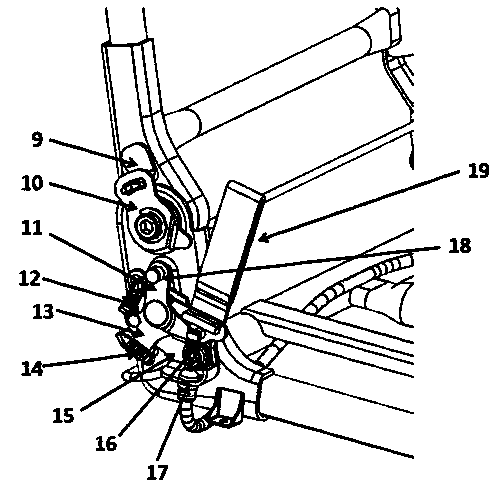

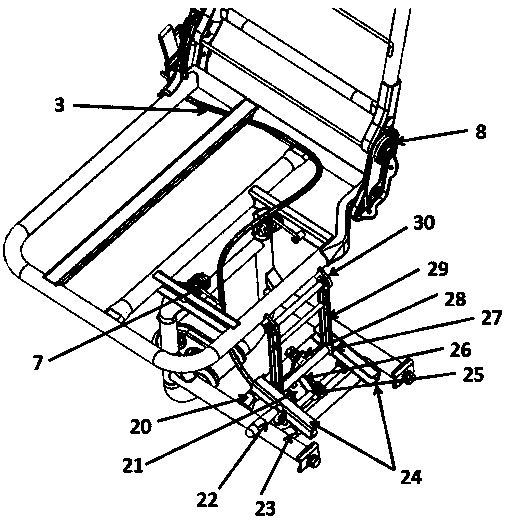

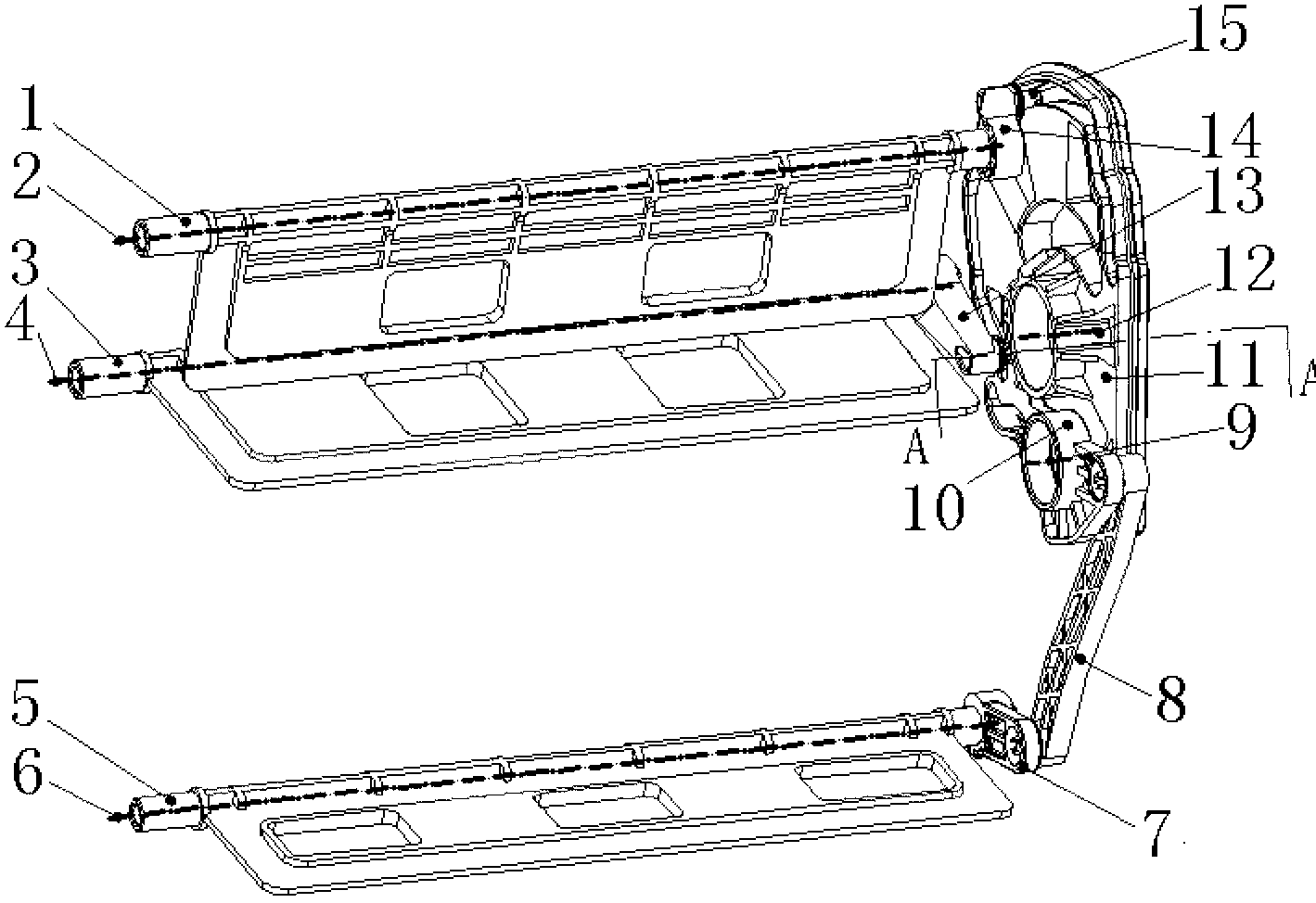

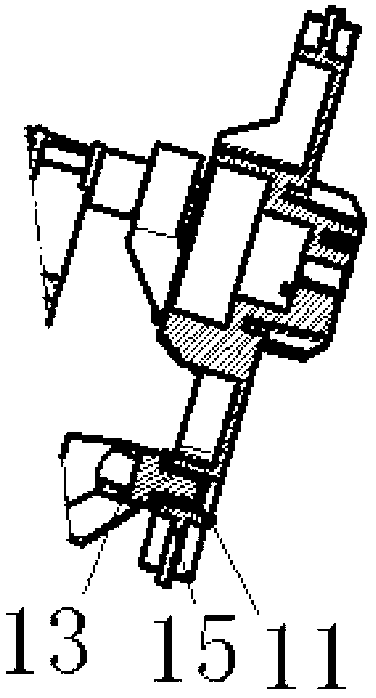

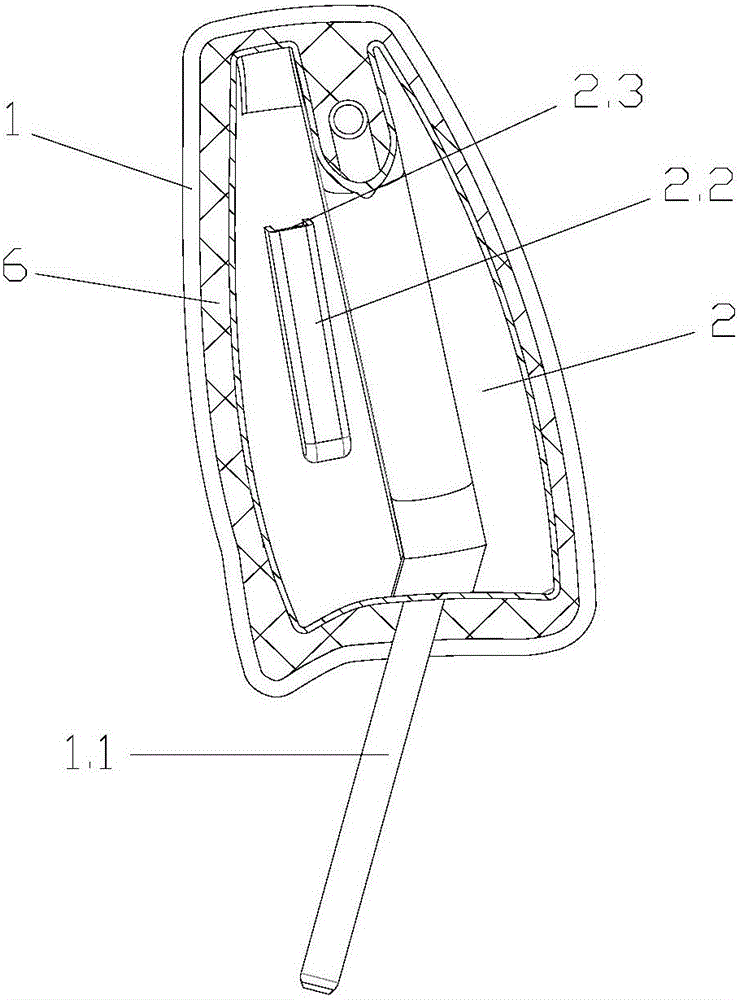

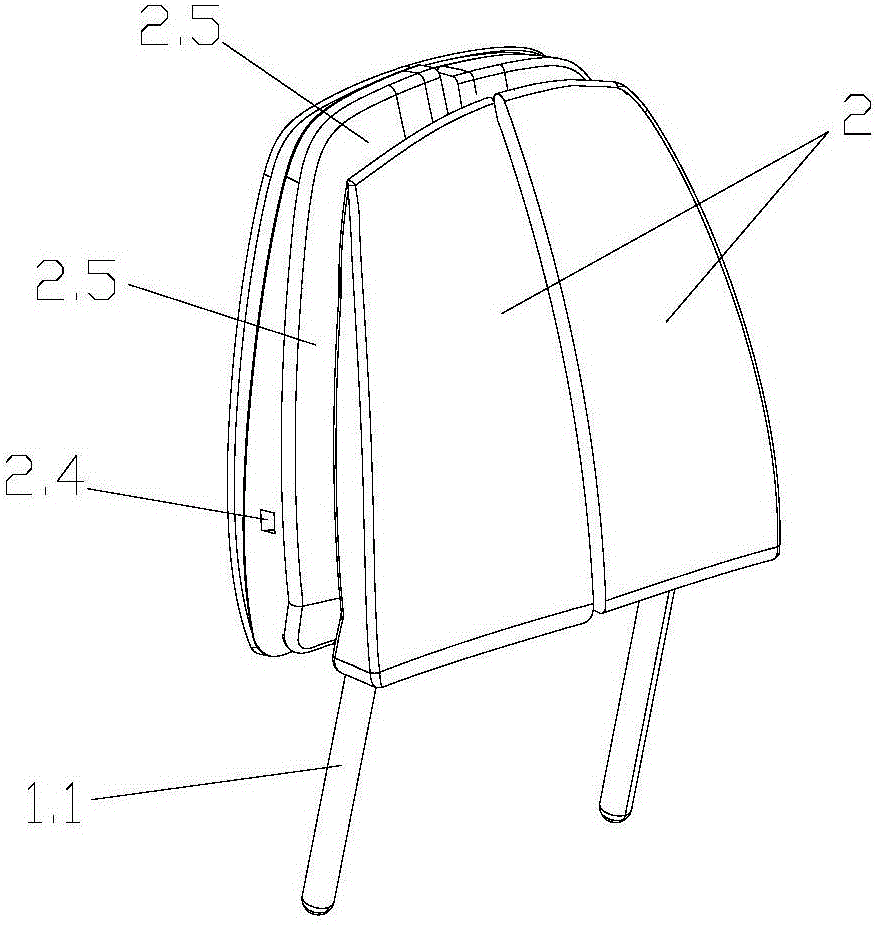

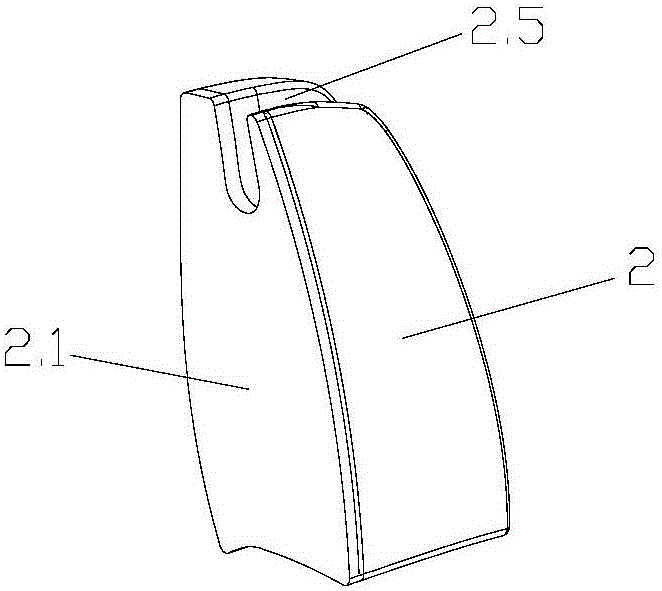

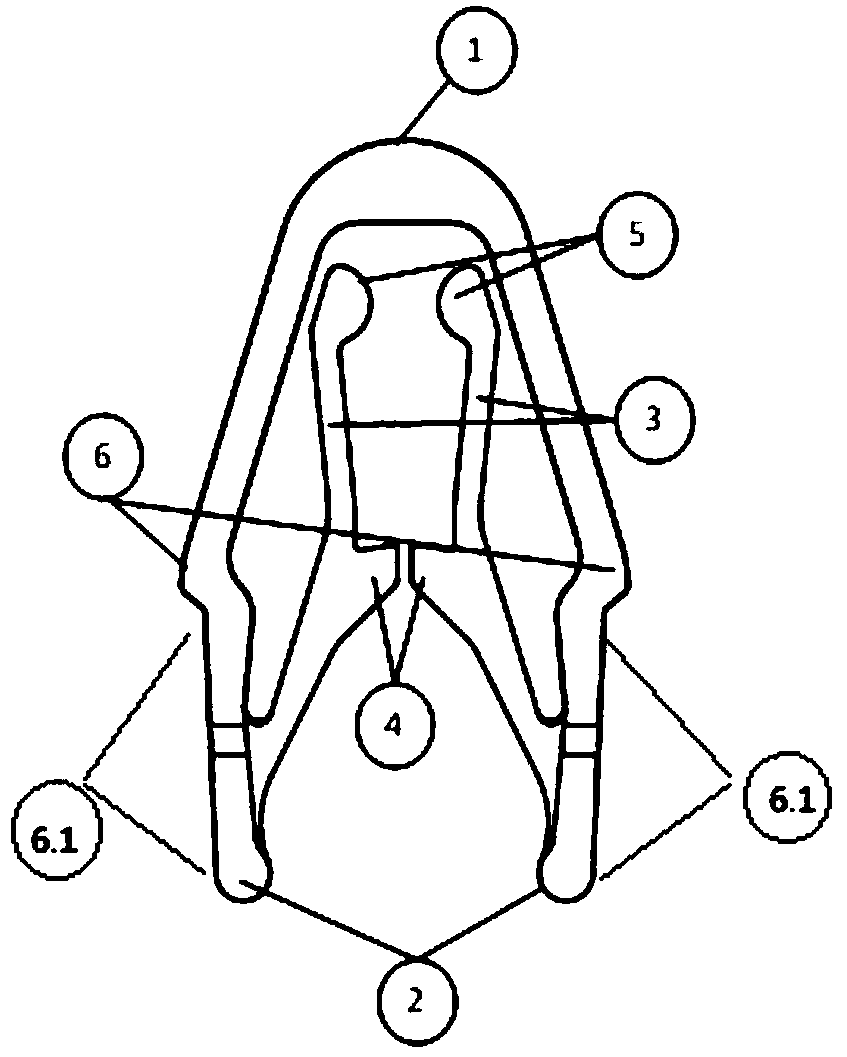

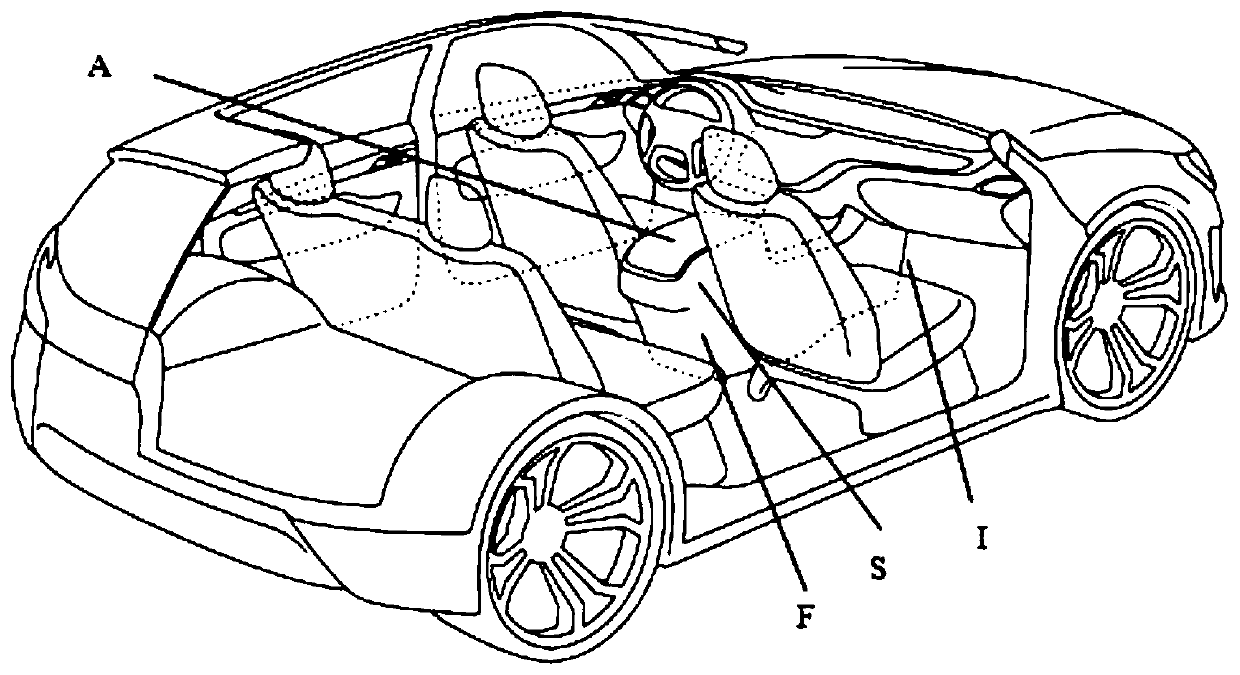

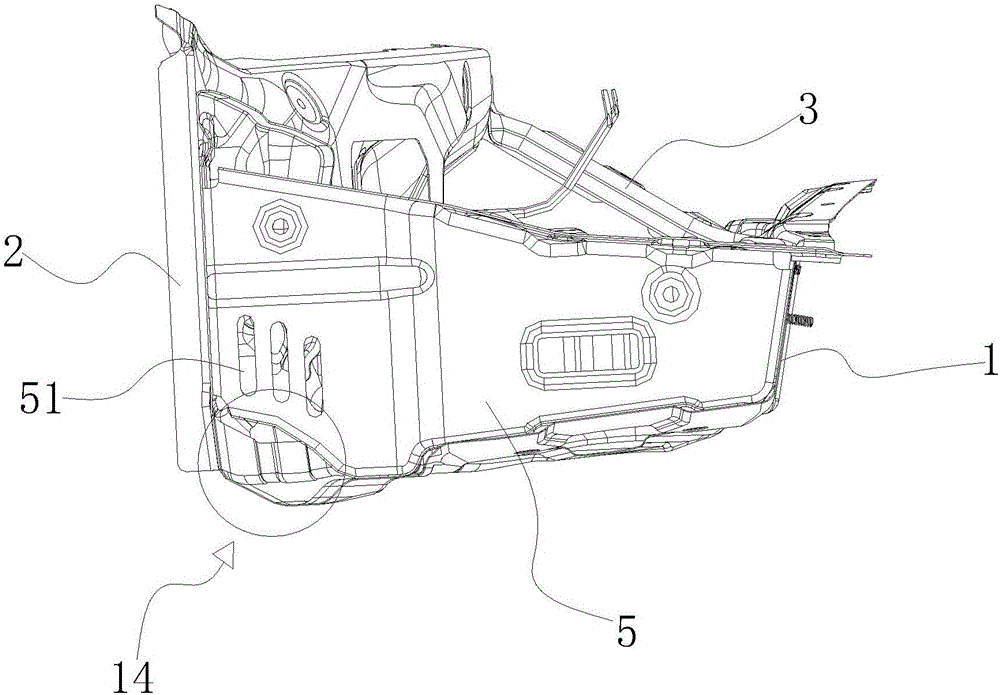

Car seat with automatic folding and turning function

ActiveCN104309503AImprove the convenience of getting on and offImprove security levelMovable seatsDismountable/non-dismountable seatsCar seatCoil spring

The invention relates to car seats, in particular to a car seat with an automatic folding and turning function. The car seat mainly comprises a backrest tube framework (1), a backrest and cushion linkage unlocking mechanism (2), a cushion tube framework (4), a turning mechanism (6) and a cushion turning mechanism (7). The backrest tube framework (1) is connected with the cushion tube framework (4). The backrest and the backrest and cushion linkage unlocking mechanism (2) are disposed on the backrest tube framework (1). The turning mechanism (6) is disposed on the cushion tube framework (4). The cushion turning mechanism (7) is disposed on the cushion tube framework (4). The car seat has the advantages that the car seat satisfies the requirements of national mandatory laws and regulations, get on and get off convenience of passengers is increased, the safety performance level of a whole car is increased, onerous operation steps are eliminated, performance level of the whole car is increased, user experience is increased, and problems of seat loosening and abnormal sounds are solved by means such as backrest coil spring assisting design.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

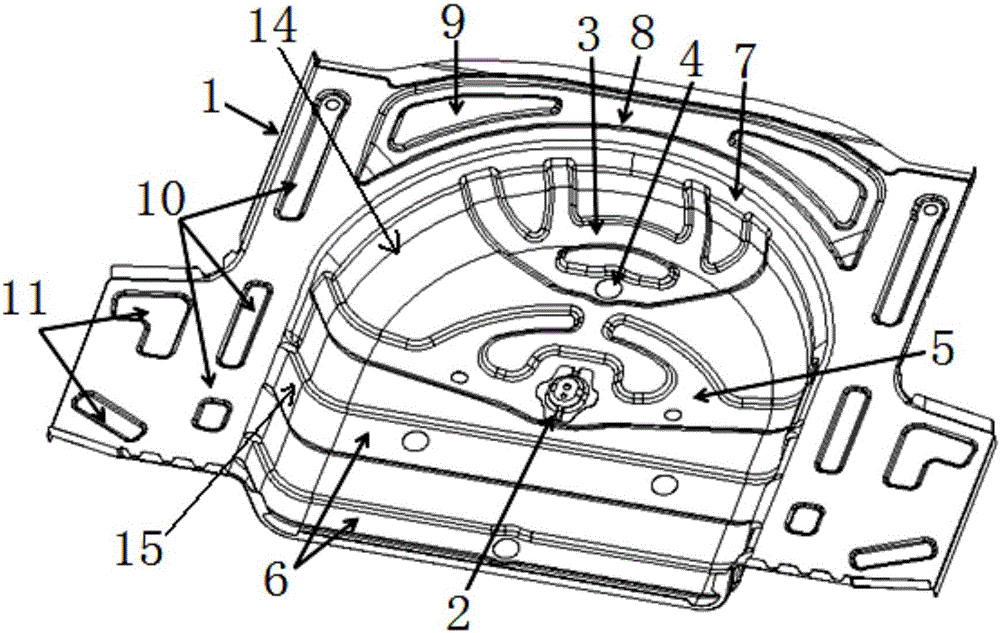

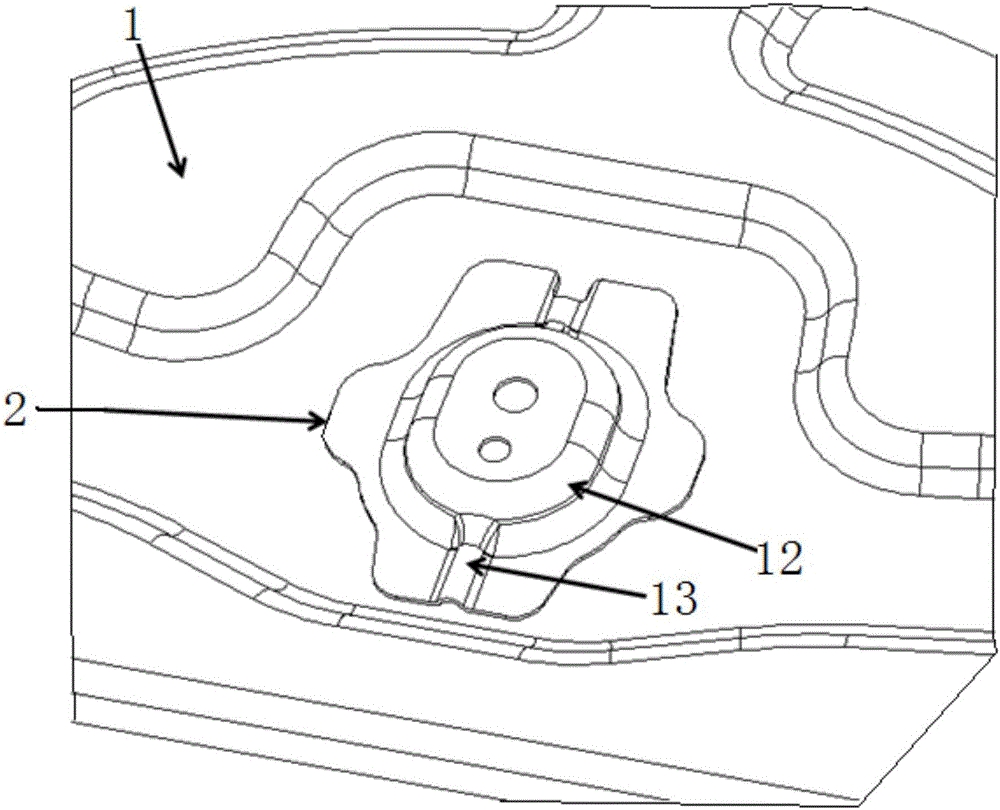

Automobile spare tire installing structure

The invention discloses an automobile spare tire installing structure, which comprises a spare tire pool arranged on a back floor, wherein the spare tire pool comprises a spare tire pool front part and a spare tire pool back part; the spare tire pool front part is of a circular arc structure; the spare tire pool back part extends out in the tangential direction of the circular arc of the spare tire pool front part; the cross section of the spare tire pool back part is in a U shape; an installing support frame used for installing an automobile spare tire is arranged in a connecting position of the spare tire pool front part and the spare tire pool back part; structure reinforcing structures are arranged on the periphery of the installing support frame and at the spare tire pool front part and the spare tire pool back part. The automobile spare tire installing structure has the advantages that the carrying capability is high; the structure is simple; the manufacturing process is simple; good modal stiffness performance is realized; the light-weight requirements can be met.

Owner:CHERY AUTOMOBILE CO LTD

Automobile air conditioner mode air damper control mechanism

The invention discloses an automobile air conditioner mode air damper control mechanism, which comprises a defrosting air damper, a defrosting air damper rotating shaft, a defrosting air damper driving rod, a face air damper, a face air damper rotating shaft, a face air damper driving rod, a foot air damper, a foot air damper rotating shaft, a foot air damper driving rod and a mode air damper driving plate which is used for driving three air dampers to rotate to control air conditioner air outlet modes, wherein a face / defrosting air damper movement track groove and a foot air damper movement track groove are arranged on the mode air damper driving plate; the foot air damper, the foot air damper driving rod, a foot air damper movable connecting rod and a foot air damper fixed connecting rod form a four-link mechanism; one ends of the face air damper driving rod and the defrosting air damper driving rod are arranged in the face / defrosting air damper movement track groove; and one end of the foot air damper fixed connecting rod is arranged in the foot air damper movement track groove. The automobile air conditioner mode air damper control mechanism has the advantages of simple transmission process, compact structure, high stability and low cost.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

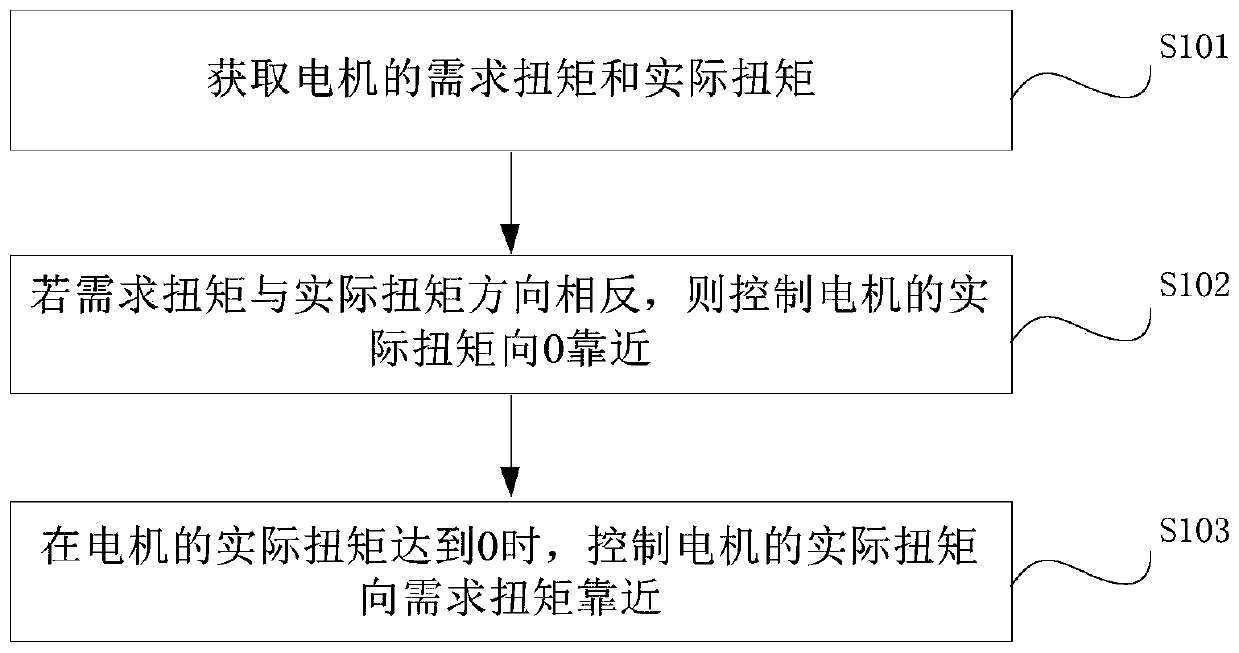

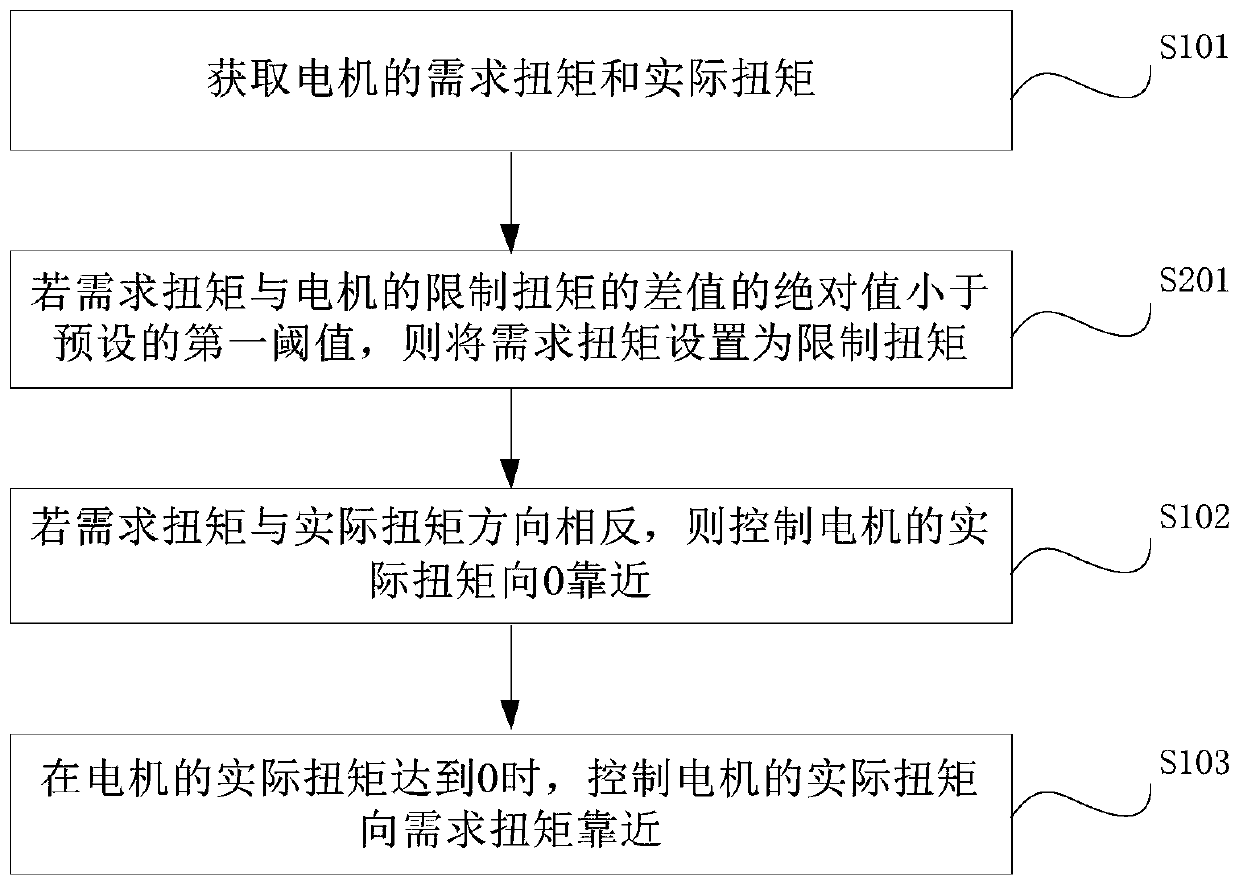

Motor torque control method, device, storage medium, and vehicle

ActiveCN110356248AAvoid direct switchingImprove experienceSpeed controllerElectric energy managementDrive shaftControl theory

The invention provides a motor torque control method, a device, storage medium, and a vehicle. A required torque and an actual torque of a motor can be acquired, and when the required torque is opposite from the actual torque, the actual torque of the motor can be moved towards 0, and when the actual torque of the motor reaches 0, the actual torque of the motor is moved towards the required torque. The torque of the motor is prevented from being directly switched between the positive torque and the negative torqued, and the abnormal noise of the transmission shaft of the motor can be eliminated, and therefore driving comfort can be improved, and user experience can be improved.

Owner:WEICHAI POWER CO LTD

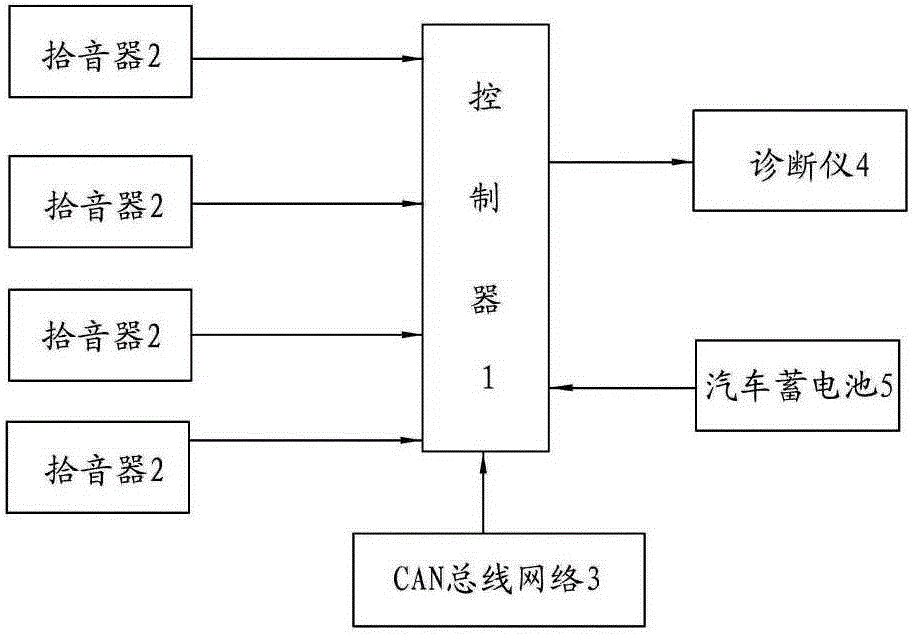

An automobile abnormal sound monitoring and diagnosing device

InactiveCN106652085AEliminate abnormal noiseReduce distractionsVehicle testingRegistering/indicating working of vehiclesDevice MonitorComputer module

An automobile abnormal sound monitoring and diagnosing device is provided, and belongs to the technical field of automobiles. The device overcomes the problem that only sounds of different zones of automobiles are memorized, and automobiles are not provided with a preliminary diagnosis function in the prior art. The device includes an automobile storage battery supplying components with electric power, a sound collecting module for collecting automobile sound, and a controller used for respectively comparing and matching the automobile sound collected by the sound collecting module with typical abnormal sound cases memorized in advance inside. The controller is connected to an automobile CAN bus network for transmitting automobile running information signals. The sound collecting module is connected to the controller also used for memorizing abnormal sound after the collected automobile sound is successfully matched with abnormal sound parameters memorized inside and corresponding automobile conditions when the abnormal sound occurs. The device monitors and records the abnormal sound of a local part of an automobile under present automobile running conditions and performs preliminary diagnosis.

Owner:重庆唯馨科技有限公司

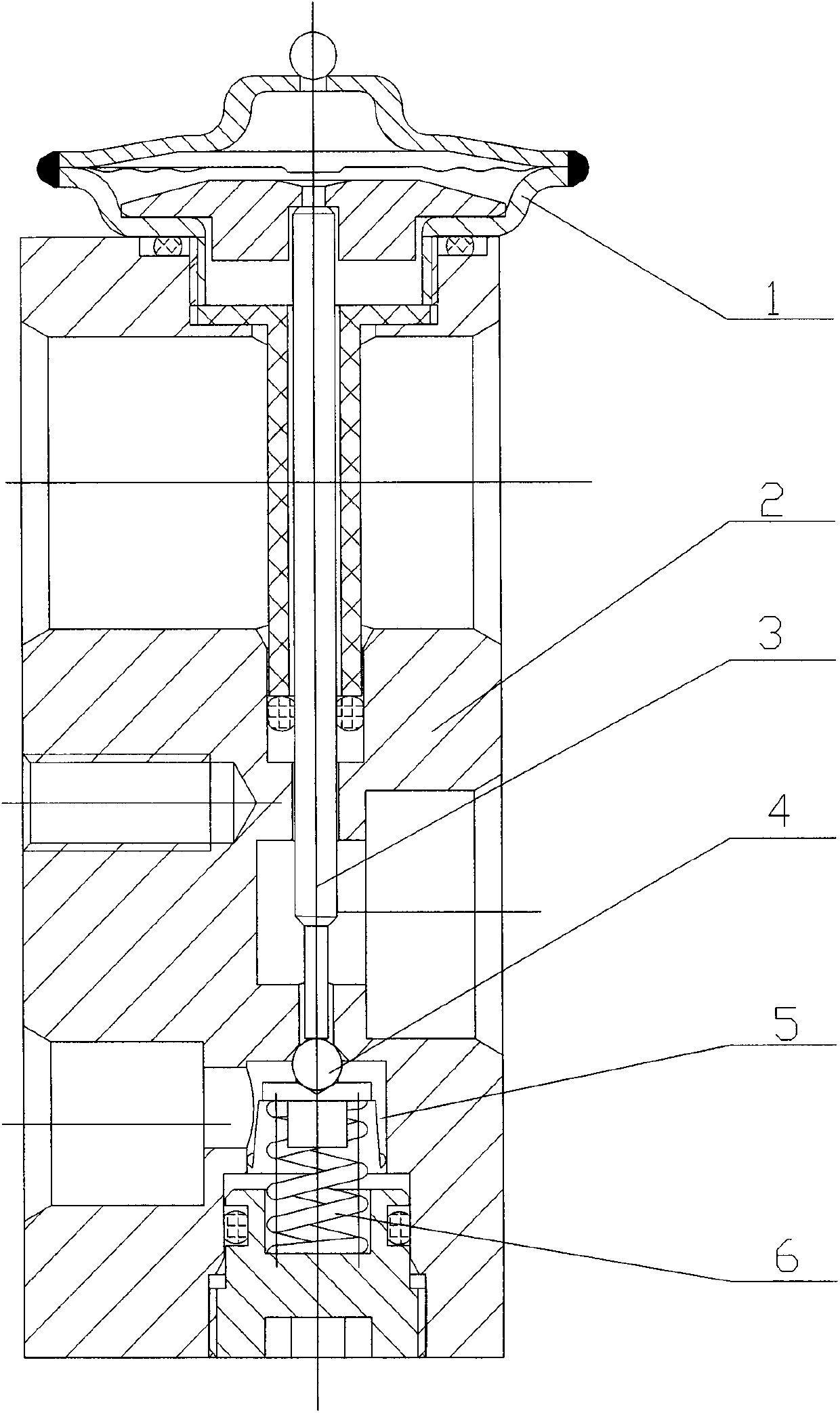

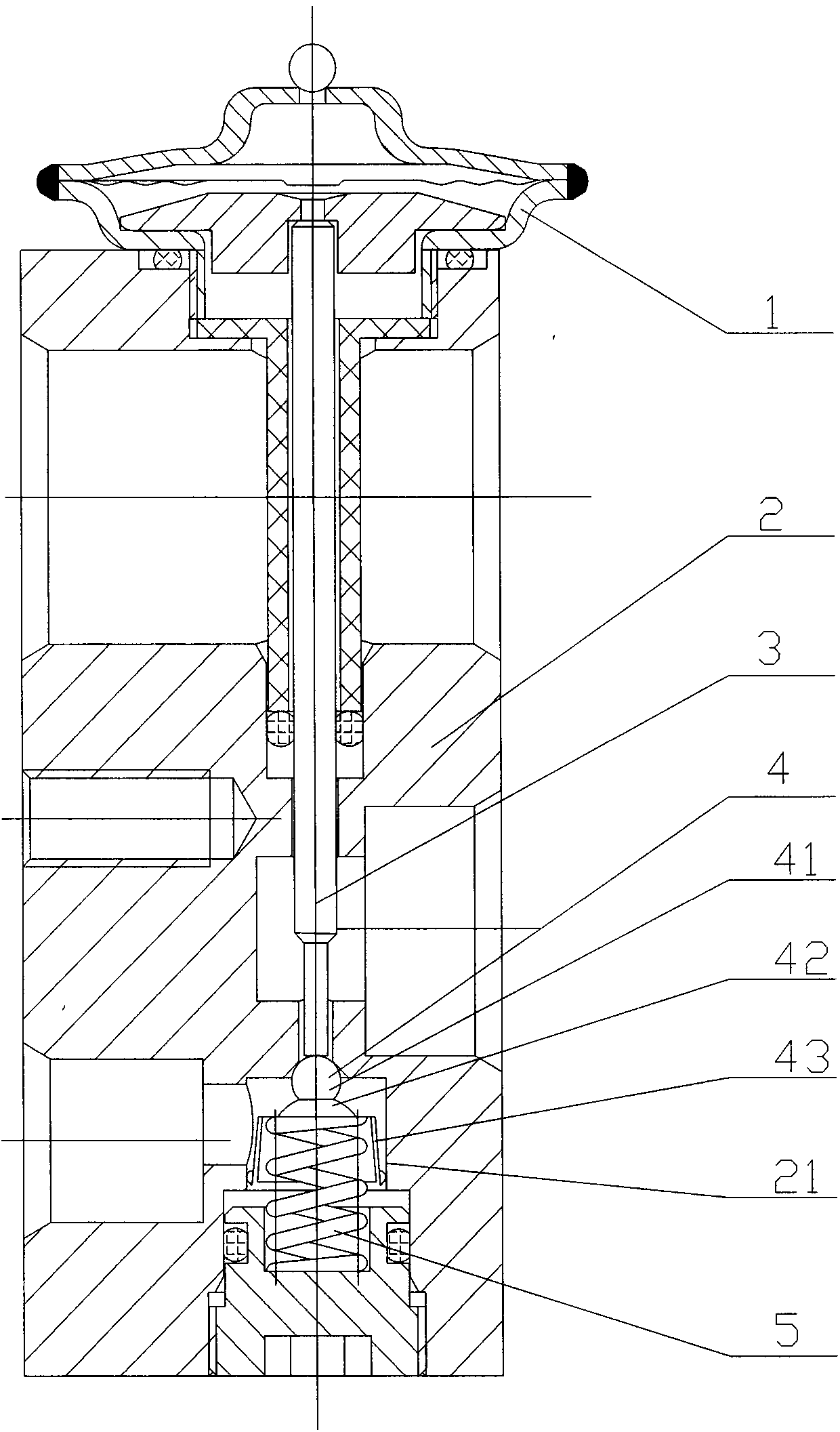

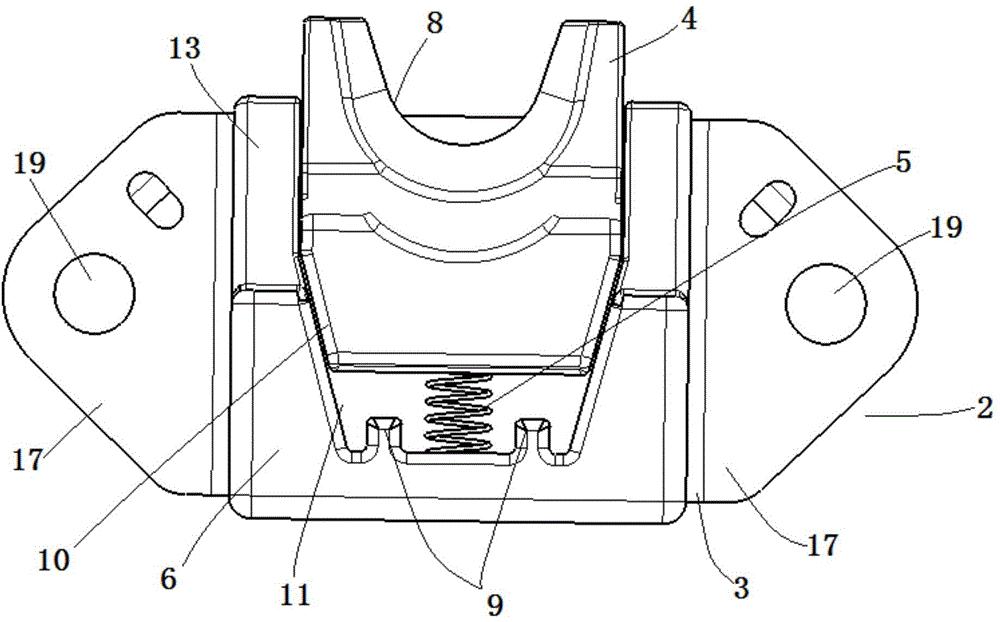

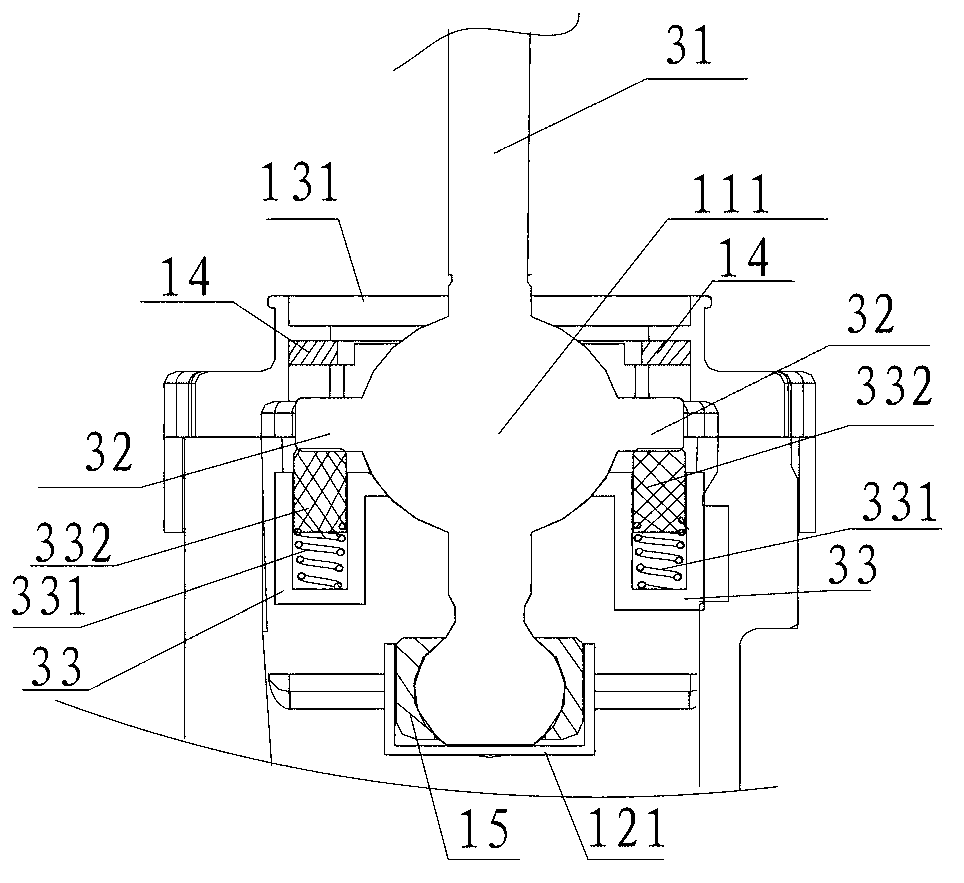

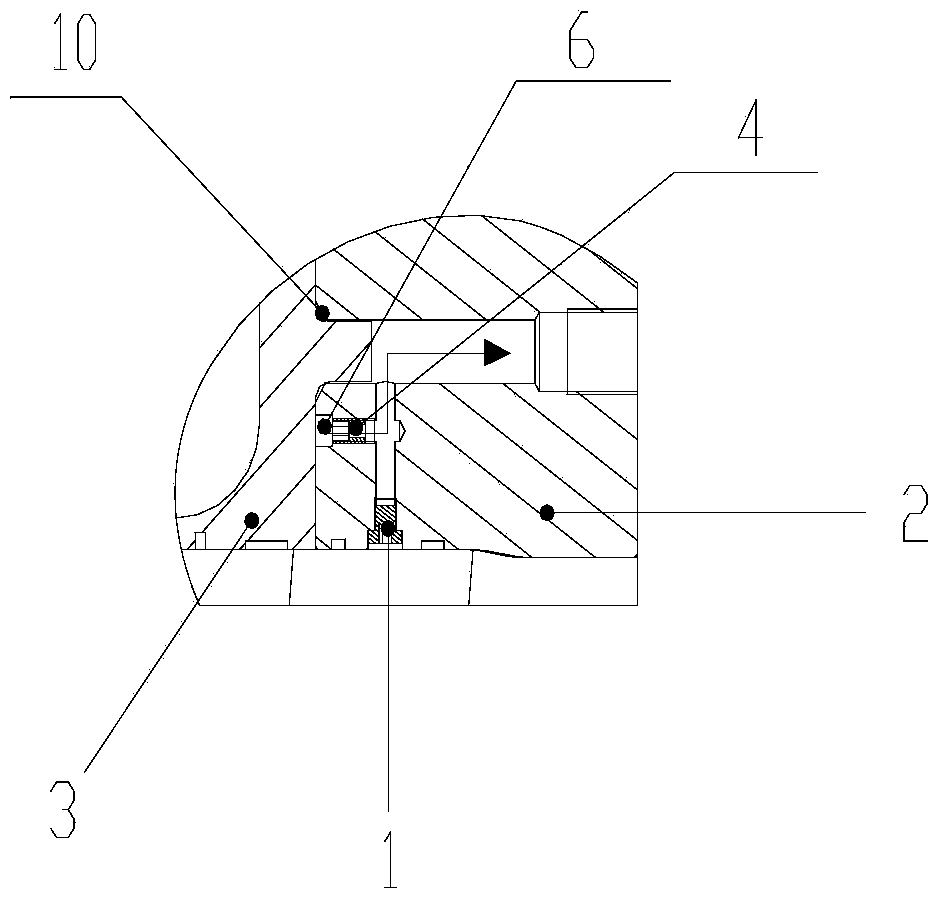

Thermal expansion valve

InactiveCN103994613AEliminate abnormal noiseAvoid vibrationValve members for absorbing fluid energyFluid circulation arrangementThermal HeadThermal expansion

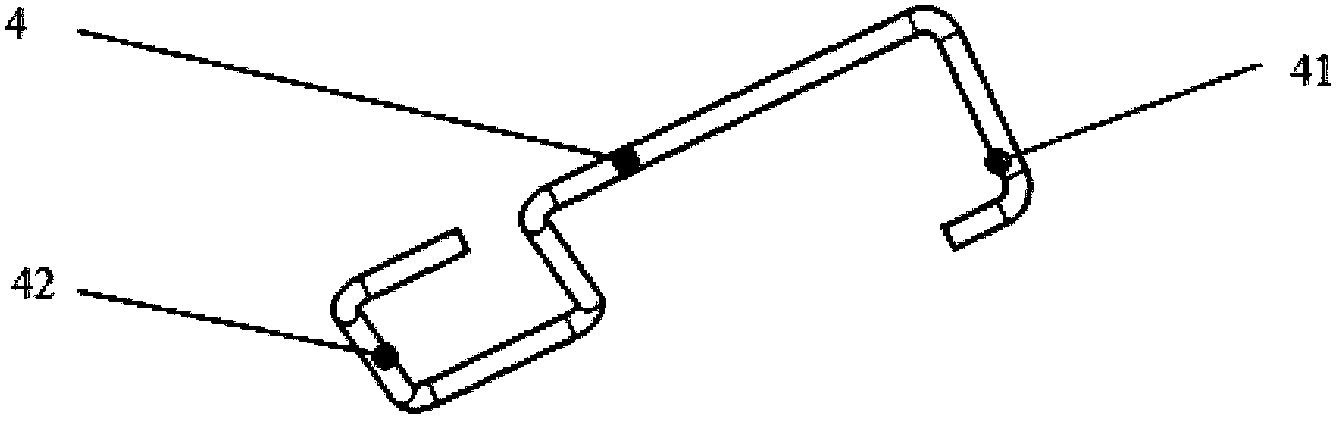

The invention discloses a thermal expansion valve, belongs to the technical field of vapor compression-type refrigerating, and is suitable for an automobile air conditioner system. The thermal expansion valve mainly comprises a thermal head 1, a valve body 2, a valve rod 3, a steel ball base assembly 4, an adjustment spring 5 and the like. The thermal expansion valve is characterized in that the steel ball base assembly 4 comprises a steel ball 41, a steel ball base 42 and a damping spring 43. When a driver suddenly starts the automobile air conditioning system, the steel ball 41, the steel ball base 42 and the damping spring 43 constituting the steel ball base assembly 4 have constitute a whole though the valve rod 3 and the steel ball base assembly 4 may disengage, and the damping spring 43 is in interference fit with a valve hole 21. By means of the inhibition function of the damping spring 43, the situation that the steel ball base assembly 4 and the adjustment spring 5 vibrate due to external excitation and disturbance is not prone to occurring, and accordingly the thermal expansion valve cannot sound abnormally.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

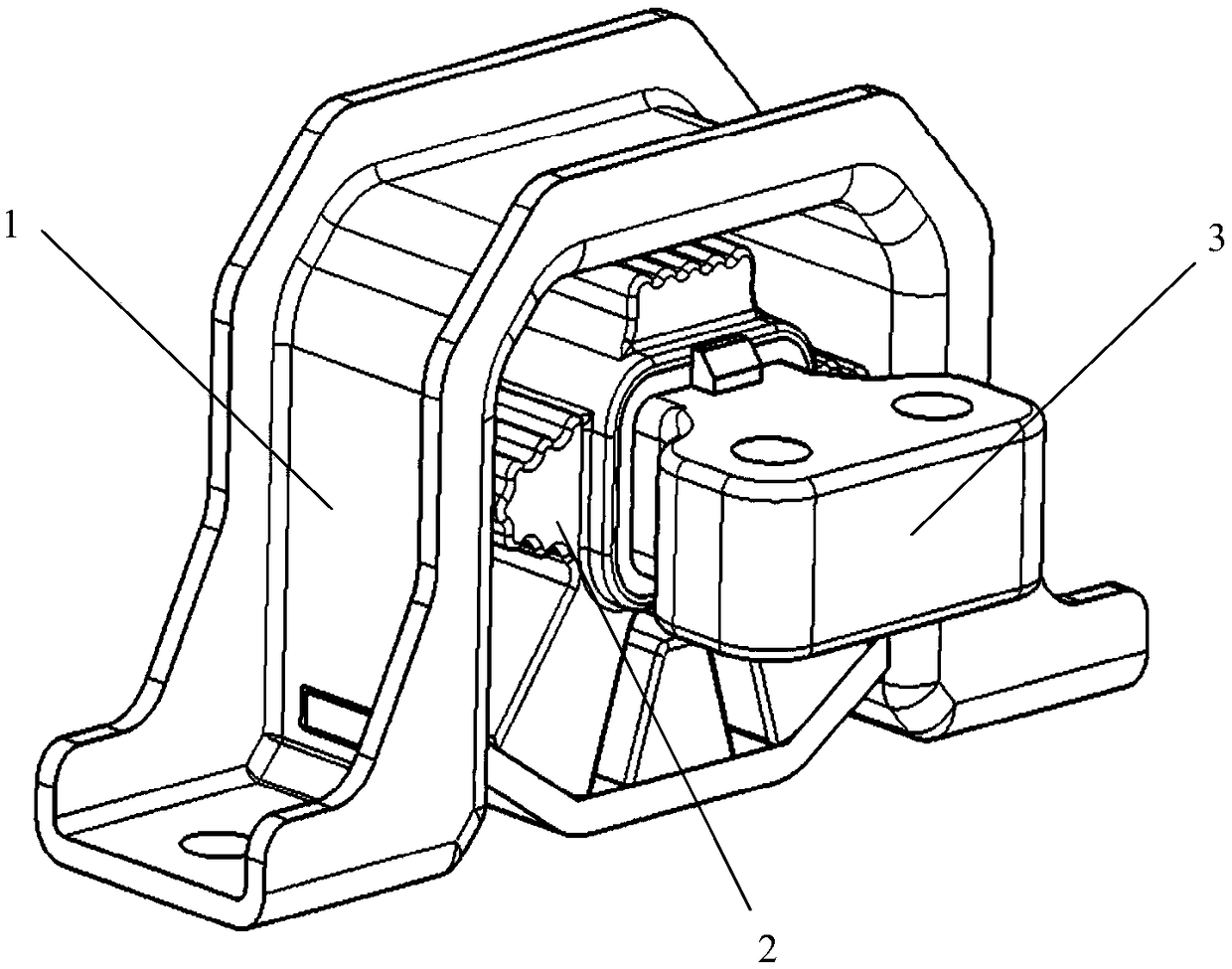

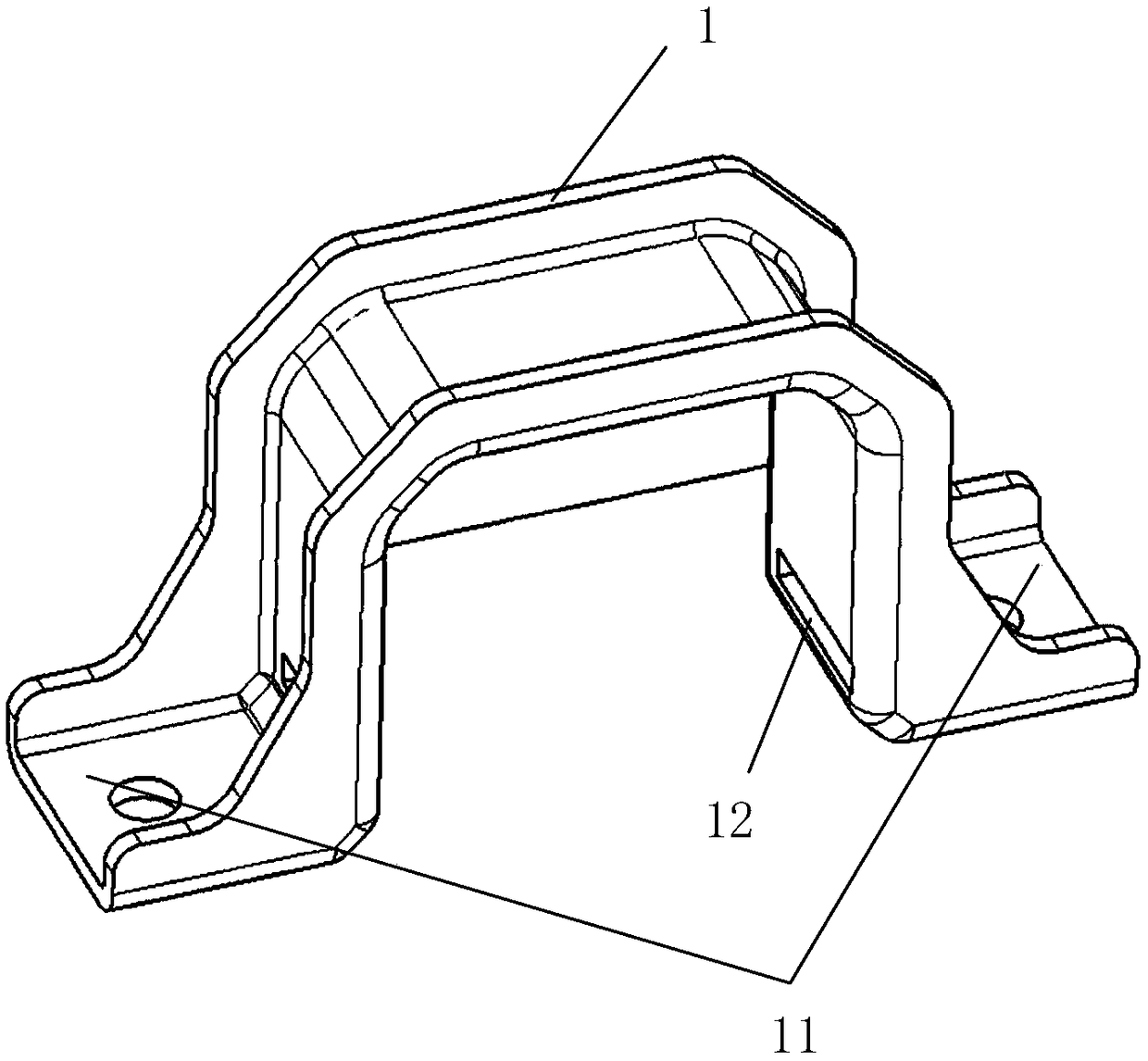

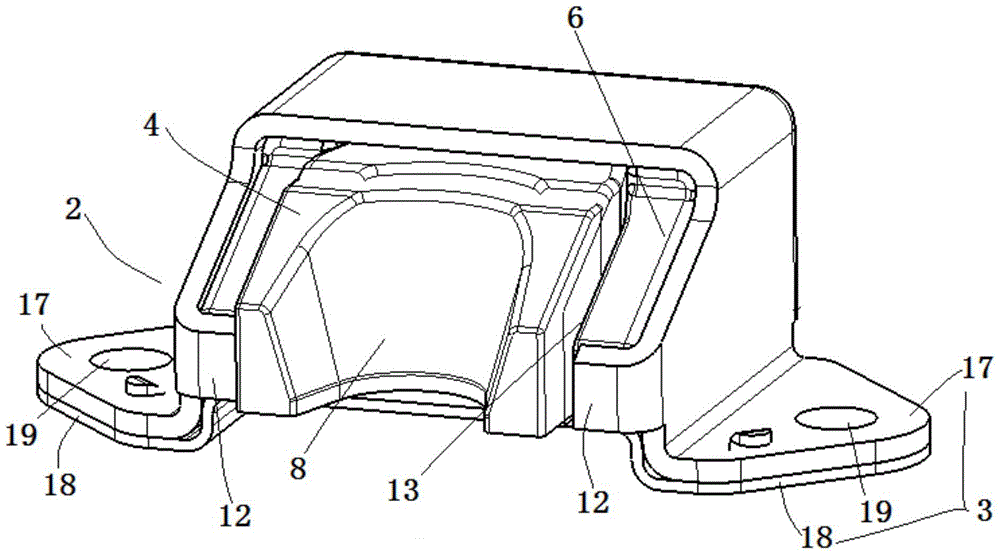

Electric vehicle suspension structure and electric vehicle

InactiveCN109398058AThe distance is easy to adjustSimplify the assembly processNon-rotating vibration suppressionElectric propulsion mountingEngineeringElectric vehicle

The invention provides an electric vehicle suspension structure and an electric vehicle. The electric vehicle suspension structure comprises a U-shaped suspension bracket, an elastic main spring located in a U-shaped opening of the suspension bracket, and a supporting arm connected with the elastic main spring; the U-shaped ends of the suspension bracket extend out of the U-shaped opening to formfixing parts; fixing grooves are formed in the inner wall of the U-shaped opening; one end of the elastic main spring is provided with a plurality of main spring limiting blocks, and the other end ofthe elastic main spring is provided with bulges; and the bulges are connected with the fixing grooves in a clamped mode. The elastic main spring of the electric vehicle suspension structure is connected with the fixing grooves of the suspension bracket in a clamped mode through the bulges at one end, the electric vehicle suspension structure is simplified, and meanwhile the elastic main spring andthe suspension bracket are also conveniently assembled.

Owner:BEIJING ELECTRIC VEHICLE

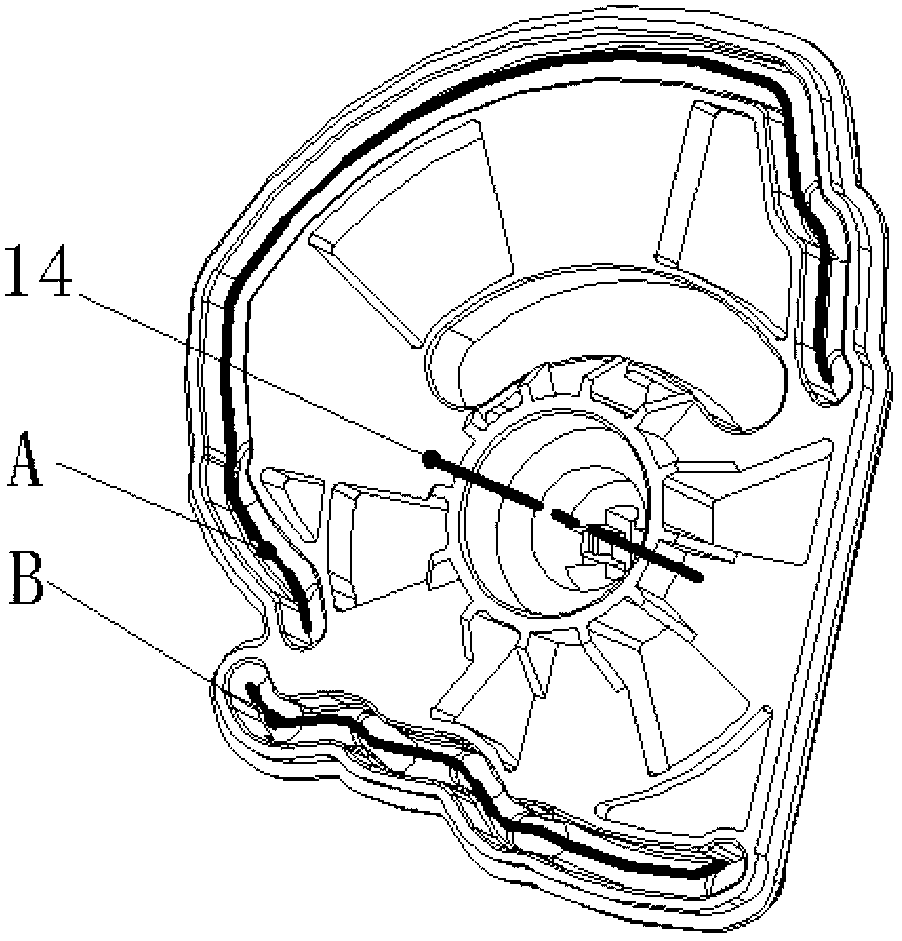

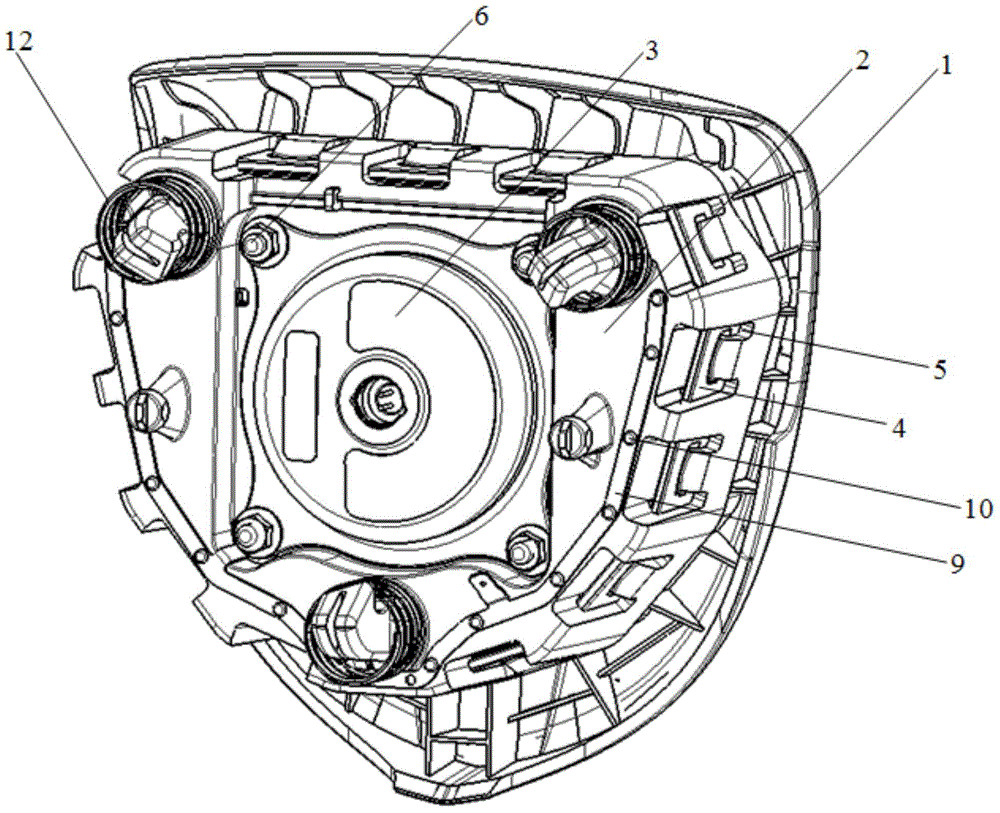

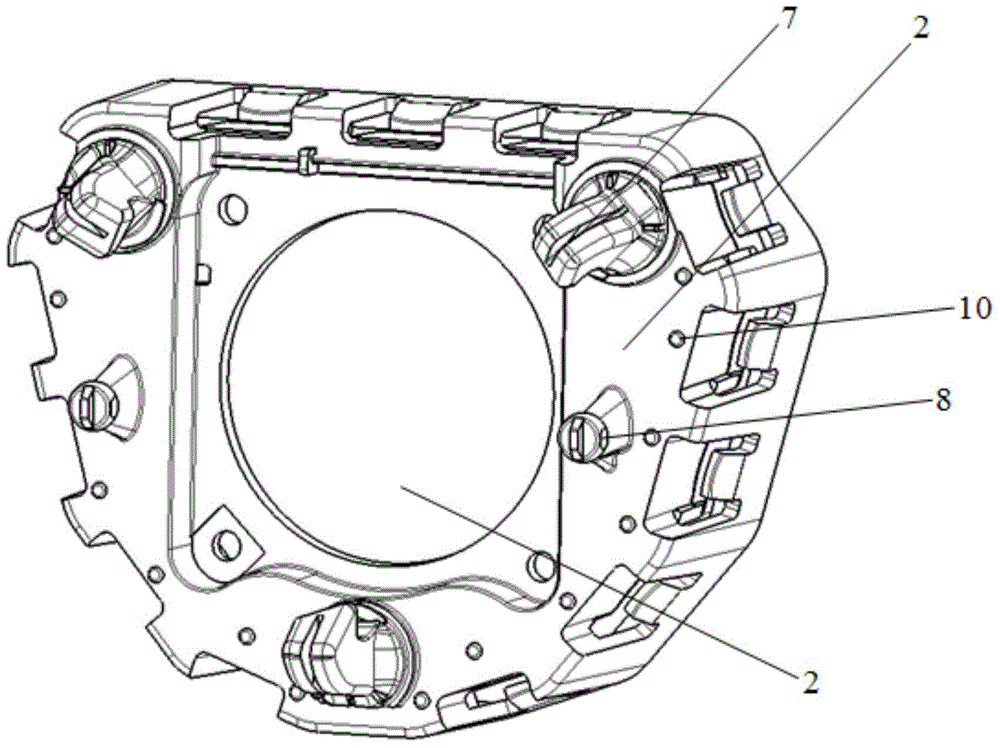

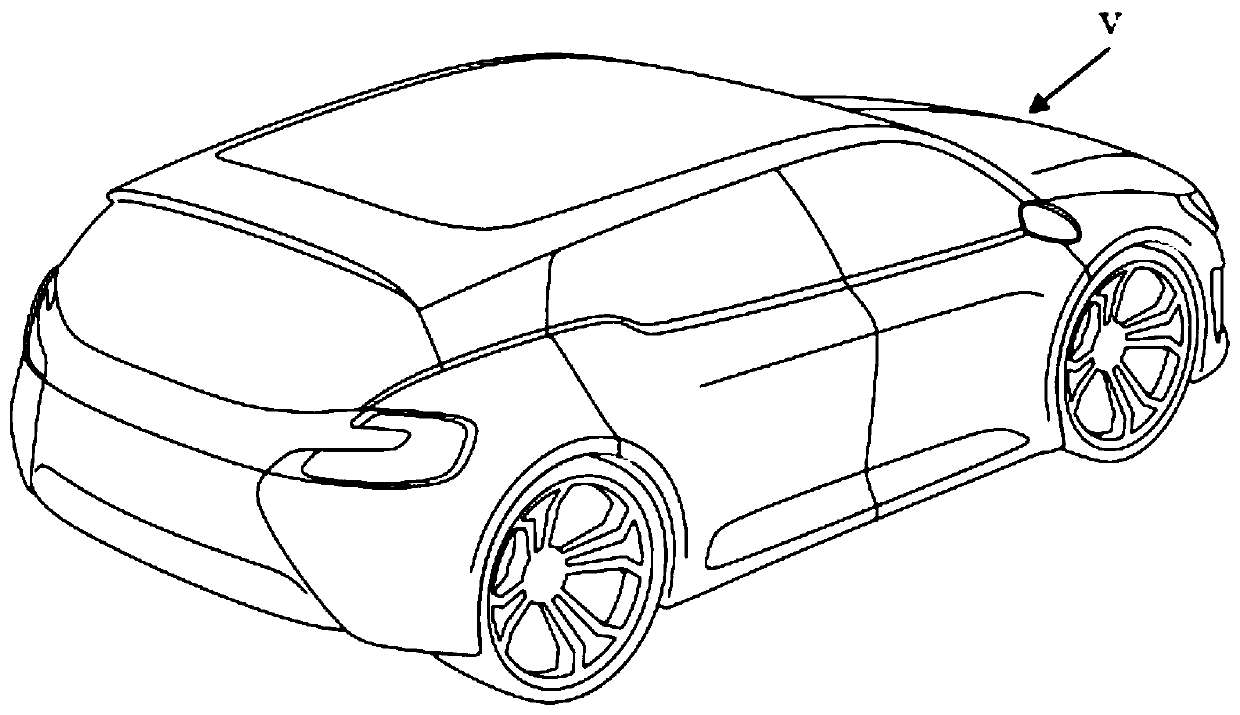

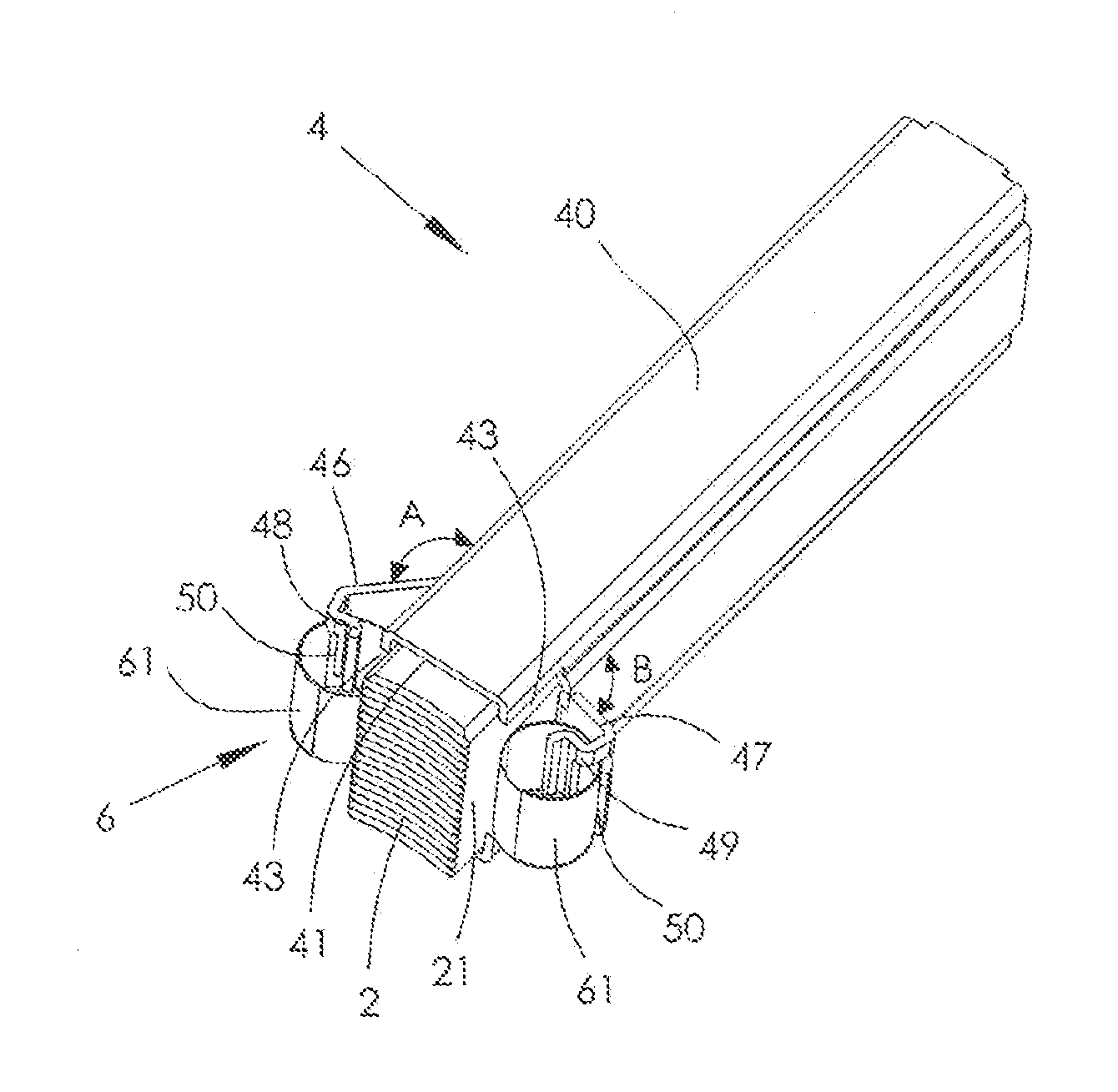

Plastic clamping buckle type safety air bag integrated with ringing structure

InactiveCN104859577AReasonable designReduce weightPedestrian/occupant safety arrangementState of artPlastic materials

The invention relates to the field of automobile safety air bags, and particularly belongs to a plastic clamping buckle type safety air bag integrated with a ringing structure. The plastic clamping buckle type safety air bag comprises a cover plate, a shell and a generator. Inverted buckles are arranged on the cover plate, and buckling grooves matched with the inverted buckles are formed in the shell; and the inverted buckles are assembled in the buckling grooves to complete fixed connection between the cover plate and the shell. The generator is fixed to a through hole in the center of the shell through bolts, and the shell is formed by injection molding of plastic materials; and the shell is further provided with clamping hooks, fixed columns and a loudspeaker copper piece. The plastic clamping buckle type safety air bag is reasonable in design, plastic materials are used for replacing metal materials to reduce the weight, and meanwhile abnormal sounds are also eliminated; and a loudspeaker pressing mechanism in the prior art is integrated on the shell, the whole structure is more compact, assembling is more easy, and more materials are saved.

Owner:HEFEI JIANGHUAI TAIHANG CHANGQING AUTOMOTIVE SAFETY SYST

Novel vehicle-mounted vibration and radiation headrest surrounding sound system

ActiveCN105835734AReduce volumeLow costVehicle seatsFrequency/directions obtaining arrangementsSurround soundSound system

The invention belongs to the technical field of automobile parts and particularly relates to a novel vehicle-mounted vibration and radiation headrest surrounding sound system. At least one resonance box capable of making sounds is arranged in a headrest body. The space between the resonance boxes and the headrest body is filled with filler. The resonance boxes are embedded in the headrest body, make sounds independently and have a good low-frequency sound effect.

Owner:BESTAR HLDG

Hatchback door limiting device

InactiveCN104527381AEliminate abnormal noiseAvoid X-direction movement too sharpDoorsCar drivingElectrical and Electronics engineering

The invention discloses a hatchback door limiting device. The hatchback door limiting device comprises a limiting block and a limiting seat, wherein the limiting block is arranged on an inner board of a hatchback door, and the limiting seat is arranged on a side wall. The limiting seat is provided with a sliding block which is matched with the limiting block and slides in the limiting seat, and a spring is arranged between the sliding block and the limiting seat. The hatchback door limiting device can restrain vertical and horizontal shake and swing of the hatchback door to the maximum degree during driving of a car, effectively limit the hatchback door, improve the durability and reliability of the car door, estimate abnormal sound generated by shake of the hatchback door and improve NVH performance of the car; in addition, the spring is arranged between the sliding block and the limiting seat, the phenomenon that X-direction shift of the hatchback door is sharp when the hatchback door is closed or when the car drives can be effectively avoided, the durability and reliability of the car door are further improved, and the NVH performance and the reliability of the whole car can be improved.

Owner:CHERY COMML VEHICLE ANHUI

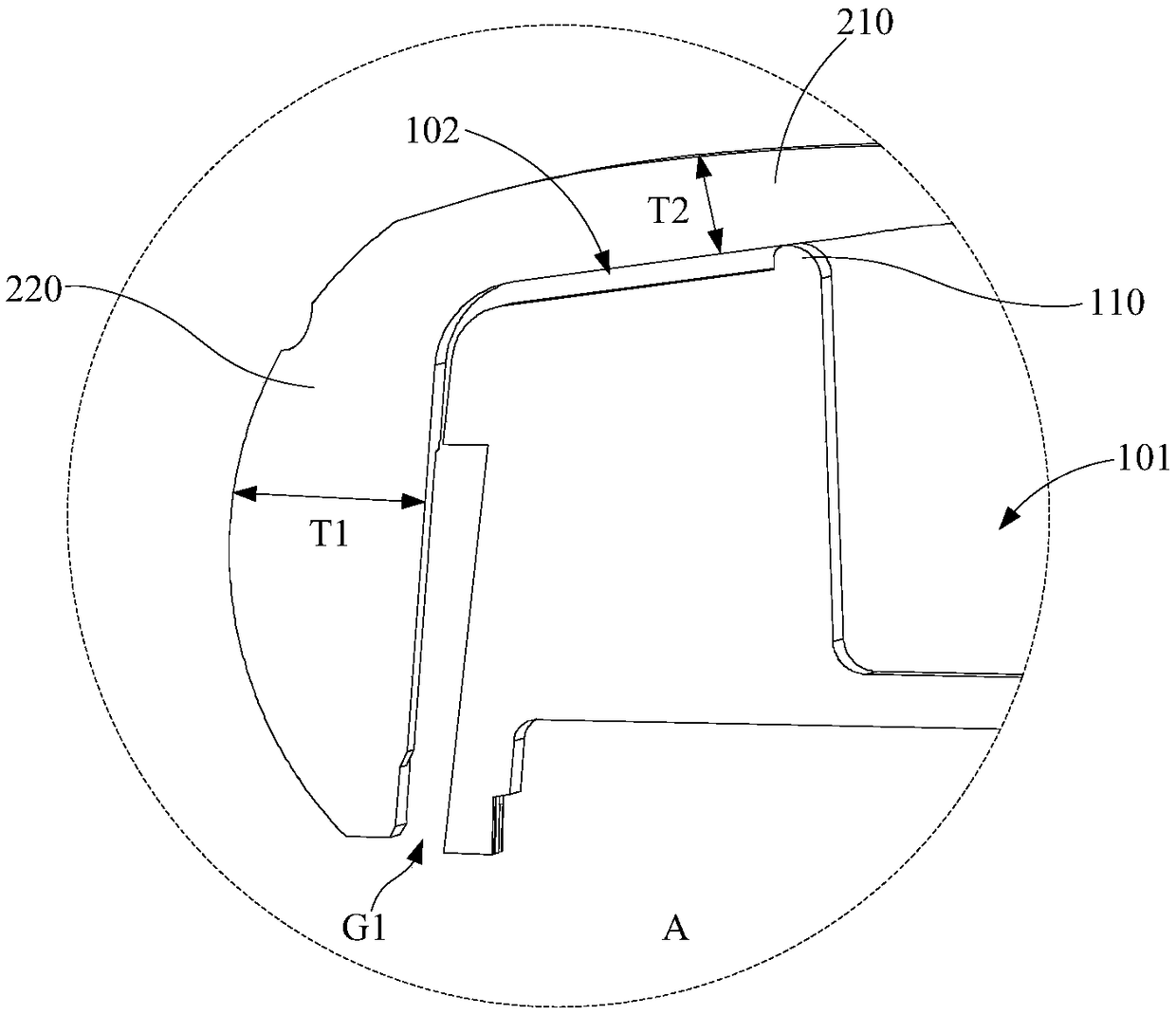

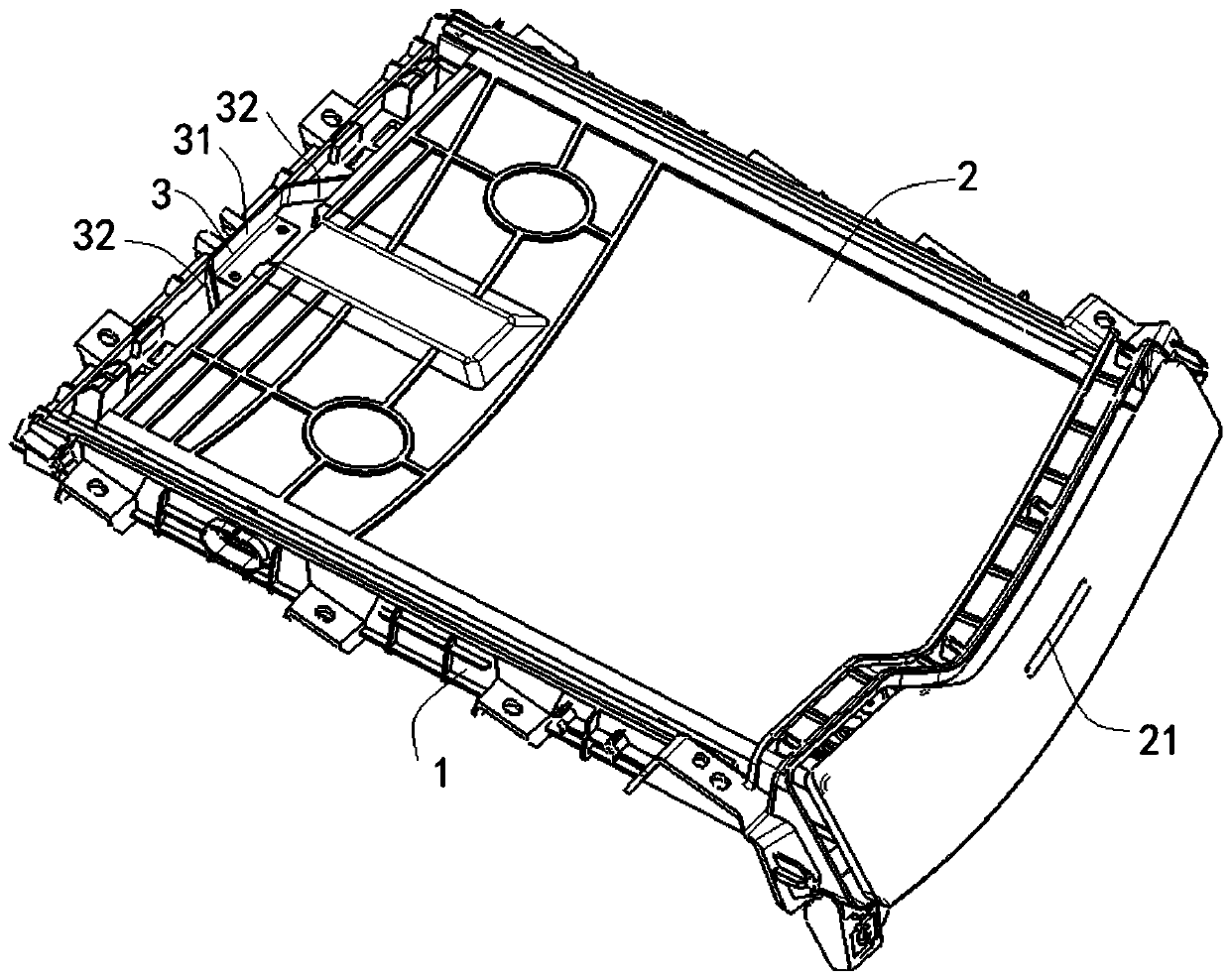

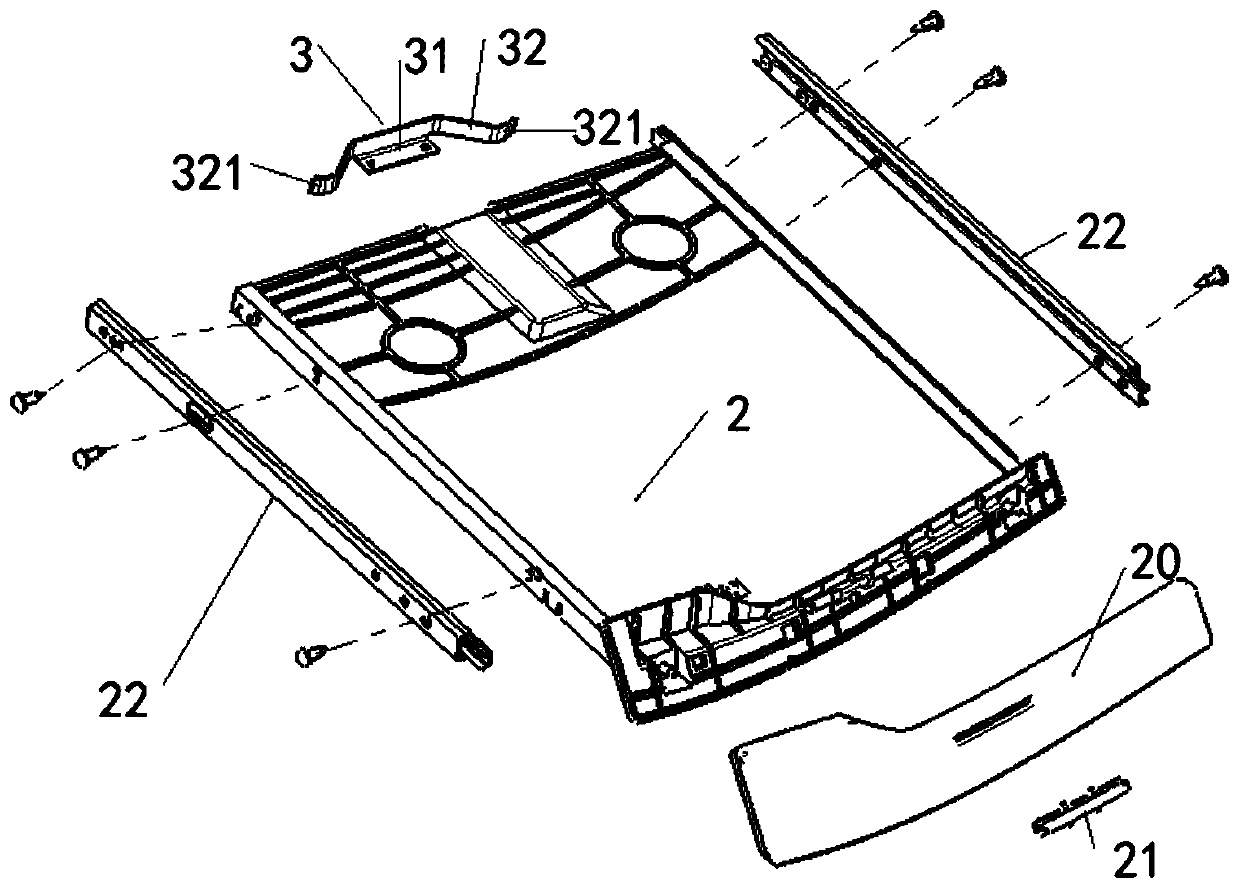

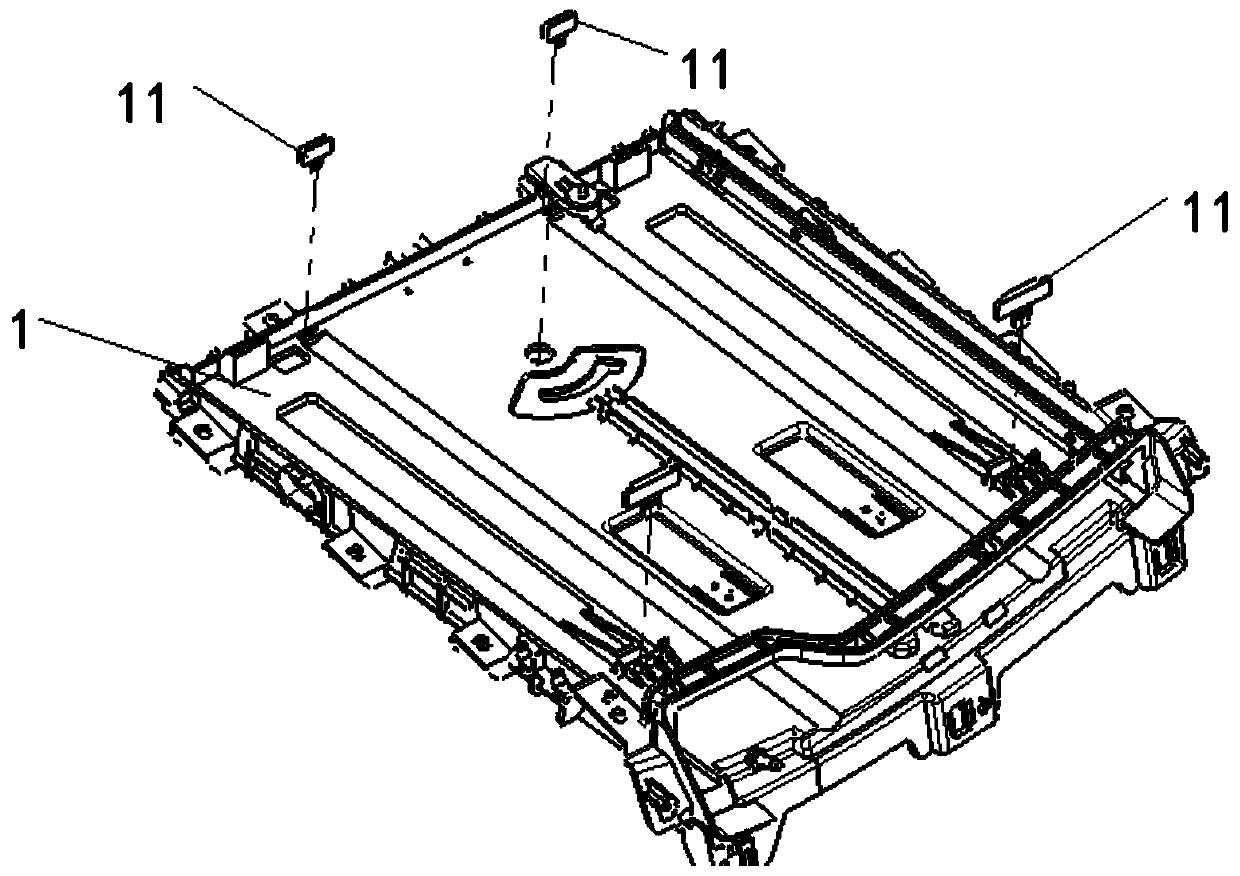

Mobile terminal and housing assembly thereof

ActiveCN109040372AEliminate abnormal noiseAvoid contact frictionTelephone set constructionsEngineeringComputer terminal

A mobile terminal and a housing assembly thereof are provided. The housing assembly includes a middle frame and a battery cover. One side of the middle frame is provided with a battery accommodation groove, and the battery cover is arranged on the side of the middle frame with the battery accommodation groove; the battery cover comprises a cover pressing part and a buckling part, wherein the buckling part is integrally arranged along the edge of the cover pressing part, the cover pressing part is arranged in the battery receiving groove, and the buckling part is engaged with the side edge of the middle frame; a support rib is arranged at the opposite side edge positions of the battery accommodation groove, and the support rib holds the cover pressure part of the battery cover so as to forma deformation accommodation gap between the cover pressure part and the middle frame. The housing assembly enables the mobile terminal to achieve wire support in the thickness direction, a deformation accommodation gap is formed between the battery cover and the middle frame. When the battery cover is deformed due to external force, the deformation accommodation gap can be used to accommodate thedeformation amount of the battery cover, thereby avoiding large-area contact friction between the battery cover and the middle frame, and effectively eliminating abnormal noise of the battery cover due to external force.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

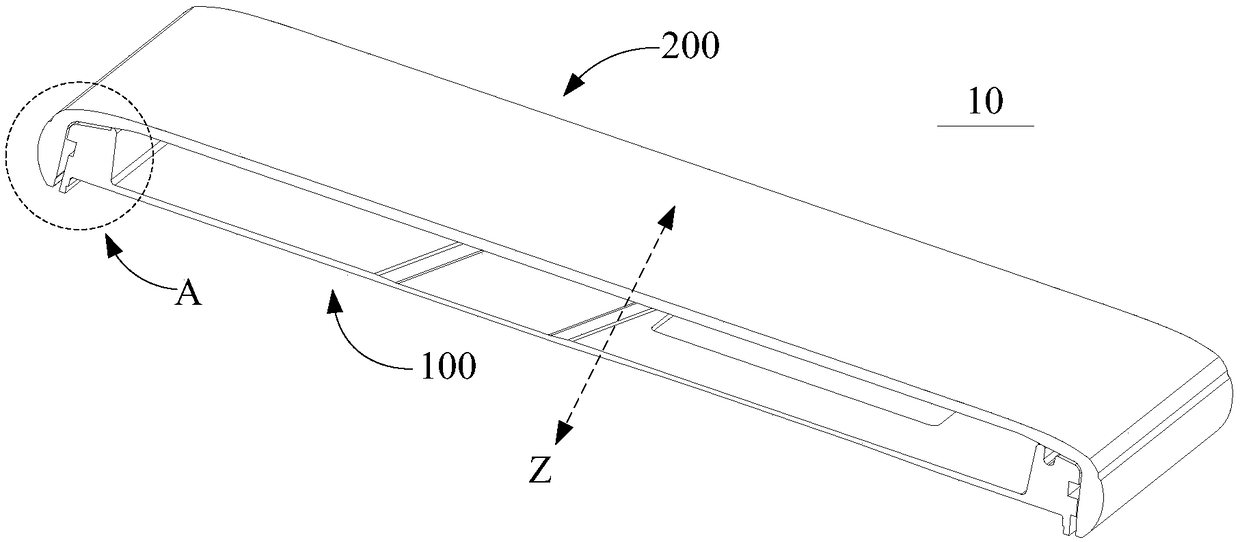

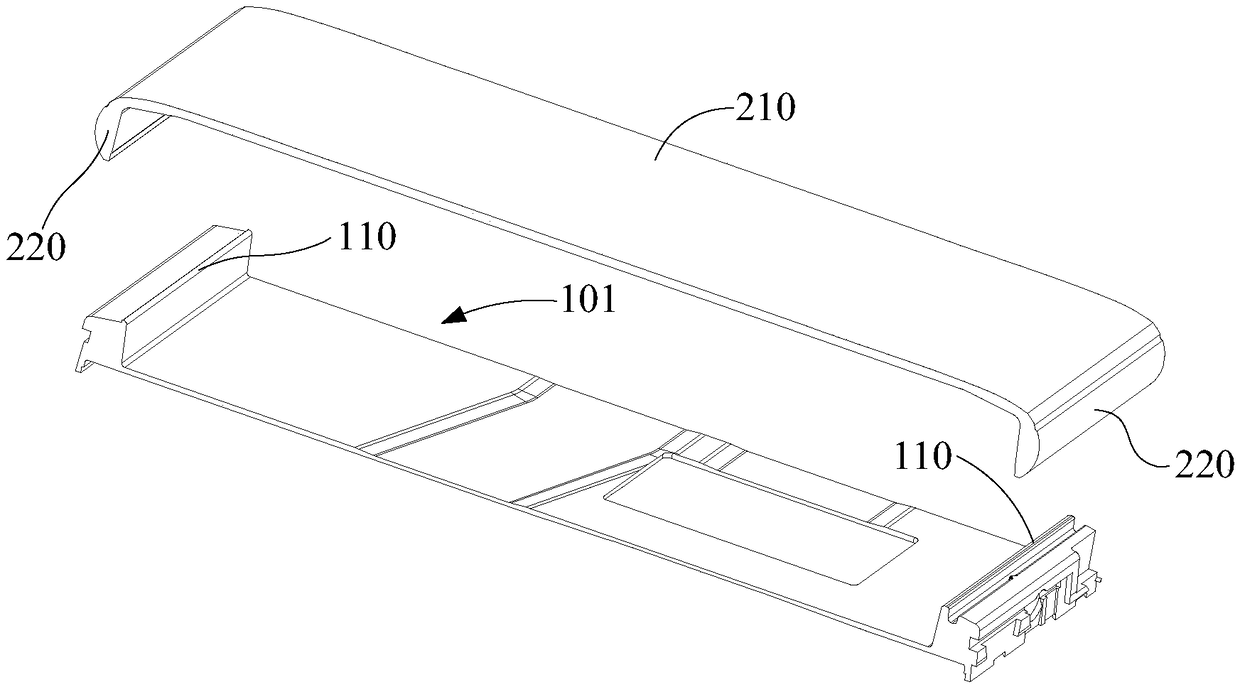

Hidden vehicle-mounted small table plate assembly and commercial vehicle

PendingCN111391736AGuaranteed no leakage defectsEliminate abnormal noiseVehicle arrangementsIn vehicleStructural engineering

The invention discloses a hidden vehicle-mounted small table plate assembly and a commercial vehicle, and relates to the technical field of small table plates for vehicles. The small table plate assembly comprises a supporting plate; a small table plate assembled on the supporting plate and reciprocating along the supporting plate so that the small table plate can be completely contained in the vehicle or partially stretch out of the supporting plate; and an elastic sheet of an integrally-formed structure and comprising an elastic sheet body and two elastic sheet pins at the two ends of the elastic sheet body. The elastic piece body is fixedly arranged on the supporting plate, an opening formed by the elastic piece body and the two elastic piece feet faces the small table plate, and the elastic sheet pins deform when abutting against the small table plate. According to the invention, the abnormal sound problem of an existing small table plate during opening or closing can be eliminated, and the inside of the vehicle is effectively kept clean when the small table plate is not used.

Owner:DONGFENG COMML VEHICLE CO LTD

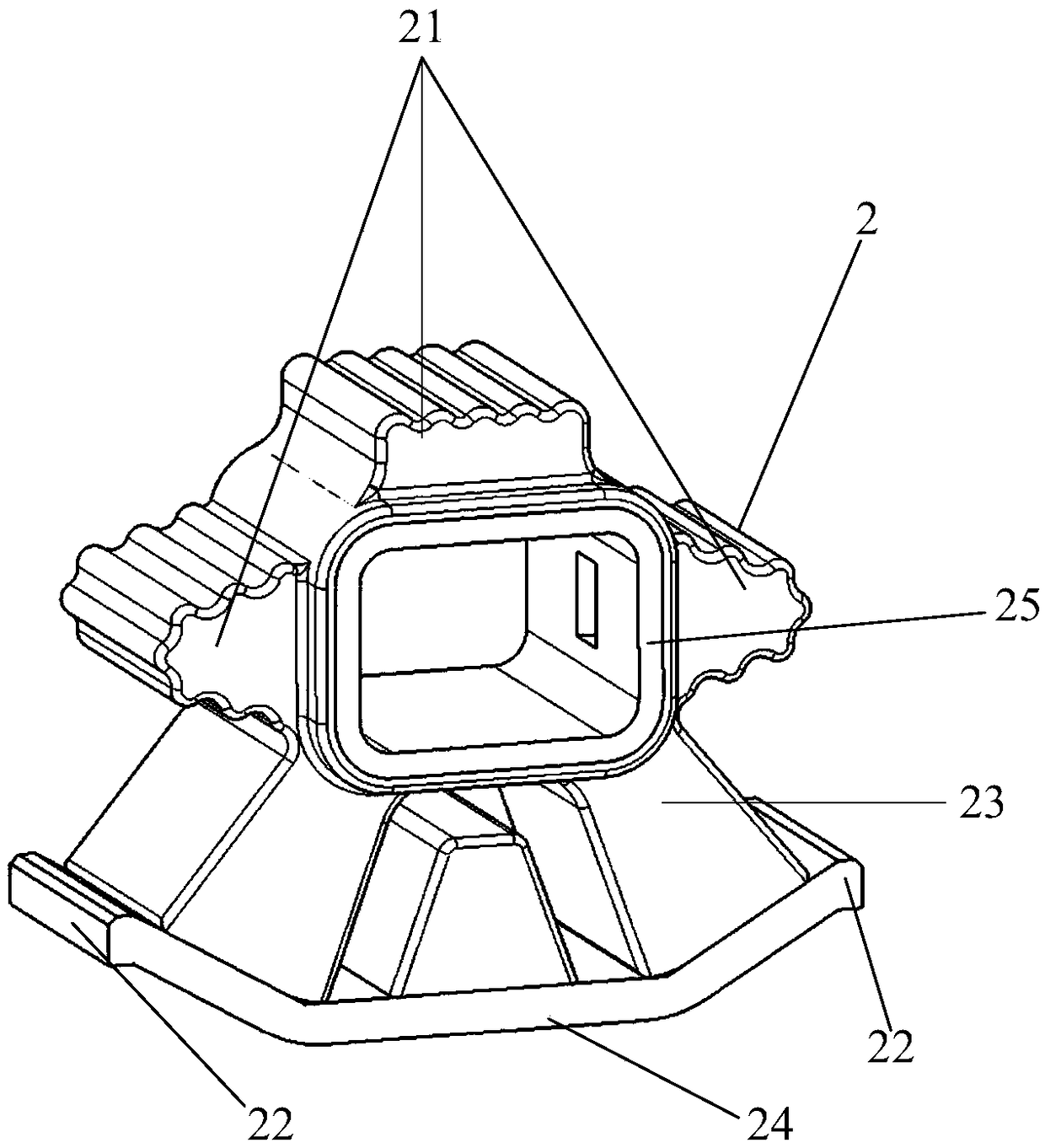

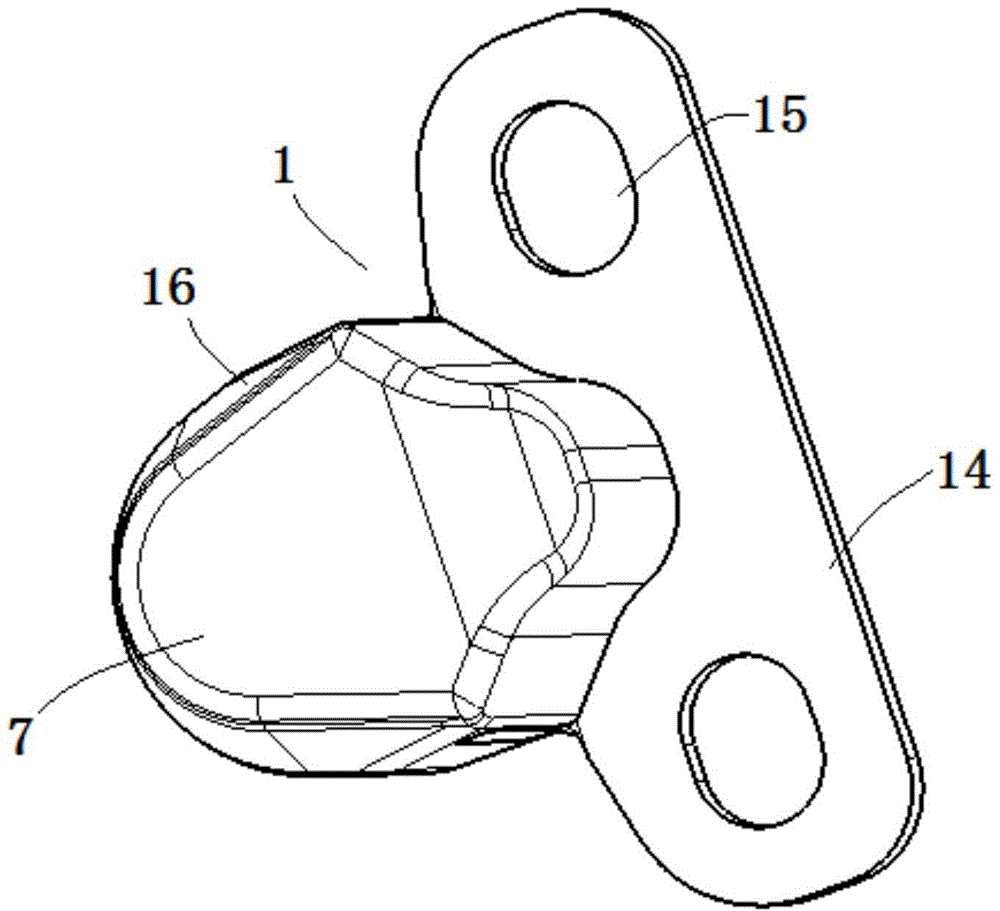

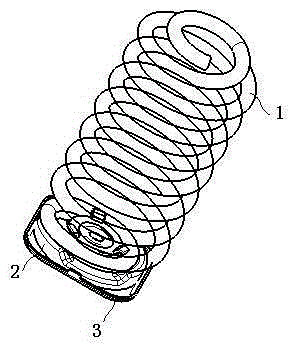

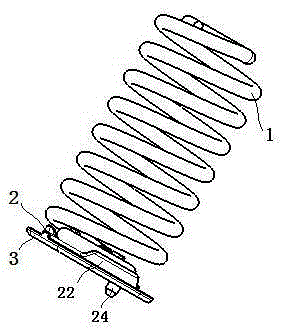

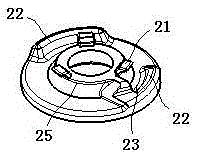

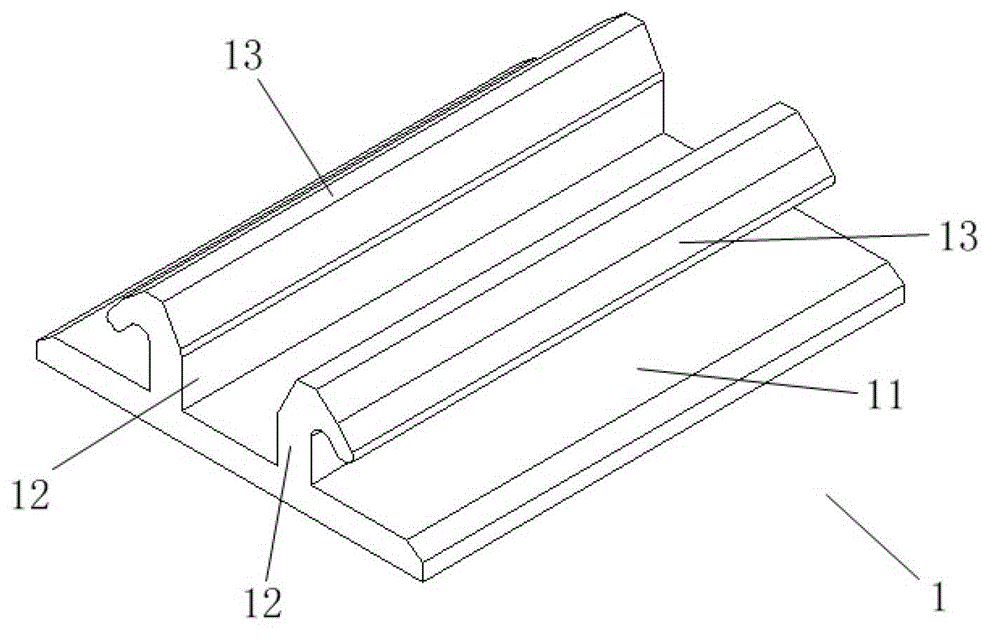

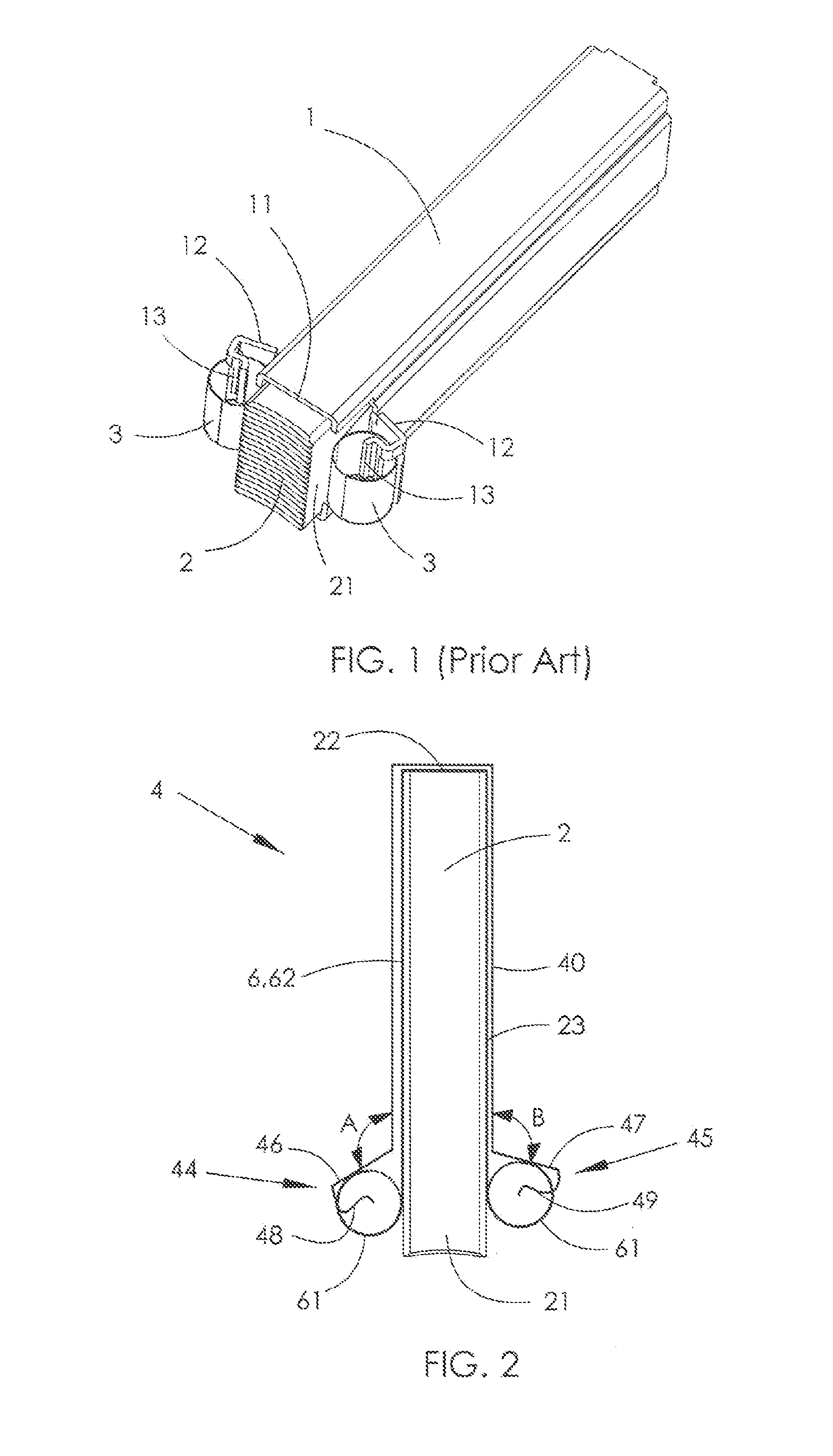

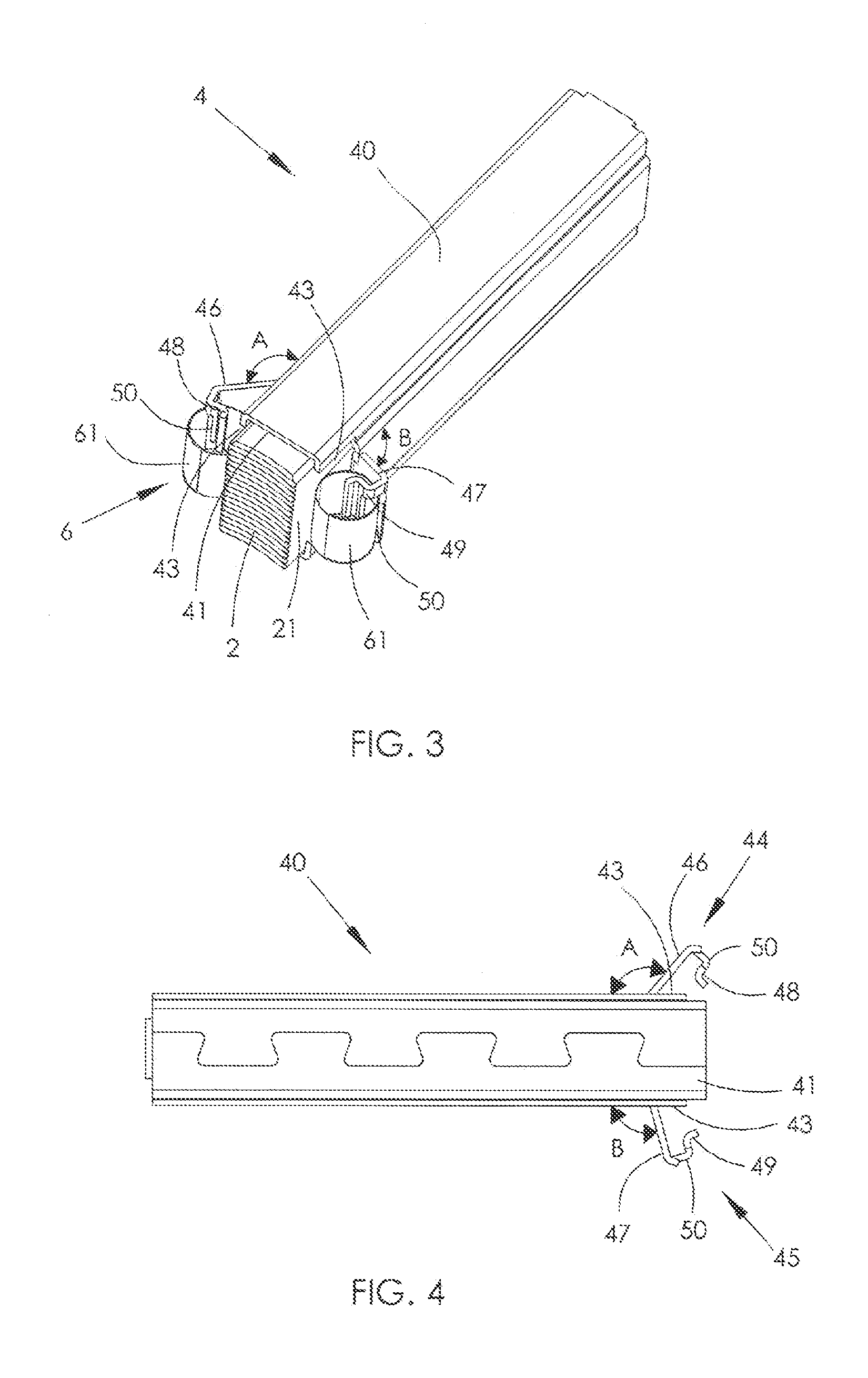

Mounting structure for automobile spring mattress saddle and automobile chassis suspension spring

The invention relates to a mounting structure for an automobile spring mattress saddle and an automobile chassis suspension spring. The mounting structure comprises a helical spring (1), a spring mattress saddle (2) and a spring tray (3), wherein a supporting end of the helical spring (1) is assembled on the spring mattress saddle (2); the spring mattress saddle (2) is fixed on the spring tray (3); the center of the upper surface of the spring mattress saddle (2) is provided with a mounting lug boss (25); a supporting ring at the supporting end of the helical spring (1) is spliced with the mounting lug boss (25); the side edge of the upper end surface of the mounting lug boss (25) is distributed with three or more than three clamping jaws (21) in a circumferential direction to clamp the supporting ring of the helical spring (1) to prevent the helical spring (1) from loosening; the upper surface of the spring mattress saddle (2) is further provided with a limiting slot (23); an axial through hole is formed in the center of the mounting lug boss (25); the side edge of the upper surface of the spring mattress saddle (2) is further provided with a protective lug boss (22); and a dowel pin structure (24) is further arranged on the lower surface of the spring mattress saddle (2).

Owner:CHERY AUTOMOBILE CO LTD

Transmission control mechanism

ActiveCN103216612AEliminate abnormal noiseNon-rotating vibration suppressionGearing controlEngineeringMechanical engineering

The invention provides a transmission control mechanism, and relates to parts of motor vehicles. The transmission control mechanism solves the problem that when an existing transmission control mechanism is used, and an engine is in an idling condition and an urgent acceleration condition, an existing transmission can generate abnormal sounds. The transmission control mechanism comprises a bulb piece and a selecting shifting gear shaft, wherein one end of the bulb piece is arranged inside a clamping groove of the selecting shifting gear shaft in a clamped mode, the bulb piece and the selecting shifting gear shaft are respectively arranged inside a shell body of a transmission, vibration reducing pads are arranged in gaps between the bulb piece and an upper end cover of the shell body, and a vibration reducing isolating sleeve is arranged inside the clamping groove of the selecting shifting gear shaft.

Owner:GREAT WALL MOTOR CO LTD

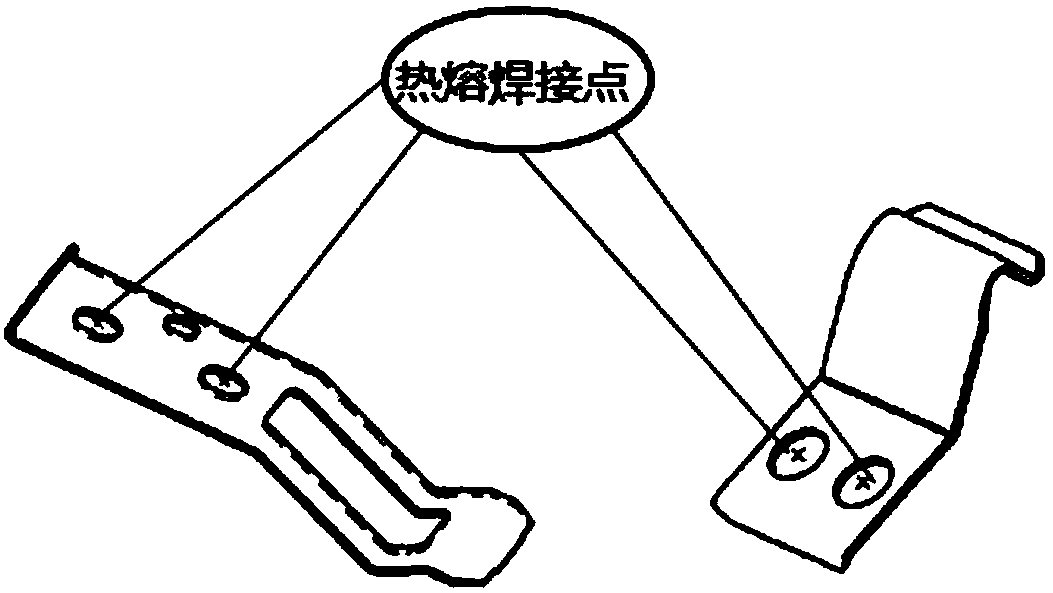

Automotive trim clip

PendingCN107740798ALow costLightweightVehicle componentsFriction grip releasable fasteningsHigh energyFusion welding

The invention discloses a buckle for an automobile interior decoration, which comprises a buckle body. The outer sides of the buckle body are respectively provided with anti-falling undercut protrusions. The lower part of the anti-falling underturn protrusion is an outer clamping part. A pair of ribs are provided on the inner side of the buckle body, the ribs are provided with anti-falling barbs, and the ribs or the inner side of the buckle body are provided with clamping bosses, and the anti-falling barbs are fixed on the target connecting piece. The mounting holes or mounting protrusions fix the target connecting piece to prevent falling off. Compared with the traditional metal shrapnel, the present invention completely solves the technical problems of shrapnel shaking, abnormal noise, loose connection and difficult maintenance caused by the high energy consumption and poor welding risk of traditional metal shrapnel hot-melt welding. Undercut protrusions, anti-falling barbs and clamping bosses can firmly connect the target connecting parts, which are easy to install and easy to replace.

Owner:SUMMIT PLASTICS (NANJING) CO LTD

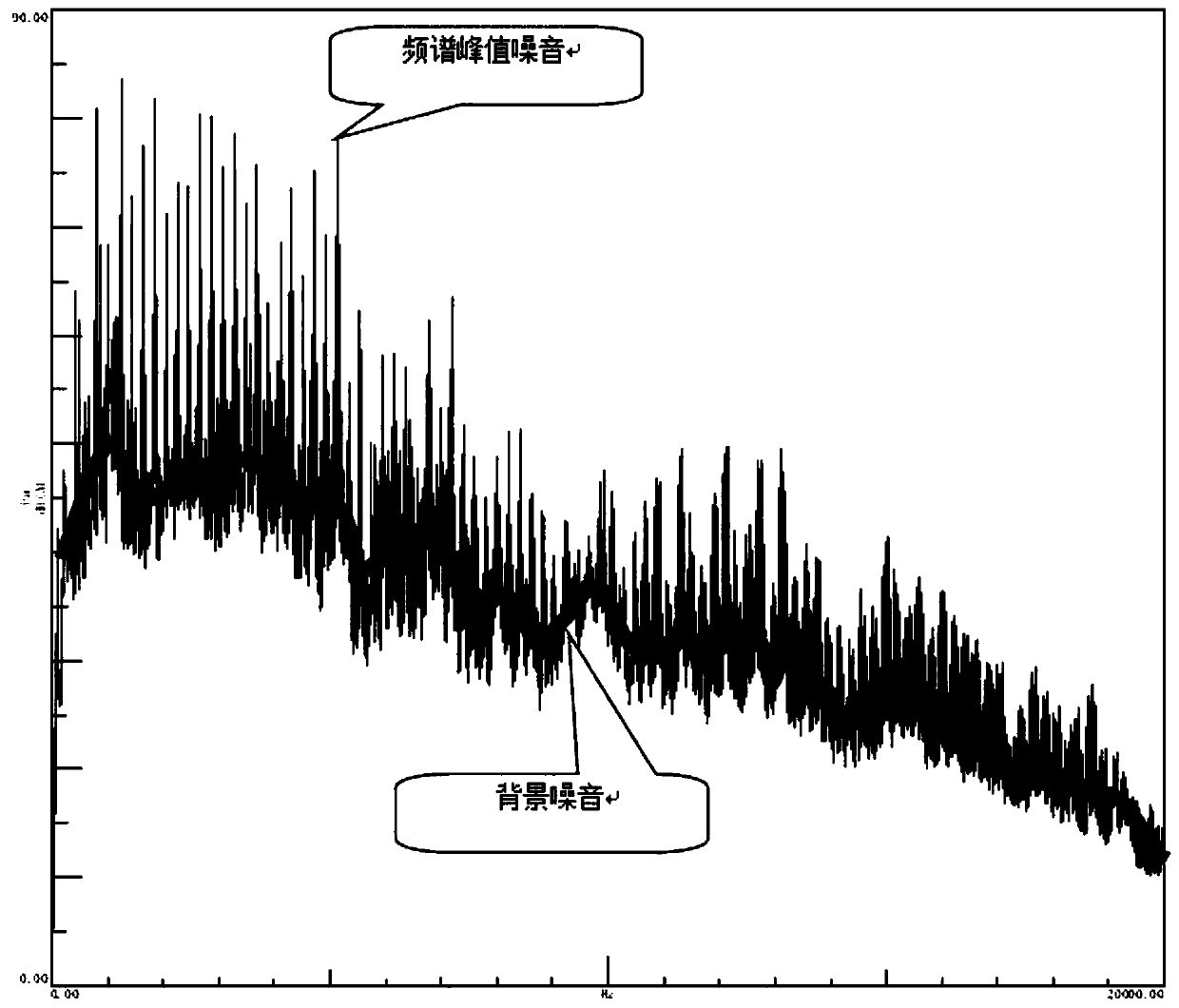

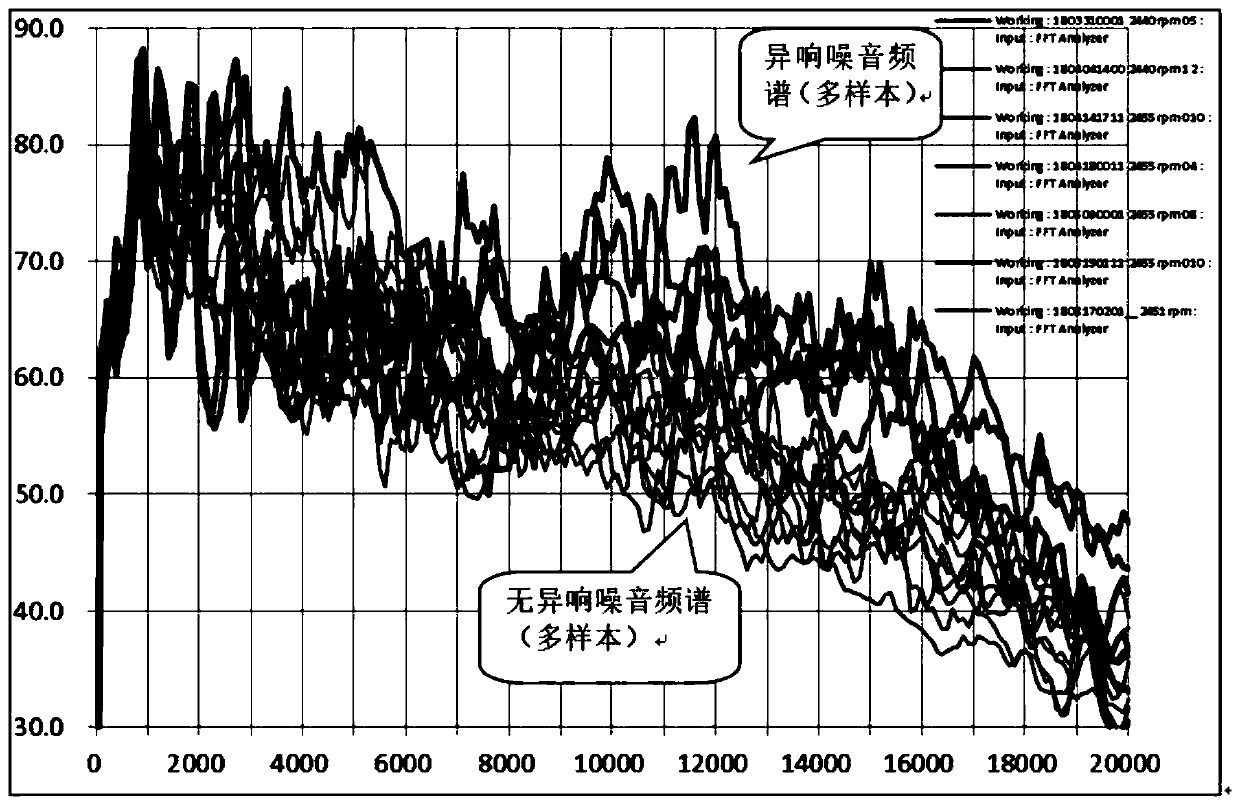

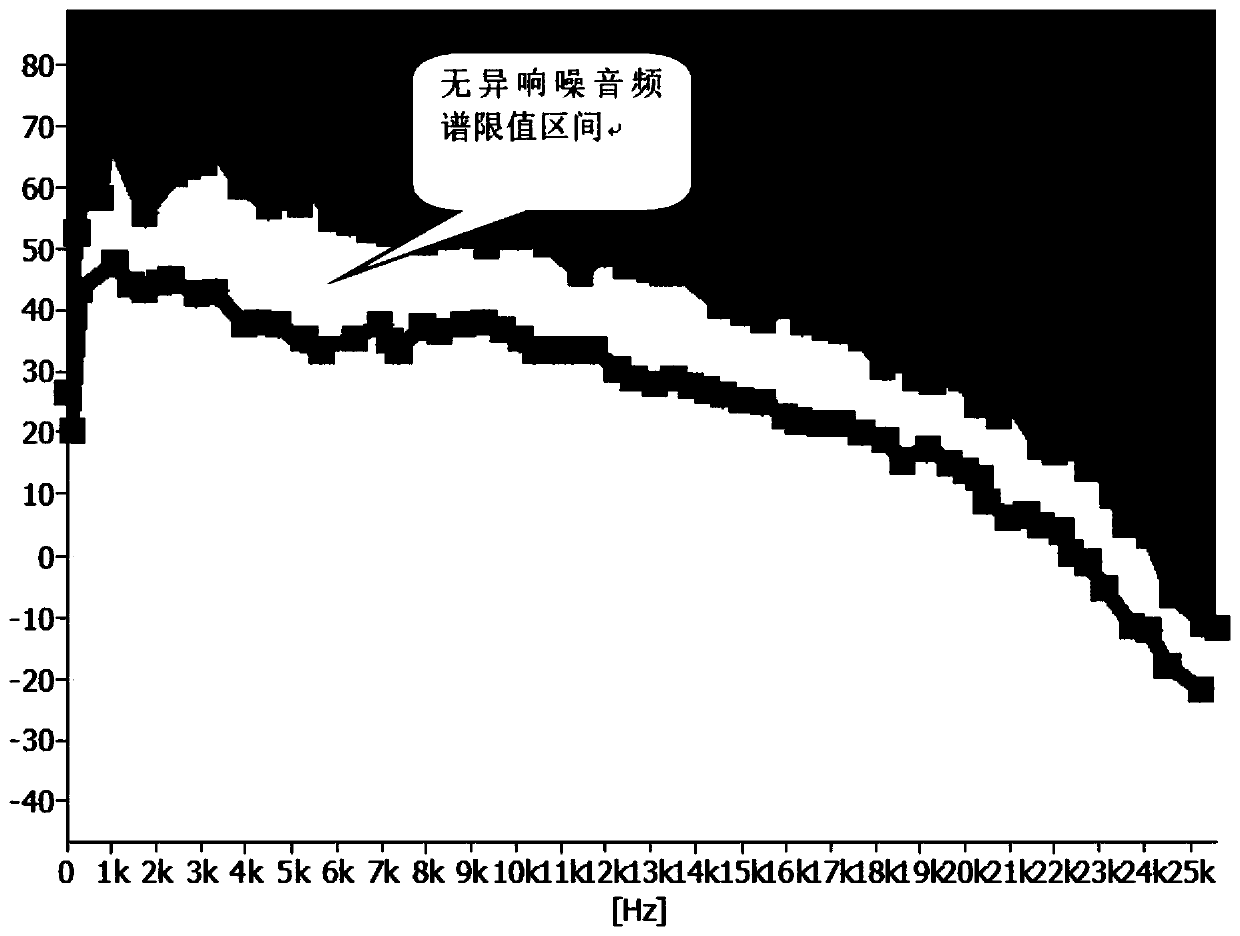

Method for judging if abnormal noise is caused in rotary vane compressors

ActiveCN110630499AAvoid exceptionStandardized investigationMachines/enginesEngineeringAudio frequency

The invention discloses a method for judging if abnormal noise is caused in rotary vane compressors. The method for judging if the abnormal noise is caused in the rotary vane compressors includes: S1,collecting information of an abnormal sound site, and recording noise frequency of the compressors which send out abnormal noise and noise frequency of the compressors which do not send out the abnormal noise; and S2, performing abnormal noise reappearing test which includes the steps: S2.1, preparing needed equipment, instruments and samples for the test; S2.2: respectively performing the abnormal noise reappearing test on the compressors which send out the abnormal noise and the compressors which do not send out the abnormal noise, setting test conditions according to the collected information of the abnormal sound site, collecting test noise through a microphone sensor, and analyzing the test noise through a noise analysis meter; S2.3, analyzing the recorded noise frequency of the compressors which send out the abnormal noise and the recorded noise frequency of the compressors which do not send out the abnormal noise; and S2.4, confirming abnormal noise problem scope according to analysis results of the step S2.2 and the step S2.3, and confirming criterion scope of the compressors which send out the abnormal noise.

Owner:CHONGQING BUILDING VEHICLE USE AIR CONDITIONER

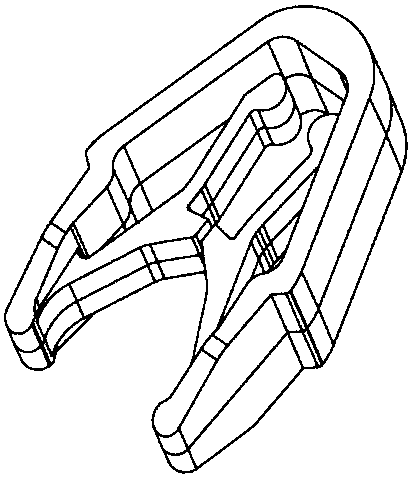

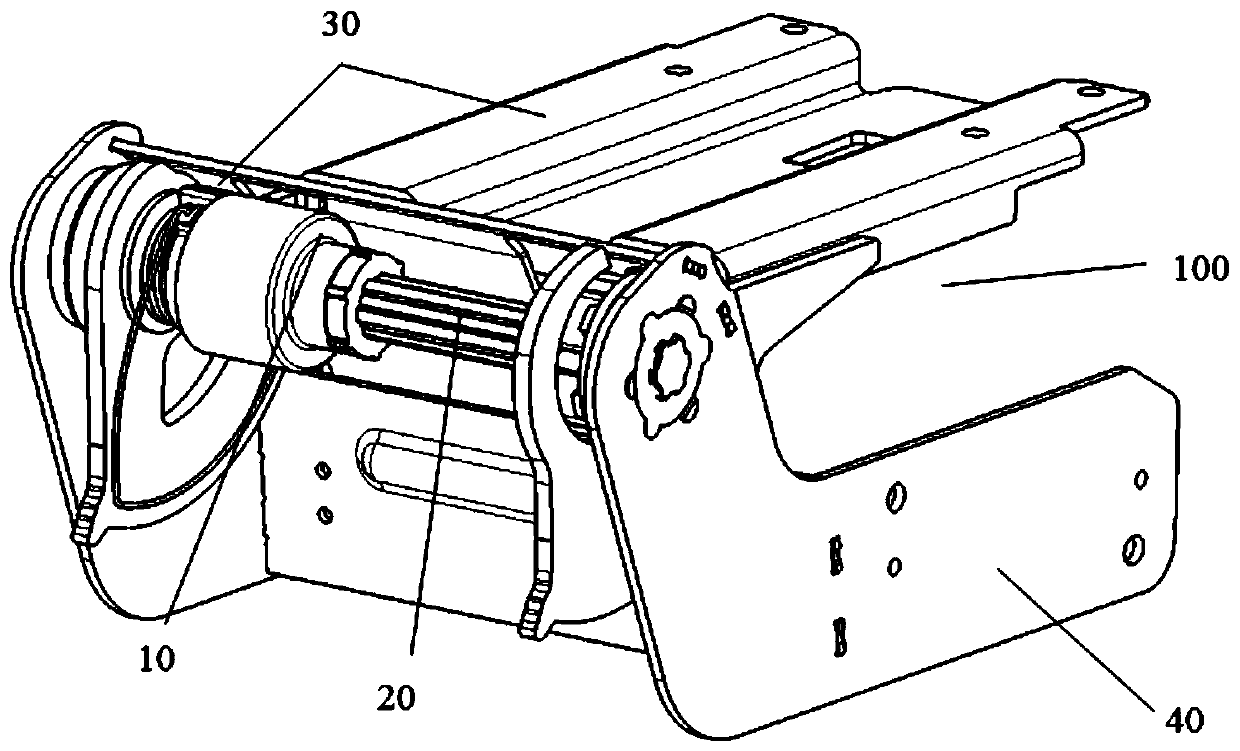

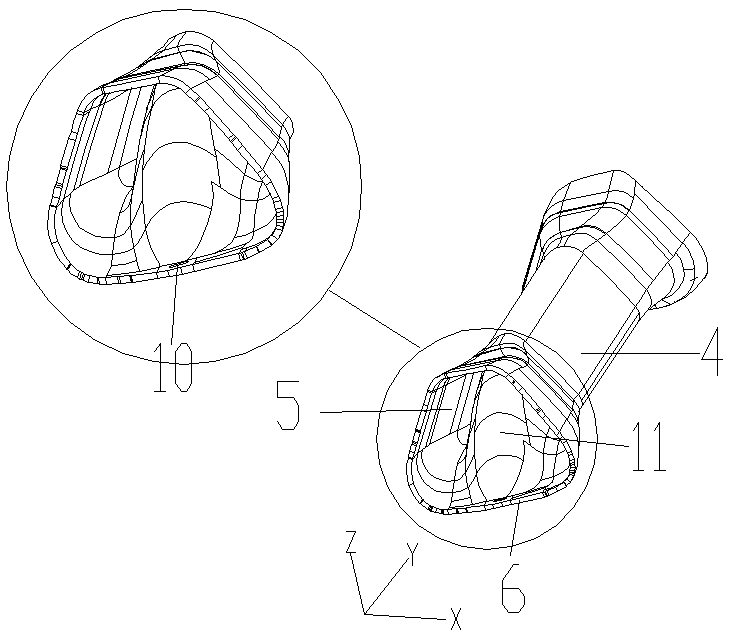

One-way bearing assembly and mechanism, armrest box and cup holder with the one-way bearing assembly

ActiveCN110341571AAvoid intermittent meshingEliminate abnormal noisePassenger spaceArm restsRetaining ringEngineering

The present invention provides a one-way bearing assembly comprising a rotating ring and a fixing ring which are coaxially arranged; a plurality of wedges arranged between the rotating ring and the fixing ring; and an unlocking mechanism used to cause the rotating ring to switch between a locked state and an unlocked state under driving of a switch. The rotating ring is rotatable in a first direction when the rotating ring is in the locked state, but is non-rotatable in a second direction opposite the first direction; and when the rotating ring is in the unlocked state, the rotating ring is rotatable in the first direction and in the second direction. The present invention also provides an armrest box and a cup holder having the one-way bearing assembly. The one-way bearing assembly of thepresent invention can be stopped at any desired position by the one-way bearing and can unlock the one-way bearing in response to the user's needs.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

Buffer piston energy accumulator

InactiveCN104006008ASimple structureAdjustable buffer effectMechanical apparatusEngineeringCylinder block

The invention discloses a buffer piston energy accumulator. According to the buffer piston energy accumulator, an end cover of a cylinder body is arranged at one end of the cylinder body, a piston is arranged in the cylinder body and located at one side of the end cover of the cylinder body, an oil discharge opening is formed in the circle center of the end cover of the cylinder body and penetrates through the end cover of the cylinder body, one side, opposite to the end cover of the cylinder body, of the piston is provided with a boss, the surface, opposite to the piston, of the end cover of the cylinder body is provided with a buffer hole, a throttle plug is arranged in the buffer hole, the side face of the end cover of the cylinder body is provided with a process hole, and a process plug is arranged in the process hole. When the piston moves towards the end cover of the cylinder body, the boss plugs up the oil discharge opening to enable oil to flow to the oil discharge opening through the throttle plug, and the section area of the throttle plug is far smaller than that of the oil discharge opening, so that the movement speed of the piston is reduced, and the buffer effect is achieved. The buffer piston energy accumulator is simple in structure, adjustable in buffer effect and low in manufacturing cost, eliminates abnormal sounds of the hydraulic system generated when the piston hits against the end cover of the cylinder body, eliminates hydraulic impact generated when the piston hits against the end cover of the cylinder body and prolongs the service life of the energy accumulator and sealing pieces.

Owner:SANY HEAVY EQUIP

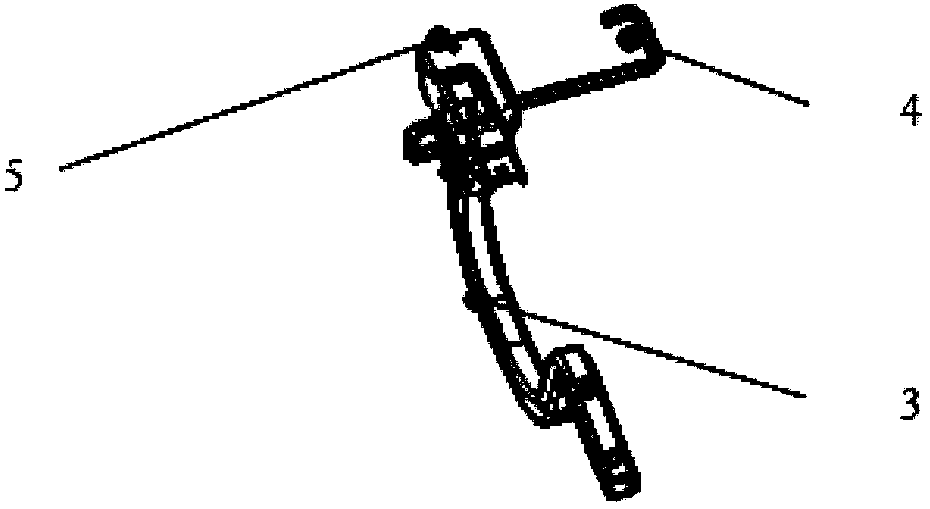

Bouncing mechanism of car trunk

A bouncing mechanism of a car trunk comprises arch hinges, installation base boards and torsion rod springs. The left side and the right side inside the car trunk are respectively provided with one arch hinge, one installation base board and one torsion rod spring, and the two arc hinges, the two installation base boards and the two torsion rod springs are respectively arranged symmetrically and are identical in structure. One end of an arch arm of each arch hinge is hinged to the corresponding installation base board, each installation base board is installed on a lateral rail assembly, and the other end of each installation base board is hinged to a trunk cover. The inner end of each torsion rod spring is fixed to the corresponding installation base board and the outer end of each torsion rod spring is fixed to a clamping groove of a lateral rail inner board at the same side. Each arch arm is further hinged to a torsion spring connecting rod, the middle of each torsion rod spring is clamped with the corresponding torsion spring connecting rod, a fixing installation point at each inner end, a fixing point at the corresponding outer end and a clamping point of the middle of the corresponding torsion rod spring are not on the same line, and therefore it is guaranteed that a four-bar linkage mechanism is formed. According to the bouncing mechanism, the structure and the installation position of each torsion rod spring are changed and the torsion rod springs are arranged at the left side and the right side of the trunk instead of transversely penetrating through the trunk and then being fixed. The bouncing mechanism has the advantages of being simple and practical in structure, stable and reliable in performance, low in cost and weight and capable of being widely applied to a car trunk system with an arch hinge torsion rod spring mechanism.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

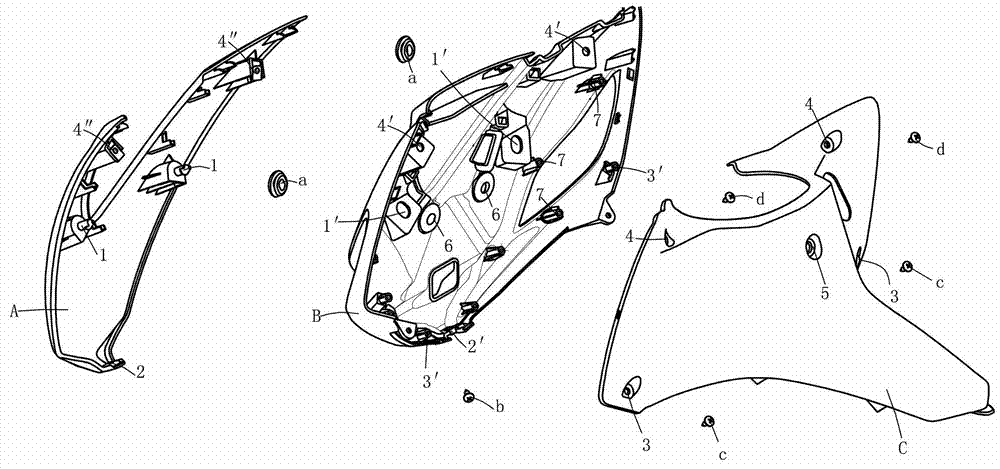

Installing structure for motorcycle front mask, front mask decoration plate and middle protection plate

InactiveCN102774451AReduce in quantityReduce vibrationWeather guardsAgricultural engineeringFace shield

The invention discloses an installing structure for a motorcycle front mask, a front mask decoration plate and a middle protection plate. The front mask decoration plate (A) is positioned in front of the front mask (B), the middle protection plate (C) is positioned at the back side of the front mask (B), the front mask decoration plate and the front mask as well as the front mask and the middle protection plate are in pairwise connection, the front mask decoration plate, the front mask and the middle protection plate are connected through self-tapping screws, and a mode of combining rigid connection and soft connection is adopted between the front mask decoration plate and the front mask. The installing structure has the characteristics that the installation structure is simple, the stability is good, the vibration is small, the integral feeling is strong, the appearance quality is good, the mounting and the dismounting are convenient and fast, and the like.

Owner:力帆科技(集团)股份有限公司

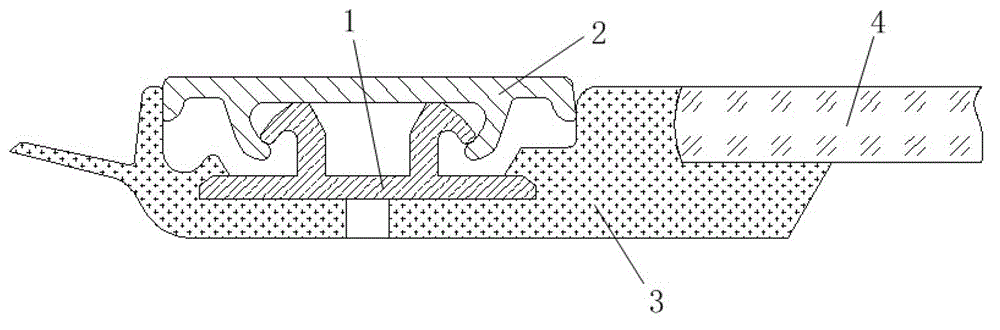

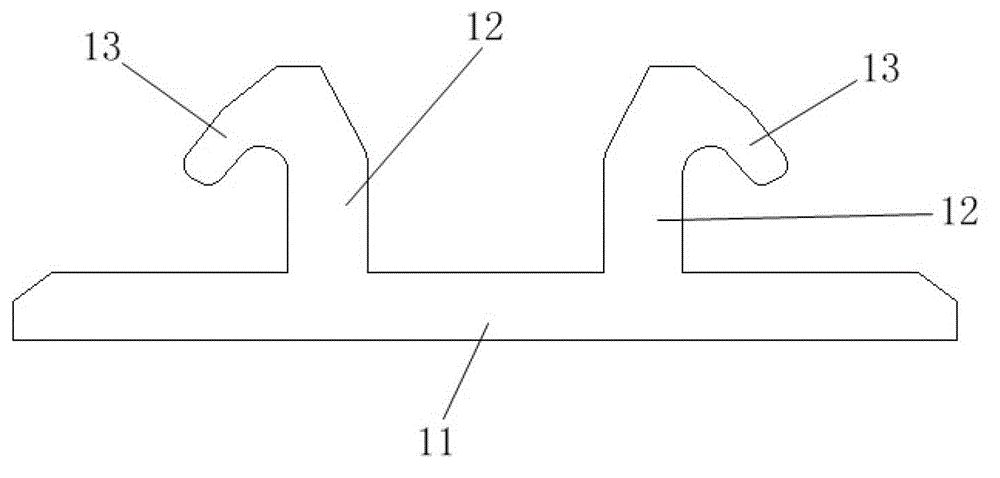

Middle insert part and glass window comprising same

The invention relates to the technical field of the installation of decoration strips on a glass window, in particular to a middle insert part which is used for installing bright decoration strips onto cladding edges of an automobile glass, and a glass window comprising the bright decoration strips, the middle insert part and cladding edges, and further relates to a method for installing the bright decoration strips onto the cladding edge of the automobile glass through the middle insert part. The middle insert part comprises a base and two fixed blocks, wherein the top end of each of the two fixed blocks is provided with an inclined part. Meanwhile, the invention further provides the glass window comprising the middle insert part. The middle insert part provided by the invention is simple in structure, so that the complexity degree can be reduced, and the labor cost can be reduced; material selectivity is large, so that the assembly cost can be reduced; the abnormal sound of the bright decoration strips can be eliminated in the manner that a plastic material is adopted or a layer of elastic material is arranged on the surface of each inclined part, so that the assembly efficiency and the use comfortable level can be improved; and a fixed part is arranged to prevent the bright decoration strips from freely sliding on the cladding edge, so that the installing precision of the bright decoration strip on the cladding edge can be guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD +1

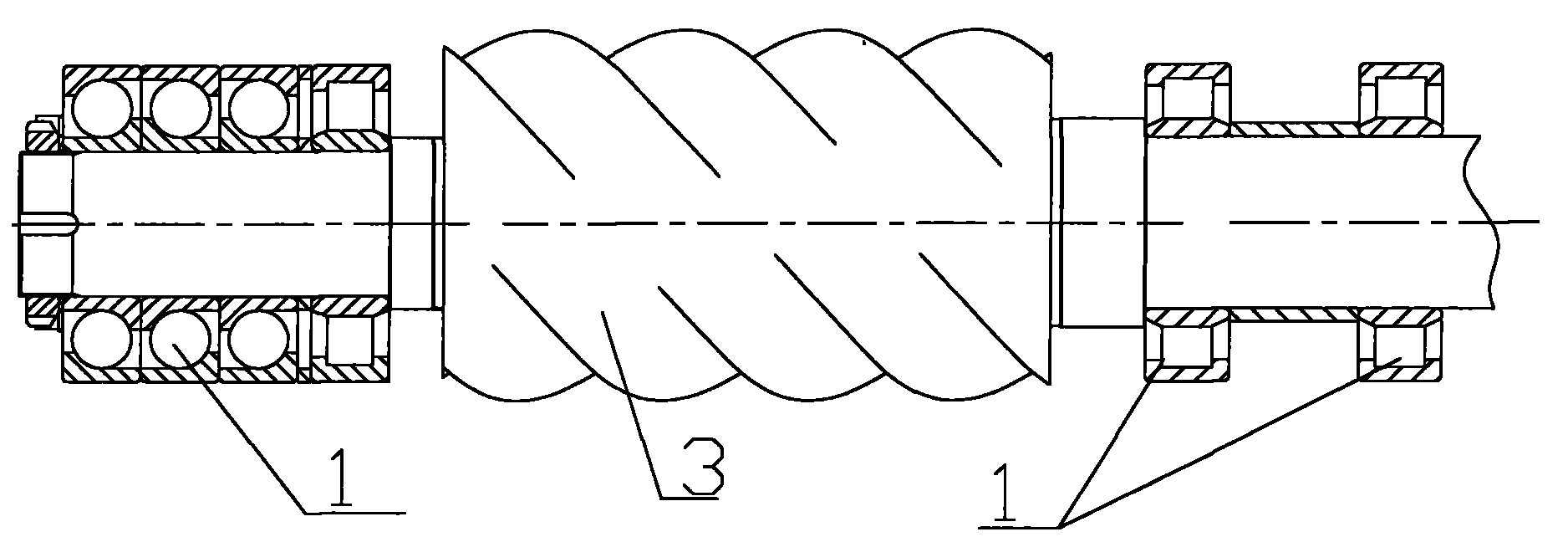

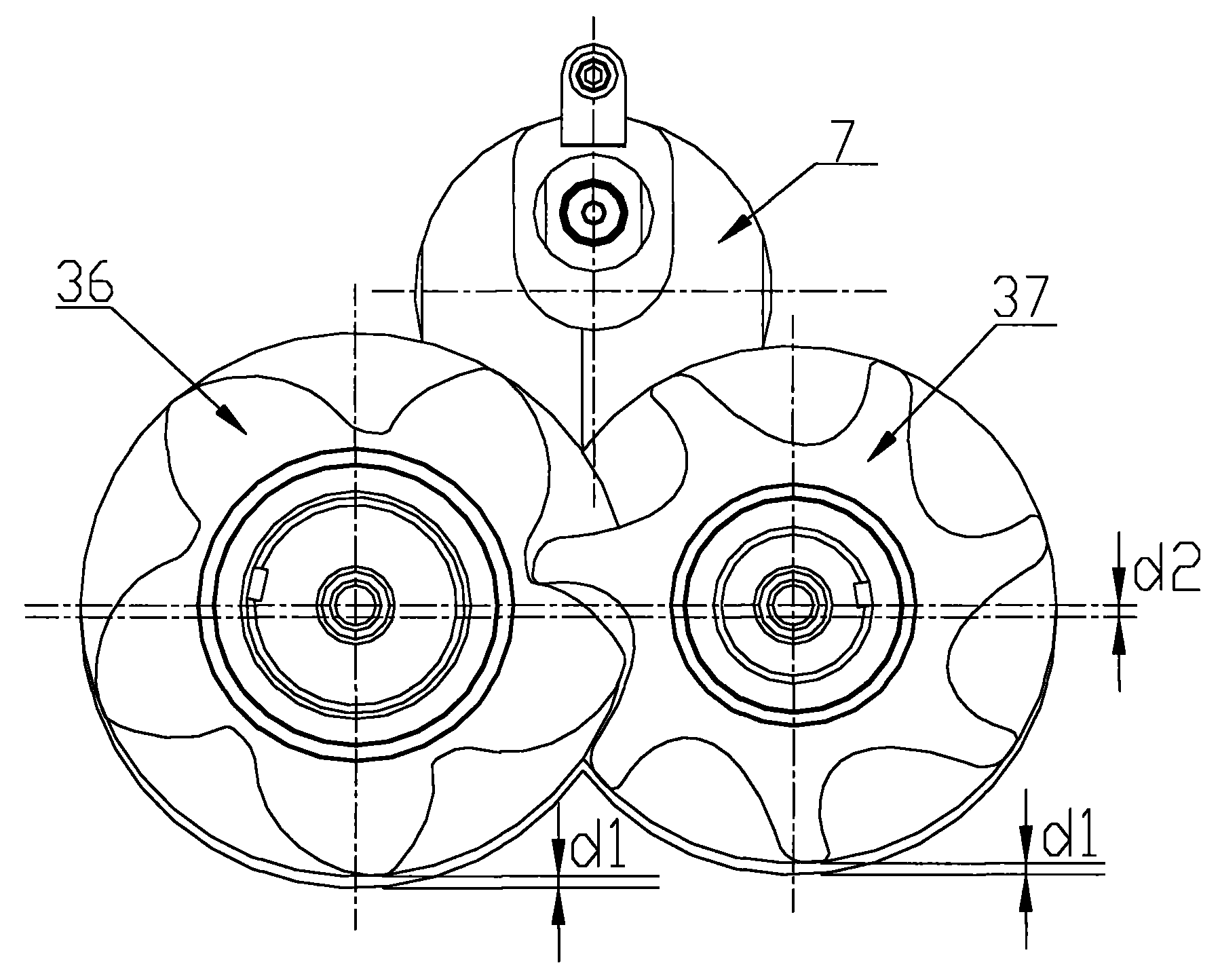

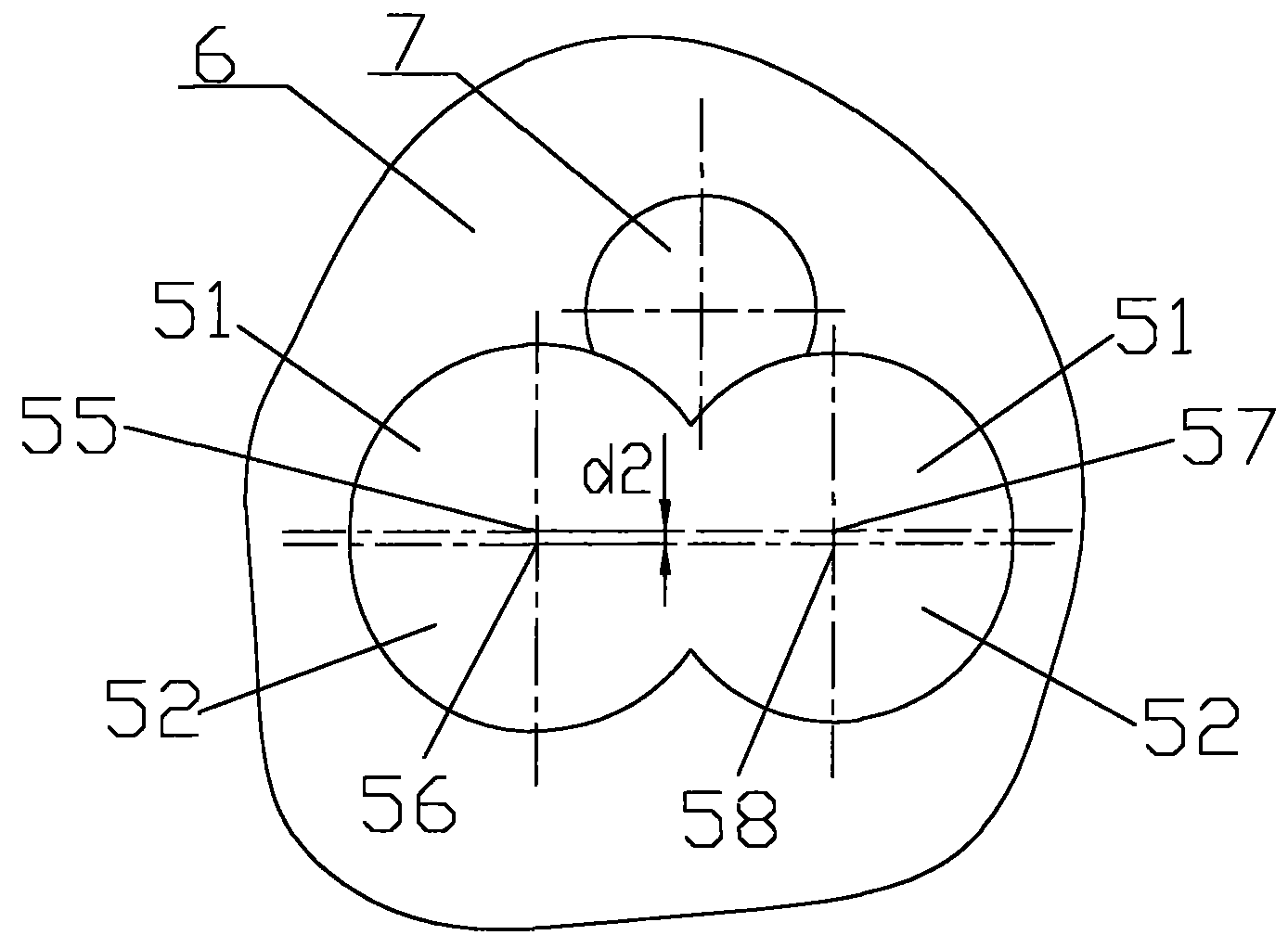

Screw compressor

ActiveCN102052315AEliminate abnormal noiseRotary piston pumpsRotary piston liquid enginesGas compressorEngineering

The invention provides a screw compressor, which comprises a body, a compressor rotor, a bearing and a sliding valve. The body is provided with a sliding valve cavity for accommodating the sliding valve and a compression cavity for accommodating the compressor rotor, and the compressor rotor is supported inside the compression cavity by the bearing; and the distance d1 from the lowermost end of the circumscribed circle of the compressor rotor to the lowermost end of the compression cavity is larger than the distance from the uppermost end of the circumscribed circle of the compressor rotor tothe uppermost end of the compression cavity. The inventive screw compressor can effectively prevent the compressor rotor and the body compression cavity from scratching each other during the loading process, eliminates abnormal noise of the compressor, and improves the reliability of the screw compressor.

Owner:GREE ELECTRIC APPLIANCES INC

Ridging die for damping package inner assembly of vehicle exhaust system

PendingCN110666043AEasy to operateDimensional stability in productionShaping toolsMetal-working feeding devicesPipe fittingClassical mechanics

The invention relates to a ridging die for a damping package inner assembly of a vehicle exhaust system. The ridging die comprises a ridging assembly and a clamping tool assembly, wherein the ridgingassembly comprises a ridging movable plate, positioning rings, pull rods, a ridging fixed plate, outer sleeve rods, positioning mechanisms, cone rods, clamping and locking die bodies and end clampingheads, and the clamping tool assembly comprises a tool base plate, tool fixed plates, tool movable plates, pipe fitting positioning blocks, profiling plates, guide pillars, guide sleeves, oil cylinders, oil cylinder connecting rods and floating joint bases. By means of the ridging die, part of metal of a damping pipe is stretched and deformed, and the inner assembly assembling process of fixing two parts of a clapboard and the damping pipe is achieved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

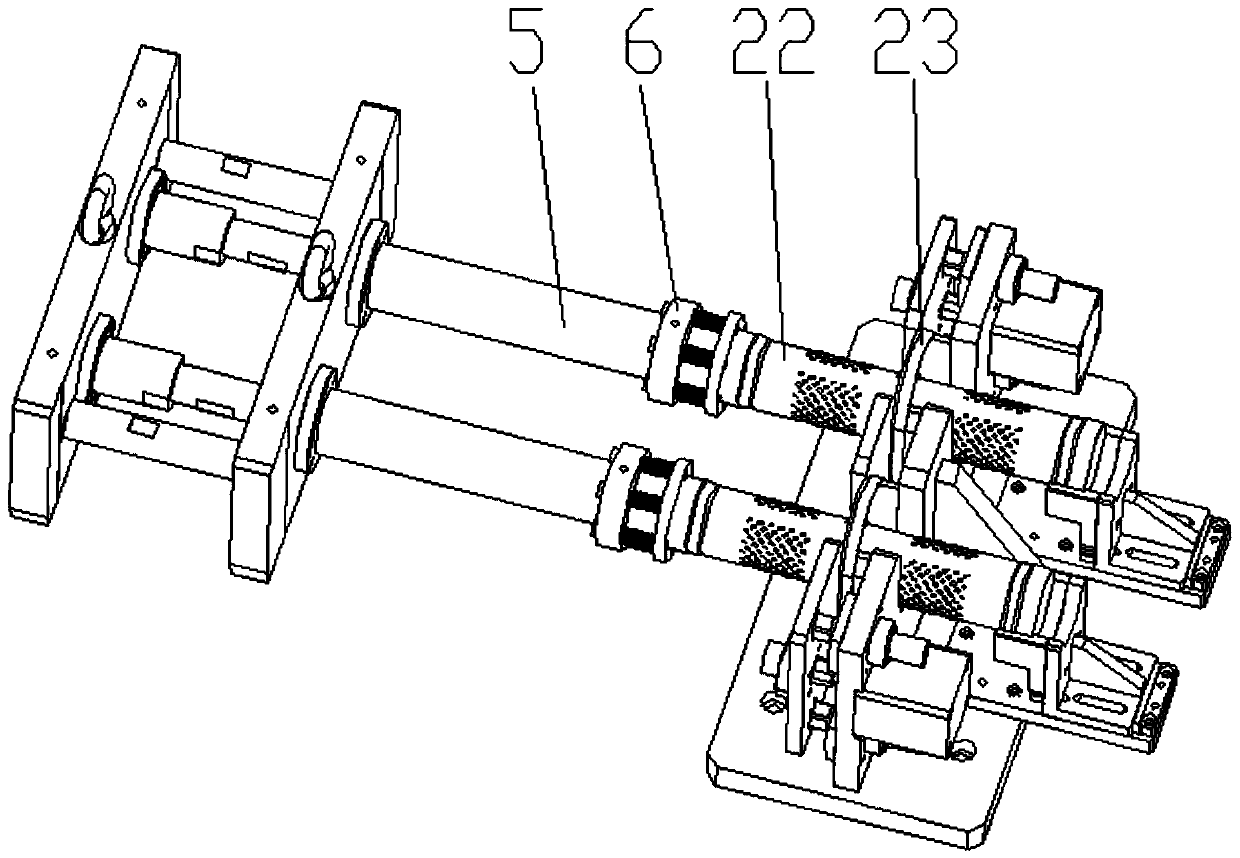

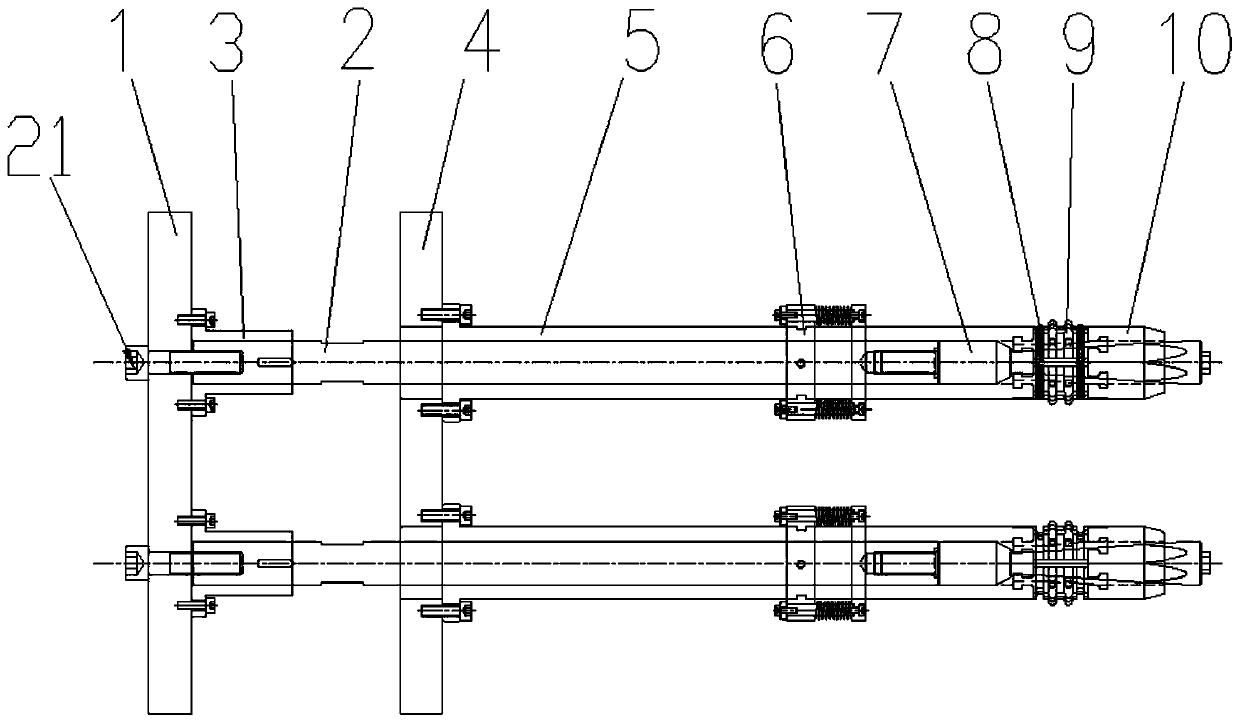

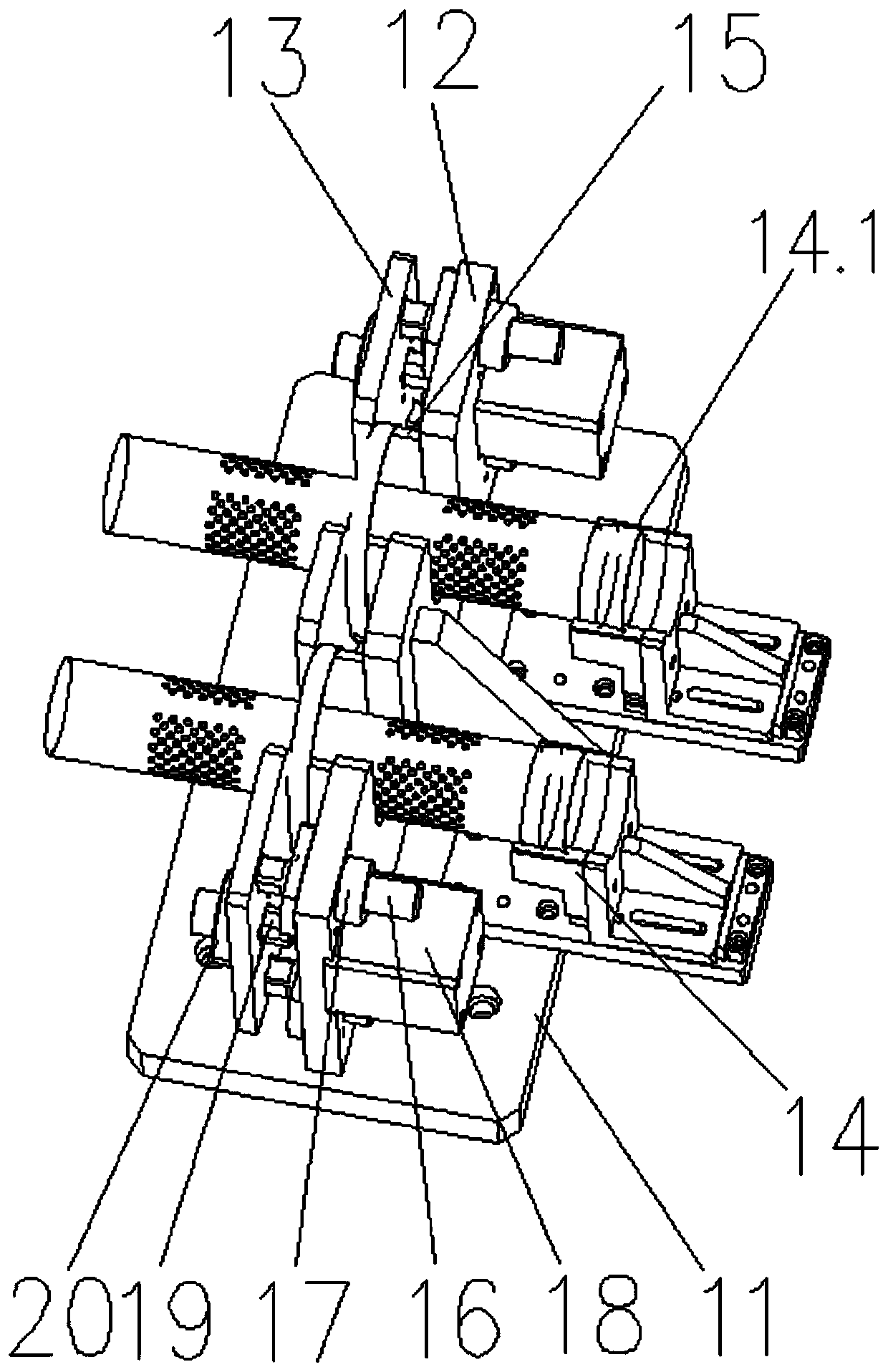

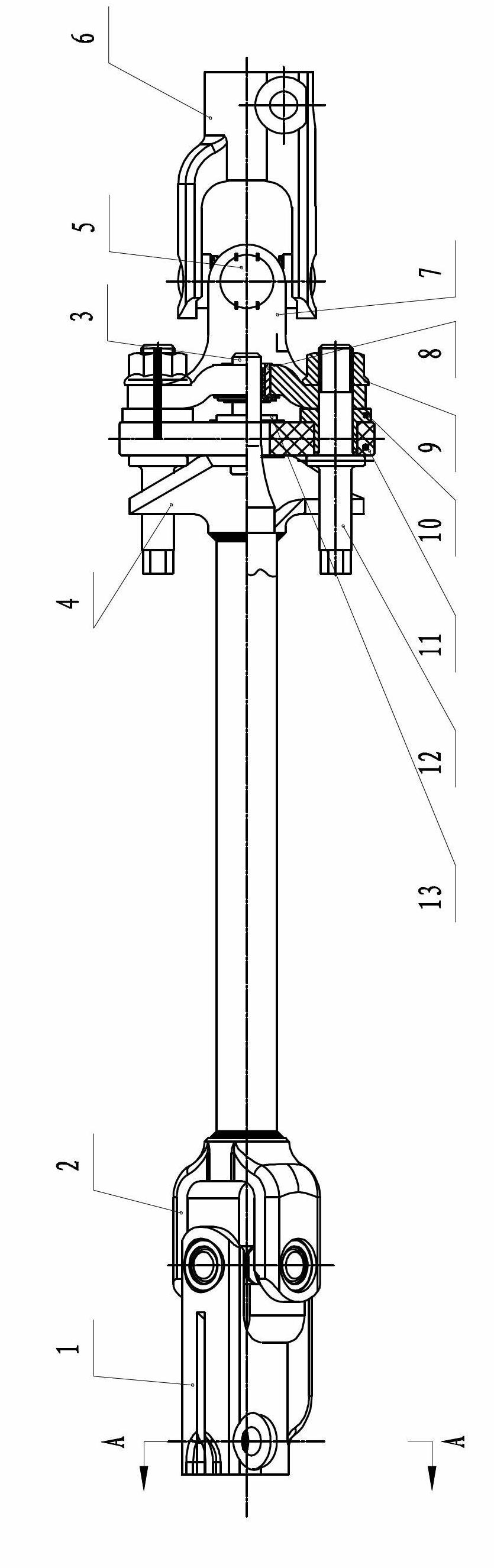

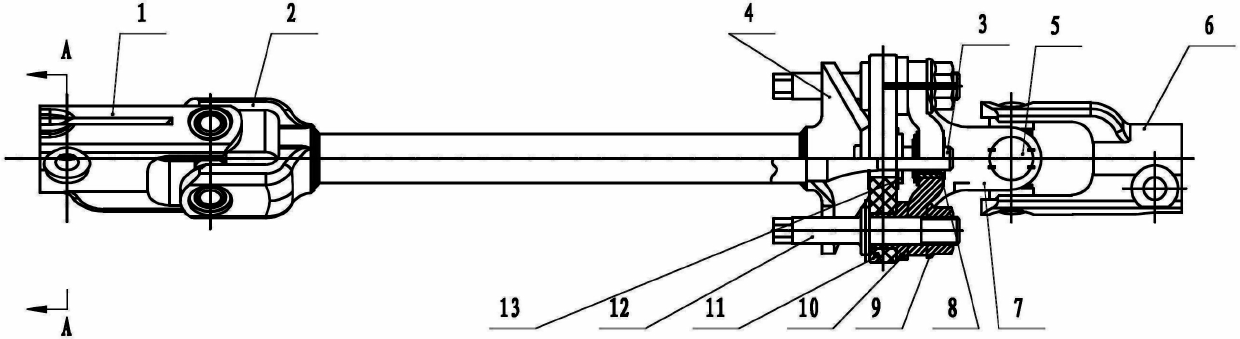

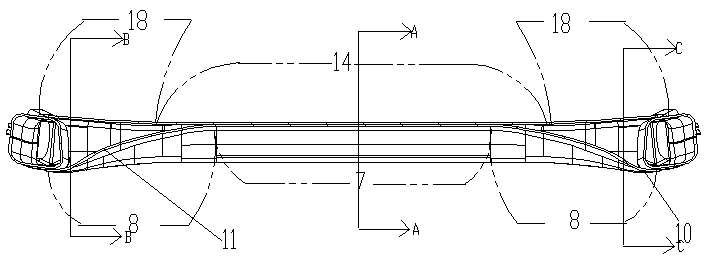

Steering under-drive shaft assembly

InactiveCN102673633AExtended service lifeReduce vibrationSteering linkagesSteering columnsUniversal jointDrive shaft

The invention relates to a steering under-drive shaft assembly, especially being used for an automobile steering mechanism and belonging to the technical field of auto spare parts. The steering under-drive shaft assembly mainly adopts a lower universal joint fork to be connected with a shaft universal joint fork, wherein the shaft universal joint fork is connected with an under-drive shaft in a welding way; the under-drive shaft is connected with a coupling disc in the welding way; the coupling disc is connected with a rubber disk through short rivets; the rubber disk is connected with a middle universal joint fork through bolts, gaskets, and flange face locking nuts; the middle universal joint fork is connected with the universal joint forks through a universal joint crossing shaft; a positioning pin is arranged on the nose of the under-drive shaft; a positioning hole is arranged in the coupling disc; and a rubber positioning sleeve is arranged in the positioning hole of the coupling disc. The steering under-drive shaft assembly can ensure the axiality of the composite structure of the under-drive shaft, plays a role in floatation positioning, thereby eliminating the defect of frequent abnormal sound resulting from rigid contact, and is remarkable in shock absorption effect, thereby improving the safety performance of vehicle travelling.

Owner:无锡金也汽车部件有限公司

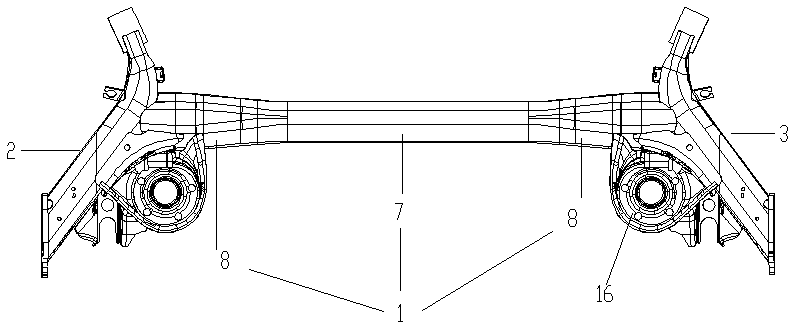

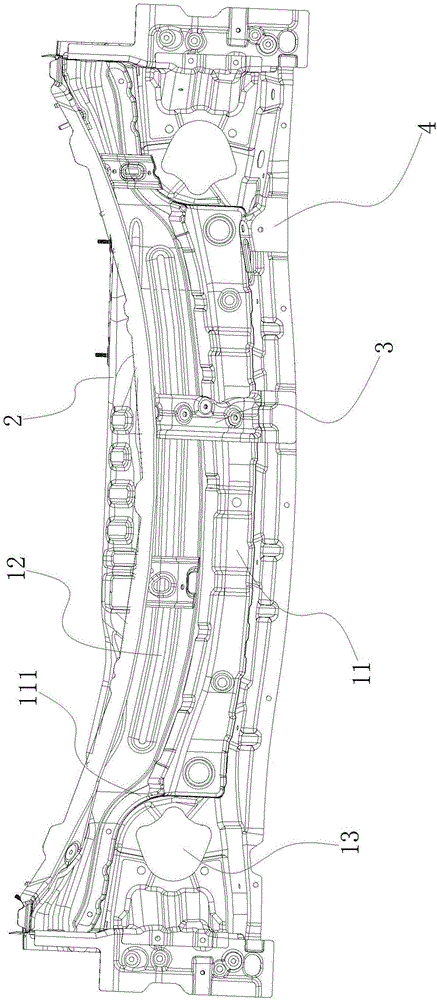

Manufacturing method for main beam capable of improving overall NVH capacity of automobile

PendingCN110696918AEliminate abnormal noiseConsistent thicknessLiquid surface applicatorsUnderstructuresMechanical engineeringAutomotive engineering

The invention relates to the field of automobiles and automobile part manufacturing, in particular to a manufacturing method for a main beam capable of improving the overall NVH capacity of an automobile. The maximum specific content of the lubricating oil and the extremely low cost are defined, and after heat treatment is carried out in the manufacturing process of the main beam, a special oil film layer is formed on the inner wall of the main beam to separate the front layer from the rear layer which are attached to each other, so that abnormal sounds caused by the main beam structure are basically eliminated. The method comprises the following steps that 1, a corresponding main cross beam is manufactured, and the structure of the main cross beam mainly corresponding to the technical range comprises a front plate and a rear plate, and the re-extrusion expansion section of a lower beam is V-shaped, C-shaped, U-shaped, arc-shaped, L-shaped, U-shaped, L-shaped and the like; the distancebetween the folded top plate overlapping position of the front plate and the rear plate and the inner wall of the expanded lower plate is not equal to 0 mm but smaller than 2-0.2 mm of the contact distance in the whole top plate overlapping position or in the most central part of the top plate overlapping position.

Owner:ZHEJIANG TUOWEI AUTOMOBILE PARTS CO LTD

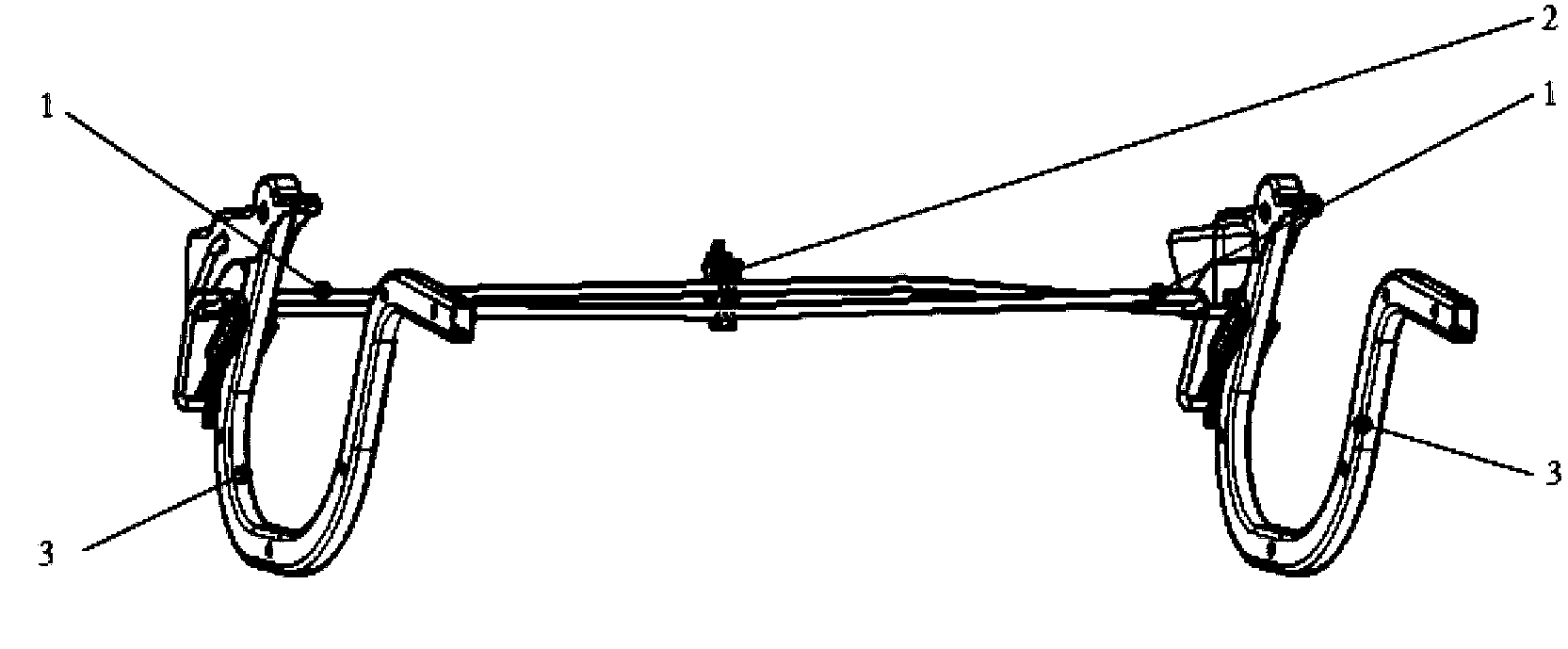

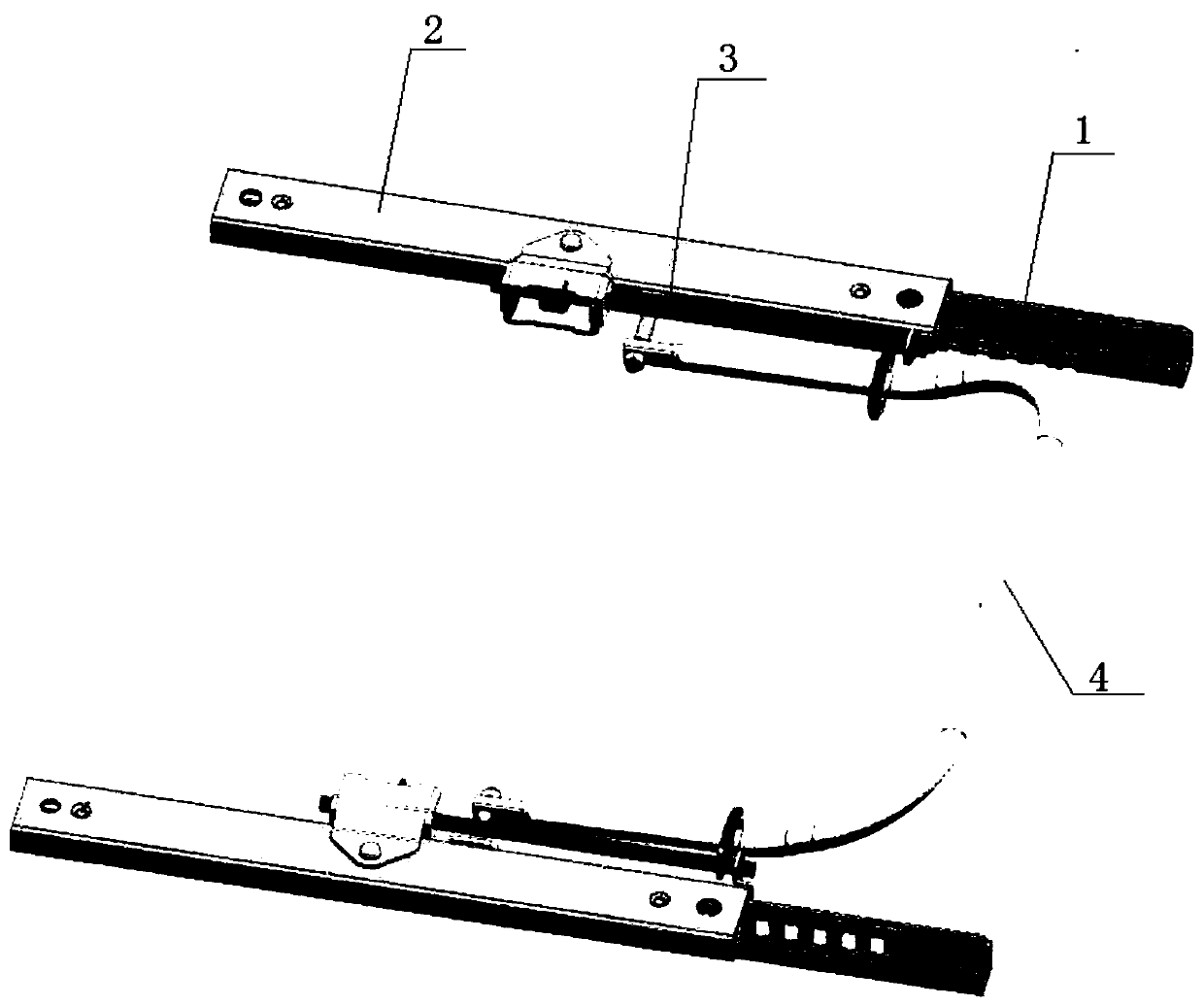

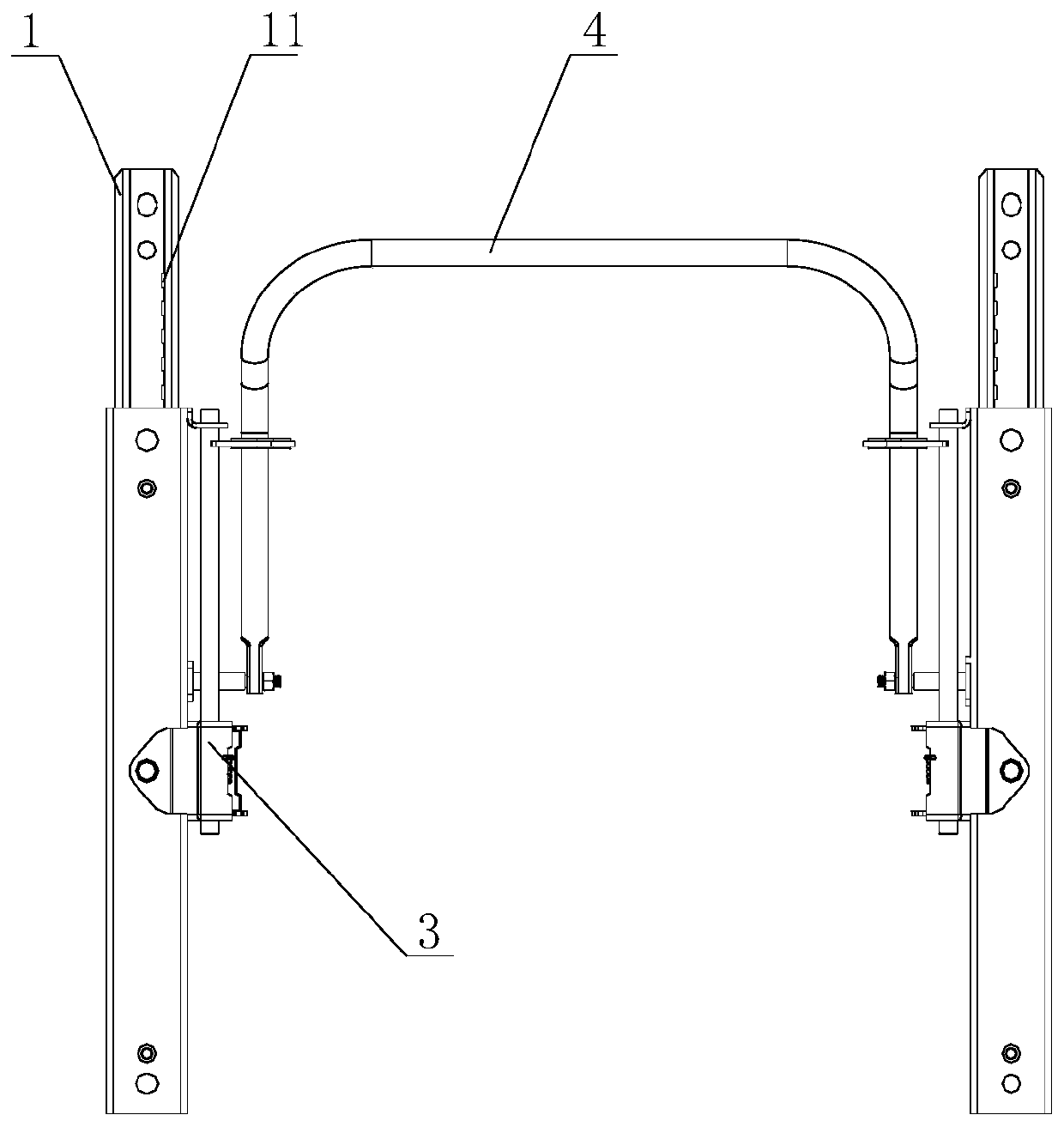

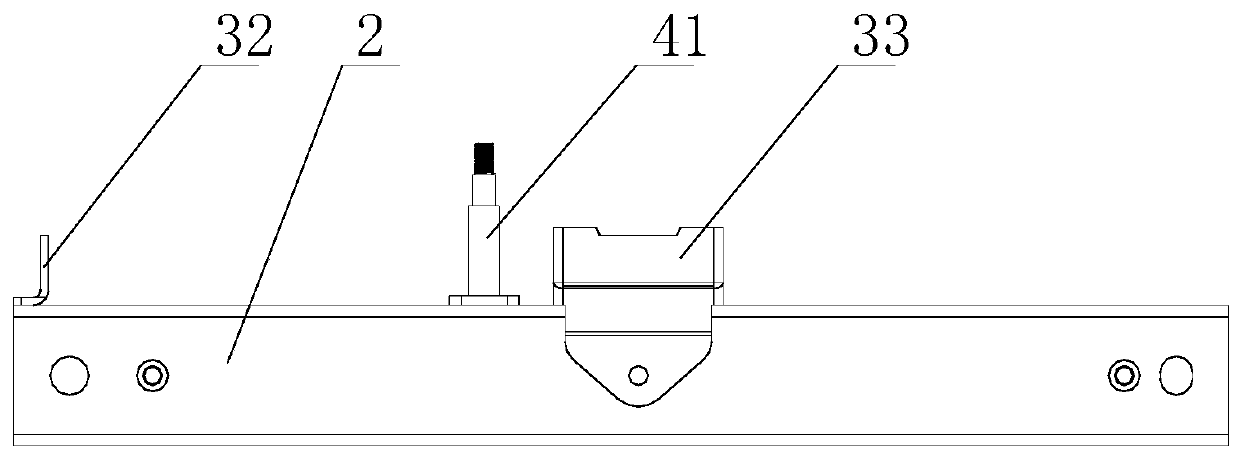

Abnormal sound prevention automobile seat control device

InactiveCN111055734AEliminate abnormal sound defectsEliminate abnormal noiseMovable seatsCar seatEngineering

The invention discloses an abnormal sound prevention automobile seat control device, which relates to the technical field of automobile accessories, and comprises two groups of inner slide rails and outer slide rails matched with each other, and further comprises two locking mechanisms and a control handle. The locking mechanism comprises a locking long rod, a rocker arm, a locking plate and a torsion spring; the rocker arm is fixedly arranged at the position, close to the front end, of the long locking rod; a through hole matched with the control handle is formed in the rocker arm; a silencing bush is arranged in the through hole in a sleeved mode; the locking plate is fixedly arranged at the rear end of the locking long rod and is opposite to the fixing plate; the torsion spring sleevesthe locking long rod; one end of the torsion spring is connected with the locking plate, and the other end of the torsion spring is connected with the fixing plate; the control handle is of a U-shapedstructure, and the two ends of the control handle penetrate through the corresponding through holes respectively and then are connected with the outer slide rails through fixing pin shafts; a lockinggroove matched with the locking plate is formed in the inner slid rail; and a through groove for the locking plate to penetrate through is formed in the position, corresponding to the locking plate,of the outer slide rail.

Owner:HUBEI WEISHITONG AUTOMOTIVE PARTS CO LTD

Brush Assembly for an Electric Motor

ActiveUS20150303635A1Improve stabilityEliminate abnormal noiseRotary current collectorDynamo-electric machinesEngineeringSliding contact

A brush assembly has a brush, a brush cage, and a spring. The spring is a constant force spring having two coil portions and a connecting portion. The connecting portion the brush are together received in the brush cage. The brush has a contact end arranged to make sliding contact with a commutator and a second end remote from the contact end against which the spring applies its force, to urge the brush out of the brush cage. A hook is formed at each of two opposite sides of the brush cage, at a first end portion of the brush cage adjacent the contact end of the brush. The coil portions respectively engage the hooks. The hooks extend at different angles to a corresponding outer surface of the brush cage.

Owner:JOHNSON ELECTRIC SA

Front windshield water guide plate assembly

The invention particularly relates to a front windshield water guide plate assembly. The front windshield water guide plate assembly which can improve the locating accuracy of a wiper motor mounting point and enhance the mounting strength comprises a U-shaped water guide groove and a wiper motor mounting support, wherein the U-shaped water guide groove is welded to a front windshield lower transverse beam. The wiper motor mounting support comprises a support A and a support B. The front end of the support A is welded to the upper edge of a front plate of the U-shaped water guide groove, the rear end of the support A is welded to the front windshield lower transverse beam, and the support B is welded to the upper edge of the front plate of the U-shaped water guide groove. Due to the support A and the support B in a combined mode, the distance between the support A and the support B can be adjusted according to the mounting point positions of a wiper motor and a wiper arm, and the locating accuracy of mounting points is improved. Due to the fact that the front end and the rear end of the support A are fixedly arranged on the U-shaped water guide groove and the front windshield lower transverse beam respectively, the strength and the rigidity of the wiper motor mounting point are improved, the phenomenon that a wiper severely shakes in the using process is avoided, usage abnormal noise and water brushing and wiping badness of the wiper are eliminated, and the torsional rigidity of the water guide plate assembly is improved.

Owner:重庆比速汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com