Steering under-drive shaft assembly

A technology of transmission shaft and assembly, applied in steering column, steering mechanism, steering tie rod, etc., can solve problems such as aggravating the wear of related parts, hidden dangers of automobile driving safety, affecting driving performance, etc., so as to prolong the service life and increase the safety performance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

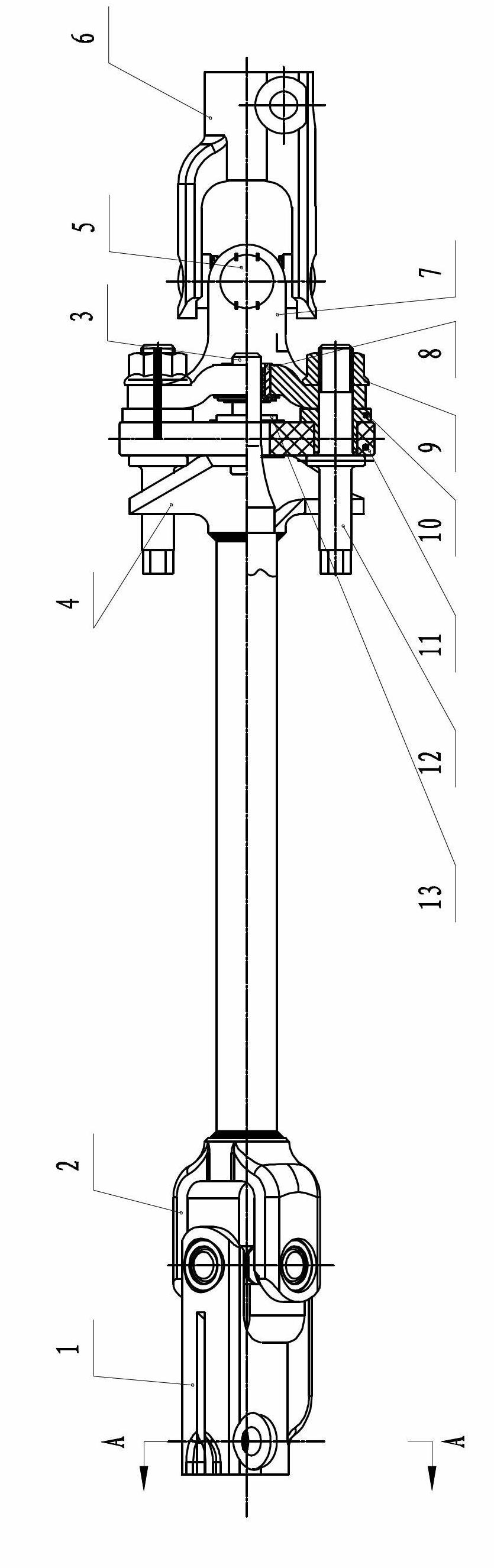

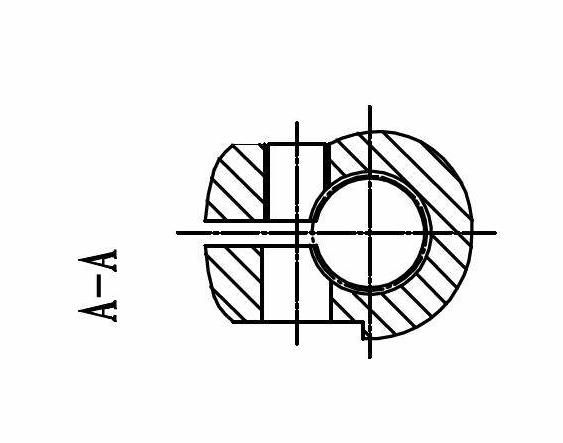

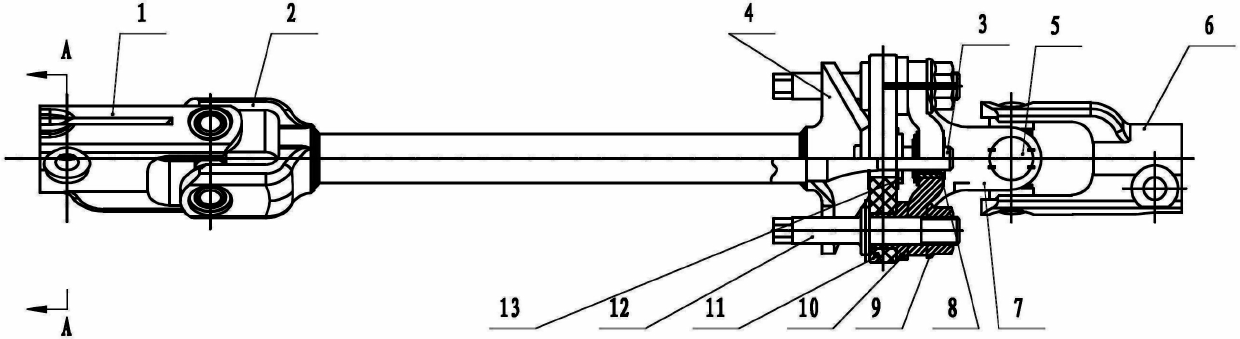

[0013] Such as figure 1 As shown, it includes the lower universal joint fork 1, the shaft universal joint fork 2, the lower transmission shaft with positioning pin 3, the coupling piece 4, the universal cross shaft 5, the upper universal joint fork 6, and the middle universal joint Fork 7, rubber positioning sleeve 8, flange face lock nut 9, washer 10, rubber plate 11, bolt 12, short rivet 13 and positioning pin 14.

[0014] In the present invention, the lower universal joint yoke 1 is connected with the shaft universal joint yoke 2, and the shaft universal joint yoke 2 and the lower transmission shaft 3 with positioning pins are connected by welding, and the lower transmission shaft 3 with positioning pins and The coupling piece 4 is connected by welding, the coupling piece 4 and the rubber disc 11 are connected by short rivets 13, the rubber disc 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com