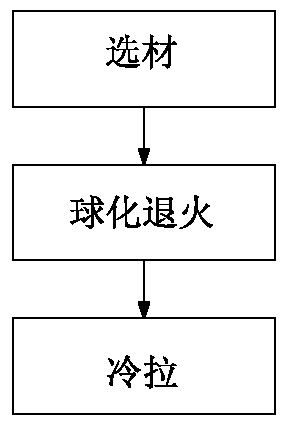

Production process of tiny chamfering special-shaped line for precise products

A production process and special-shaped wire technology, applied in wire drawing dies and other directions, can solve the problems of large chamfer size, incomplete sharp corners, irregular shapes, etc., and achieve the effects of high plastic deformation capacity, uniform grains, and considerable economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Material selection: Select carbon structural steel material, its chemical composition contains: 0.08% C, 0.20% Si, 0.35% Mn, 0.020% P, 0.028% S, and the rest is Fe.

[0023] (2) Spheroidizing annealing: Put the carbon structural steel material into the atmosphere protection furnace, add a protection atmosphere in the atmosphere protection furnace, raise the temperature to 20°C above the austenite transformation temperature, keep it for 4 hours, and then heat it at 10°C / Hours slowly cooled to 20°C below the austenite transformation temperature, kept for 3 hours, and then cooled with the furnace until it came out of the furnace. The protective atmosphere is methanol, and the flow rate of methanol gas is 2L / min.

[0024] (3) Cold drawing: use a wire drawing machine to draw carbon structural steel materials, select a wire drawing die, the working cone angle of the wire drawing die is 8°, the sizing length is 3 mm, and the rounded corner of the die is 0.1 mm. The princ...

Embodiment 2

[0027] (1) Material selection: Select carbon structural steel material, its chemical composition contains: 0.11% C, 0.29% Si, 0.45% Mn, 0.034% P, 0.038% S, and the rest is Fe.

[0028] (2) Spheroidizing annealing: Put the carbon structural steel material into the atmosphere protection furnace, add a protection atmosphere in the atmosphere protection furnace, raise the temperature to 30°C above the austenite transformation temperature, keep it for 6 hours, and then heat it at 10°C / Slowly cool within 1 hour to 30°C below the austenite transformation temperature, keep the temperature for 4 hours, and then cool with the furnace until it comes out of the furnace. The protective atmosphere is methanol, and the flow rate of methanol gas is 2L / min.

[0029] (3) Cold drawing: use a wire drawing machine to draw carbon structural steel materials, select a wire drawing die, the working cone angle of the wire drawing die is 8°, the sizing length is 3 mm, and the rounded corner of the die ...

Embodiment 3

[0032](1) Material selection: Select carbon structural steel material, its chemical composition contains: 0.095% C, 0.25% Si, 0.41% Mn, 0.028% P, 0.032% S, and the rest is Fe.

[0033] (2) Spheroidizing annealing: Put the carbon structural steel material into the atmosphere protection furnace, add a protection atmosphere in the atmosphere protection furnace, raise the temperature to 26°C above the austenite transformation temperature, keep it for 5 hours, and then heat it at 10°C / Hours slowly cooled to 25°C below the austenite transformation temperature, kept for 3.5 hours, and then cooled with the furnace until it came out of the furnace. The protective atmosphere is methanol, and the flow rate of methanol gas is 2L / min.

[0034] (3) Cold drawing: use a wire drawing machine to draw carbon structural steel materials, select a wire drawing die, the working cone angle of the wire drawing die is 8°, the sizing length is 3 mm, and the rounded corner of the die is 0.1 mm. The pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com