A Forging Method of R5 Mooring Chain Attachment Rotary Shackle

A mooring chain and accessory technology, which is applied to engine components, mechanical equipment, etc., can solve the problems of difficult forging, high strength, and large volume of rotating shackles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

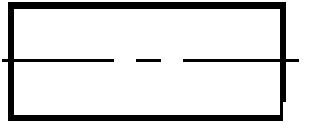

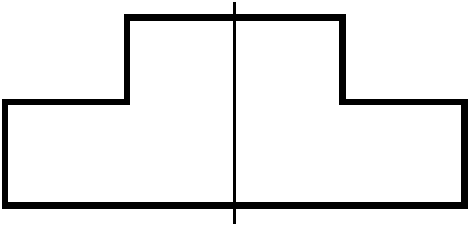

[0011] A method for forging a rotary shackle for an R5 grade mooring chain accessory, characterized in that blanking is performed on raw materials according to the diameter and length dimensions specified in the design drawings, and the blanking length tolerance is ±1mm; The non-destructive testing of the material is carried out by the instrument; the heating is carried out in the box-type reverberatory furnace, and there must be no overheating or over-burning surface quality defects; When thick, there should be no interlayer and crack defects; use a 3-ton belt hammer to forge both ends of the cuboid forging into steps, and there should be no interlayer, crack, groove and other defects that reduce product performance during forging; put the forging into the forming die , with a 3-ton belt hammer, forging and forming, there must be no interlayers, cracks, grooves and other defects that reduce product performance during forging; tempering, put the forgings in the tempering furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com