Installing structure for motorcycle front mask, front mask decoration plate and middle protection plate

A technology for installation structure and front cover, which is applied to weather guards, transportation and packaging, bicycle accessories, etc., can solve the problems that parts are prone to vibration, affect motorcycle sales, and affect driving comfort, etc., so as to reduce vibration, install Easy to disassemble, good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

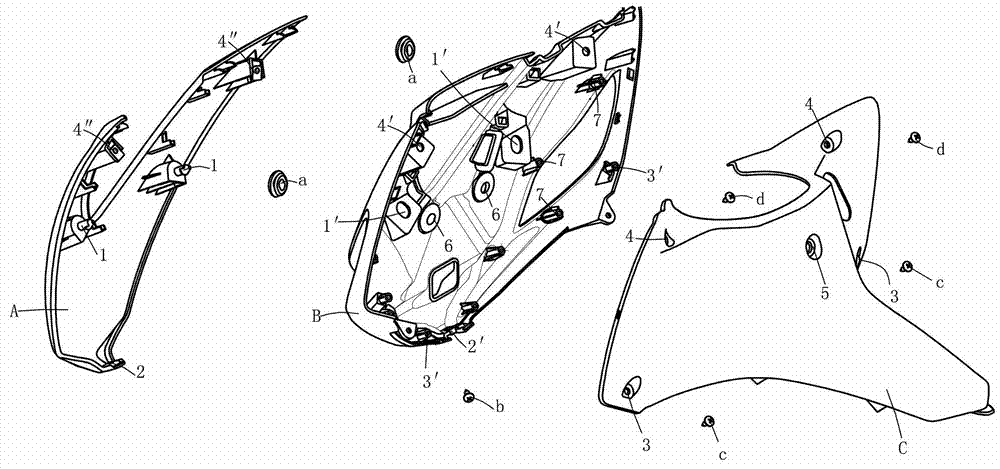

[0015] Such as figure 1 As shown, the front panel trim A is located in front of the front panel B, and the center guard panel C is located behind the front panel B.

[0016] There are three installation points between the front cover trim A and the front cover B: (1) There are two mushroom head clips 1 distributed left and right on the inner middle of the front cover trim A, and there are two mushroom head clips 1 on the front cover B. The clamping hole 1' corresponding to the position of the head clamp 1, the mushroom head clamp 1 is inserted into the clamping hole 1' equipped with the annular rubber pad a, which are two installation points; (2) The bottom of the front cover trim A faces inward The extended mounting plate is provided with a first screw through hole 2, and the bottom of the front cover B extends inwardly. The hole 2 is driven into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com