Sintered diamond circular saw blade machining process

A processing technology and circular saw blade technology, which is applied in the field of sintered diamond circular saw blade processing technology, can solve the problems that the accuracy of the center hole of the substrate cannot be guaranteed, and the inner hole becomes smaller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

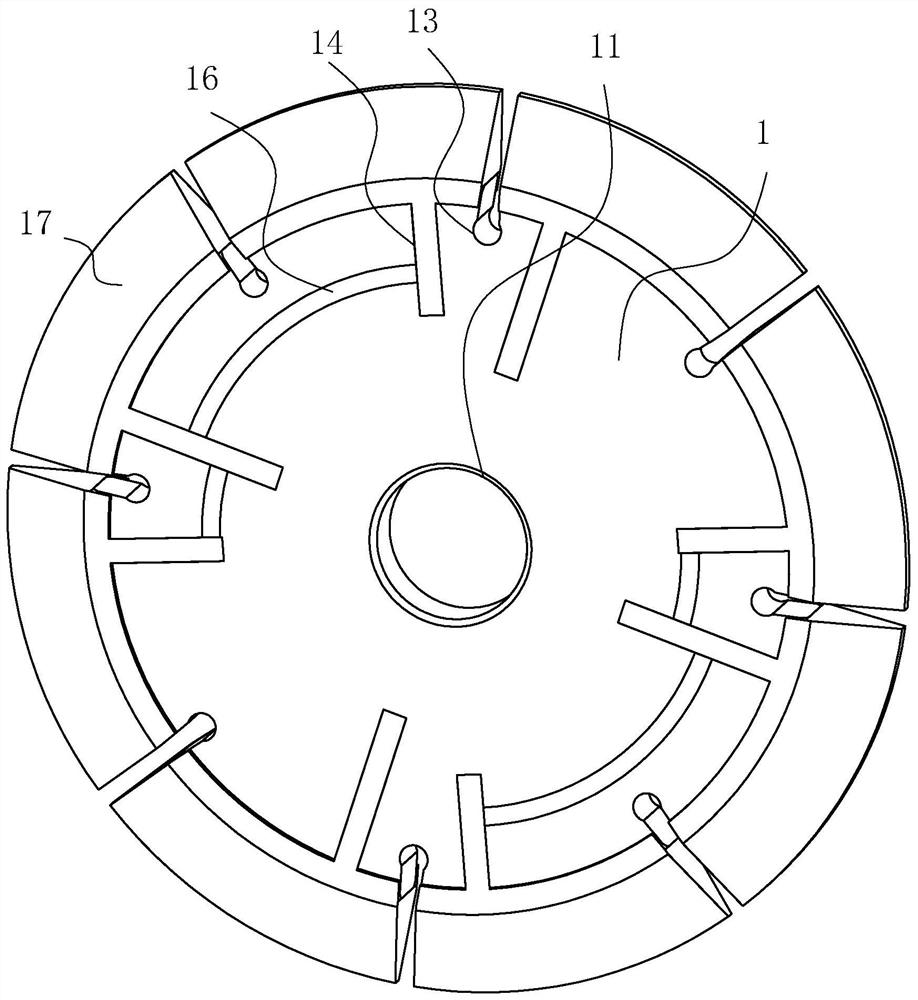

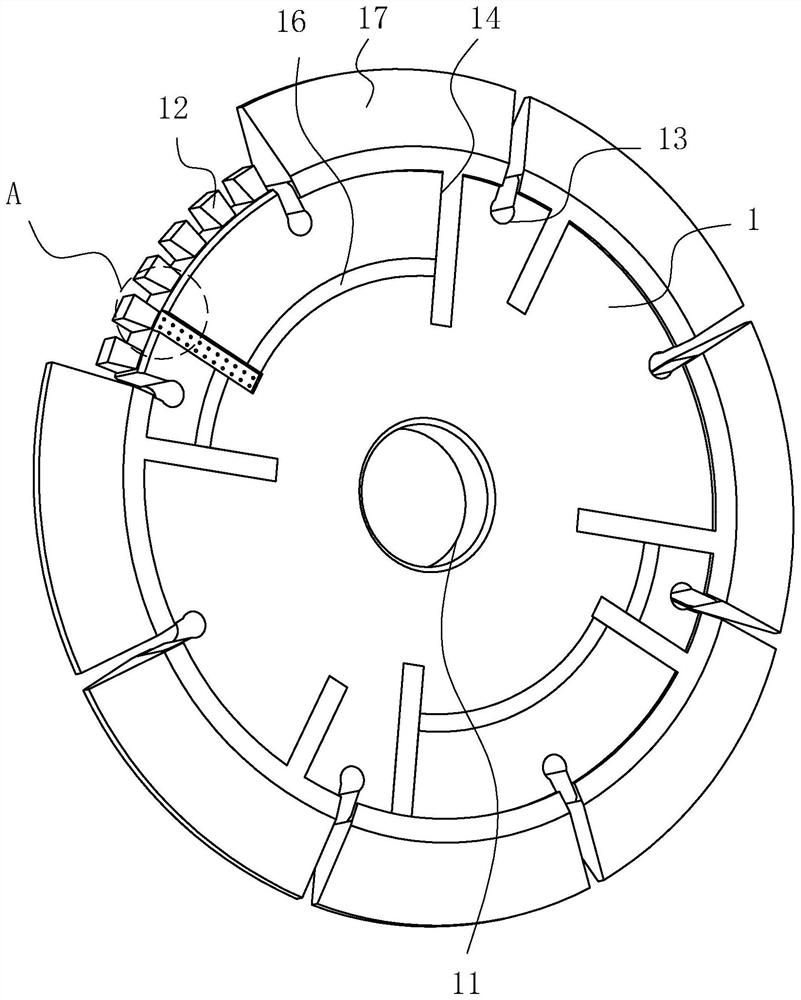

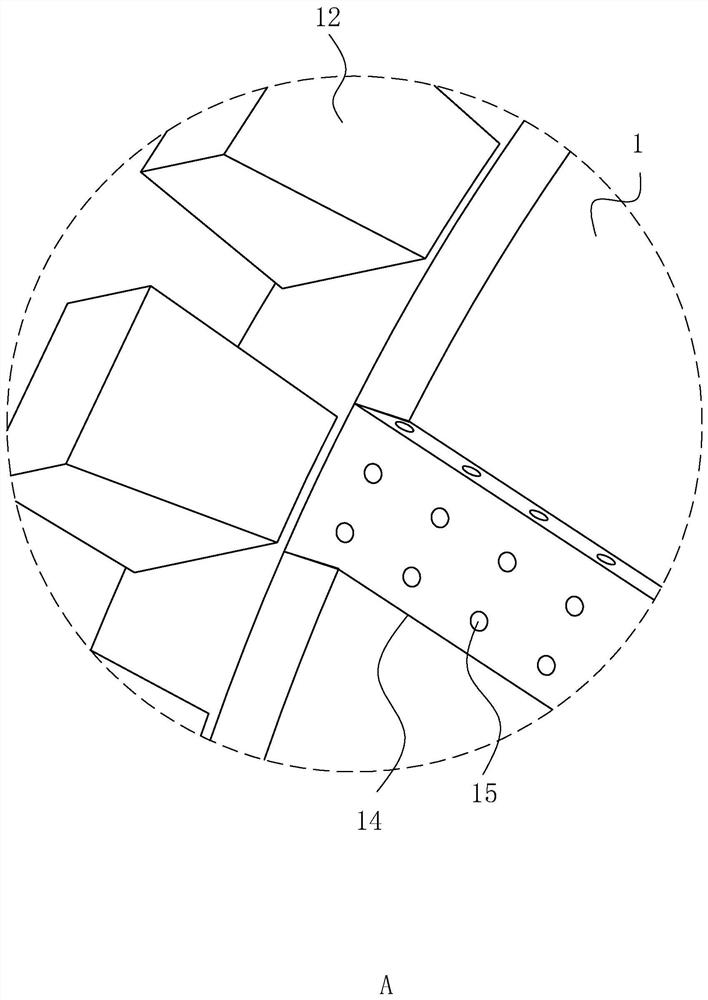

[0044] The embodiment of the present application discloses a process for processing a sintered diamond circular saw blade. refer to figure 1 and figure 2 , a sintered diamond circular saw blade processing technology includes the following steps:

[0045] S1: The steel strip passes through the punch press to stamp the primary center hole, sawtooth, and process hole. The diameter of the primary center hole is smaller than the design diameter of the product center hole, and the diameter of the primary center hole is 2mm smaller than the design diameter of the product center hole. The thickness of the substrate is 2mm. The diameter is 250mm. Afterwards, there are reinforcement grooves on both sides of the substrate. The reinforcement grooves extend from the edge of the substrate to the center of the substrate. The depth of the reinforcement grooves is 1 / 5 of the thickness of the substrate. All reinforcement grooves on both sides of the substrate Interlaced with each other, any ...

Embodiment 2

[0050] The difference with Example 1 is:

[0051] A kind of sintered diamond circular saw blade processing technology comprises the following steps:

[0052] A1: Leveling, check the flatness and stress of the substrate obtained in S1, when the flatness of the substrate is greater than 0.9mm or the stress is greater than 0.4mm, perform the pre-processing step, otherwise do not perform the pre-processing step and directly perform S2; pre-processing step Including, while flattening the substrate (flattening pressure 80KN), keep warm at 800°C for 14h;

[0053] S2: The diamond powder is pressure-formed in the position of the cutter head and the reinforcement groove of the machine body. The diamond powder is the same as in Example 1. The pressure of the pressure forming is 155 tons, and the time is 3 seconds to obtain the initially formed circular saw blade;

[0054] S3: Pressurize and sinter the initially formed circular saw blade. The pressure and sintering pressure is 140KN, the...

Embodiment 3

[0056] The difference with Example 1 is:

[0057] A kind of sintered diamond circular saw blade processing technology comprises the following steps:

[0058] A1: Leveling, check the flatness and stress of the substrate obtained in S1, when the flatness of the substrate is greater than 0.9mm or the stress is greater than 0.4mm, perform the pre-processing step, otherwise do not perform the pre-processing step and directly perform S2; pre-processing step Including, while flattening the substrate (flattening pressure 100KN), keep warm at 850°C for 12-18h;

[0059] S2: The diamond powder is pressure-formed at the position of the cutter head and the reinforcement groove of the machine body. The diamond powder is the same as in Example 1. The pressure of the pressure-forming is 160 tons, and the time is 5 seconds to obtain the initially formed circular saw blade;

[0060] S3: Pressurize and sinter the initially formed circular saw blade. The pressure and sintered pressure is 200KN, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com