Patents

Literature

100 results about "Abnormal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual endoscopy with improved image segmentation and lesion detection

InactiveUS7747055B1Exact matchAccurate representationUltrasonic/sonic/infrasonic diagnosticsImage enhancementBody organsLesion detection

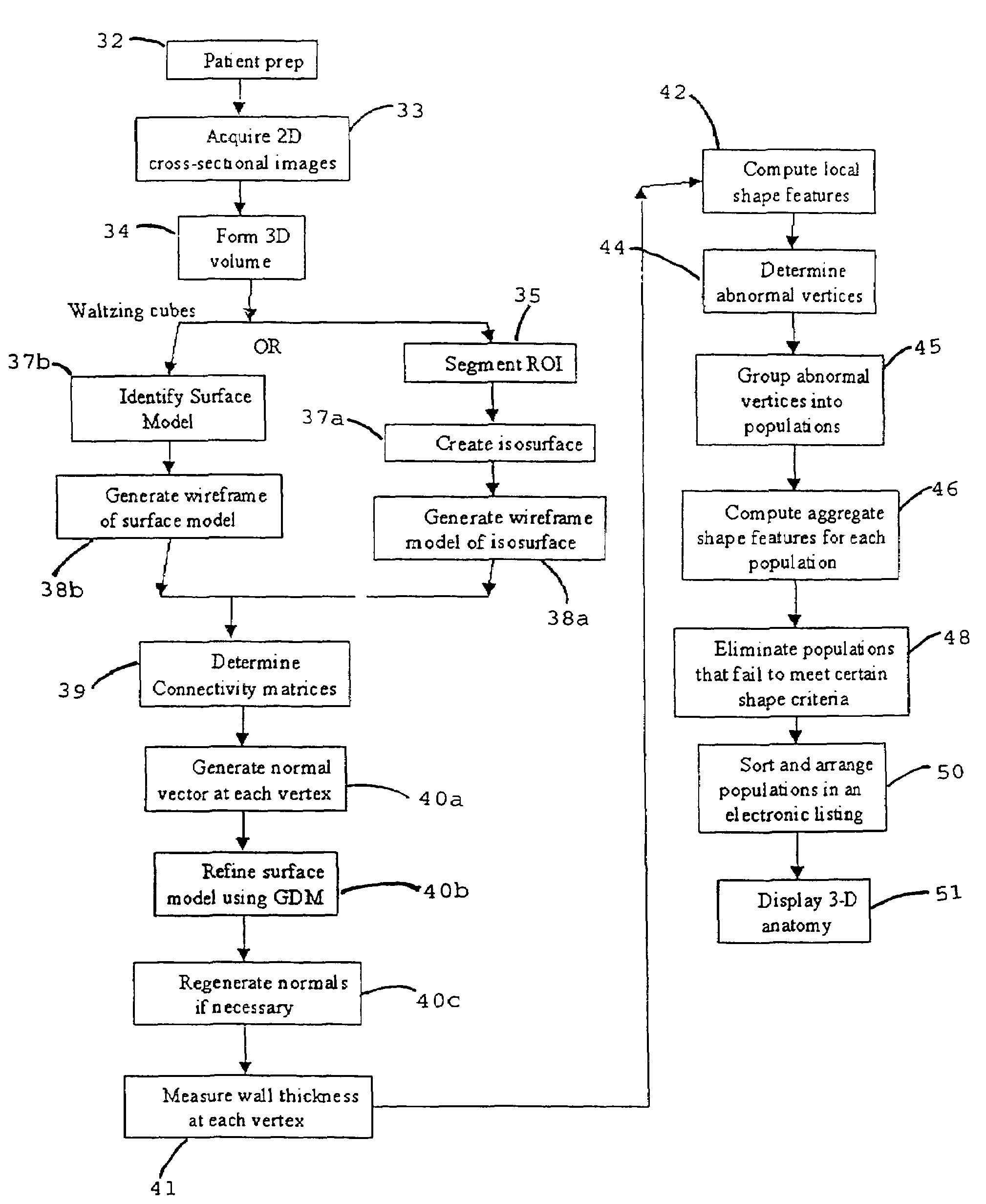

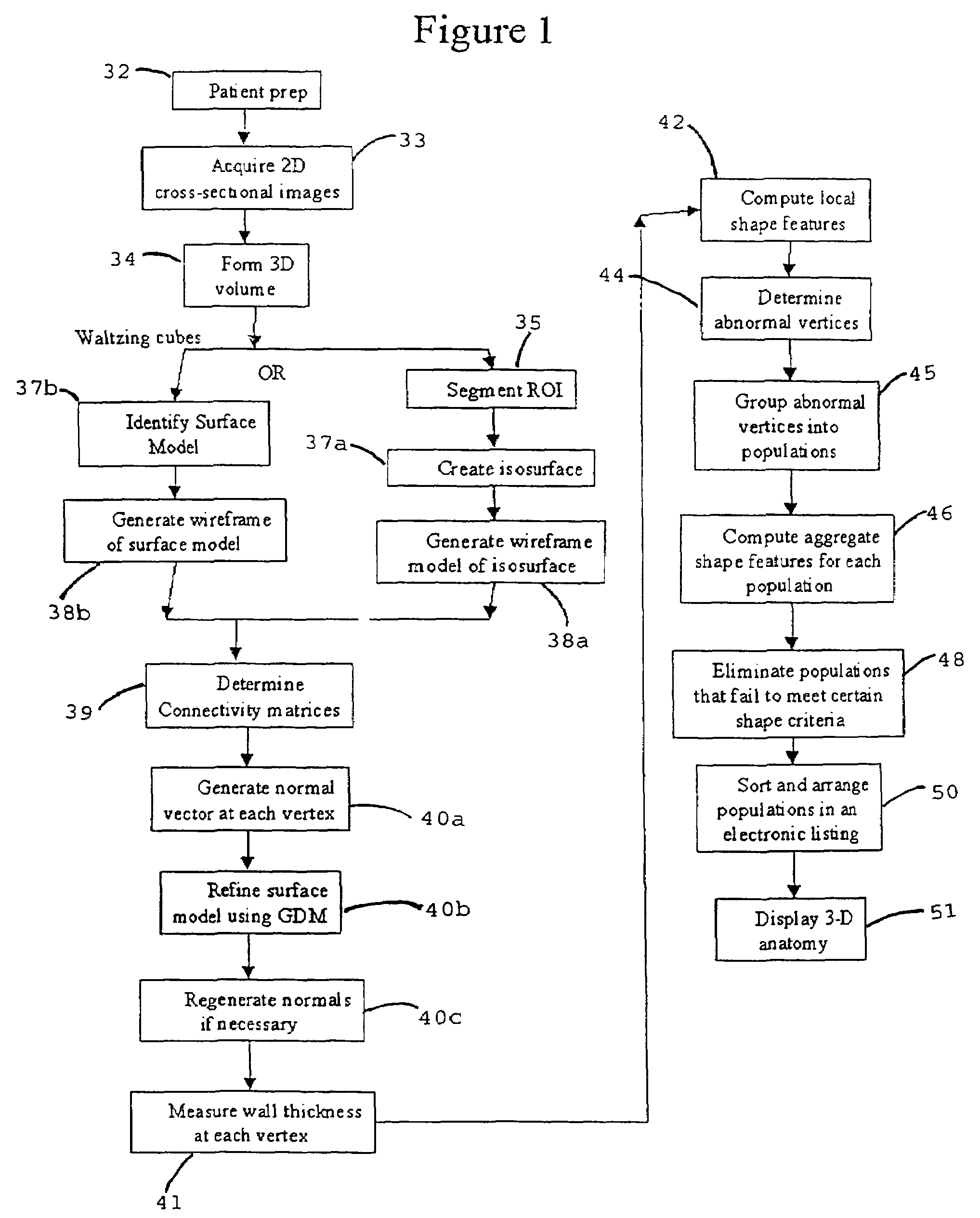

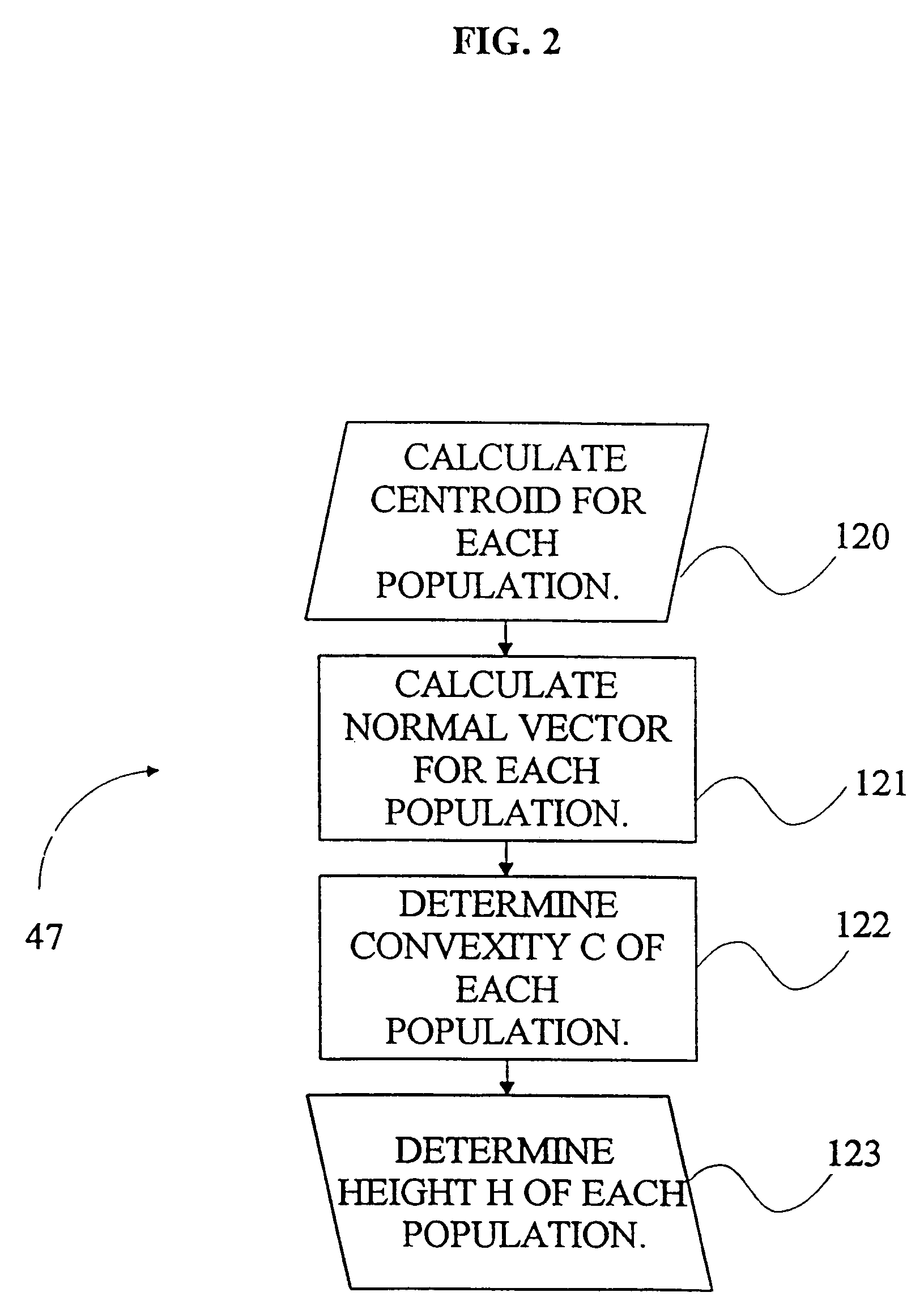

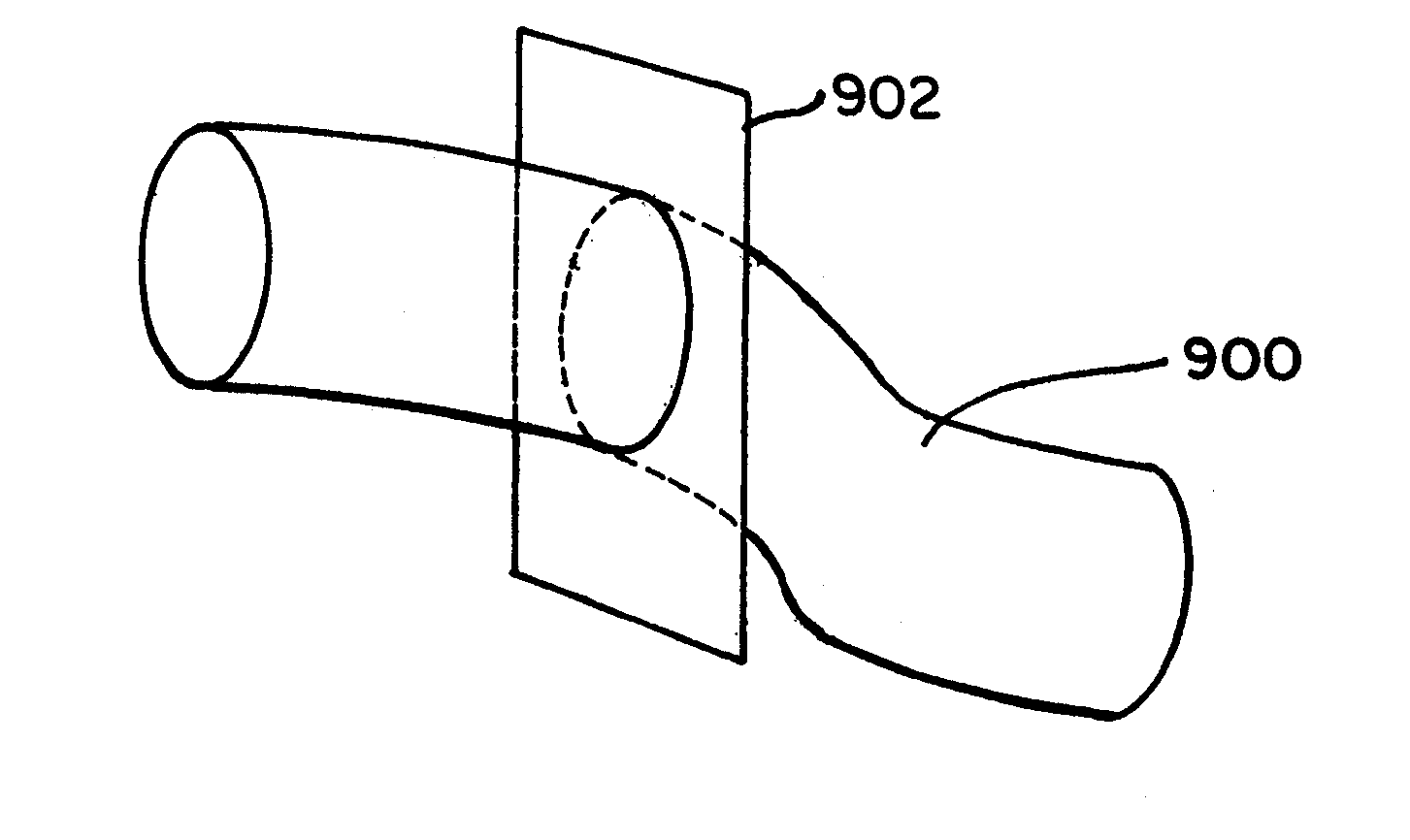

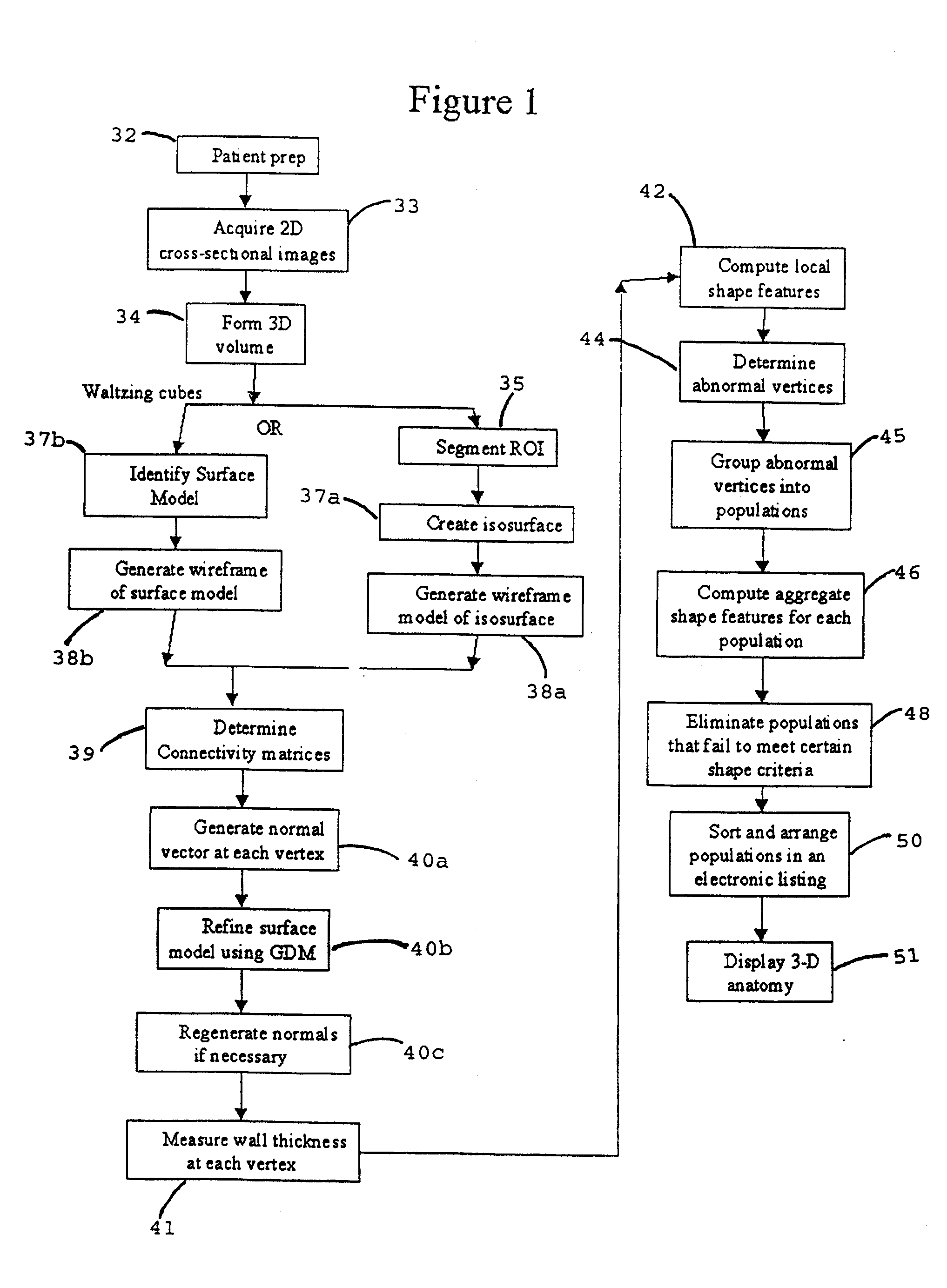

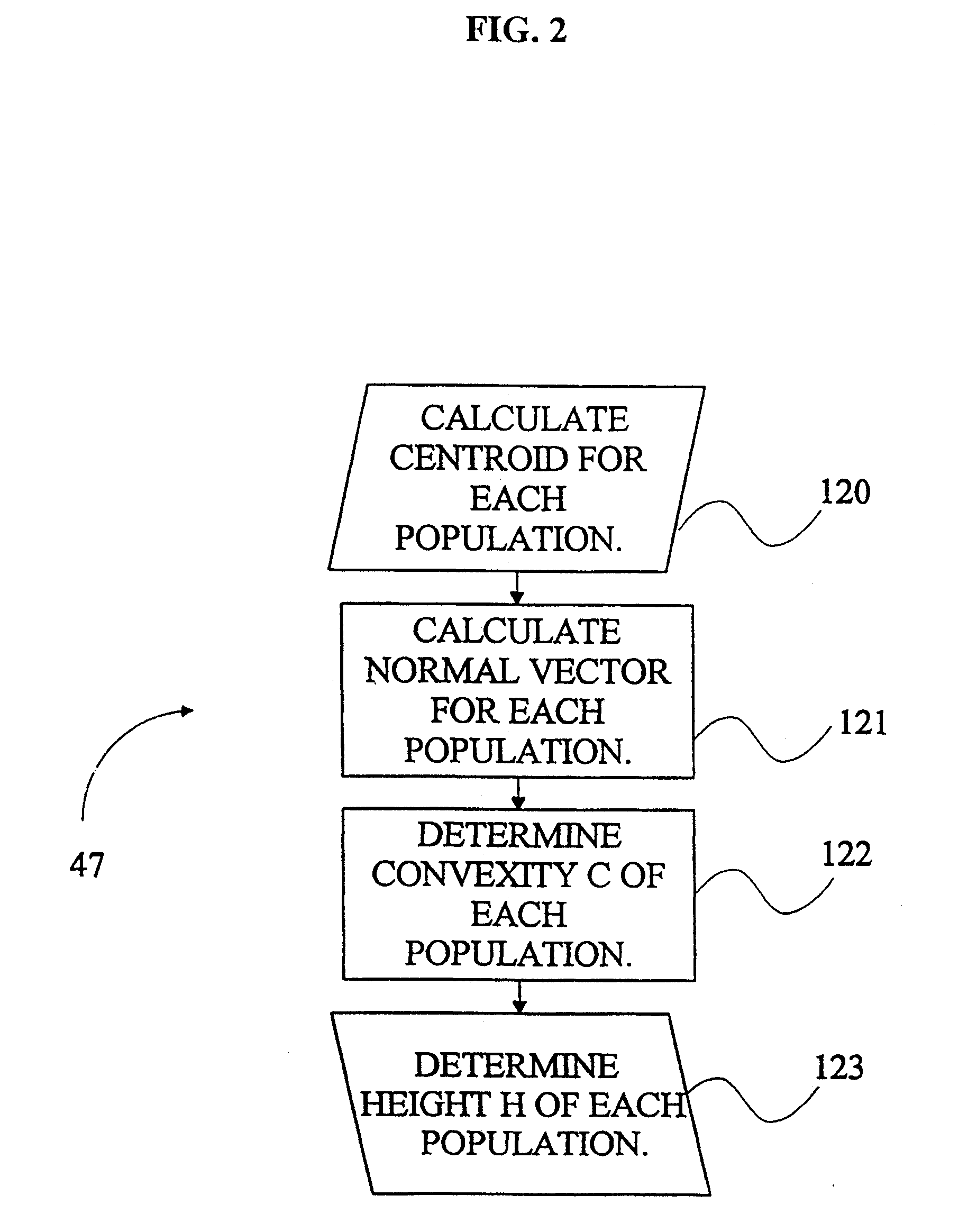

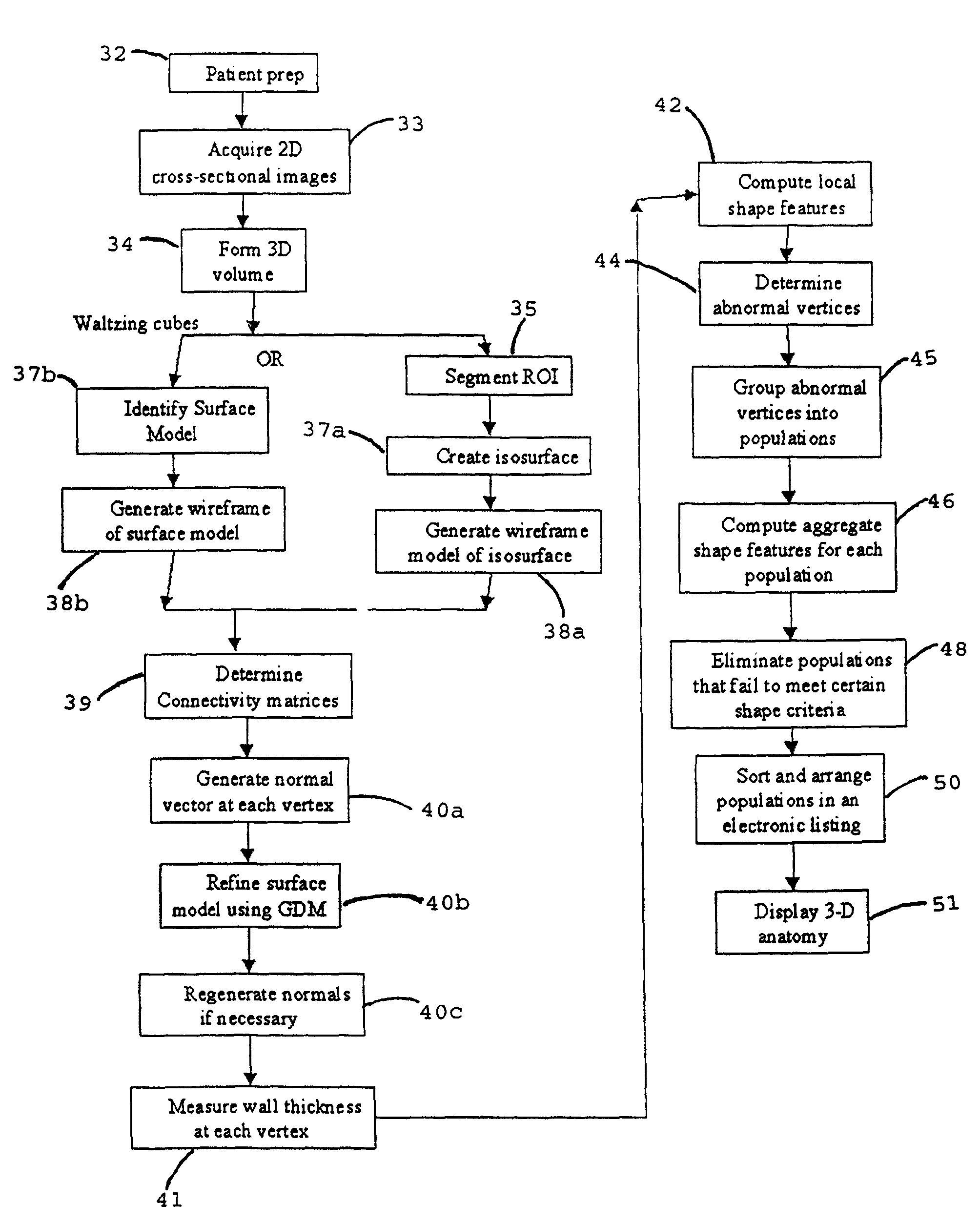

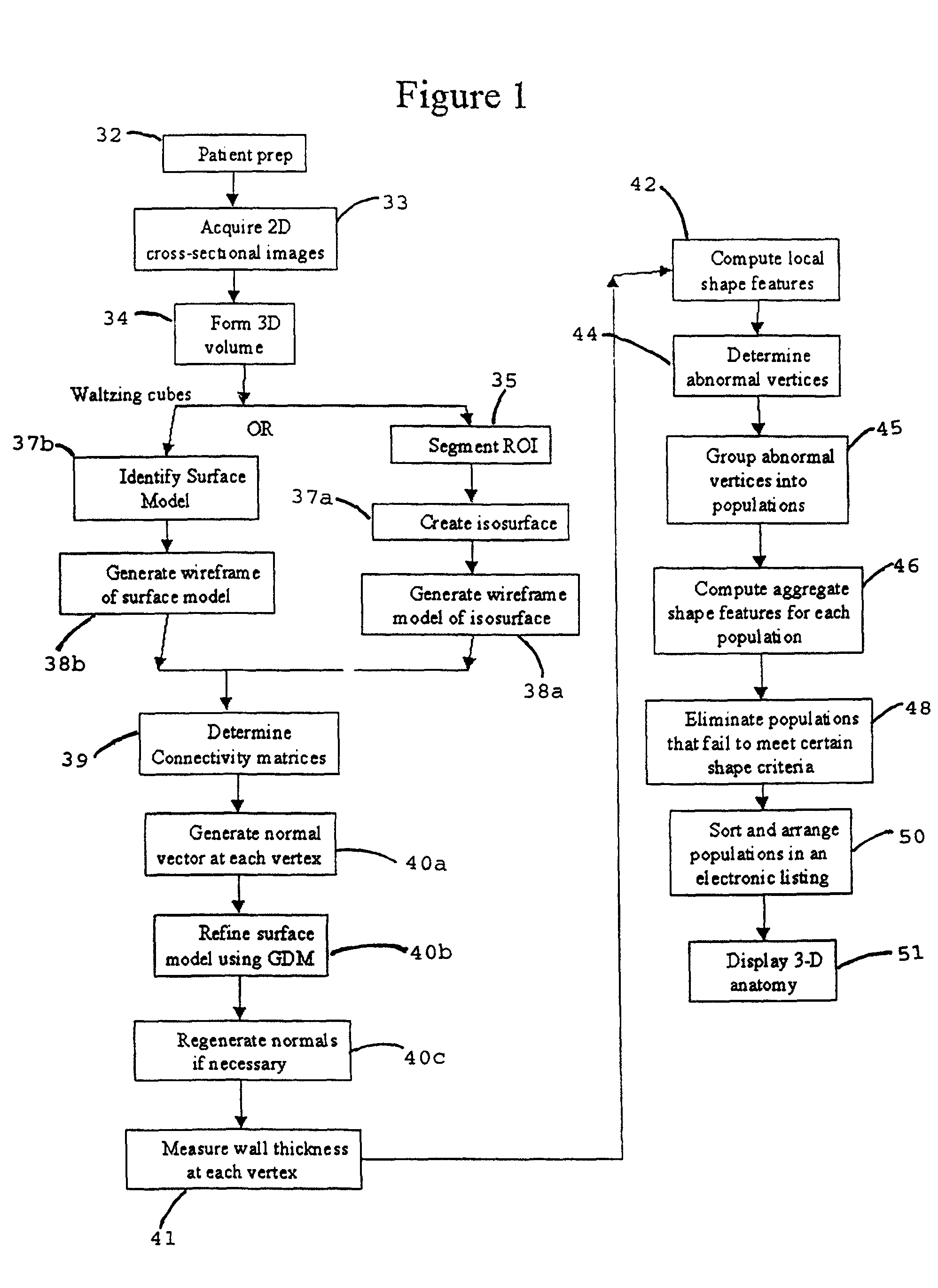

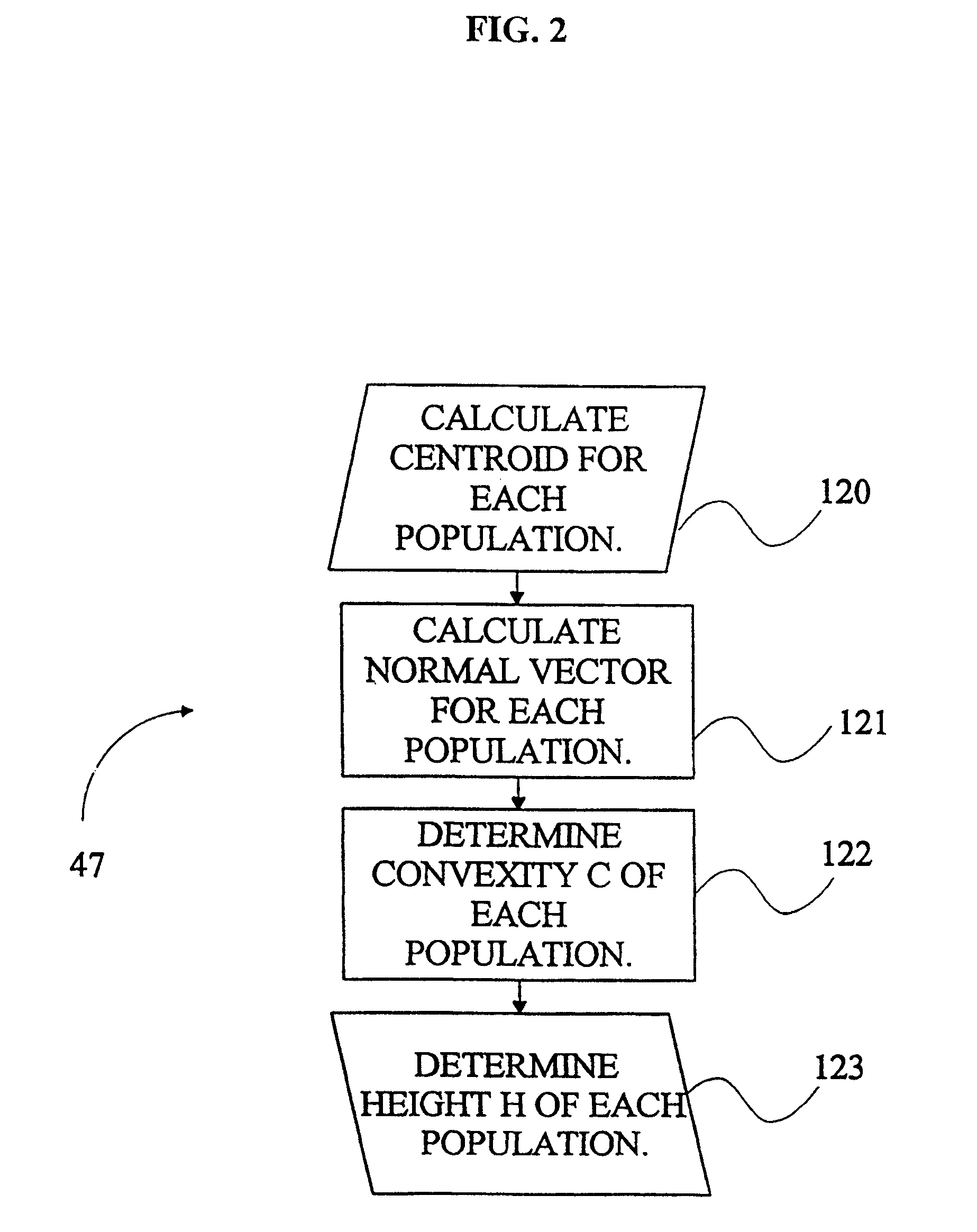

A system, and computer implemented method are provided for interactively displaying three-dimensional structures. Three-dimensional volume data (34) is formed from a series of two-dimensional images (33) representing at least one physical property associated with the three-dimensional structure, such as a body organ having a lumen. A wire frame model of a selected region of interest is generated (38b). The wireframe model is then deformed or reshaped to more accurately represent the region of interest (40b). Vertices of the wire frame model may be grouped into regions having a characteristic indicating abnormal structure, such as a lesion. Finally, the deformed wire frame model may be rendered in an interactive three-dimensional display.

Owner:WAKE FOREST UNIV HEALTH SCI INC

Virtual Endoscopy with Improved Image Segmentation and Lesion Detection

InactiveUS20100265251A1Exact matchAccurate representationImage enhancementImage analysisBody organsLesion detection

A system, and computer implemented method are provided for interactively displaying three-dimensional structures. Three-dimensional volume data (34) is formed from a series of two-dimensional images (33) representing at least one physical property associated with the three-dimensional structure, such as a body organ having a lumen. A wire frame model of a selected region of interest is generated (38b). The wireframe model is then deformed or reshaped to more accurately represent the region of interest (40b). Vertices of the wire frame model may be grouped into regions having a characteristic indicating abnormal structure, such as a lesion. Finally, the deformed wire frame model may be rendered in an interactive three-dimensional display.

Owner:WAKE FOREST UNIV

Virtual endoscopy with improved image segmentation and lesion detection

A system, and computer implemented method are provided for interactively displaying three-dimensional structures. Three-dimensional volume data (34) is formed from a series of two-dimensional images (33) representing at least one physical property associated with the three-dimensional structure, such as a body organ having a lumen. A wire frame model of a selected region of interest is generated (38b). The wireframe model is then deformed or reshaped to more accurately represent the region of interest (40b). Vertices of the wire frame model may be grouped into regions having a characteristic indicating abnormal structure, such as a lesion. Finally, the deformed wire frame model may be rendered in an interactive three-dimensional display.

Owner:WAKE FOREST UNIV

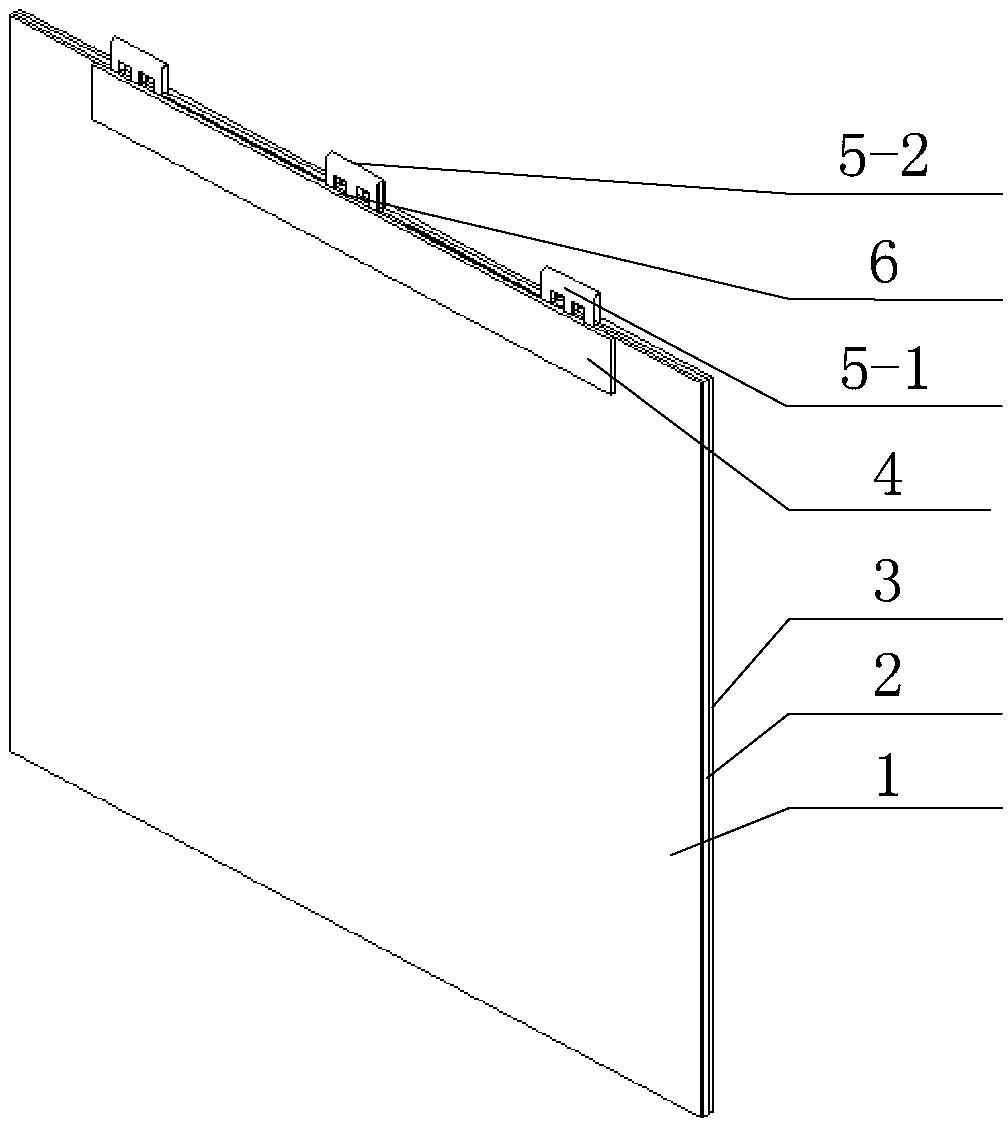

Fiber-shaped flexible electrochromic device and preparation method thereof

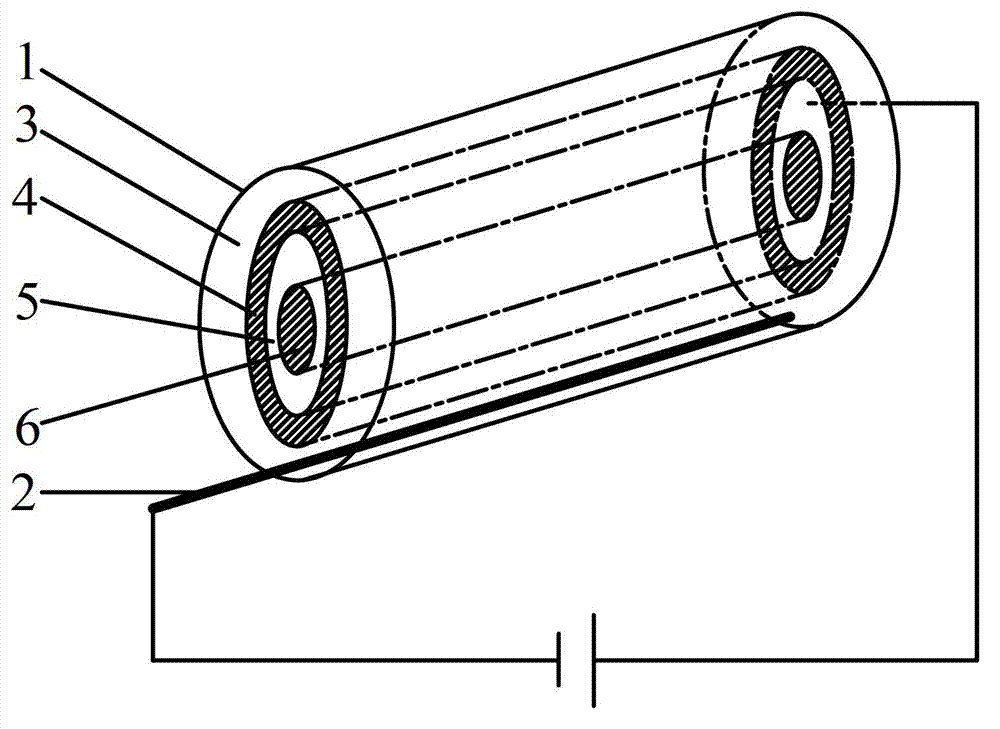

The invention discloses a fiber-shaped flexible electrochromic device comprising a transparent polymer protection layer, a silver wire counter electrode, an electrochromic layer, a transparent conductive layer and a core material. The invention further discloses a preparation method of the fiber-shaped flexible electrochromic device. The method comprises the following steps of: forming the transparent conductive layer on the surface of the core material by utilizing a thermal evaporation method or an ion sputtering method; forming the electrochromic layer on the transparent conductive layer by utilizing a coating method, a solution Czochralski method or an electric deposition method; coating a gel polyelectrolyte on the surface of the electrochromic layer to form a polyelectrolyte layer; placing the silver wire counter electrode into the polyelectrolyte layer which is parallel to the core material; and then, covering a transparent polymer protection layer on the outer surface of the polyelectrolyte layer, and carrying out heat seal treatment to obtain the device. According to the fiber-shaped flexible electrochromic device and the preparation method disclosed by the invention, the process is simple and the prepared fiber-shaped flexible electrochromic device is a flexible and bendable fiber-shaped abnormal structure; and the fiber-shaped flexible electrochromic device can be used as an assembling unit of a more complicated abnormal structure device, and a method foundation for assembling the other abnormal structure devices is provided.

Owner:XIAN UNIV OF SCI & TECH

Multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and preparation method of multifunctional fiber

ActiveCN106835348AIncrease surface areaImprove moisture wickingFilament/thread formingConjugated synthetic polymer artificial filamentsPerspirationAbnormal shapes

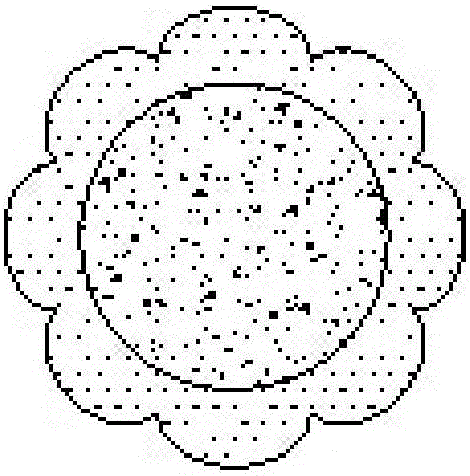

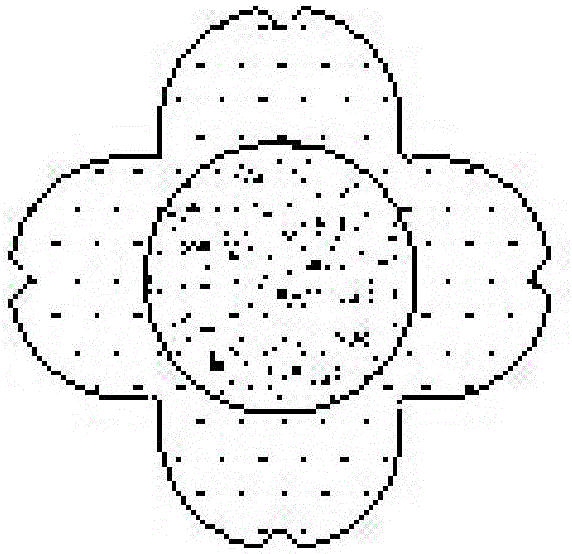

The invention discloses a multifunctional fiber with moisture absorption and perspiration, antibacterial and heating functions and a preparation method of the multifunctional fiber and belongs to the technical field of functional fiber materials. The multifunctional fiber disclosed by the invention comprises a multifunctional fiber body; the multifunctional fiber body is composed of a fiber skin layer and a fiber core layer; the section shape of the fiber body is of an abnormal structure that a plurality of convex abnormal-shape structures are uniformly and outward formed on the round circumference; the fiber skin layer is formed by bundling bacterium-inhibiting fiber monofilaments together in parallel; the fiber core layer is formed by bundling heating fiber monofilaments together in parallel. The fiber with moisture absorption and perspiration, antibacterial and heating functions is prepared through a melting spinning technology and can be used for the field of smart clothing.

Owner:WUHAN TEXTILE UNIV

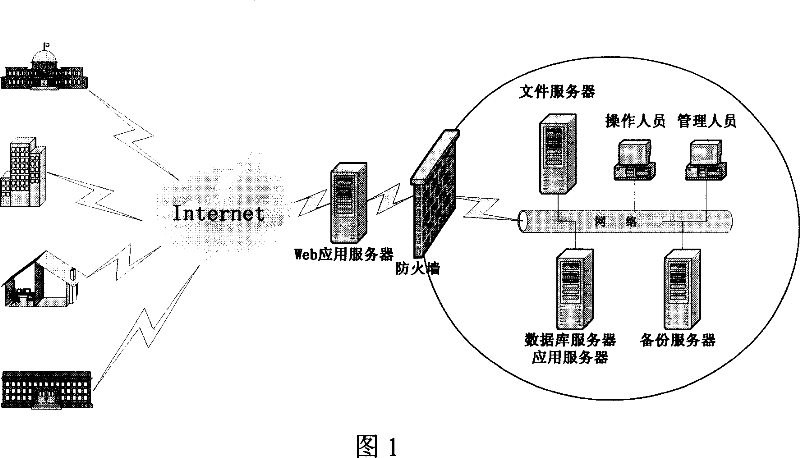

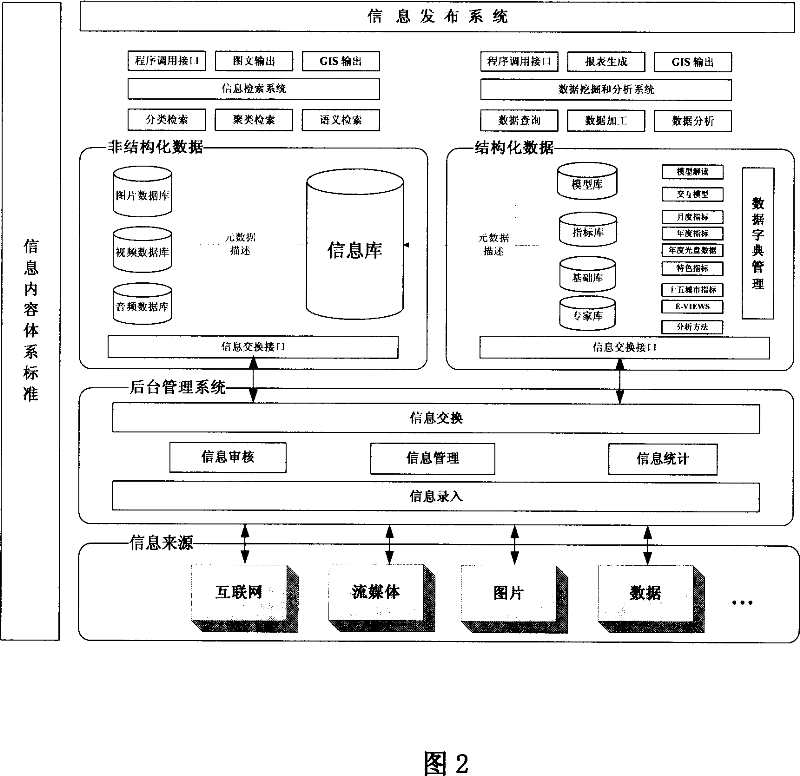

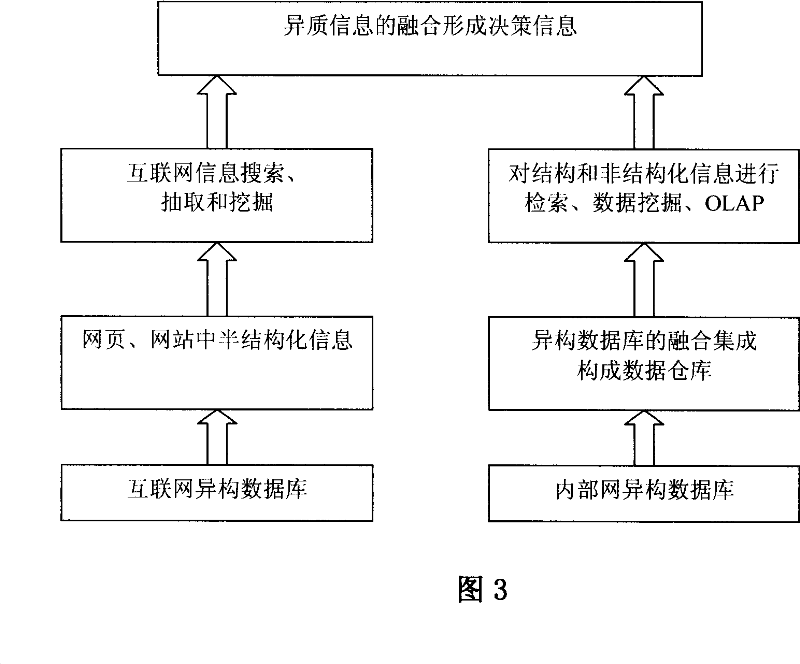

Economic operation analysis system

InactiveCN101042747AEfficient managementEffective maintenanceResourcesSpecial data processing applicationsData warehouseSustenance

This invention relates to one economics operation analysis system and in detail to one data effective integration through mathematics module result and non-structure data, which displays the results through space geometry information system on map by integrated data, wherein, the system adopts data ware technique to integrate abnormal structure information, data and knowledge through one series of extracting, clearing, conversion and loading operation to store the data into data ware for effective management and sustenance to provide inquire tools.

Owner:SHANGHAI SHEINET

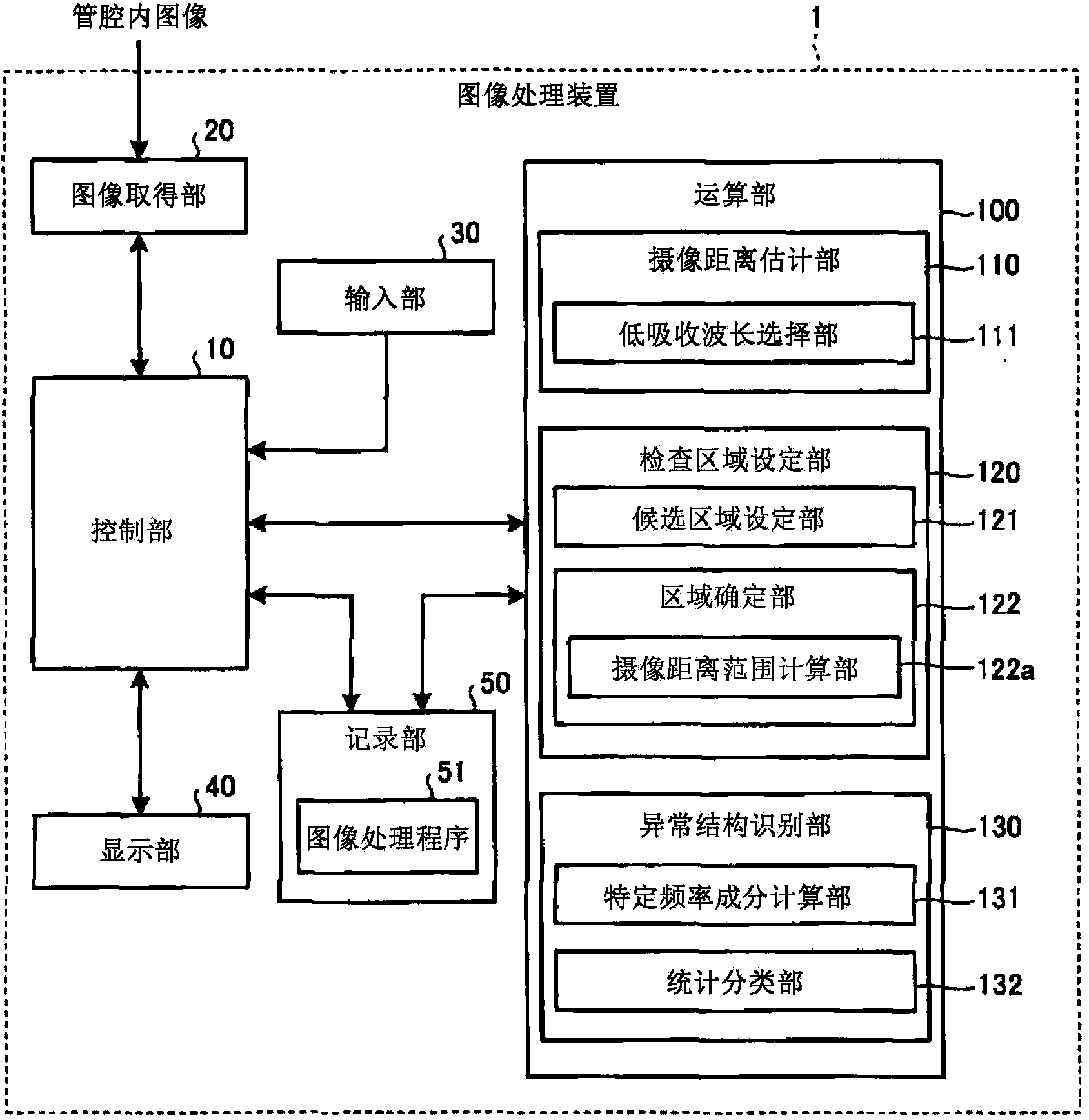

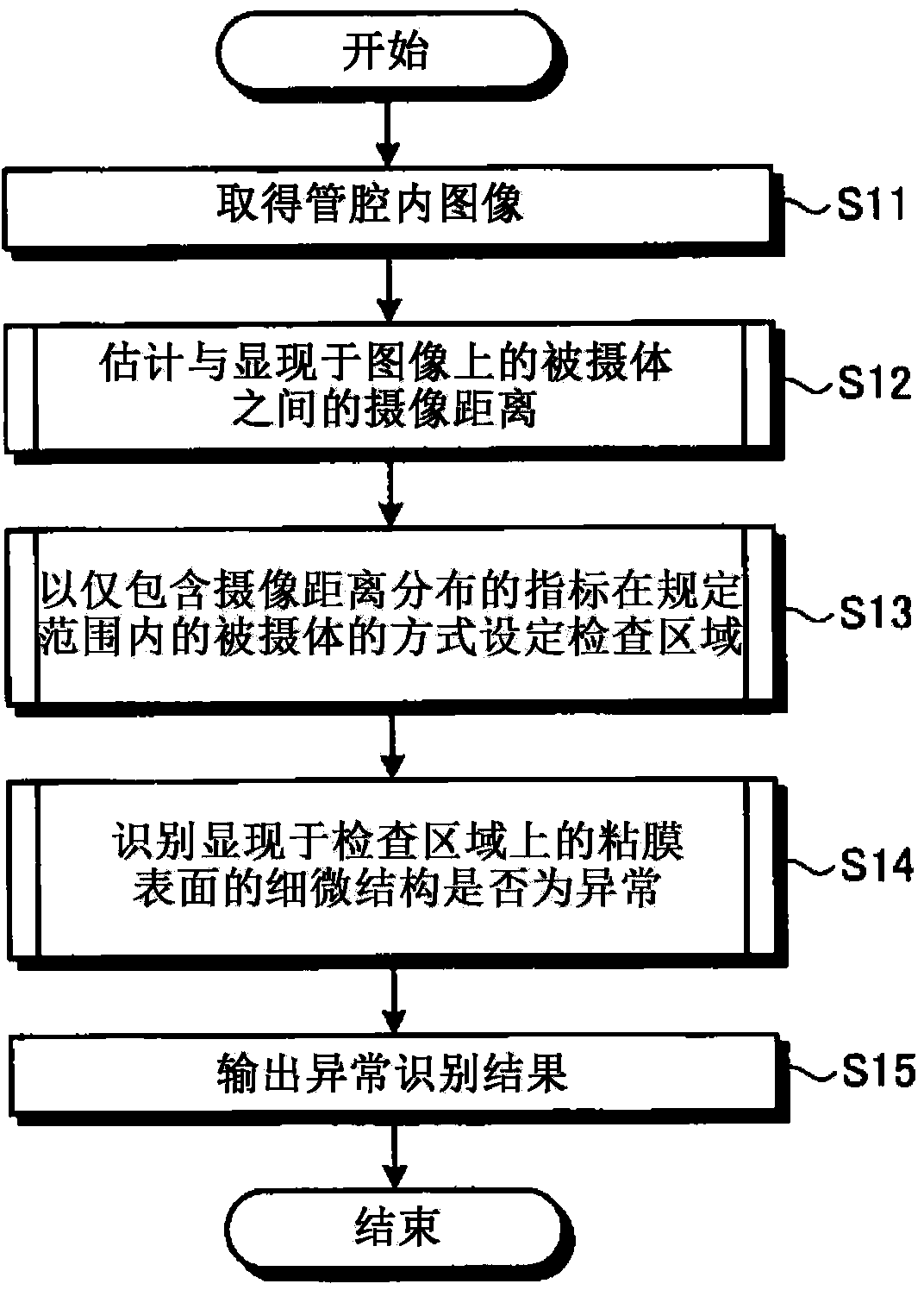

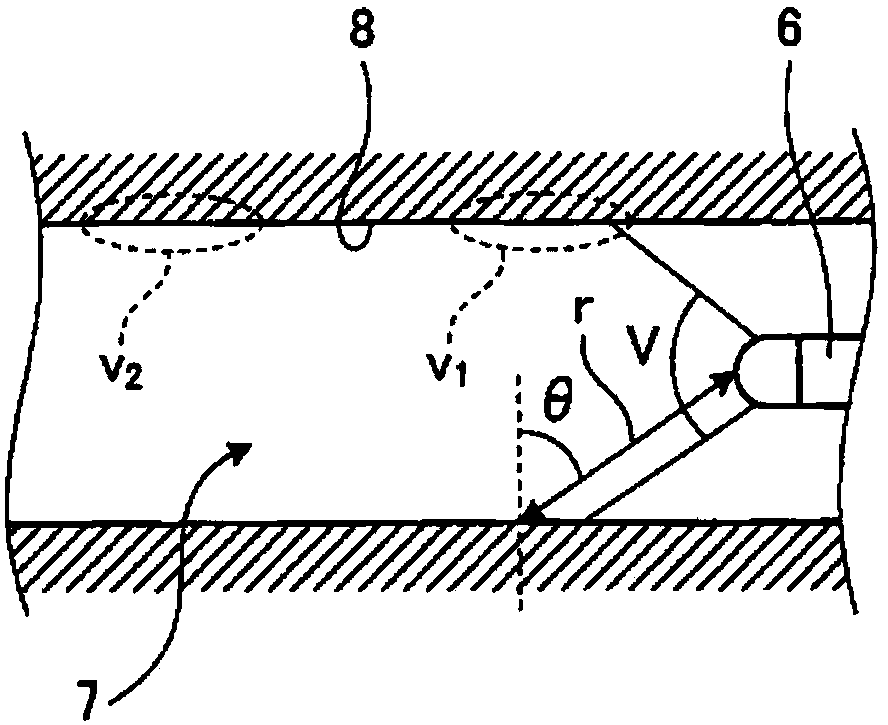

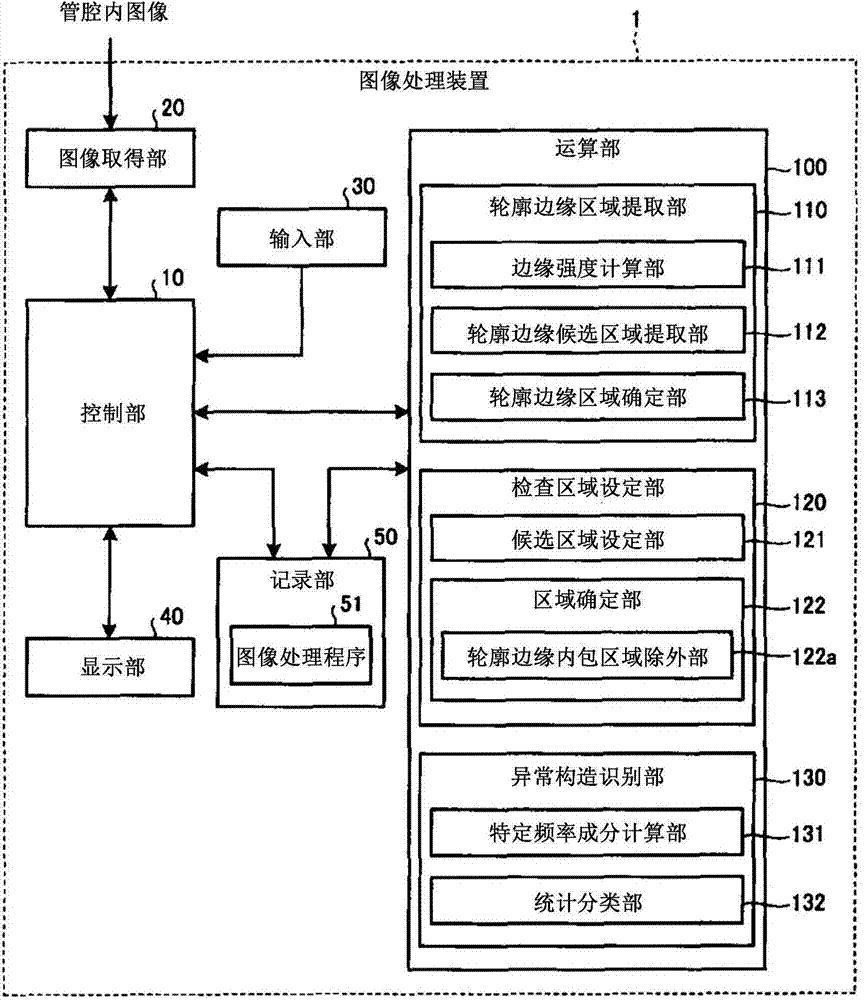

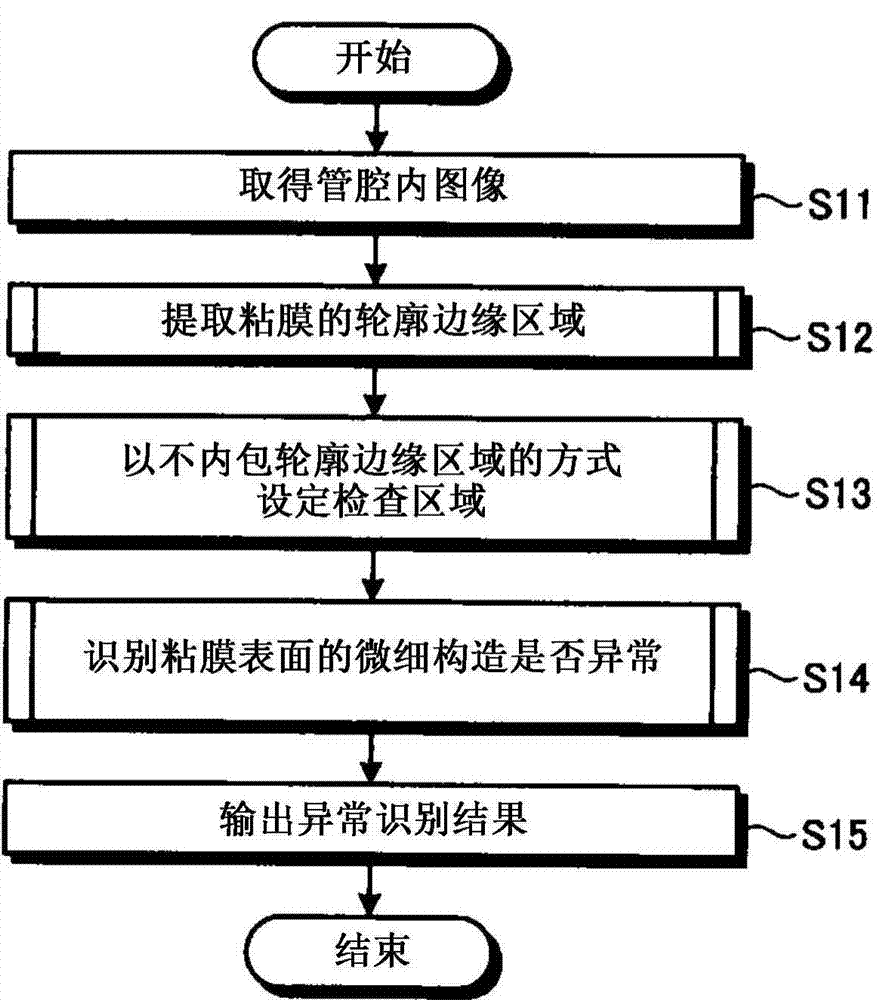

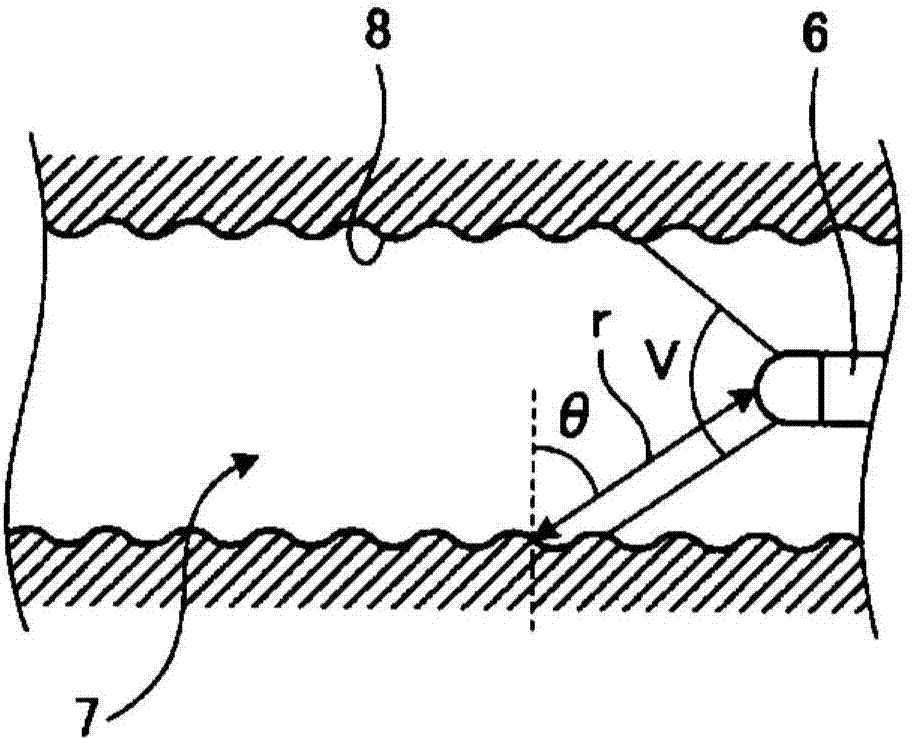

Image processing device, image processing method, and image processing program

ActiveCN104363815AEfficient identificationImage enhancementImage analysisImaging processingImage resolution

Provided are an image processing device and other devices capable of accurately identifying an abnormality of the microscopic structure of a subject even when the difference in resolution occurs in the microscopic structure of the subject due to the difference in image capturing distance. The image processing device (1) comprises: an image capturing distance estimation unit (110) for estimating an image capturing distance to a subject to be image-captured in an image; an inspection region setting unit (120) for setting an inspection region to be within said image so that an indicator becomes within a predetermined range, the indicator indicating the broadening of the distribution of the image capturing distance of the subject to be image-captured in the inspection region; and an abnormal structure identifying unit (130) for identifying whether the microscopic structure of the subject to be image-captured in the inspection region is abnormal or not, by using a texture feature amount by which an abnormality of the microscopic structure of the subject to be image-captured in the inspection region can be identified, said abnormality being specified according to the inspection region.

Owner:OLYMPUS CORP

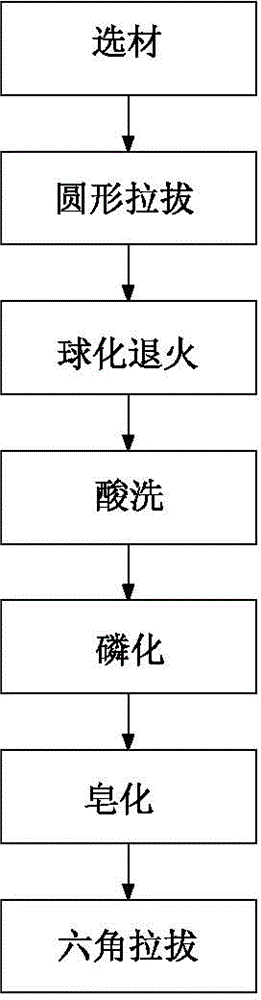

Production process of alloy steel material for high-strength internal hexagonal wrench

The invention discloses a production process of an alloy steel material for a high-strength internal hexagonal wrench. The production process comprises the following steps of 1, material selecting, wherein a material with the trade mark of 50CrVa is selected as a base material; 2, round drawing; 3, spheroidizing annealing; 4, acid pickling; 5, phosphating; 6, saponifying; 7, hexagon drawing. By selecting specific material and adopting specific matched drawing process and spheroidizing process, a wire made according to the invention has relatively high plastic deformation capability, meets the bending forming requirements of customers, is uniform in annealed structure grains, is high in rate of spheroidization and is free of abnormal structures; the product size is stable, the precision is high, the tolerance of opposite sides is + / -0.02mm, and the tolerance of opposite angles is + / -0.03mm; the material meets the use requirements of the customers, after the material is subjected to quenched-tempered heat treatment, the hardness HRC of the obtained wrench is greater than or equal to 55, the wear resistance is good, and the service life is long; meanwhile, the softening time in the spheroidizing annealing working procedure is shortened by a larger margin, and the goals of shortening the production cycle, reducing energy consumption, raising work productivity, reducing the production cost, protecting the environment and the like are achieved.

Owner:DONGGUAN KELEE STEEL WIRE

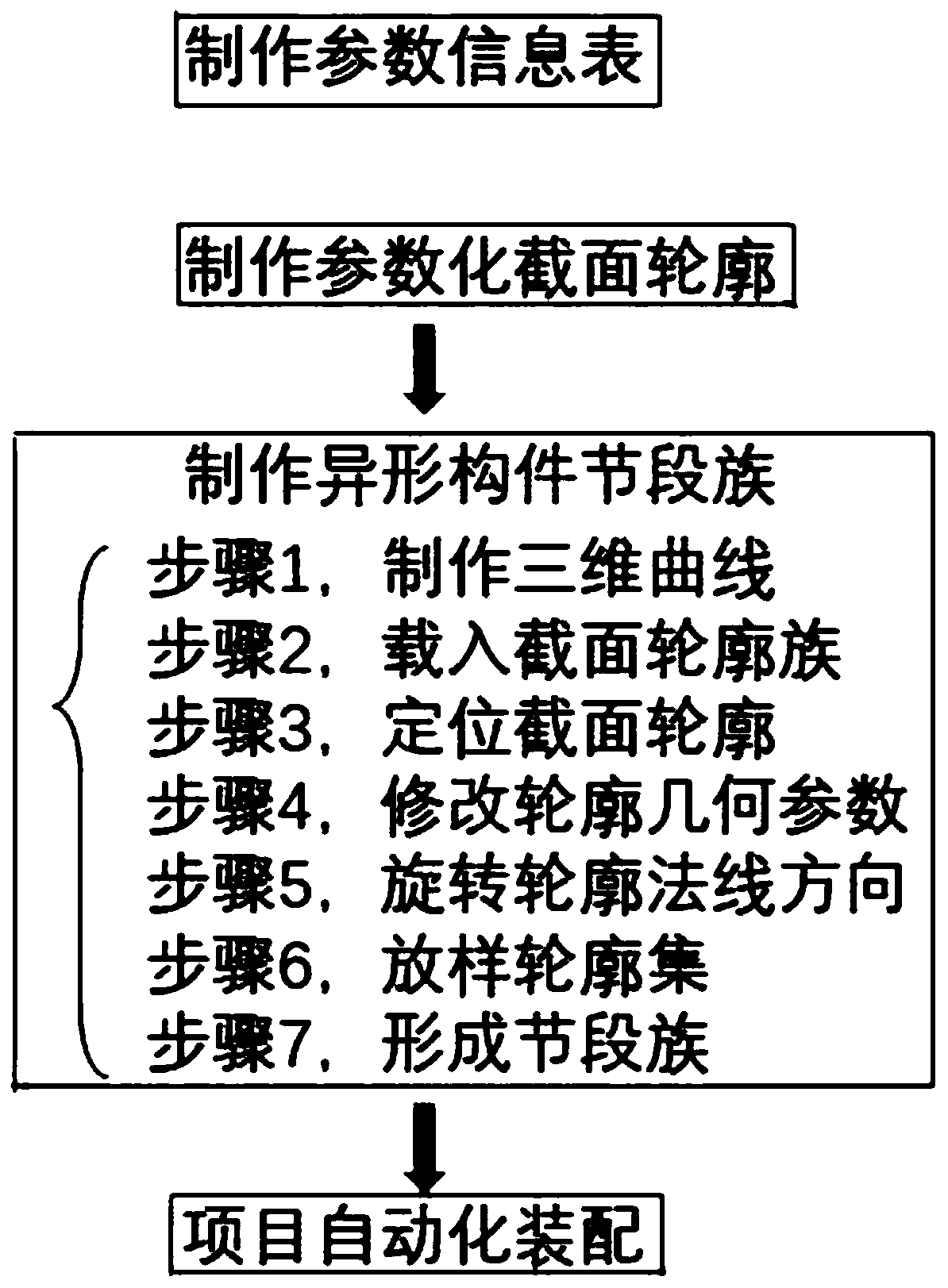

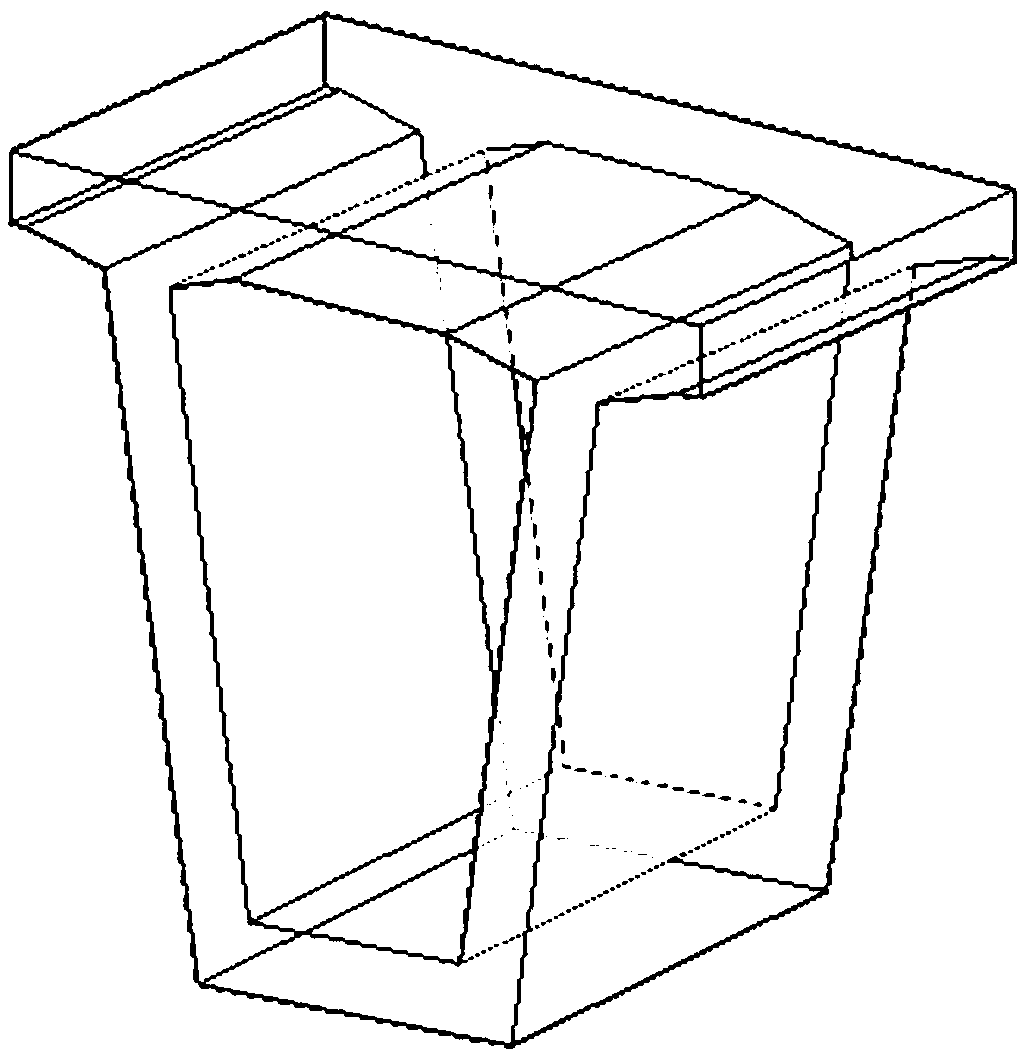

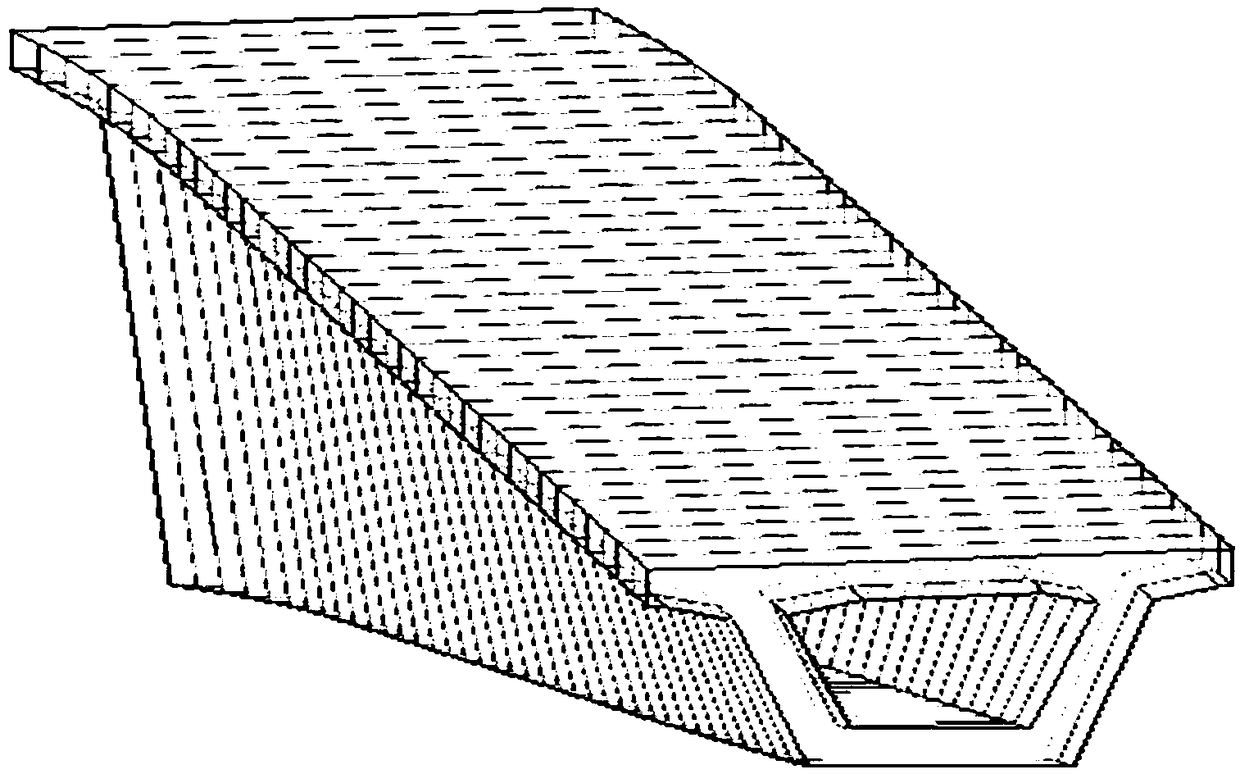

Parametric modeling method of special-shaped components based on Revit secondary development

ActiveCN109408912AAddressing Modeling ShortcomingsSmooth connectionData processing applicationsDesign optimisation/simulationSimulationDimensional modeling

The invention discloses a parametric modeling method of abnormal component based on Revit secondary development, which belongs to the technical field of BIM and can be used for three-dimensional modeling of complex abnormal component in municipal public engineering. The method comprises the following steps: (1) preparing a parameter information table; (2) making parameterized section contour; (3)Fabrication of segmental families of special-shaped members; (4) Project automatic assembly. The method can solve the problem of three-dimensional modeling of spatial abnormal structures in the fieldof municipal public works, increase the modeling efficiency and improve the modeling accuracy.

Owner:中铁八局集团第二工程有限公司

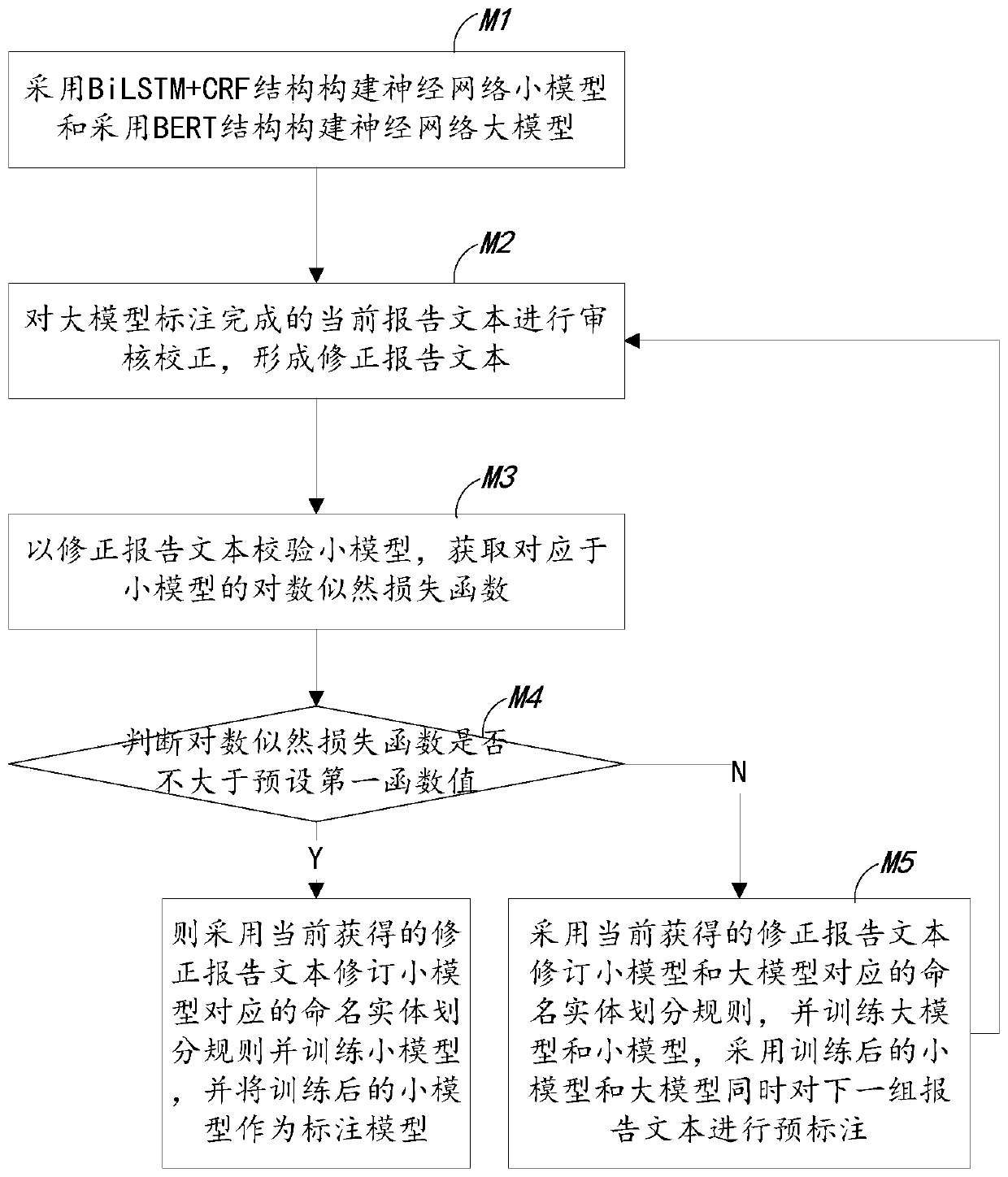

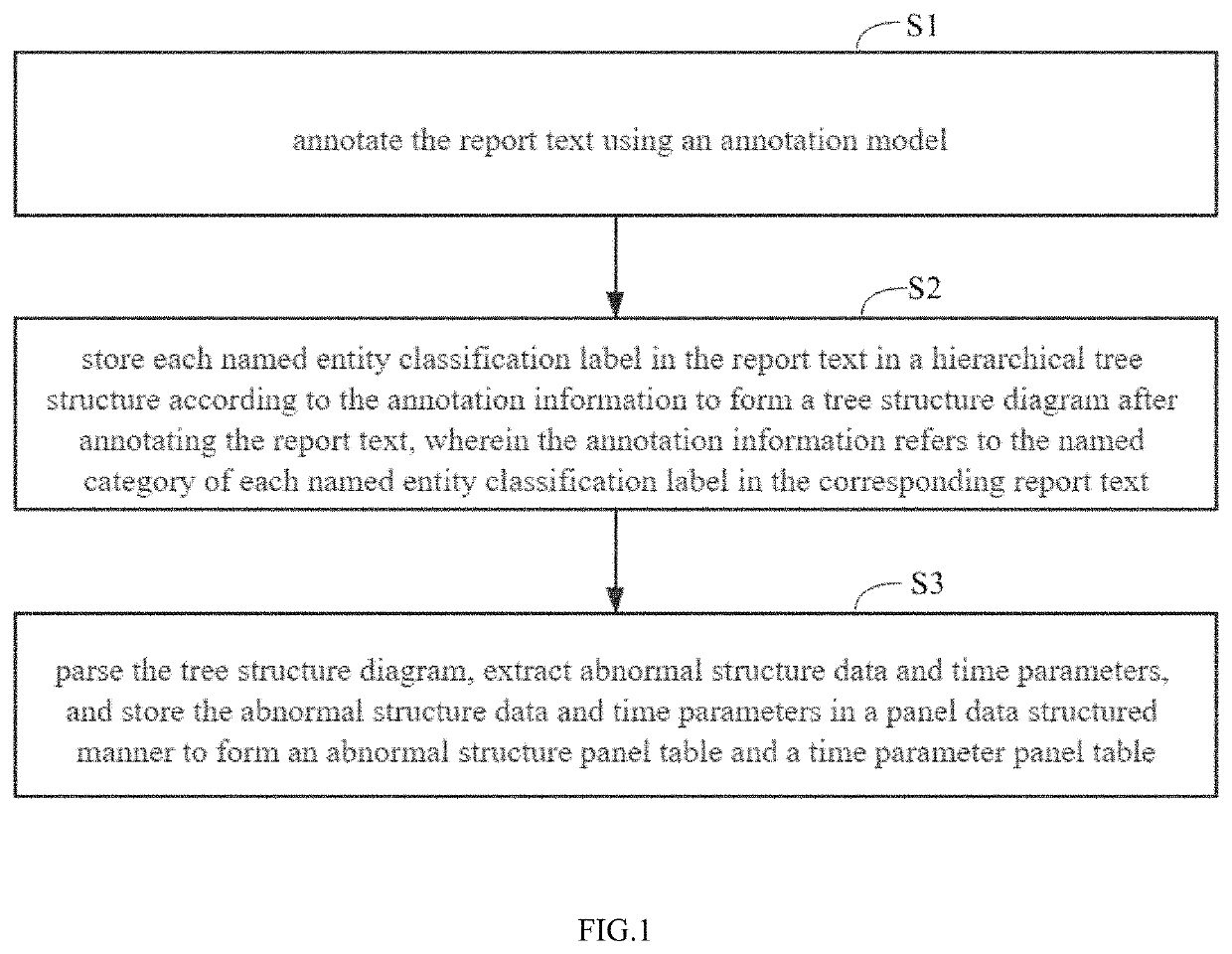

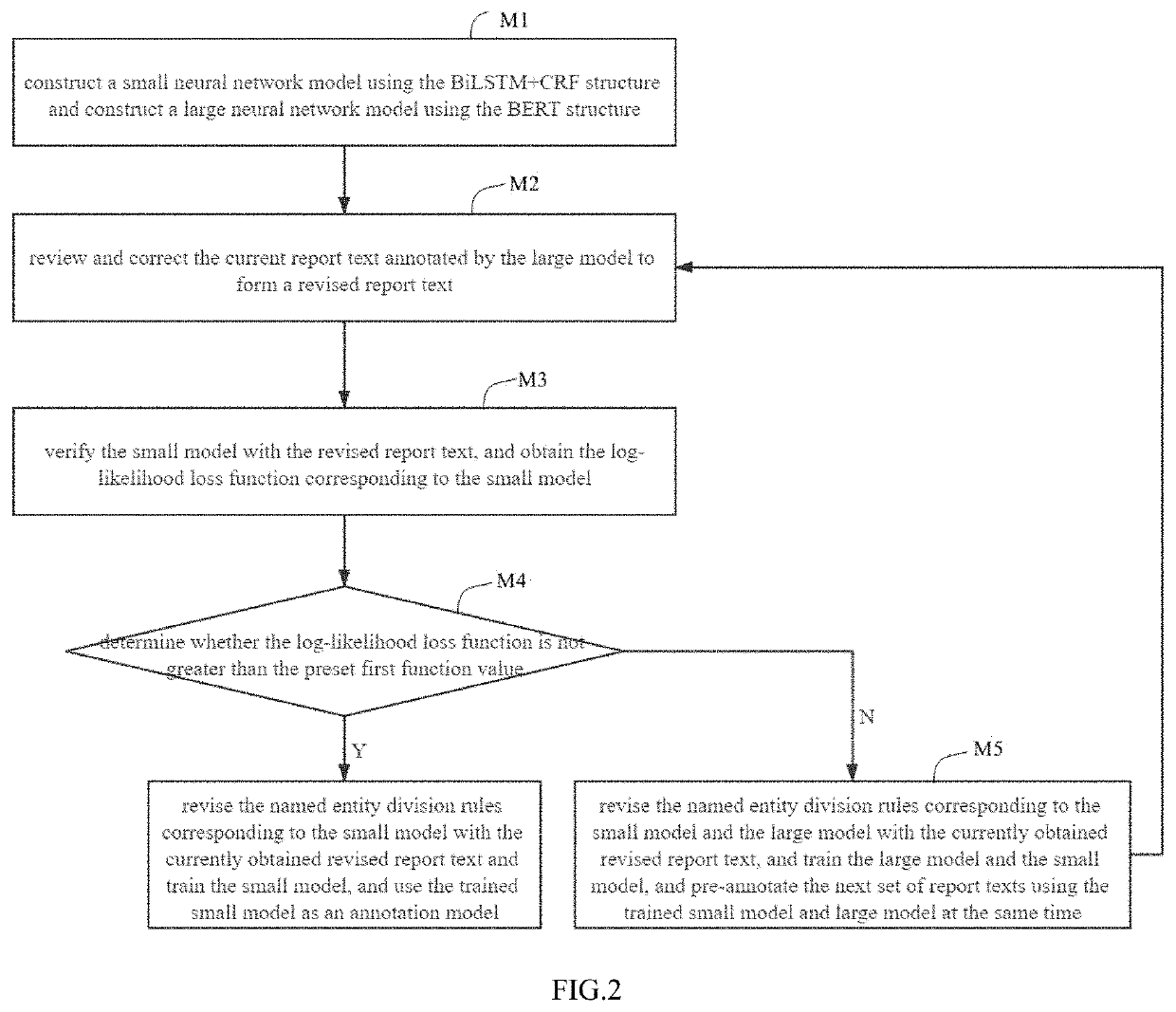

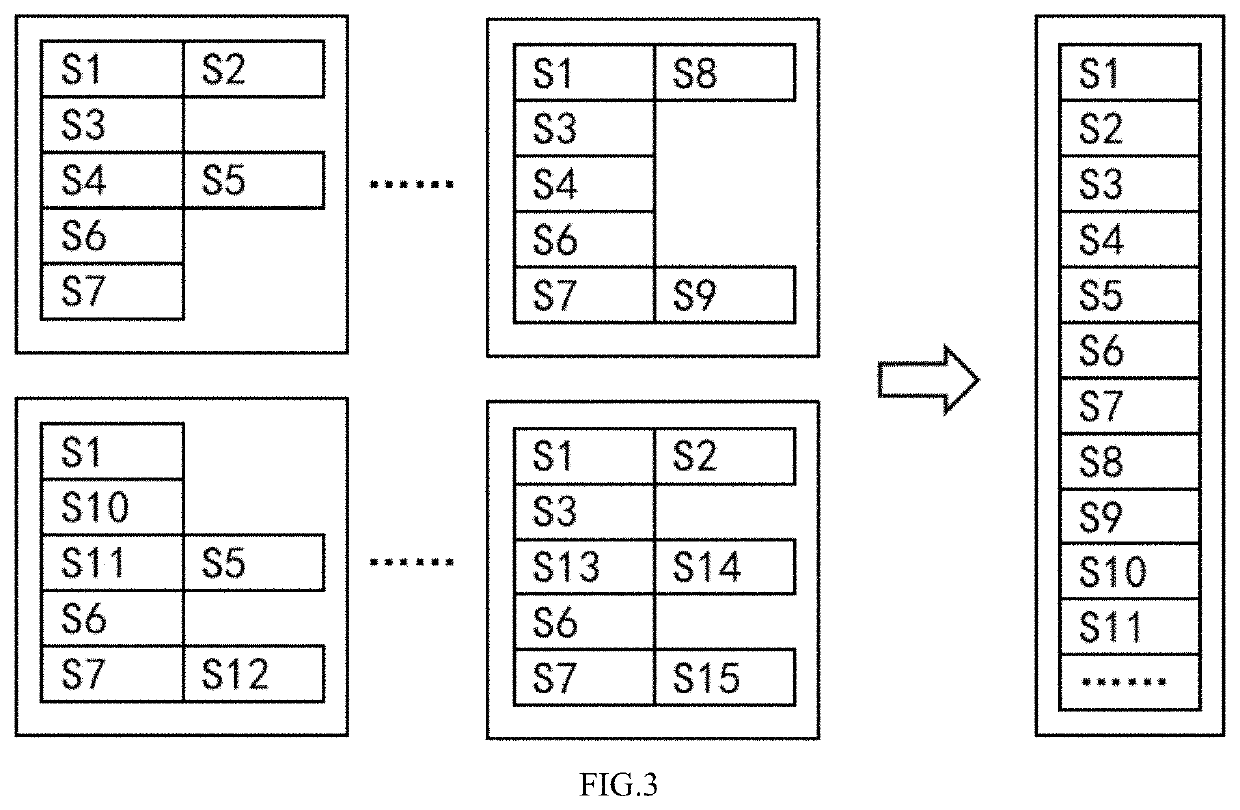

Capsule endoscopy report text structuring method and device and medium

ActiveCN111026799AAccurate quality controlSemantic analysisMedical imagesG i endoscopyVideo capsule endoscopy

Owner:安翰科技(武汉)股份有限公司

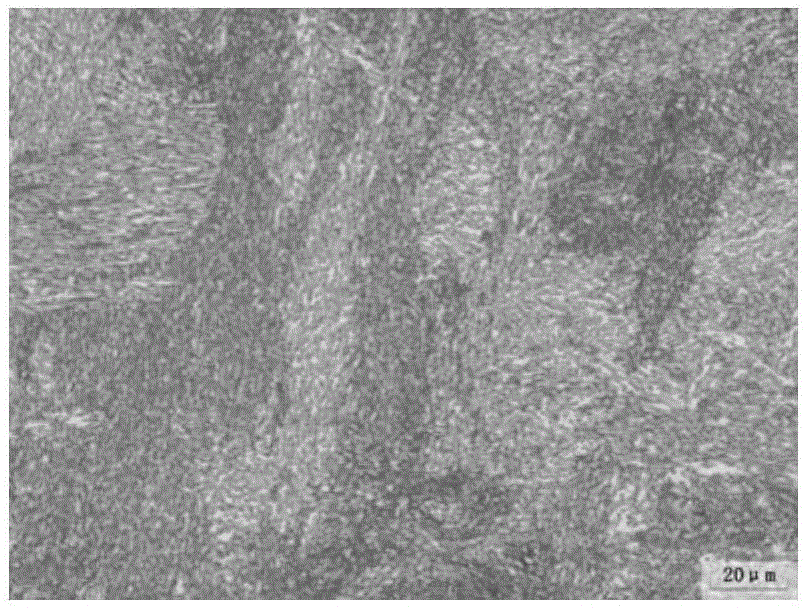

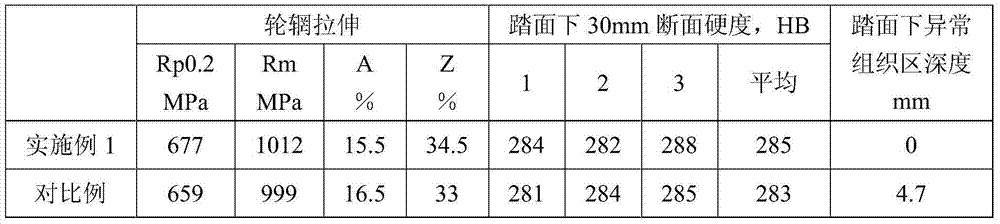

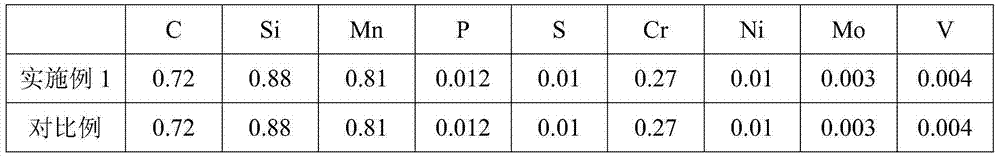

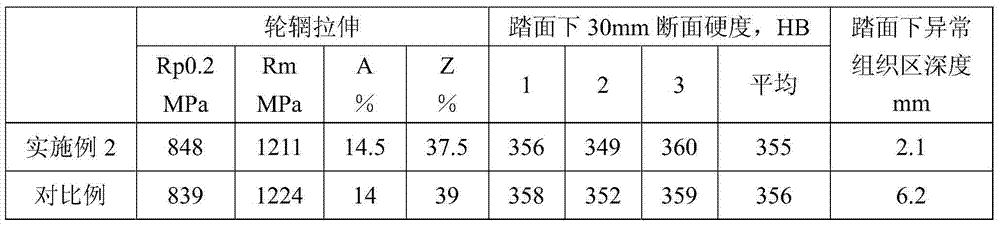

Heat treatment method of medium carbon low-alloy steel railway wheel

ActiveCN107586938AEasy to useReduce depthIncreasing energy efficiencyFurnace typesSlow coolingMechanical property

The invention provides a heat treatment method of a medium carbon low-alloy steel railway wheel, comprising the following processes: heating by quenching a railway wheel at 840-860 DEG C after rollingand slow cooling, cooling by spraying water after discharging, tempering at 500+ / -10 DEG C, carrying out power frequency induction heating at 890-910 DEG C, and carrying out pressure-air cooling. Theheat treatment method aims to remarkably reduce depth of an abnormal structure area on near surface of a tread or completely eliminate the abnormal structure layer on the basis of maintaining original mechanical properties of the wheel, so as to improve use performance of the wheel and lower cutting process cost.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

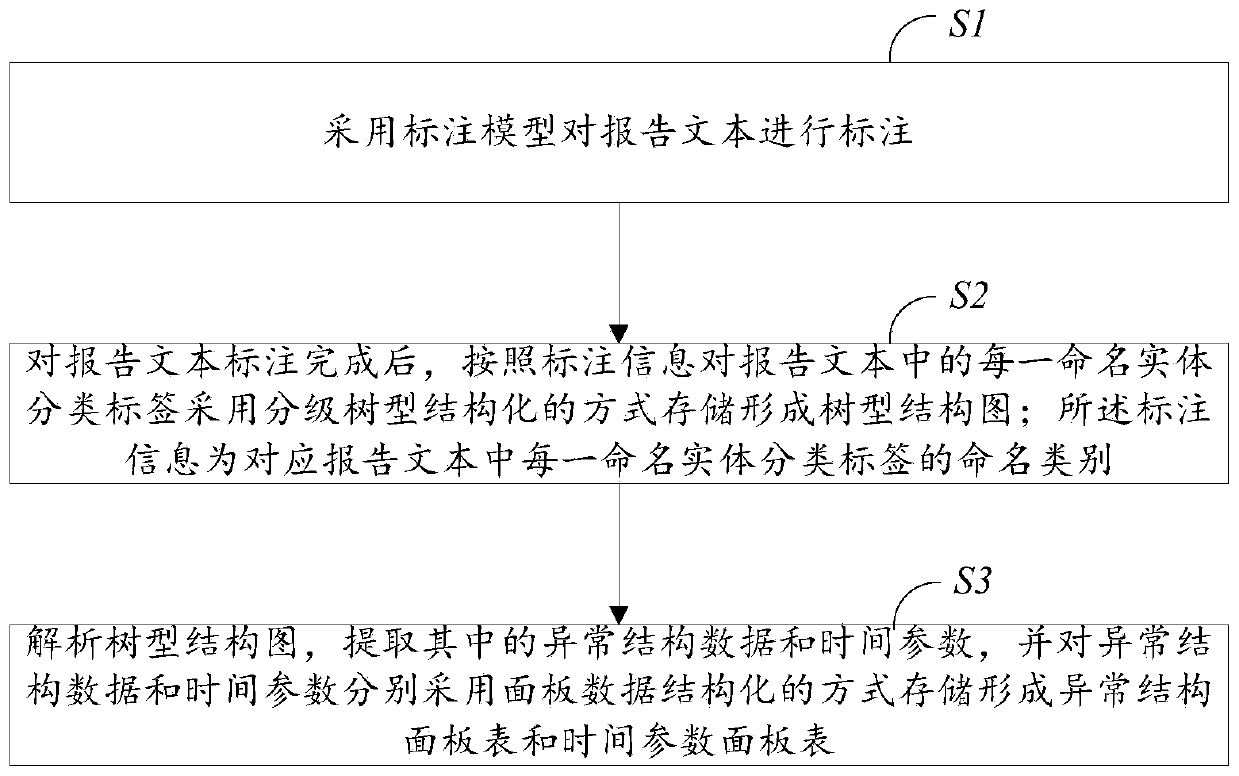

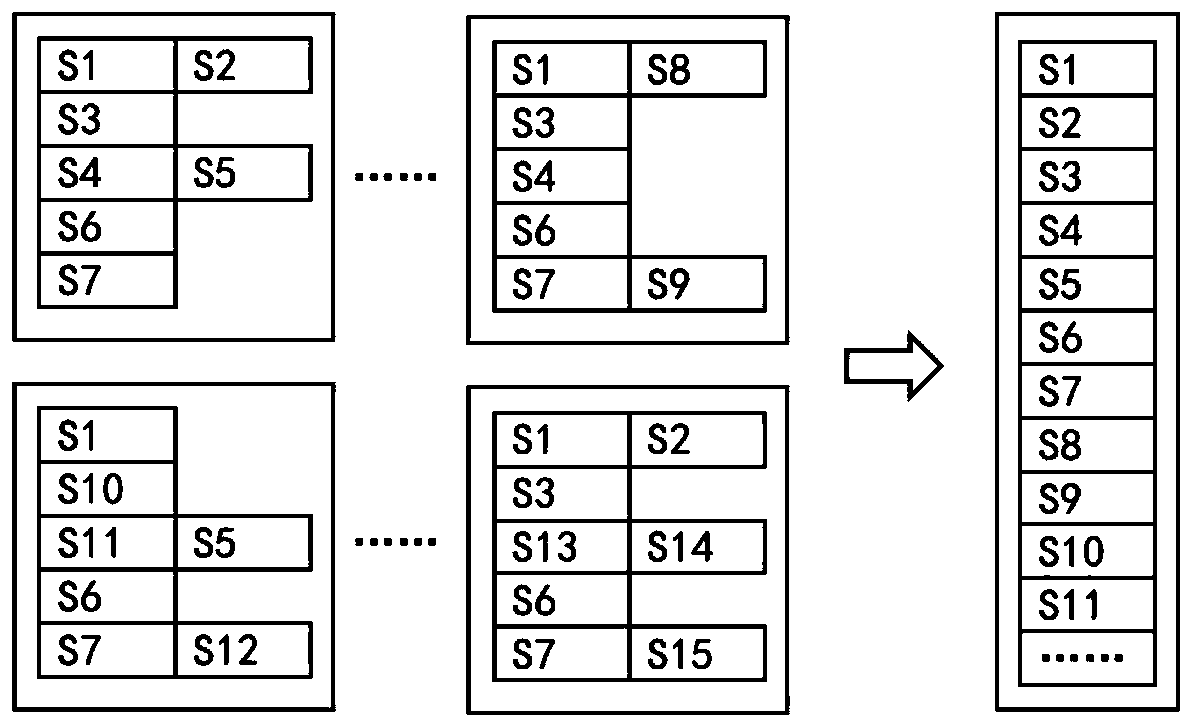

Method, device and medium for structuring capsule endoscopy report text

PendingUS20210174923A1Solve the lack of convenienceSemantic analysisMedical imagesVideo capsule endoscopyNamed entity classification

The present invention discloses a method, device and medium for structuring a capsule endoscopy report text. The method includes: annotating the report text using an annotation model; storing each named entity classification label in the report text in a hierarchical tree structure according to the annotation information to form a tree structure diagram; parsing the tree structure diagram, extracting abnormal structure data and time parameters, and storing the abnormal structure data and time parameters in a panel data structured manner to form an abnormal structure panel table and a time parameter panel table. The present invention can automatically annotate the capsule endoscopy report through the annotation model, and output parameters of different amount of information in different structures, and quantitative and accurate quality control of the capsule endoscopy process and examination results, which provide sufficient convenience for the electronic medical information of the capsule endoscopy.

Owner:ANKON MEDICAL TECH (SHANGHAI) CO LTD +1

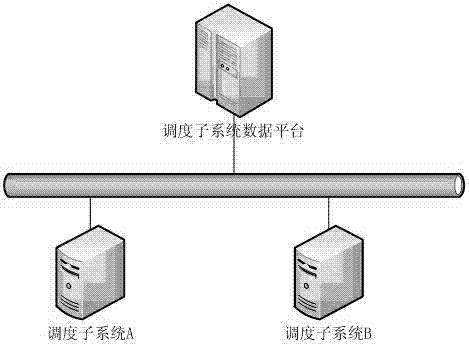

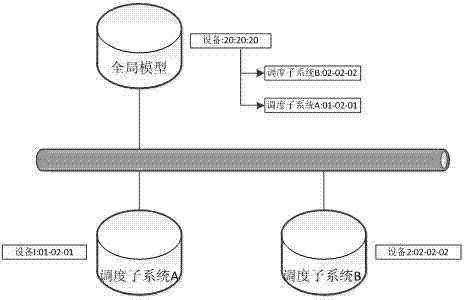

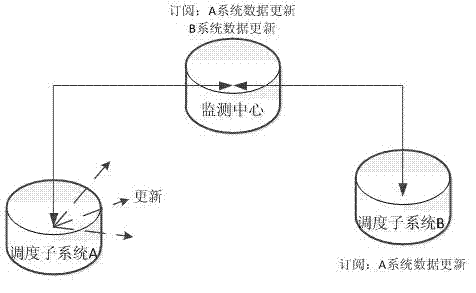

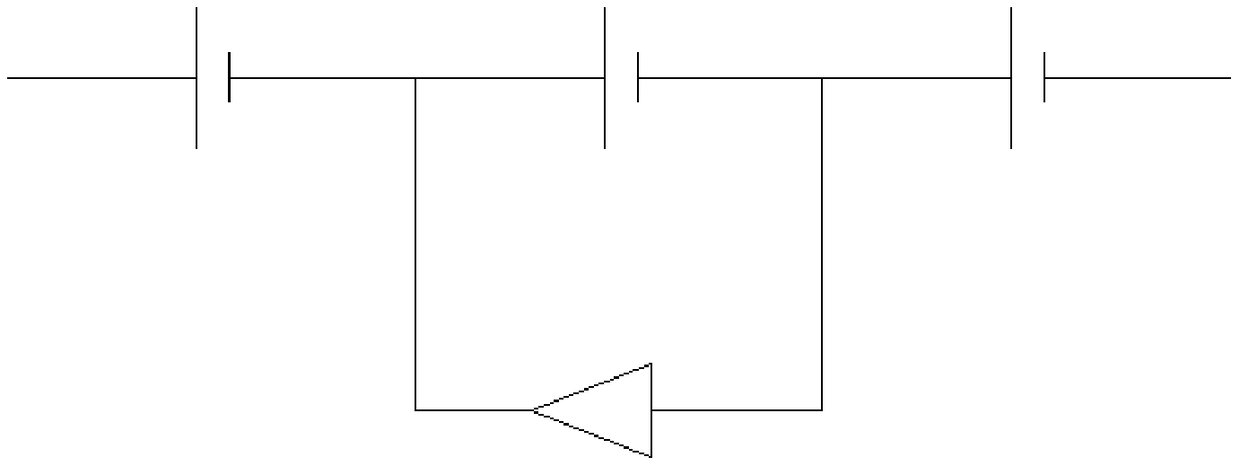

Method of Data Interaction and Modeling of Scheduling Subsystem

ActiveCN102262563ASolving Interaction ProblemsLittle effect of loadMultiprogramming arrangementsMulti dimensionalElectric equipment

The invention discloses a method for data interaction and modeling of a dispatching subsystem, which performs the data interaction on the dispatching subsystem after building object mapping attributes and electric equipment measuring models of the dispatching subsystem, wherein the method comprises the following steps of: a) associating the multi-dimensional data of the dispatching subsystem with a global public object model, and building a mapping relationship of the public object attributes and the multi-dimensional object attributes of the multi-dimensional data of the dispatching subsystem in the global public object model; b) utilizing data interaction of the dispatching subsystem in a subscription / publish mode, and synchronizing the multi-dimensional data of the object attributes which form a mapping relationship with the dispatching subsystem to an abstract caching template in real time via a real-time caching model and an information mechanism; and c) performing generation of an XML (Extensive Makeup Language) description file of the multi-dimensional data model of the dispatching subsystem and the data interaction between the dispatching subsystems based on the driving of a cross-platform database via a subscription / publish mode driven by an event. The method for the data interaction and the modeling of the dispatching subsystem ensures the reuse of the abnormal-structure dispatching subsystem model in a manner of a mapping model, so that the data mode of the model is stable relatively.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

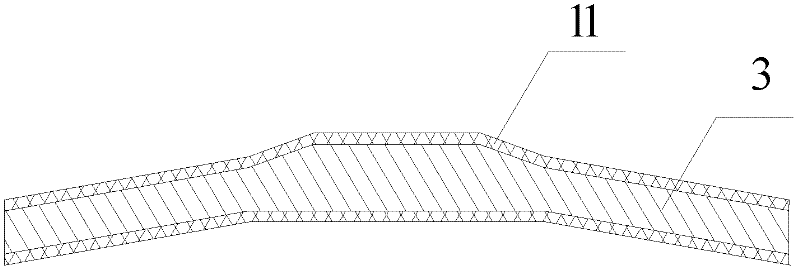

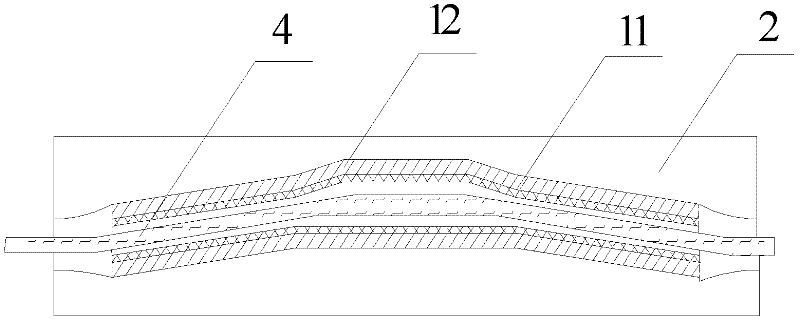

Moulding method of composite material prefabricated component

InactiveCN102514210AAvoid destructionAvoid problems such as destructionCompression moldingSemi solid

The invention discloses a moulding method of a composite material prefabricated component. The moulding method employs a secondary solidification integral moulding technology and comprises the following steps: a. preparing a semi-solid composite material core casing with thickness of 0.1-0.4 mm by a shrinkage tape moulding technology; b. removing a core casing base die body in the composite material core casing by a mechanical method and bonding the broken composite material core casing; c. carrying out coarsening treatment on a surface of the composite material core casing; d. using the bonded composite material core casing as a male mould, paving an enhancement body satisfying design requirement and preparing into a prefabricated component; and e. carrying out a secondary solidification integral moulding on the prefabricated component by an airbag pressurization moulding technology or a compression molding technology. The moulding method suits for preparation of main bearing composite material prefabricated component with hollow abnormal structure.

Owner:TIANJIN POLYTECHNIC UNIV

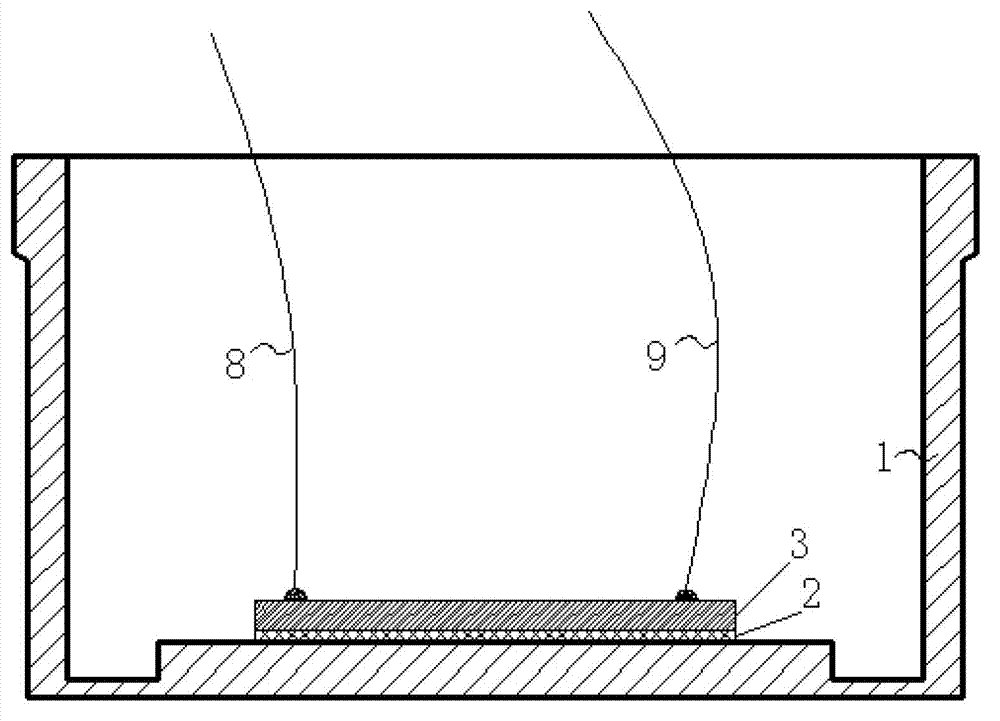

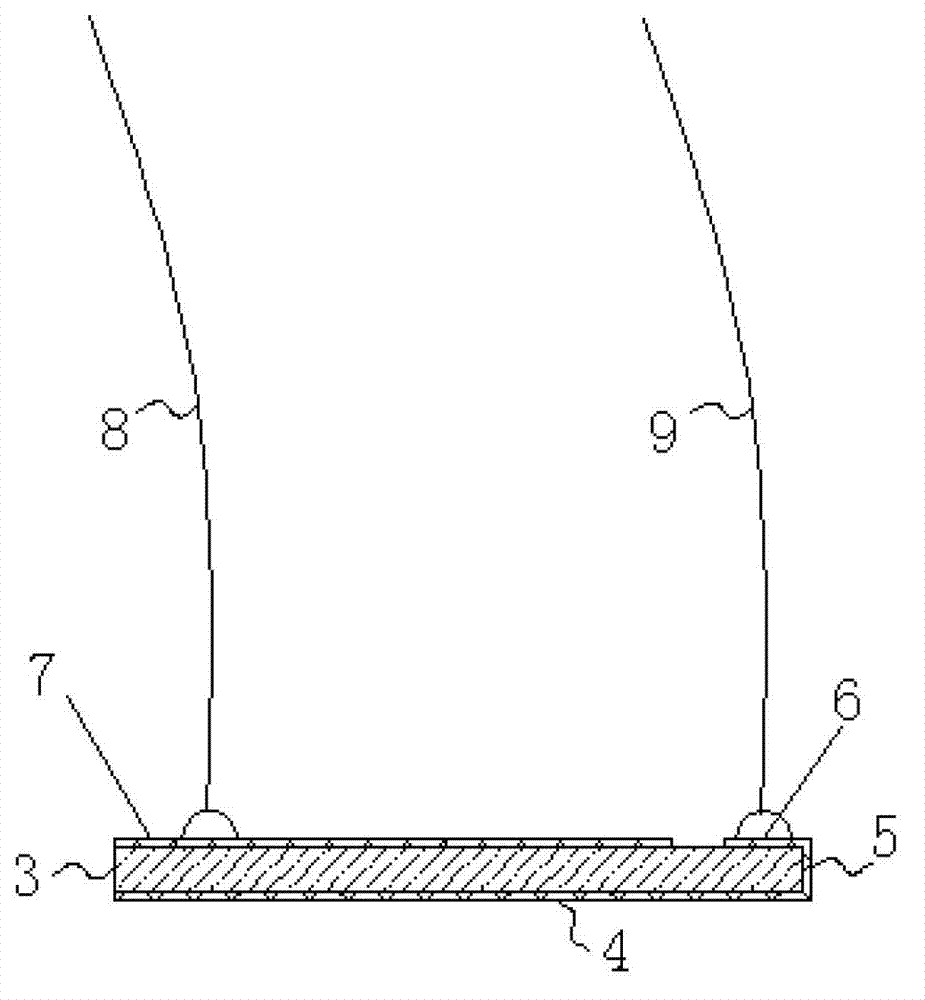

Ultrasonic transducer for automatically parking

InactiveCN103076610AHigh sensitivityLong test distanceAcoustic wave reradiationUltrasonic sensorSilver plate

The invention relates to a transducer, in particular to an ultrasonic transducer for automatically parking. The ultrasonic transducer comprises a metal shell with a chamber, wherein the metal shell is internally provided with a piezoelectric ceramic piece; a silver-plated layer is arranged on the lower surface of the piezoelectric ceramic piece; the upper surface comprises a first silver plating region and a second silver plating region; the first silver plating region and the second silver plating region are separated; the first silver plating region is connected with an anode lead wire end; the second silver plating region is connected with a cathode lead wire end; the second silver plating region is communicated with the silver-plated layer of the lower surface through a side face metal body; and the silver-plated layer of the lower surface of the piezoelectric ceramic piece is fixed in the metal shell through an adhesive layer. With the adoption of the structure, the ultrasonic transducer for automatically parking has the highest conversion efficiency and is at the lowest energy consumption rate in a process; and the transducer obtains the high flexibility and a tested distance is far. Meanwhile, the metal shell is in a gradually-changed abnormal structure so that a sound field radiation angle is changed, the angle of the transducer is reduced and erroneous judgment is prevented.

Owner:江苏波速传感器有限公司

Image processing device, image processing method, and image processing program

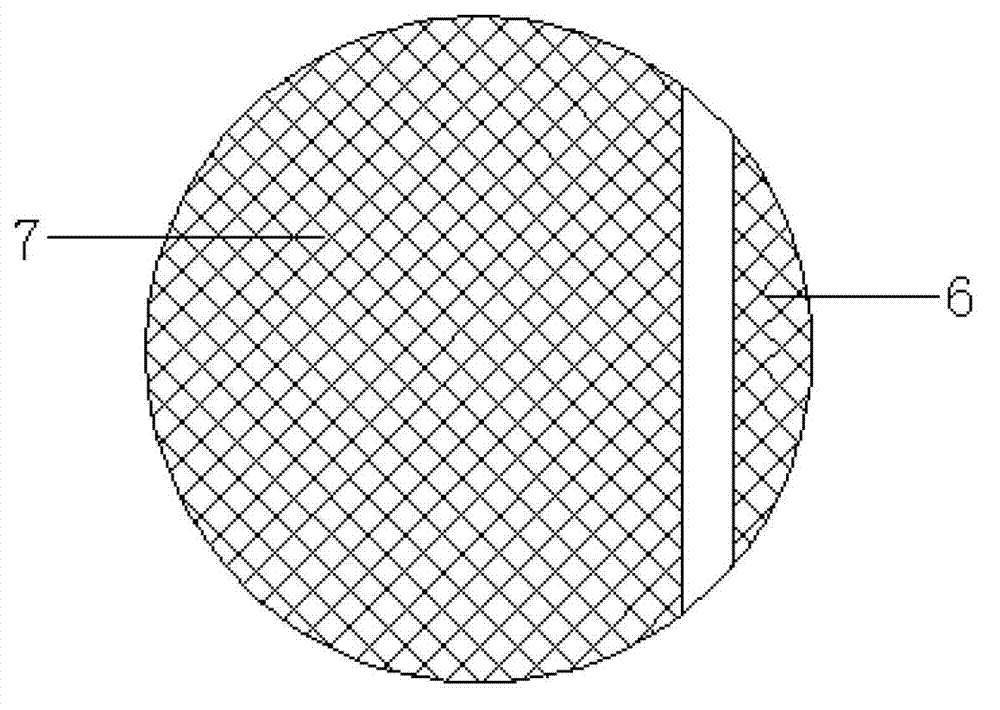

ActiveCN104812288AHigh-precision identificationImage enhancementImage analysisImaging processingMucous membrane

Provided are an image processing device and the like which enable the abnormality of the microstructure of the surface of an inspection object such as a mucous membrane to be accurately identified even when the contour edge of the inspection object is present in an intraluminal image. An image processing device (1) is provided with: a contour edge region extraction unit (110) for extracting a contour edge region of an inspection object from an image obtained by capturing an image of the inside of a lumen of a living organism; an inspection region setting unit (120) for setting an inspection region in the image such that the contour edge region is not contained therein; and an abnormal structure identification unit (130) for identifying whether the microstructure of the surface of the inspection object is abnormal or not on the basis of texture information relating to the inspection region.

Owner:OLYMPUS CORP

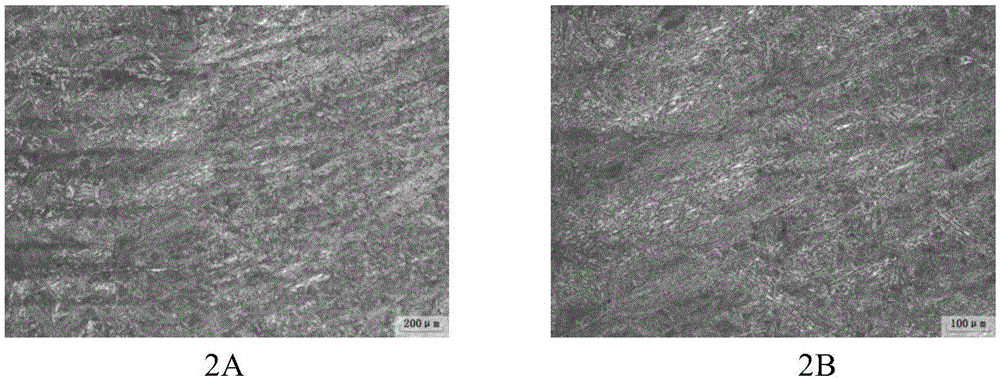

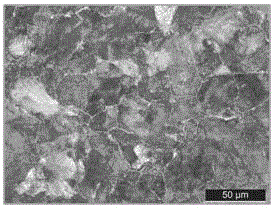

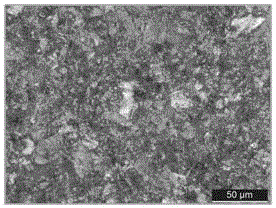

Bainitic steel and pearlitic steel thermit welding material and welding technology

ActiveCN105414797ATo achieve a homogenization effectSimple welding processRailsWelding/cutting media/materialsFerrosiliconMechanical property

The invention provides a bainitic steel and pearlitic steel thermit welding material and application of the bainitic steel and pearlitic steel thermit welding material to bainitic steel and pearlitic steel welding. The bainitic steel and pearlitic steel thermit welding material comprises, by weight percentage, 18%-19% of aluminum powder, 68%-69% of iron oxide, 2.7%-2.8% of ferromanganese, 0.6%-0.7% of ferrochromium, 1.1%-1.2% of ferrosilicon, 0.4%-0.6% of ferromolybdenum and the balance iron powder. The invention further provides a steel rail thermite welding technology characterized by utilization of the bainitic steel and pearlitic steel thermit welding material. When a pearlitic steel rail and a bainitic steel rail are welded by the use of the bainitic steel and pearlitic steel thermit welding material and the welding technology, the chemical composition of weld metal is similar to the chemical composition of bainitic steel, the microstructure of the weld metal is carbide-free bainite, no cracks or abnormal structures exist, a welded joint has good mechanical properties, and the hardness, the static bending performance and other performance meet the existing industrial standards.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

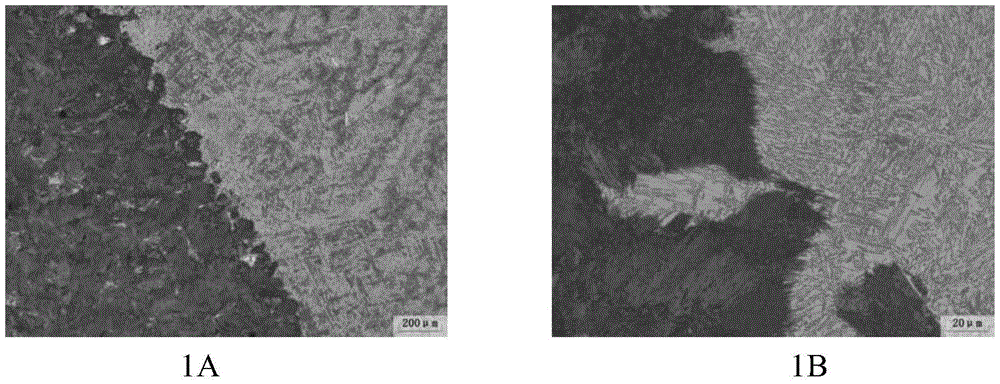

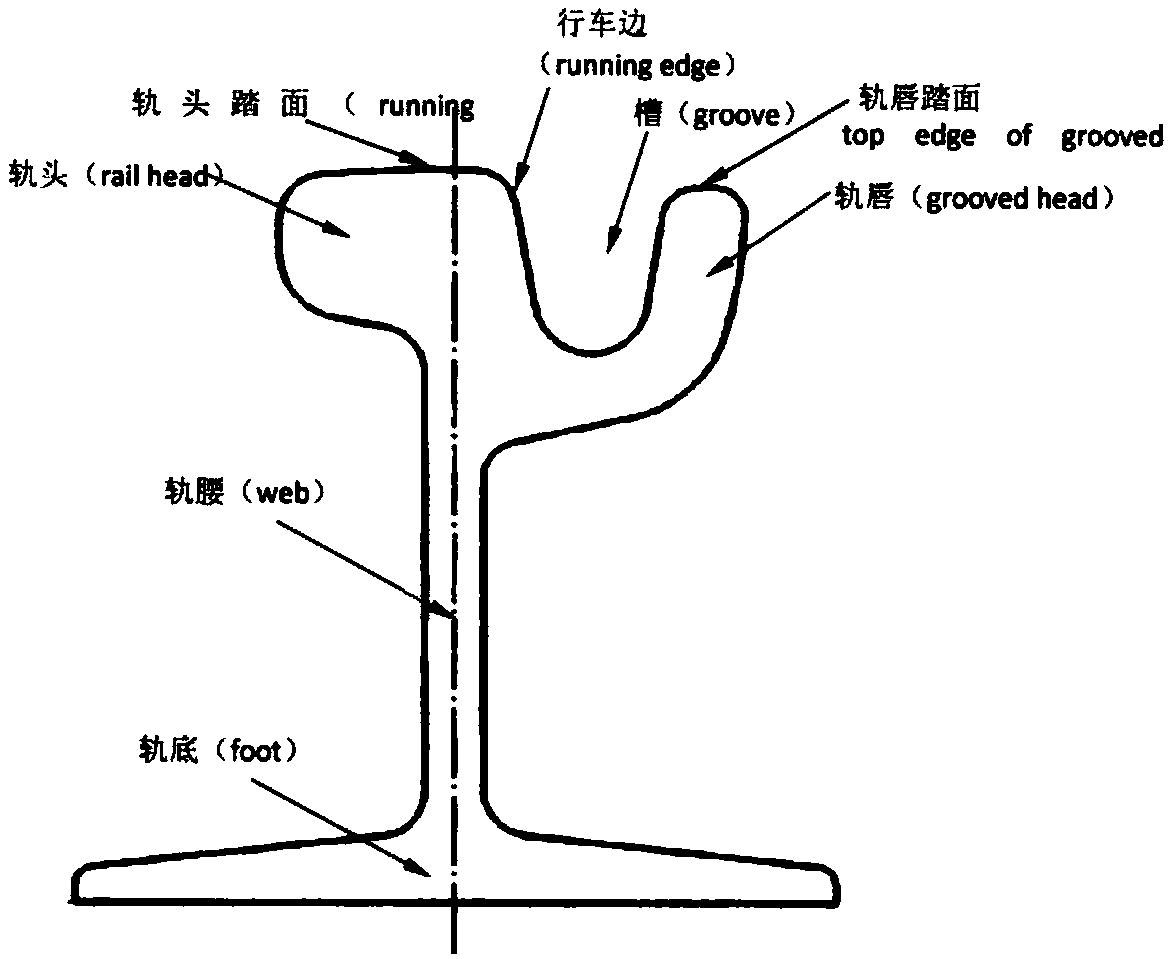

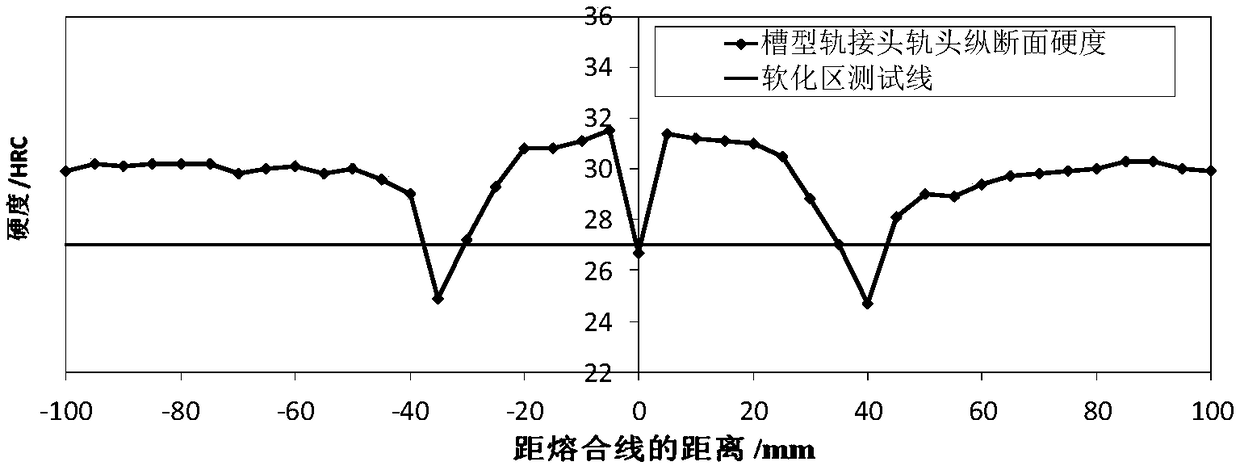

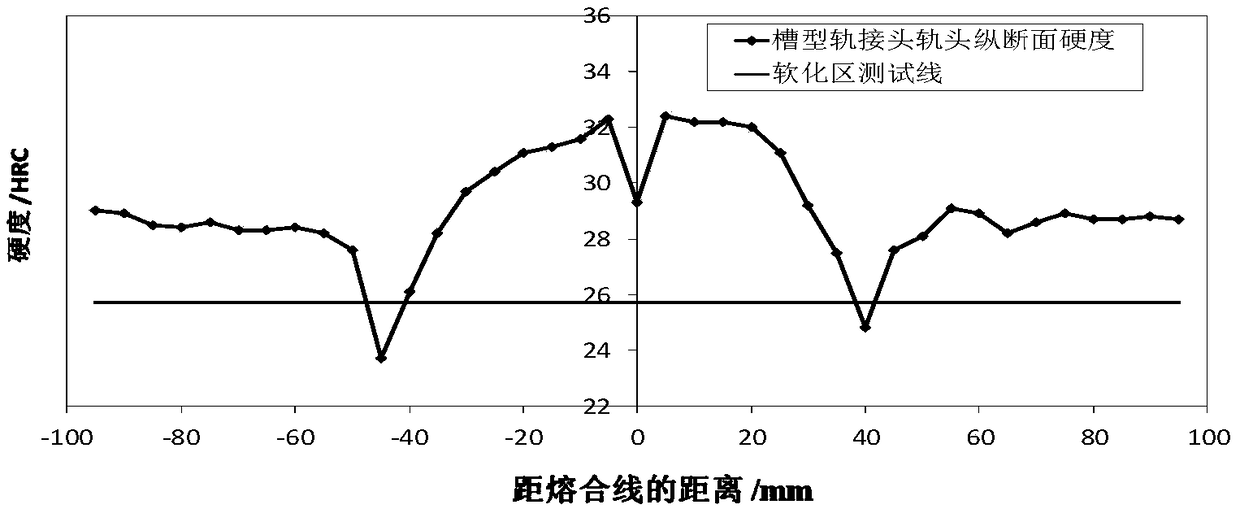

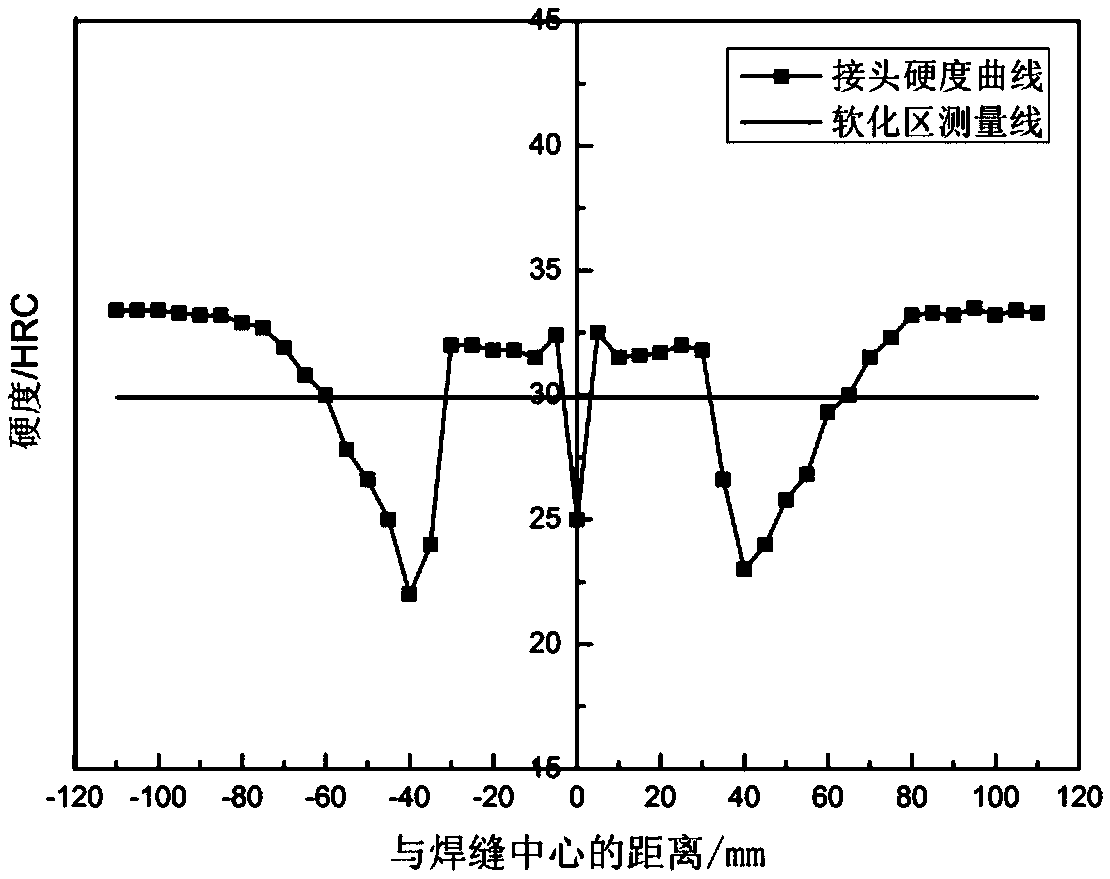

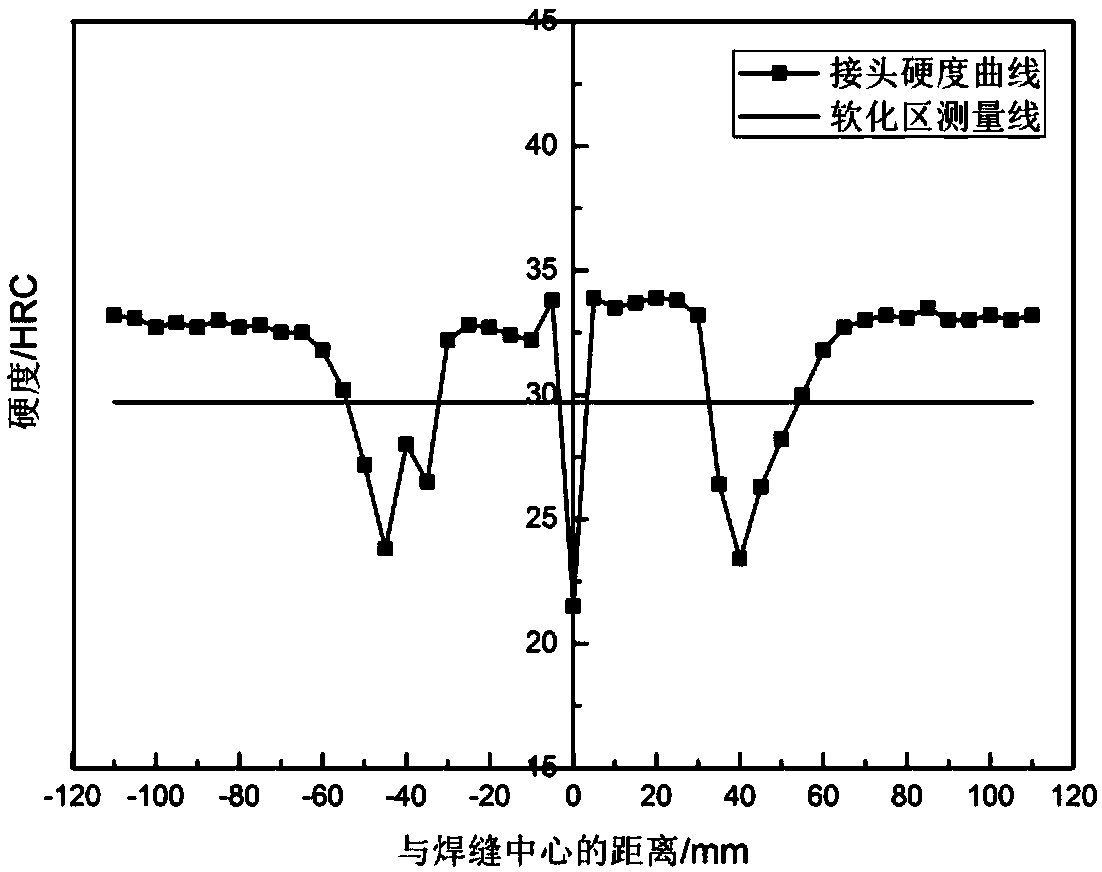

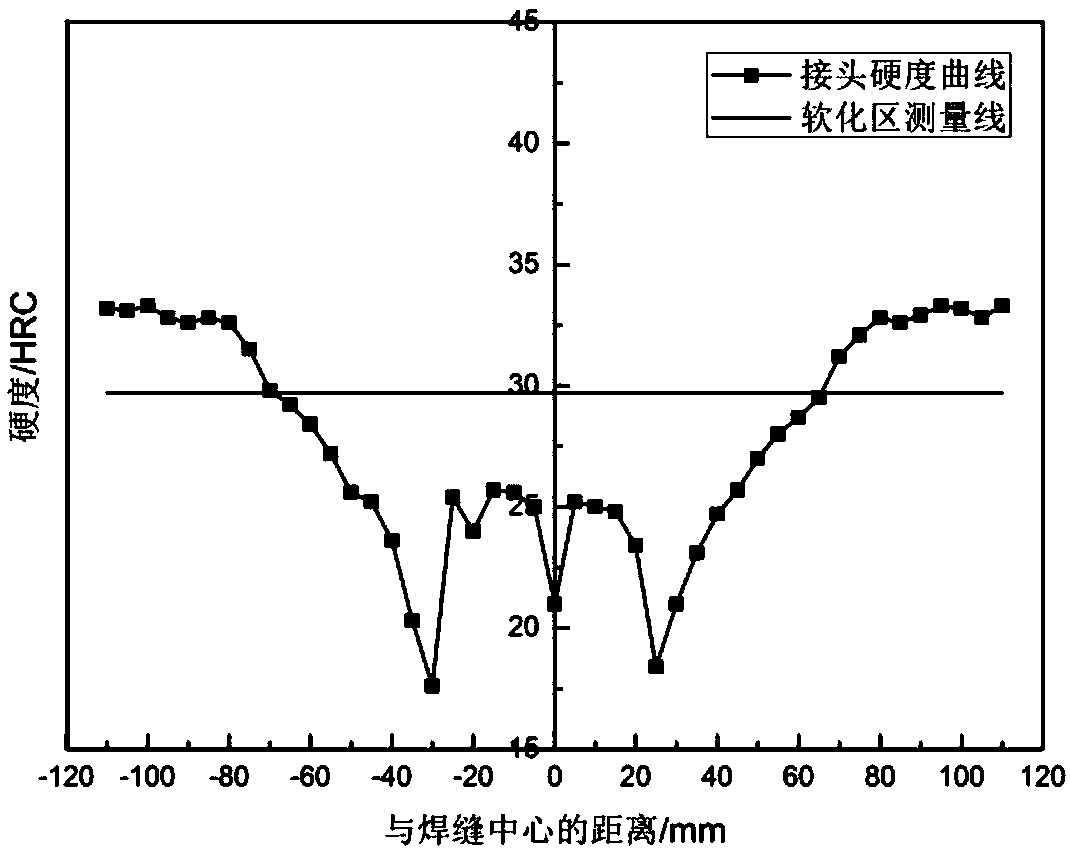

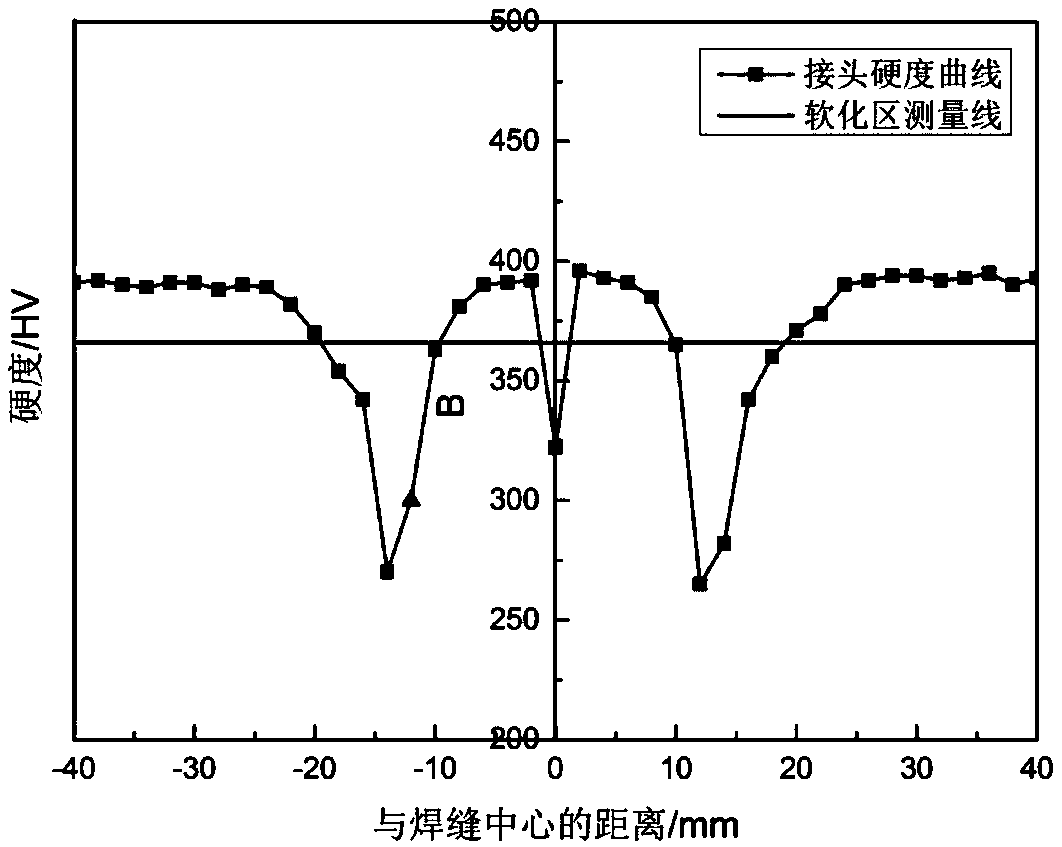

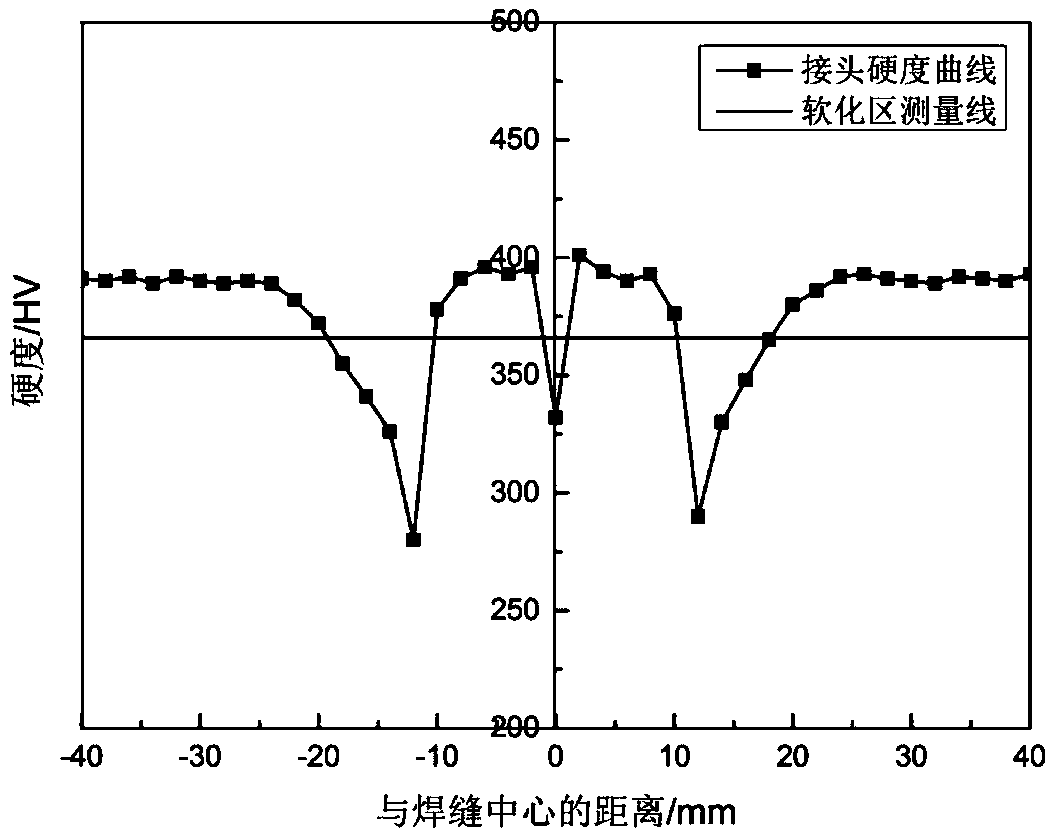

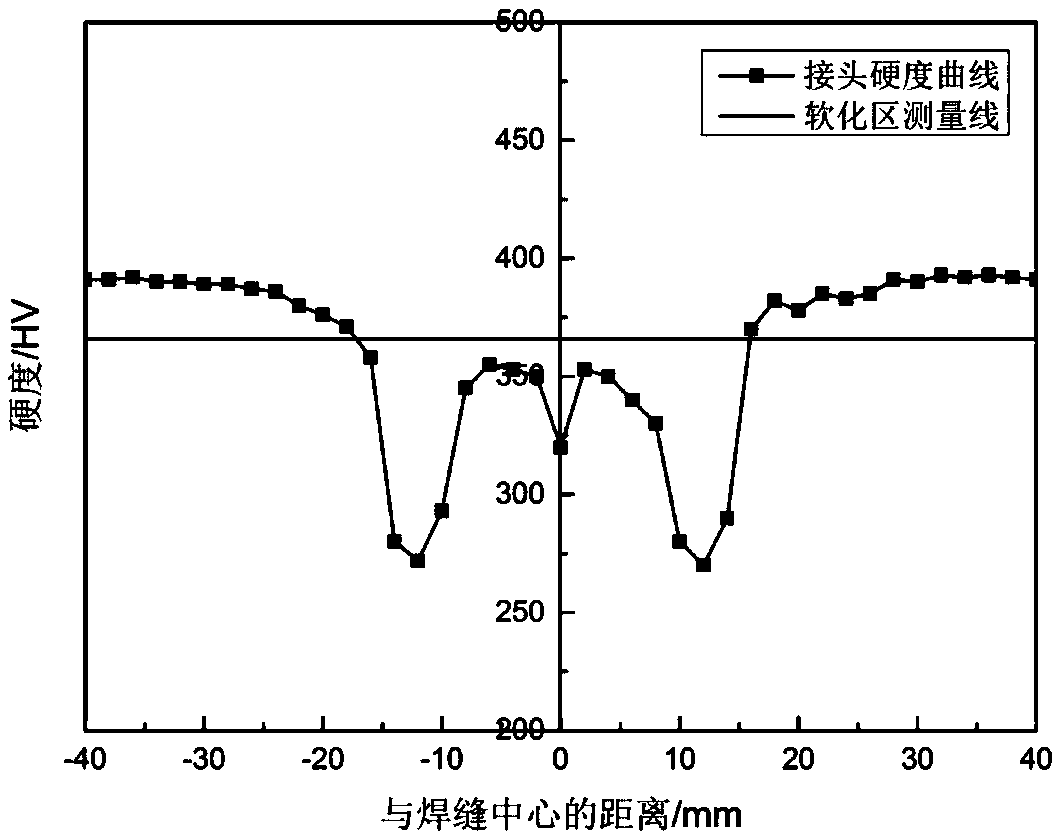

Post-welding thermal treatment method for channel type steel rail flash welding head

The invention relates to a post-welding thermal treatment method for a channel type steel rail flash welding head, belongs to the technical field of railway steel rail welding, and aims to solve the technical problems that the channel type steel rail flash welding head is low in impact toughness through air-cooling, and the hardness of the longitudinal section of the post-welded thermally-treatedrail head is low. According to the technical scheme adopted by the invention, the post-welding thermal treatment method comprises the following steps of: performing first-time cooling on a channel type steel rail welding joint until a temperature lower than 200 DEG C, stopping heating while heating the joint to a temperature of 850-920 DEG C, performing second-time cooling, stopping second-time cooling while cooling to a temperature of 430-520 DEG C, and performing third-time cooling to a temperature of 10-30 DEG C. The rail head longitudinal section hardness of the post-welded thermally treated channel type rail welding joint is 90% or more of average hardness of a steel rail base material, a joint softening region width is within 20 mm, and abnormal structures such as martensite and bainite are avoided. The post-welded thermally treated channel type steel rail all-section welding seam impact power Aku is higher than or equal to 15 J.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Bearing steel wire rod and production method thereof

ActiveCN105925909AAvoid it happening againGood spheroidizing annealing preparationWire rodChemical composition

The invention discloses a bearing steel wire rod and a production method thereof. The bearing steel wire rod is prepared from, by mass, 0.95-1.05% of C, 0.15-0.35% of Si, 0.25-0.45% of Mn,1.40-1.65% of Cr, 0.025% or less of P, 0.025% or less of S, 0.02-0.10% of Mo, 0.10-0.30% of Ni, 0.10-0.25% of Cu, 0.0012% or less of O, and the balance Fe and trace impurities. The production method comprises the following procedures of RH furnace refining, continuous casting, slow cooling, heating, dephosphorization post-rolling, spinning and air patenting. According to the bearing steel wire rod and the production method thereof, fish eye fractures and abnormal structure fractures in the rapid cooling process are prevented through control of the smelting process; and by means of rolling control and cool control, the grain size, network carbide and pearlite interlamellar spacing of the rolled wire rod are controlled, a good spheroidizing annealing preparation structure is obtained, and the spheroidizing annealing time can be remarkably shortened.

Owner:XINGTAI IRON & STEEL

Production method of railway wheels

InactiveCN103753138ALarge machining allowanceReduce hardnessFurnace typesHeat treatment furnacesSurface layerRailroad wheel

The invention discloses a production method of railway wheels. The production method comprises the steps of billet cutting, steel billet heating, shaping, rolling, slow cooling or isothermal treatment, heat treatment and finish machining. According to the production method, rough machining is cancelled, the allowance of the finish machining is appropriately increased, and accordingly the allowance of the tread machining can be increased after the heat treatment, more tread metal close to a surface layer can be removed under the condition that the requirements of the machining accuracy are met, and accordingly the depth of the abnormal structure area under the tread can be reduced or eliminated conveniently. Compared with the conventional process, the depth of the abnormal structure area under the tread is greatly reduced and the consumption of a finish machining tool is reduced under the condition that performance indicators of the produced wheels are basically identical.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Forging technology for abnormal structure of TC18 titanium alloy raw material

ActiveCN105441845AChange distribution statusWell organizedHeating/cooling devicesPhase changeTitanium alloy

The invention belongs to the technical field of forging technologies, and discloses a forging technology for an abnormal structure of a TC18 titanium alloy raw material. The forging technology comprises the following steps: a, carrying out beta forging above a phase change point on blanks by 1-2 fire, wherein forging temperature is 15-30 DEG C above the phase change point, and deformation is controlled to be between 20% and 40%; b, carrying out forging below the phase change point on the blanks by more than 2 fire, wherein the forging temperature is 20-40 DEG C below the phase change point, and the deformation is controlled to be between 15% and 30%; and c, carrying out beta forging above the phase change point on the blanks by 1 fire, wherein the forging temperature is 10-20 DEG C above the phase change point, and the deformation is controlled to be 15% and 25%. By the technology, the structure defect of fine-crystal bright bands can be avoided effectively, and TC18 titanium alloy free forge pieces can be produced in batches.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

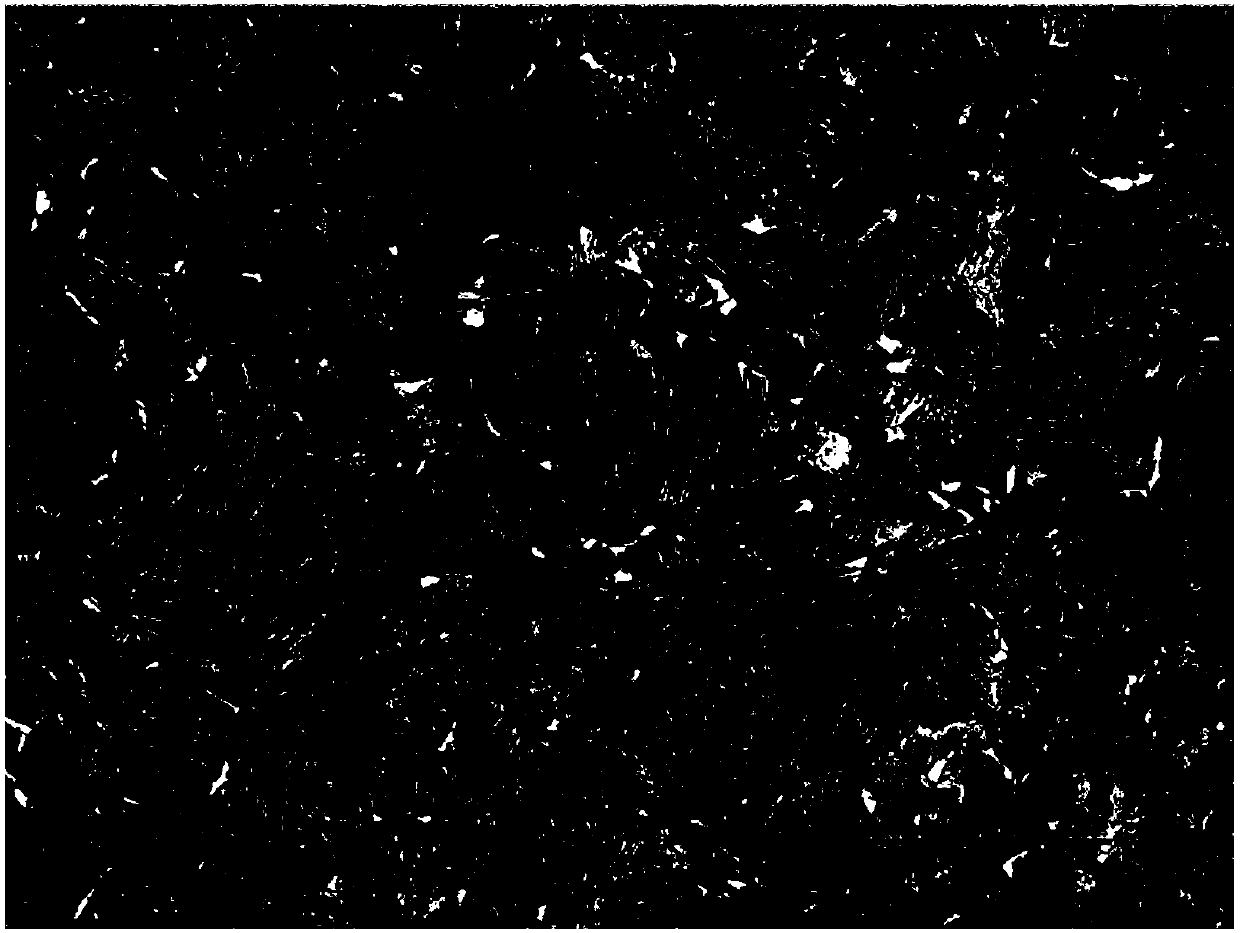

Abnormal structure identification method and device

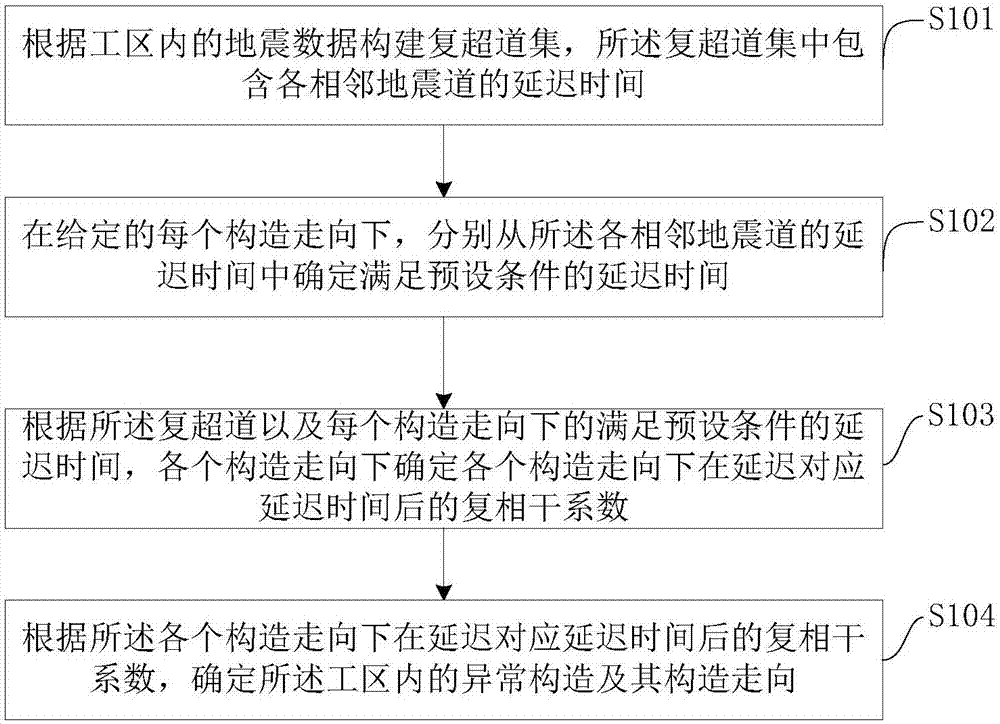

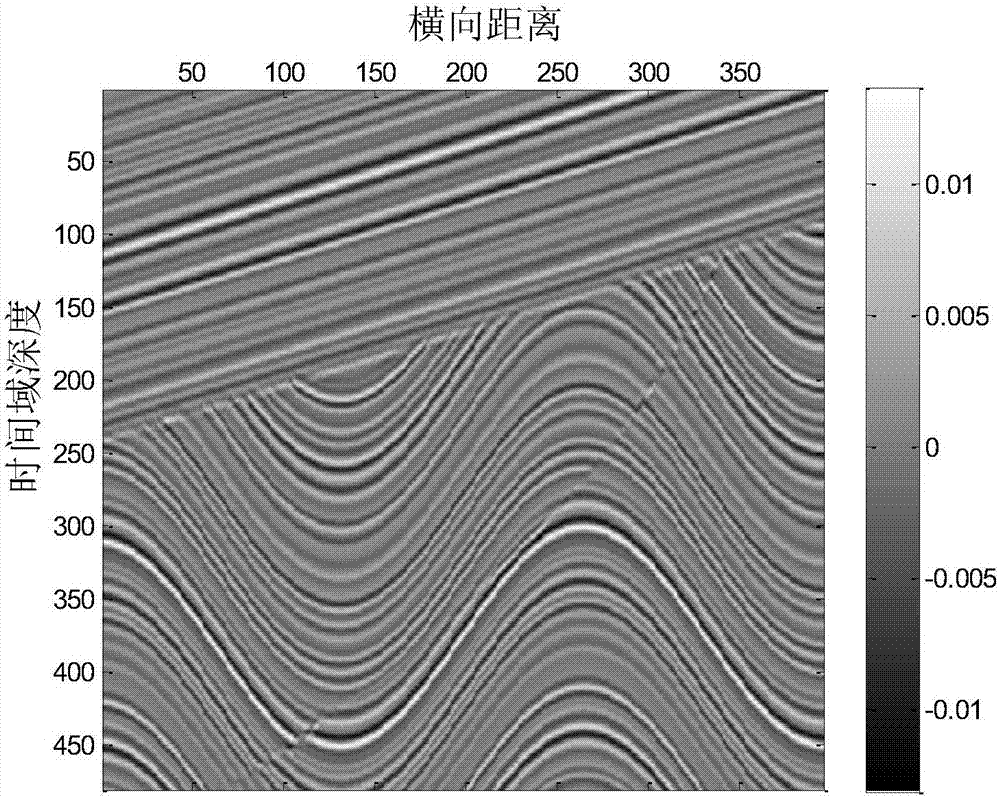

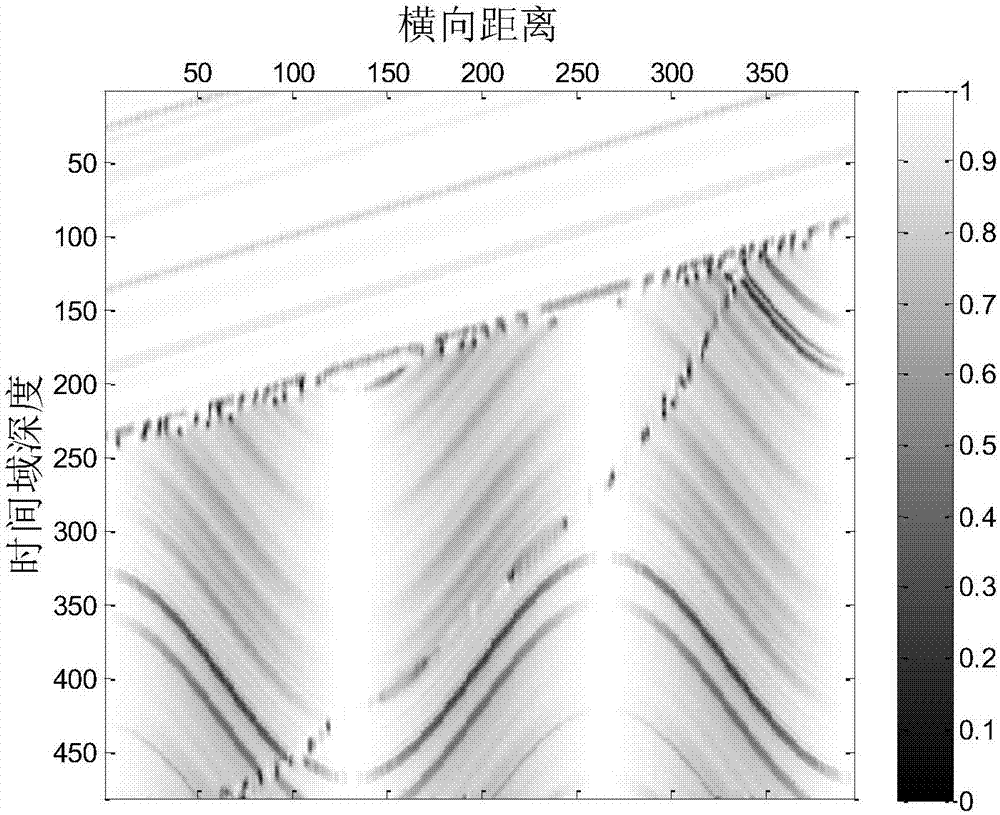

ActiveCN107144877AHigh resolutionImprove recognition accuracySeismic signal processingCorrelation coefficientSeismic trace

The embodiments of the present invention provide an abnormal structure identification method and device. The method includes the following steps that: a complex super-trace set is constructed according to seismic data within a work area, wherein the complex super-trace set contains delay time of each of adjacent seismic traces; under each given structural trend, delay time satisfying a preset condition is determined from the delay time of each of the adjacent seismic traces; under each of the structural trends, the complex correlation coefficients of the structural trends after corresponding delay time is delayed are obtained; and an abnormal structure and the structural trend thereof in the work area are determined according to the complex correlation coefficients of the structural trends after the corresponding delay time is delayed. With the abnormal structure identification method and device provided by the embodiments of the present invention adopted, the identification accuracy of the abnormal structure can be improved.

Owner:PETROCHINA CO LTD

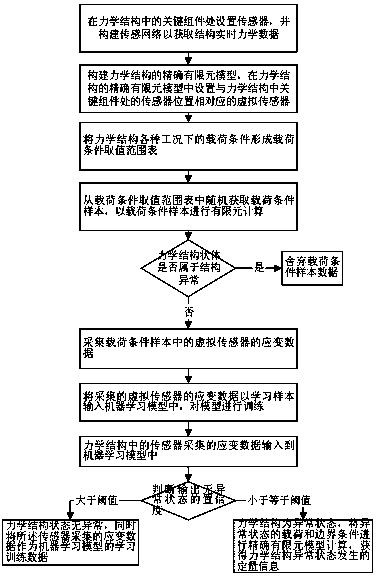

Mechanical structure abnormal state rapid identification method and storage medium

ActiveCN109918726ASolve the problem of fast abnormal state identificationRapid Predictive IdentificationKernel methodsSpecial data processing applicationsElement modelData source

The invention discloses a mechanical structure abnormal state rapid identification method. The method includes: deploying a sensor for real-time monitoring on a mechanical structure; Constructing a finite element model, arranging a virtual sensor corresponding to a sensor arranged in the mechanical structure in the finite element model; randomly obtaining a load sample according to a mechanical structure load condition for calculation; judging whether the mechanical structure is abnormal or not according to calculation; if not, collecting virtual sensor data; if yes, abandoning the load sample; and inputting the virtual sensor strain data into a machine learning model as a learning sample, carrying out model training, inputting the sensor data into the machine learning model, carrying outconfidence judgment without abnormal structure, and combining a numerical simulation method with a machine learning method, thereby solving the problems of training data source and rapid identification and prediction.

Owner:ZHENGZHOU UNIV +1

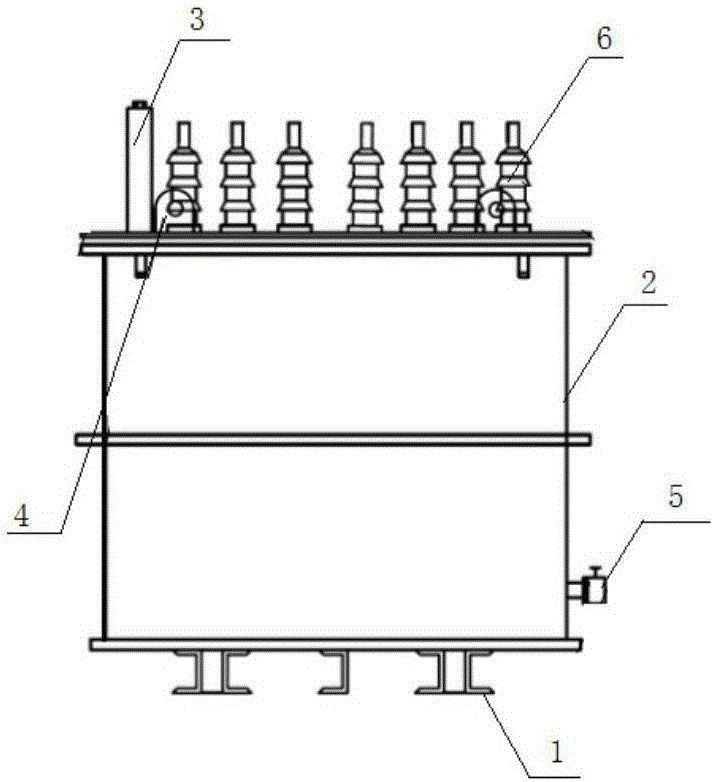

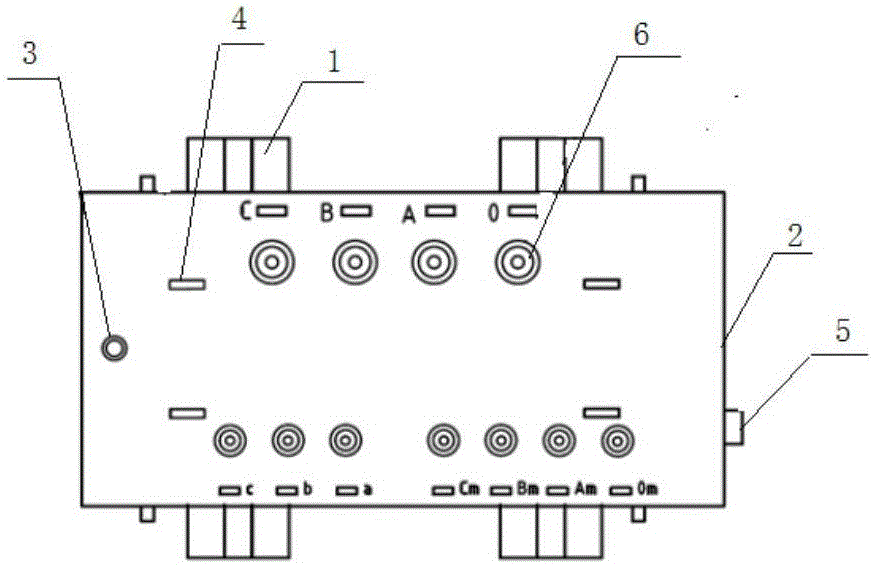

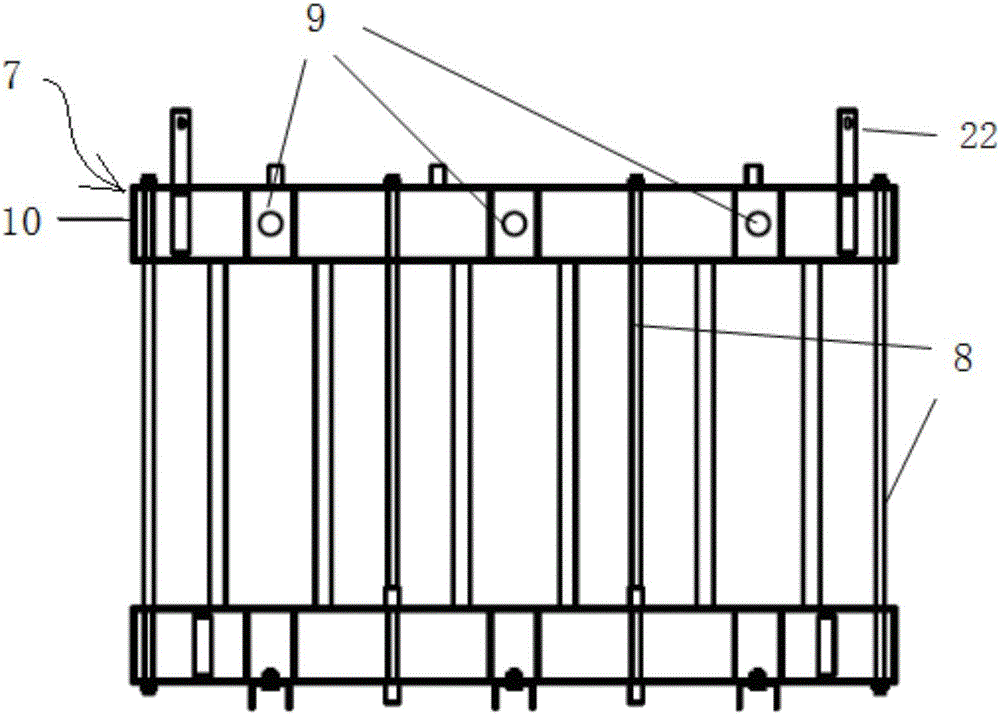

Dynamical simulator for abnormal structure change fault of transformer

InactiveCN106448377AEasy to disassembleEasy and precise resetEducational modelsTransformerEngineering

The invention provides a dynamical simulator for an abnormal structure change fault of a transformer. A transformer body, an iron core arranged in the transformer body and windings wound around a column of the iron core are included, the top of the transformer body is provided with three groups of high-voltage bushings, the three groups of high-voltage bushings are connected with the windings in the transformer body respectively, the iron core includes an upper part of silicon steel plates and a lower part of silicon steel plates, the lower part of an E-shaped structure is used to accommodate three-phase windings, the upper part is of a linear structure, a yoke on the iron core is formed by laminating the silicon steel plates, the two ends of the yoke are provided with upper clamping pieces, the yoke on the iron core and the upper clamping pieces are fastened to form an integral structure via an axial pull bar of the upper clamping pieces, each winding is of a three-segment structure, and every two segments are connected via a cold pressing joint. The dynamical simulator can simulate different fault degrees accurately, and integrate different diagnosis results to provide comprehensive data and theory support for a decision maker and further to provide basis for diagnosis on the abnormal structure change fault of the transformer.

Owner:STATE GRID CORP OF CHINA +3

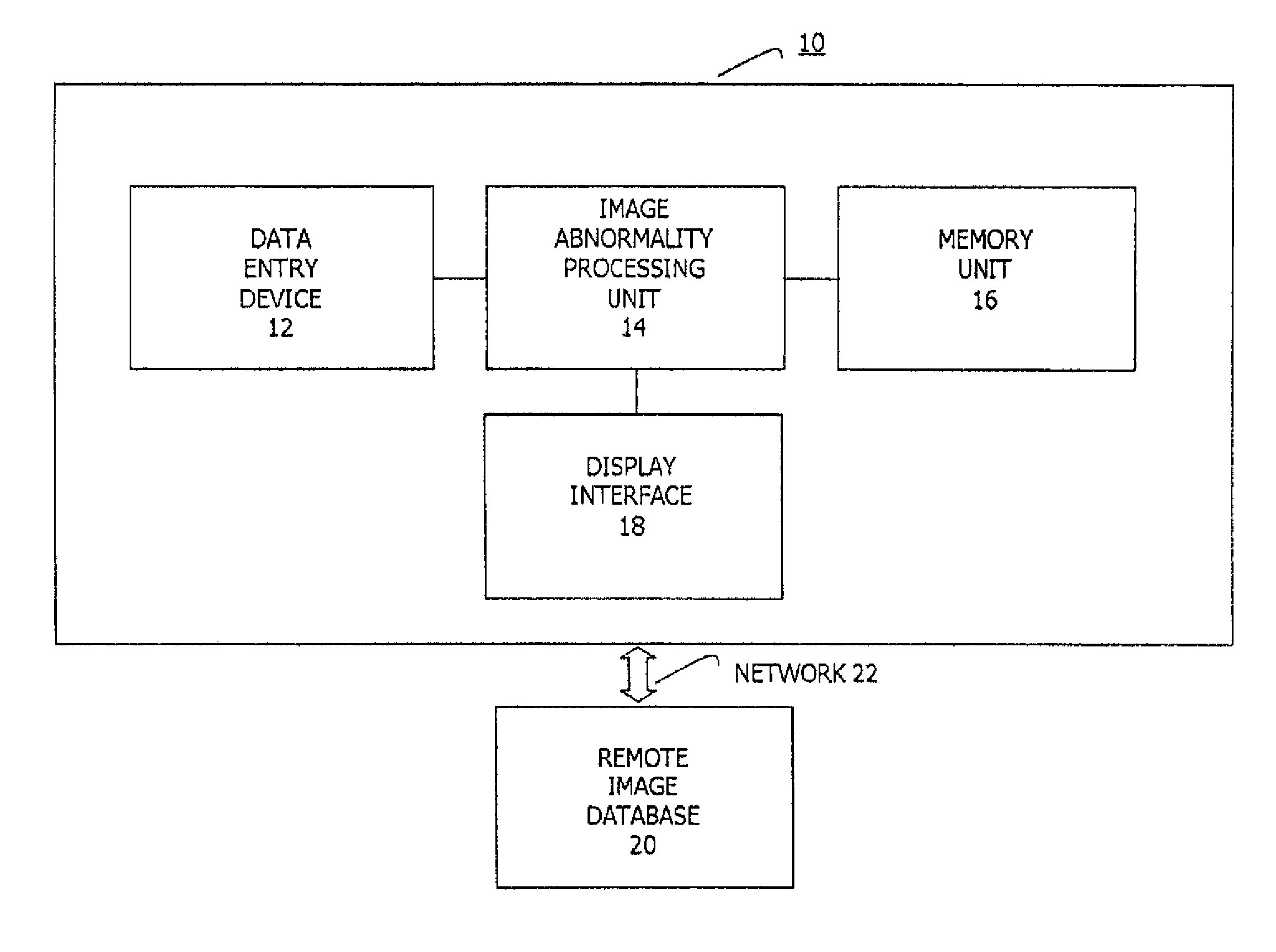

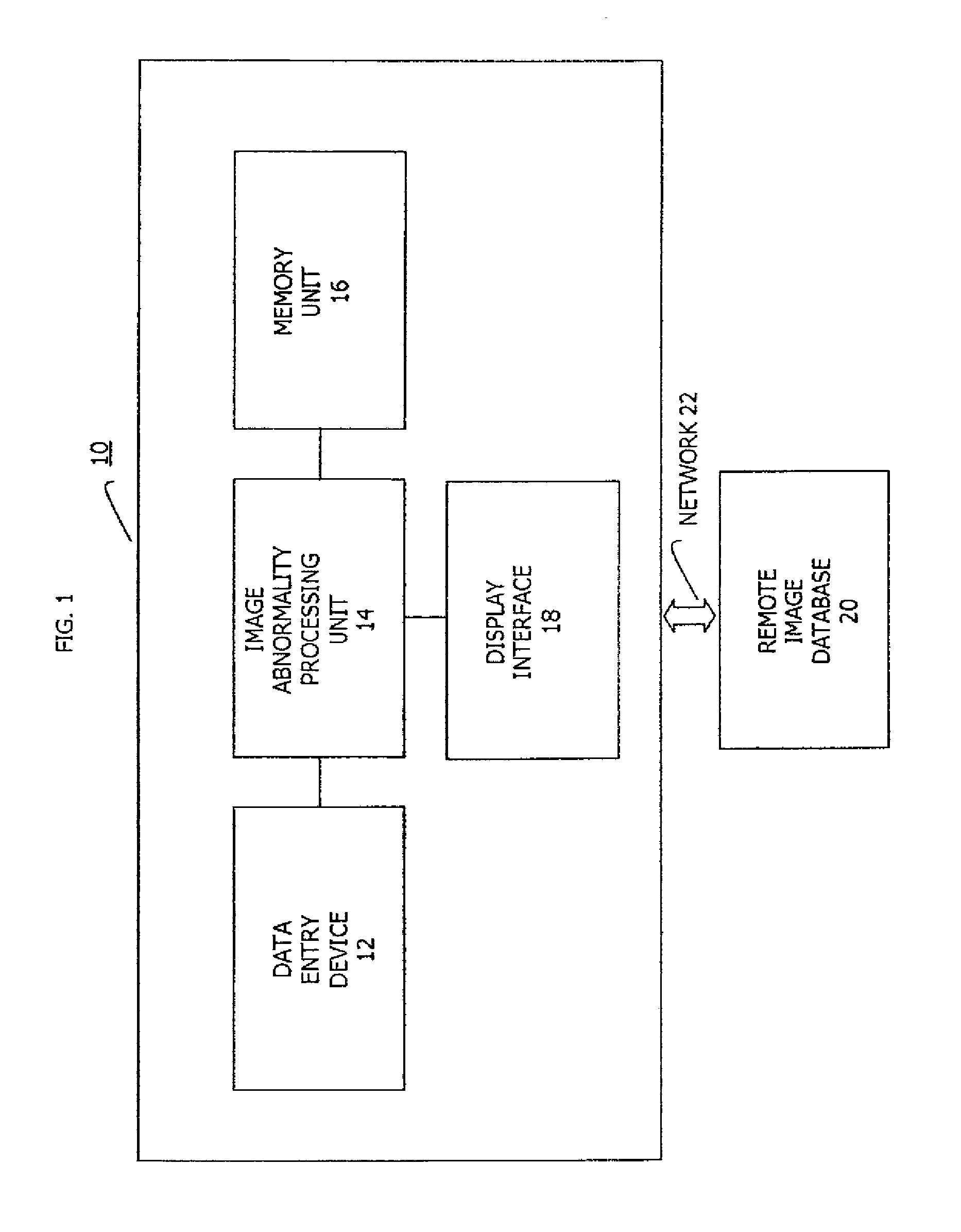

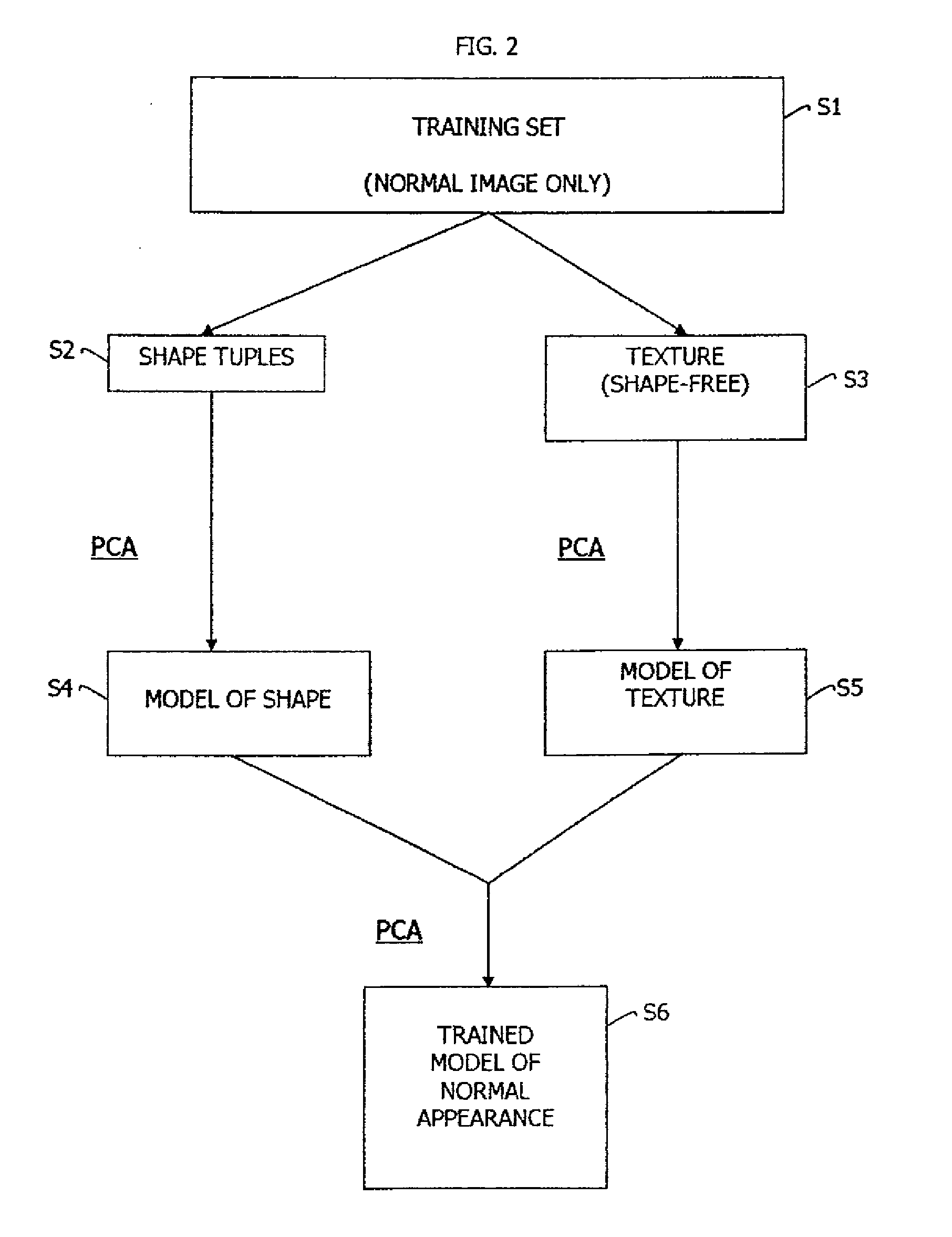

Identifying image abnormalities using an appearance model

ActiveUS20110075938A1Complicate to identifyImage enhancementImage analysisTraining phaseErrors and residuals

The identification of known normal structures within an image is preferably accomplished using an appearance model. Specifically, an active appearance model, which encapsulates a complete model of the shape and global texture variations of an object from a collection of samples, is utilized to define normal structures within an image by restricting training samples supplied to the active appearance model during a training phase to those that do not contain abnormal structures. Accordingly, the trained appearance model represents only normal variations in the object of interest. When another image with abnormalities is presented to the system, the appearance model cannot synthesize the abnormal structures which show up as errors in a residual image. Accordingly, the errors in the residual image represent potential abnormalities.

Owner:MONUMENT PEAK VENTURES LLC

Production process of tiny chamfering special-shaped line for precise products

InactiveCN105568146AImprove plastic deformation abilityUniform grainDrawing diesWire rodEconomic benefits

The invention discloses a production process for a tiny chamfering special-shaped line for precision products, comprising the following steps: (1) material selection: selecting a carbon structural steel material which contains the following chemical components in mass percent: 0.08-0.11% of C, 0.20-0.29% of Si, 0.35-0.45% of Mn, 0.020-0.034% of P, 0.028-0.038% of S and the balance of Fe; (2) spheroidizing annealing: putting the carbon structural steel material into an atmosphere protecting furnace, wherein protective atmosphere is added to the atmosphere protecting furnace, heating to the temperature of 20-30 DEG C higher than an austenite transformation temperature, preserving heat for 4-6 hours, then slowly cooling to the temperature of 20-30 DEG C lower than the austenite transformation temperature at the rate of 10 DEG C / h, preserving heat for 3-4 hours, and then cooling together with the furnace until being delivered out; and (3) carrying out cold drawing. A wire rod produced by adopting the production process has relatively high plastic deformation capability, grains of an annealed structure are uniform, no abnormal structure exists, a product angle of chamfer is less than or equal to 0.15mm, and the wire rod can meet various use requirements of clients. Various performances of the product are obviously prior to current like products on the market, and therefore, the product has excellent market prospects and can create considerable economic benefits for companies.

Owner:DONGGUAN KELEE STEEL WIRE

Post-welding thermal treatment method for hypoeutectoid steel rail

InactiveCN109355482AControl physical fatigue lifeFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention relates to a post-welding thermal treatment method for a hypoeutectoid steel rail, belongs to the technical field of railway steel rail welding, and aims to solve the technical problemsof finding the most suitable post-welding thermal treatment method, controlling tread hardness of the hypoeutectoid steel rail to be within a reasonable range, and guaranteeing the service life of thesteel rail welding joint. According to the technical scheme adopted by the invention, the post-welding thermal treatment method comprises the following steps of: performing first-time cooling on a to-be-cooled hypoeutectoid steel rail joint obtained by welding until a temperature lower than 200 DEG C, stopping heating while heating the hypoeutectoid steel rail to a temperature of 840-920 DEG C, performing second-time cooling, stopping second-time cooling while cooling to a temperature of 250-320 DEG C, and performing third-time cooling to a room temperature of 10-40 DEG C. The rail head treadlongitudinal hardness of the post-welded thermally treated welding joint is 90% or more of average hardness of a steel rail base material, abnormal structures such as martensite and bainite are avoided, and the physical fatigue service life of the joint is not less than 3 million of times.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Post-weld heat treatment method for steel rail

InactiveCN109022750AImproved "saddle" wearGuaranteed operational safetyFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention relates to a post-weld heat treatment method for a steel rail and belongs to the technical field of railway steel rail welding. According to the post-weld heat treatment method for the steel rail, a technical problem to be solved is that the hardness of a hypoeutectoid steel rail welding area is lower. According to the technical scheme of the post-weld heat treatment method for the steel rail, a welded hypoeutectoid steel rail welding joint to be cooled is cooled to 730-820 degrees centigrade in a first stage, and then is cooled to 280-360 degrees centigrade in a second stage andis finally cooled to a room temperature of 10-40 degrees centigrade in a third stage. According to the post-weld heat treatment method for the steel rail, the longitudinal stiffness of the steel railwelding joint within an area with a distance of + / - 10 mm from the center of a welding seam can be guaranteed to fall within a range of + / -30 HV of the corresponding hypoeutectoid steel rail base metal average hardness; the widths of softening areas on the two sides of the welding seam of the joint are not larger than 10 mm; and meanwhile, abnormal structures, such as martensite and bainite, in ametallographic structure of the welding joint are not available.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

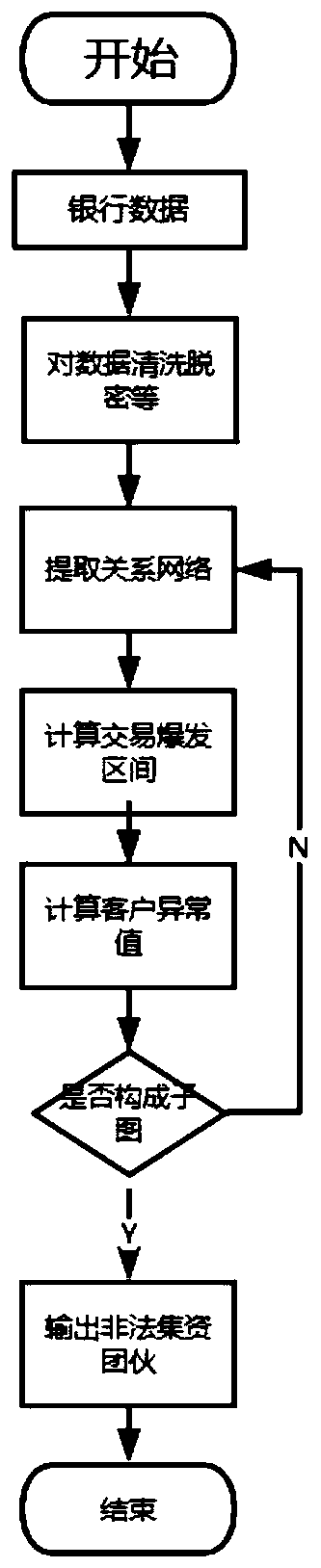

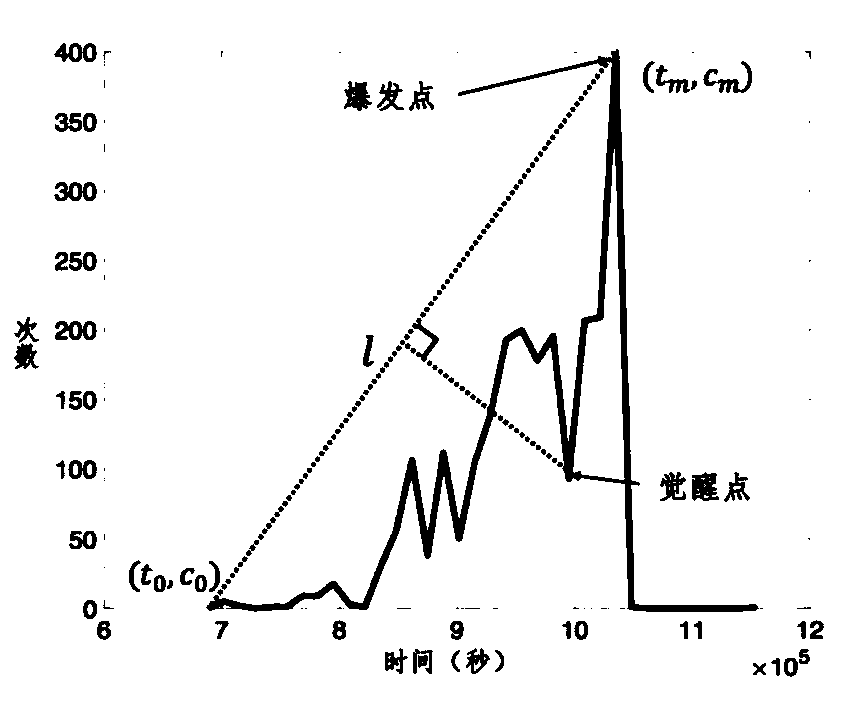

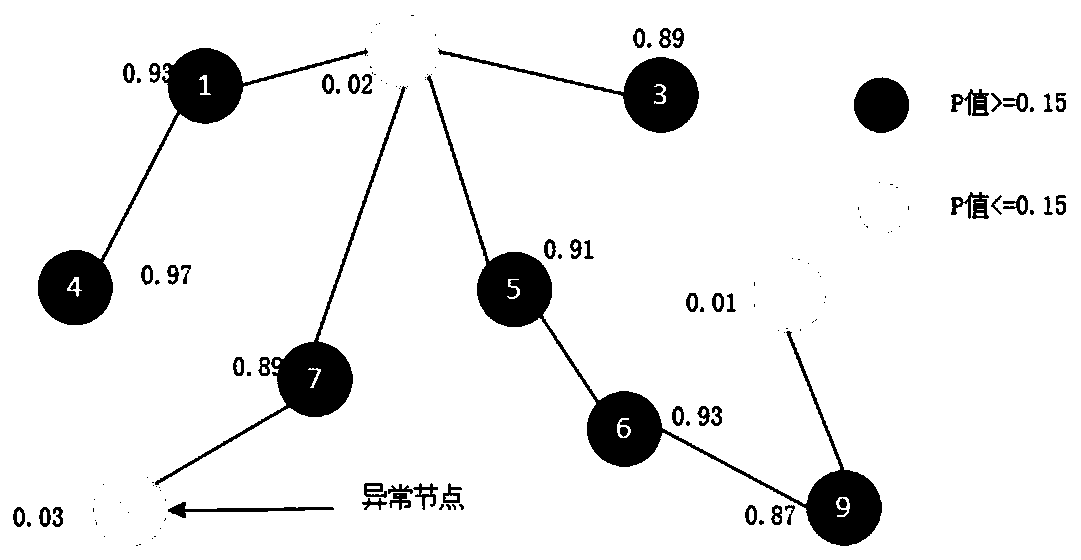

Element abnormal structure detection model construction method based on complex network

ActiveCN110795807AAccurate descriptionImprove scalabilityGeometric CADFinanceFinancial transactionData mining

The invention discloses an element abnormal structure detection model construction method based on a complex network. The element abnormal structure detection model construction method mainly comprises the following steps: firstly constructing a transaction relation network through employing an extracted transaction relation according to a dependent bank transaction flow, finding out an outbreak time interval of a transaction, and calculating an abnormal value of each customer; and then, finding out a suspicious customer in the transaction burst interval and detecting a suspicious maximum communication sub-graph. The element abnormal structure detection model construction method provided by the invention describes the suspicion degree of each client in a more formalized manner, and is usedfor detecting fraud of a real world transaction network with large edge attributes. According to the element abnormal structure detection model construction method, the inherent characteristics of the nodes are mined from the client node behavior information, and the behaviors of the nodes are researched on the time sequence, and the characteristics of the nodes are described more accurately, andthe essence of clients is mined.

Owner:TIANJIN UNIV

A semi-rigid solar cell module structure and a preparation method thereof

ActiveCN109244161AStable structureSmall mechanical responseFinal product manufacturePhotovoltaic energy generationGlass coverSpace power

The invention discloses a semi-rigid solar cell module structure and a preparation method thereof. The module structure comprises a solar cell, an interconnecting sheet, a module connecting sheet, a diode and a glass cover sheet. The glass cover sheet comprises an upper glass cover sheet and a lower glass cover sheet. The lower glass cover sheet is of an abnormal structure. The upper glass cover sheet is of the same structure as the solar cell, and the solar cell is enclosed between the upper glass cover sheet and the lower glass cover sheet. The solar cell, the diode and the module connectingpiece are connected through the interconnecting piece. The solar cell module provided by the invention has the advantages of high integration, reliable structure, small mechanical response of the solar cell module, and the diode does not occupy the power generation area of the solar cell, thus improving the space power generation capacity of the solar cell array and improving the space application capacity of the solar cell array.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com