Production method of railway wheels

A technology for wheels and railways, applied in the manufacture of tools, heat treatment equipment, furnaces, etc., can solve the problems of increased tool consumption, contact fatigue damage, accelerated early peeling, etc., and achieves reduced finishing tool consumption, good high-hardness tissue state, The effect of good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

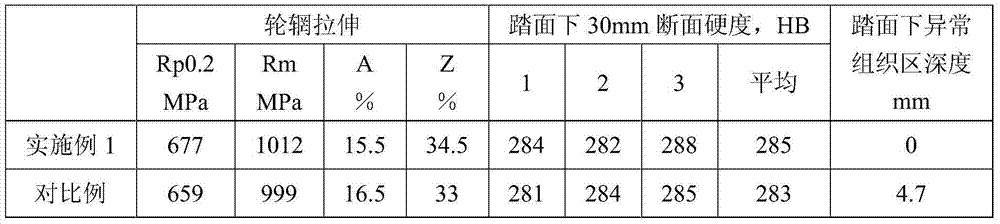

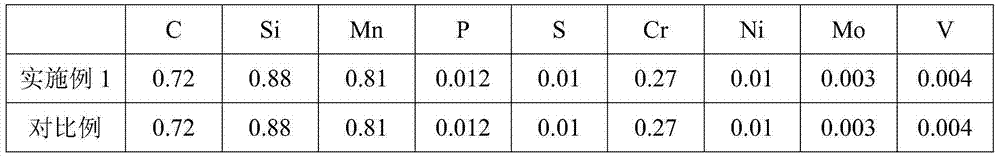

[0027] The wheels of Example 1 and Comparative Example are of the same furnace number, and the chemical composition of the wheel steel is shown in Table 1.

[0028] Table 1 Example 1 and comparative example wheel chemical composition (mass percentage, wt%)

[0029]

C

Si

mn

P

S

Cr

Ni

Mo

V

Example 1

0.57

0.29

0.73

0.01

0.004

0.18

0.01

0.01

0.002

comparative example

0.57

0.29

0.73

0.01

0.004

0.18

0.01

0.01

0.002

[0030] The wheel steel continuous casting round billet with the composition shown in Table 1 was cut according to the same process (due to the cancellation of the rough machining process, the weight of the wheel in Example 1 is slightly smaller than that of the comparative wheel), billet heating, forming, rolling and slow cooling treatment ;Example 1 does not carry out rough machining, and the comparative wheel is rough machined, an...

Embodiment 2

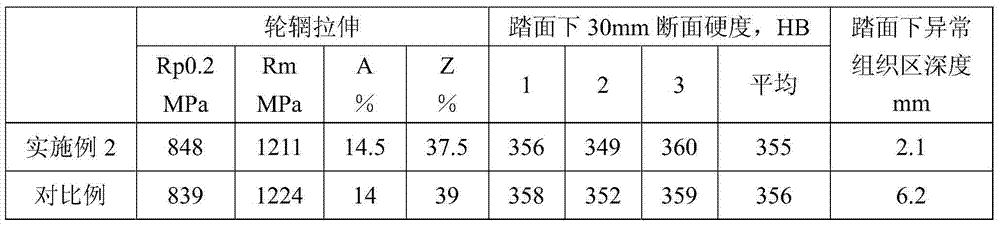

[0034] The wheels of Example 2 and Comparative Example are of the same furnace number, and the chemical composition of the wheel steel is shown in Table 3.

[0035] Table 3 Example 2 and comparative example wheel chemical composition (mass percentage, wt%)

[0036]

[0037] The wheel steel continuous casting round billet with the composition shown in Table 3 was cut according to the same process (due to the cancellation of the rough machining process, the feed weight of the wheel in Example 2 is slightly smaller than that of the comparative wheel), billet heating, forming, rolling and slow cooling treatment ;Example 2 does not carry out rough machining, rough machining is carried out for the comparative example, and the tread rough machining allowance is 3.0 mm; the wheel of embodiment 2 and the comparative example wheel are heated according to the same quenching heating process, the quenching heating target temperature is 860 ° C, and the heating time is 3.0 hours ; After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com