Fiber-shaped flexible electrochromic device and preparation method thereof

An electrochromic layer and flexible electricity technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of difficult packaging of devices, electrolyte leakage, slow discoloration speed, etc., to reduce complexity, reduce manufacturing costs, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

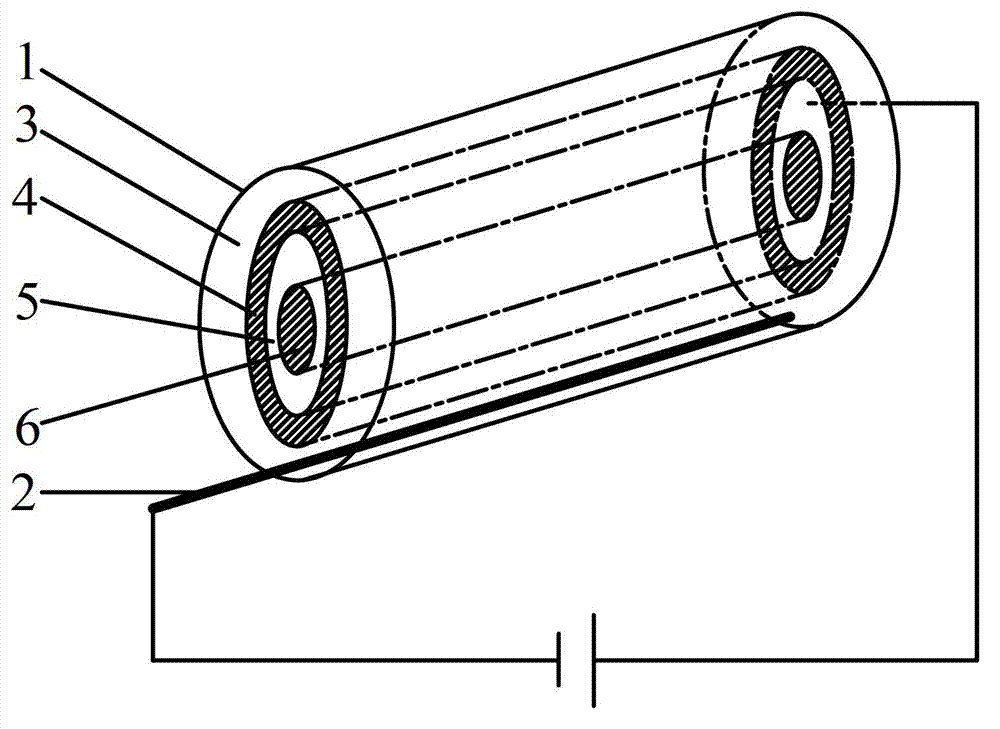

[0028] The fibrous flexible electrochromic device of this embodiment includes a core material 6, the outer surface of the core material 6 is provided with a transparent conductive layer 5, and the outer surface of the transparent conductive layer 5 is provided with an electrochromic layer 4, so The outer surface of the electrochromic layer 4 is provided with a polyelectrolyte layer 3, the outer surface of the polyelectrolyte layer 3 is provided with a transparent polymer protective layer 1, and the polyelectrolyte layer 3 is provided with a layer parallel to the core material 6. The silver wire counter electrode 2.

[0029] The preparation method of the fibrous flexible electrochromic device of this embodiment comprises the following steps:

[0030] Step 1, using a mass concentration of 5% surfactant and deionized water to clean the surface of the core material 6 successively, then drying the cleaned core material 6, and applying thermal evaporation to the outer surface of the...

Embodiment 2

[0036] The fibrous flexible electrochromic device of this embodiment includes a core material 6, the outer surface of the core material 6 is provided with a transparent conductive layer 5, and the outer surface of the transparent conductive layer 5 is provided with an electrochromic layer 4, so The outer surface of the electrochromic layer 4 is provided with a polyelectrolyte layer 3, the outer surface of the polyelectrolyte layer 3 is provided with a transparent polymer protective layer 1, and the polyelectrolyte layer 3 is provided with a layer parallel to the core material 6. The silver wire counter electrode 2.

[0037] The preparation method of the fibrous flexible electrochromic device of this embodiment comprises the following steps:

[0038] Step 1. Use a surfactant with a mass concentration of 3% and deionized water to clean the surface of the core material 6 in sequence, then dry the cleaned core material 6, and then use a thermal evaporation method to form on the su...

Embodiment 3

[0044] The fibrous flexible electrochromic device of this embodiment includes a core material 6, the outer surface of the core material 6 is provided with a transparent conductive layer 5, and the outer surface of the transparent conductive layer 5 is provided with an electrochromic layer 4, so The outer surface of the electrochromic layer 4 is provided with a polyelectrolyte layer 3, the outer surface of the polyelectrolyte layer 3 is provided with a transparent polymer protective layer 1, and the polyelectrolyte layer 3 is provided with a layer parallel to the core material 6. The silver wire counter electrode 2.

[0045] The preparation method of the fibrous flexible electrochromic device of this embodiment comprises the following steps:

[0046] Step 1, using a surfactant with a mass concentration of 4% and deionized water to clean the surface of the core material 6 in sequence, then drying the cleaned core material 6, and then using the ion sputtering method to form on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com