Abnormal sound prevention structure of automobile mechanical steering gear

A steering gear, mechanical technology, applied in the direction of mechanical steering gear, etc., can solve the problem of increasing the friction of the steering gear, the movement of the pinion of the steering gear and the steering rod is not smooth, increasing the pre-tightening force and controlling the support of the rack and the pressure block. Dimensions between shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

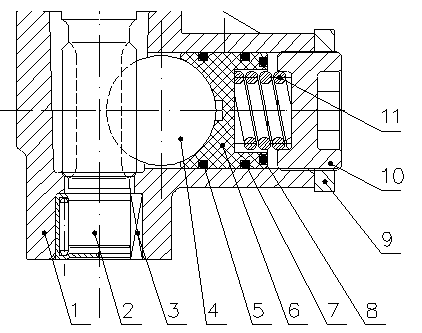

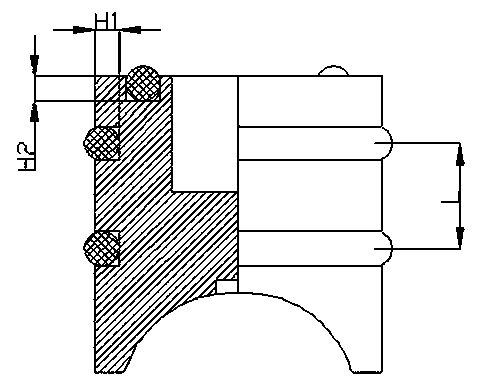

[0011] Such as figure 1 As shown, an automobile mechanical steering gear anti-abnormal structure, including steering gear main body housing 1, pinion shaft 2, gear shaft fixed bearing 3, rack 4, rack support pressure block 6, clearance adjustment and locking Nut 9, gap adjusting nut 10 and spring 11. Wherein, the pinion shaft 2 is fixed in the main housing 1 of the steering gear through the pinion shaft fixed bearing 3, the pinion shaft 2 meshes with the rack 4, and the outer side of the rack 4 is pressed by one end of the rack supporting pressure block 6, and the gap The adjusting nut 10 is screwed on the steering gear main body housing 1 and presses the spring 11 tightly, and the other end of the spring 11 is pressed tightly on the other end of the rack supporting pressure block 6 . The gap adjusting nut 10 is locked and fixed in the steering gear main housing 1 by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com