Patents

Literature

32results about How to "Change distribution status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

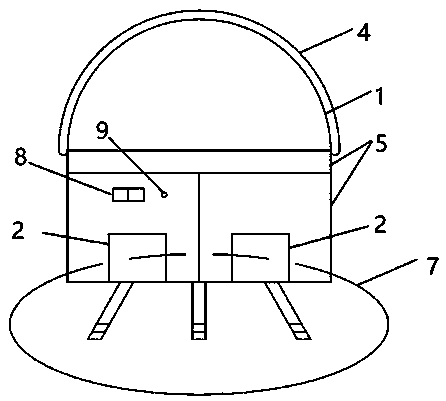

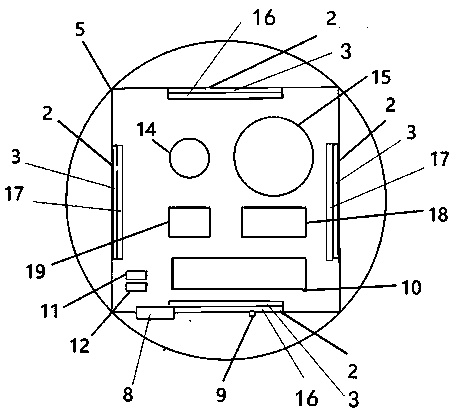

Inflatable automobile

ActiveCN101758865ALift cancellationEliminate lift dragVehicle body stabilisationAtmospheric pressurePedestrian

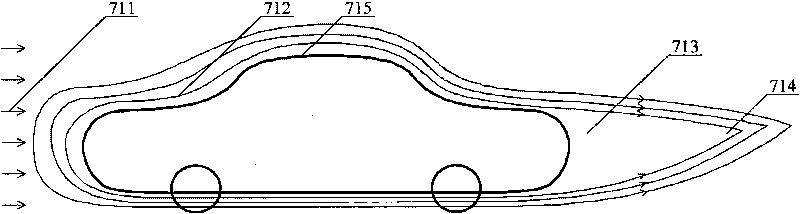

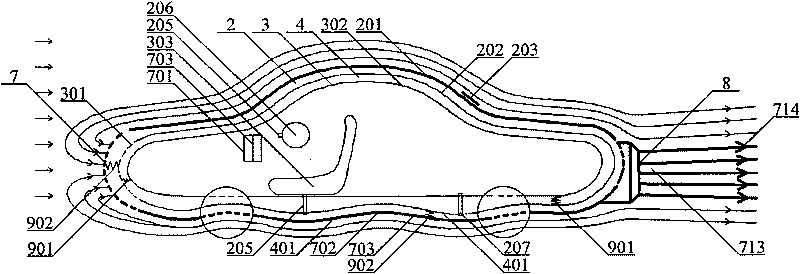

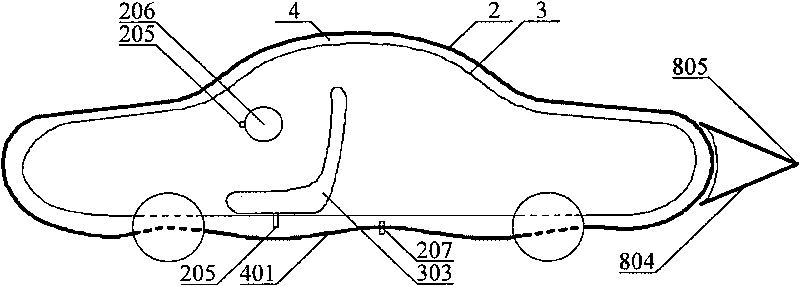

The invention provides an inflatable automobile which is characterized in that the lift force is eliminated by changing the fluid distribution state between the upper part and the lower part of an automobile to change the traditional method that the automobile overcomes the lift force by the weight in hundred years, and therefore, the weight factor does not need to be considered. The bodywork of the automobile is made of light materials; for example, the inflatable layer of the inflatable automobile can be integral or local and can be an outer layer or an inner layer, and meanwhile, a lead-in opening is communicated with a fluid passage, which can greatly reduce the fluid resistance when the automobile runs. In the inflatable automobile which is the lightest in the world, due to the fact that a path through which the fluid of the lower part of the automobile flows is longer than the upper part, and thereby, the pressure of the upper part of the automobile is slightly higher than that of the lower part, and like an invisible hand stably presses the shell of the upper part of the automobile; and compared with the traditional automobiles, the inflatable automobile is more stable and saves more energy when running at high speed. Because the bodywork is the inflatable layer, when an accident happens unfortunately, the self safety is ensured, and meanwhile, the safety of hit automobiles or pedestrians is also increased, the inflatable automobile saves the most energy in the world and is extremely safe.

Owner:朱晓义

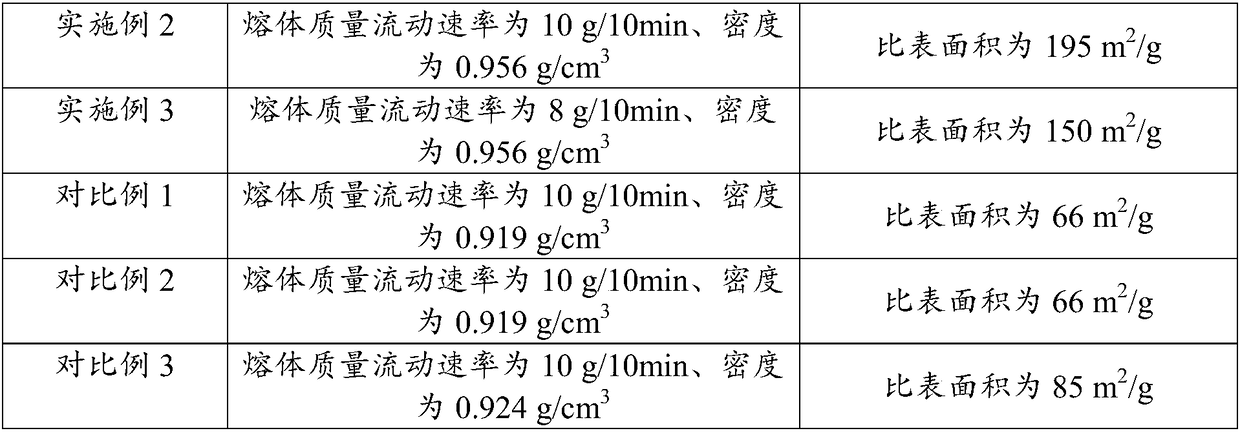

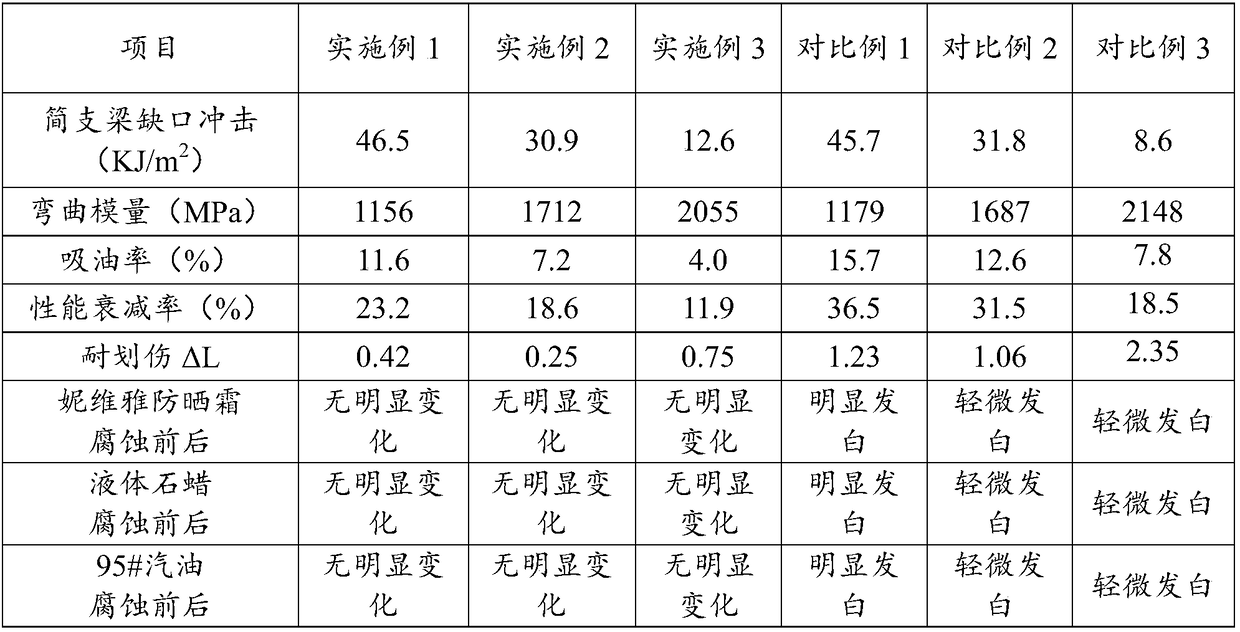

Chemical-resistant and scratch-resistant polypropylene composite material and preparation method thereof

ActiveCN108373565AGood chemical resistanceImprove scratch resistancePolypropylene compositesPolymer science

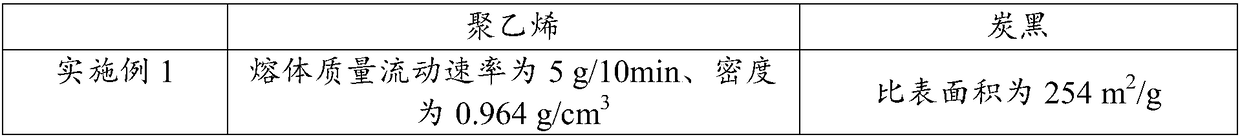

The invention discloses a chemical-resistant and scratch-resistant polypropylene composite material which is prepared from the following ingredients in parts by weight: 55 to 80 parts of polypropylene, 8 to 12 parts of polyethylene and 0.5 to 2 parts of carbon black, wherein the polyethylene is at least one of extrusion-grade high-density polyethylene and injection-molding-grade high-density polyethylene, the density of the polyethylene is 0.948 to 0.965g / cm<3>, and the melt mass flow rate of the polyethylene is 0.1 to 12g / 10min. In the polypropylene composite material disclosed by the invention, all the ingredients and contents interact with each other; meanwhile, the polyethylene and the carbon black are reasonably chosen, so that the polypropylene composite material has good comprehensive performance of chemical resistance and scratch resistance, keeps very good mechanical property at the same time and is especially suitable for being applied to automotive upholsteries. Meanwhile, the invention further discloses a preparation method of the chemical-resistant and scratch-resistant polypropylene composite material.

Owner:KINGFA SCI & TECH CO LTD

Forging technology for abnormal structure of TC18 titanium alloy raw material

ActiveCN105441845AChange distribution statusWell organizedHeating/cooling devicesPhase changeTitanium alloy

The invention belongs to the technical field of forging technologies, and discloses a forging technology for an abnormal structure of a TC18 titanium alloy raw material. The forging technology comprises the following steps: a, carrying out beta forging above a phase change point on blanks by 1-2 fire, wherein forging temperature is 15-30 DEG C above the phase change point, and deformation is controlled to be between 20% and 40%; b, carrying out forging below the phase change point on the blanks by more than 2 fire, wherein the forging temperature is 20-40 DEG C below the phase change point, and the deformation is controlled to be between 15% and 30%; and c, carrying out beta forging above the phase change point on the blanks by 1 fire, wherein the forging temperature is 10-20 DEG C above the phase change point, and the deformation is controlled to be 15% and 25%. By the technology, the structure defect of fine-crystal bright bands can be avoided effectively, and TC18 titanium alloy free forge pieces can be produced in batches.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

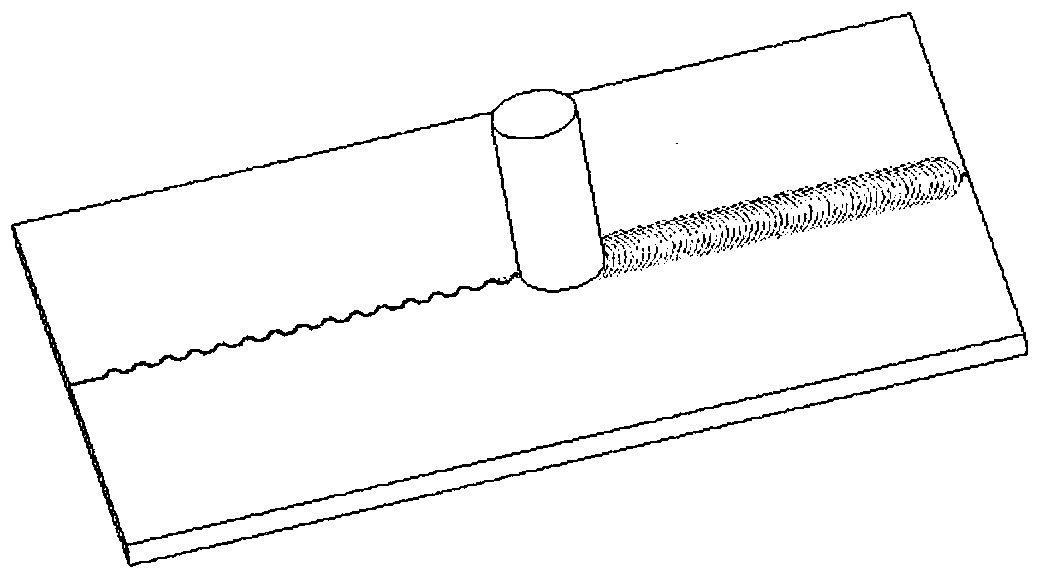

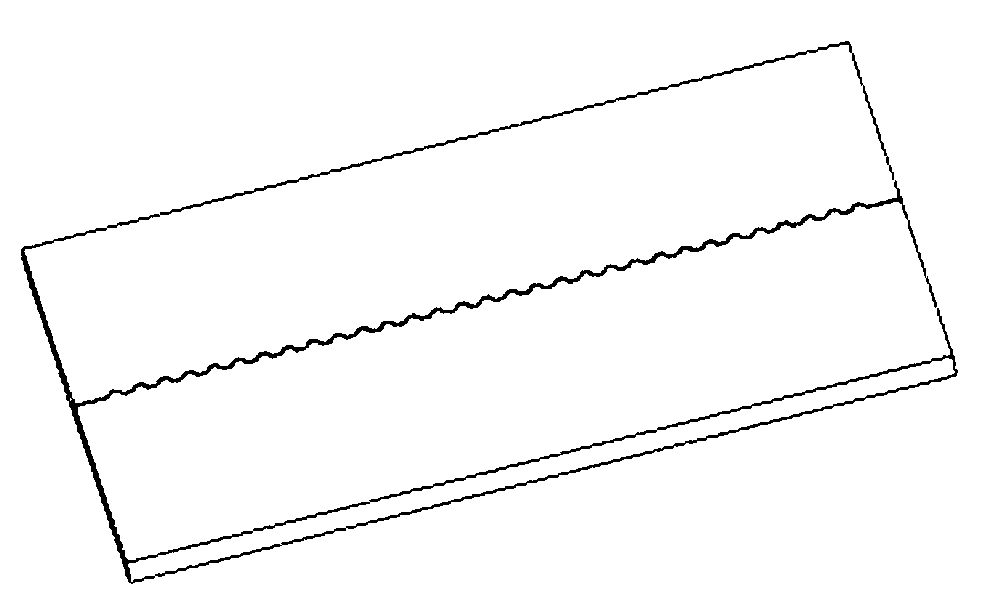

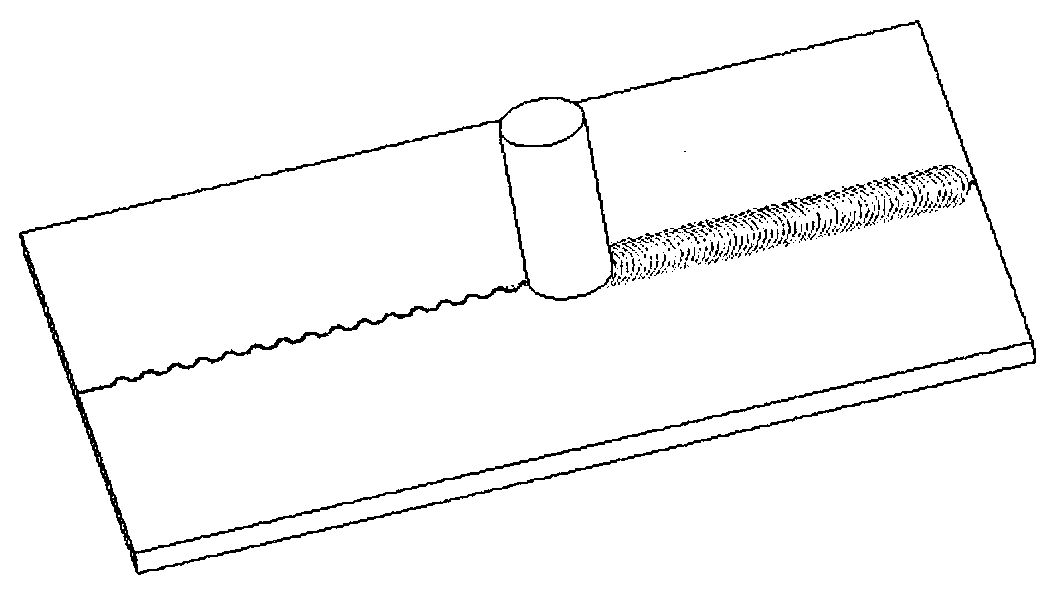

Method for improving quality of Al-Cu dissimilar metal friction stir welding butt joint

ActiveCN108620762AWell formed weldIncreased metal mixingWelding/soldering/cutting articlesWorkpiece edge portionsEngineeringWeld seam

The invention discloses a method for improving the quality of an Al-Cu dissimilar metal friction stir welding butt joint. The method specifically comprises the steps that the edges of butt-joint sidesof an aluminum welding part and a copper welding part used for welding are firstly machined into engaged sawtooth sides, then the welding parts on the two sides are in butt joint along the sawtooth sides, and then friction stir welding is carried out. The treatment method is simple, only simple machining is needed, and cost is low; welding seam forming of Al-Cu dissimilar metal friction stir welding can be obviously improved, and the metal mixing degree and the plastic flow behavior of Al-Cu dissimilar metal in the welding process are improved; and meanwhile, the area of an Al-Cu welding interface is increased, the bearing capacity of the joint is increased, the distribution state of a brittle IMC along the interface is changed, and the mechanical performance of the joint is obviously improved.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

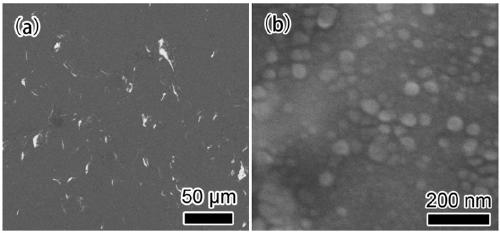

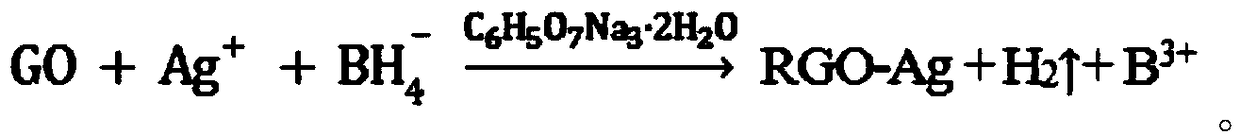

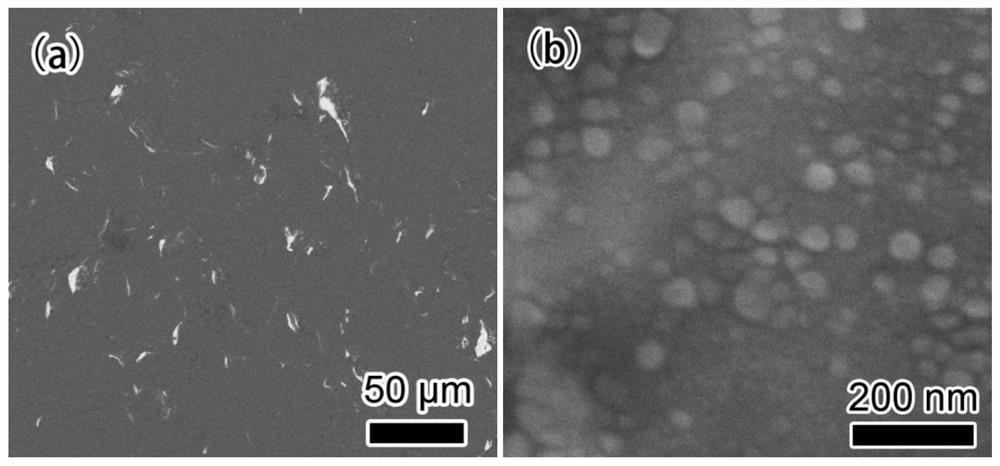

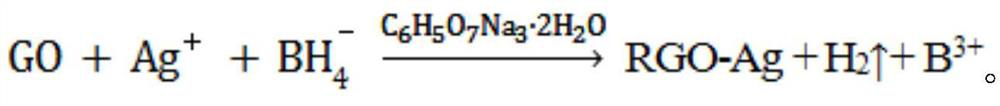

Preparation method of corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating

ActiveCN109207984AChange distribution statusDoes not change the microstructurePressure inorganic powder coatingChemical reactionStress relief

The invention belongs to the field of composite coating preparation, and particularly relates to a preparation method of a corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating. Through the method, firstly, nano-silver is formed on a graphene oxide-OH functional group through a chemical reaction in an in-situ synthesis mode, and graphene / nano-silver composite powder is obtained through reduction; secondly, the graphene / nano-silver composite powder and metal powder are ball-milled, metal / graphene / nano-silver composite powder is formed, and then stress relief annealing is conducted under inert gas protection; and finally, the composite powder is deposited into the protective coating through a cold spraying technology. Through the method, by adjusting the chemical reaction conditions, the particle size distribution of the metal powder, the weight ratio of metal / graphene / nano-silver and the ball-milling time, the distribution state of the graphene / nano-silver in the metal-based composite coating is changed, and thus the multifunctional metal-based protective coating with good corrosion resistance, antimicrobial property and biofouling property is prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

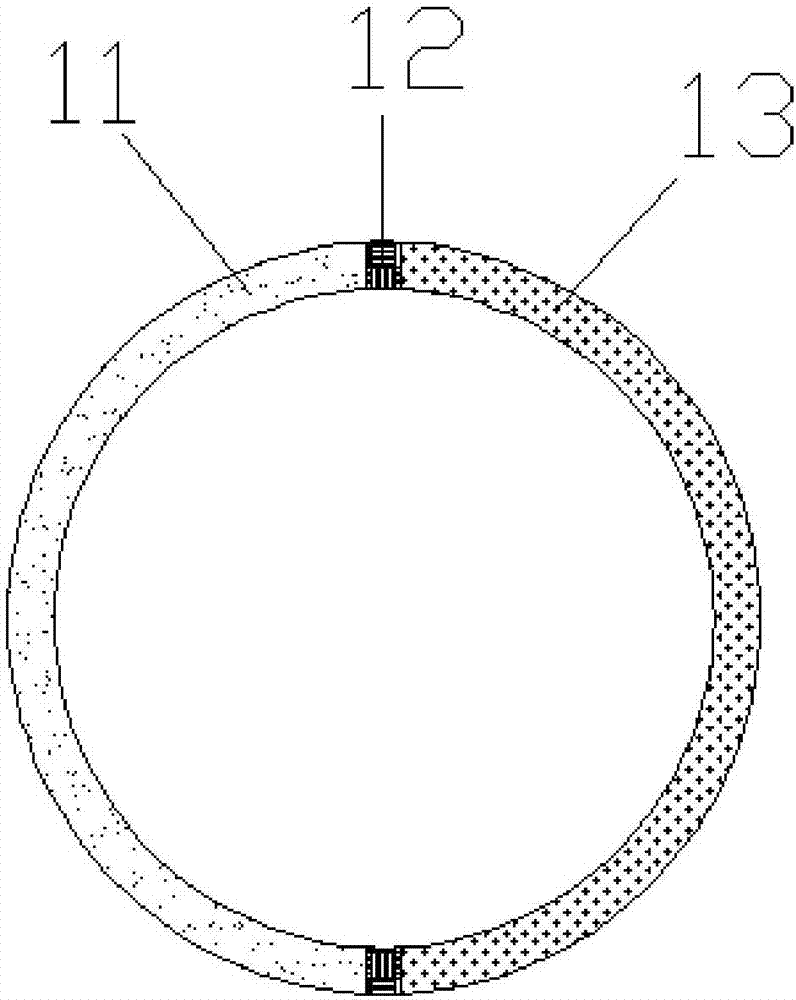

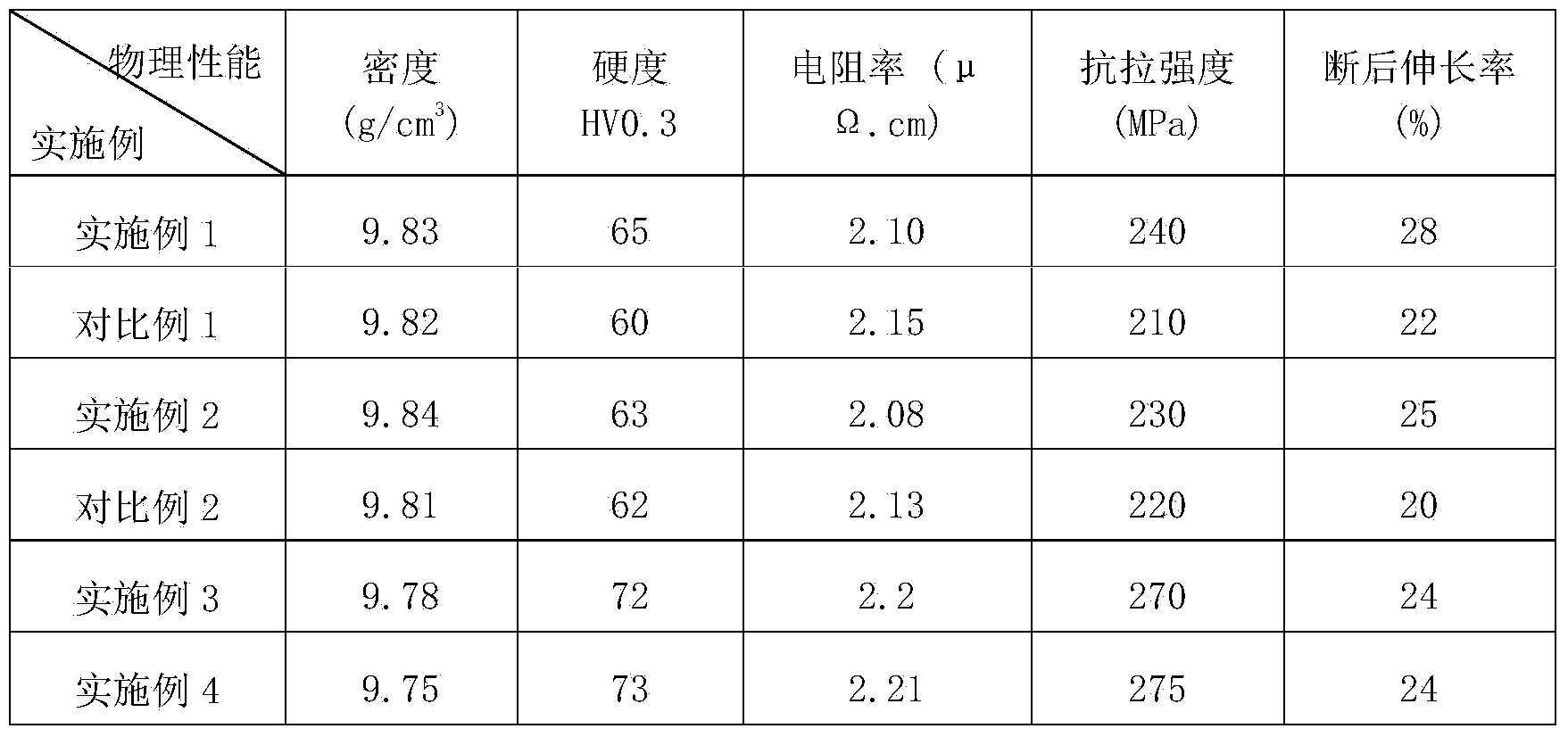

Composite CuNiIn powder, preparation method and application thereof

ActiveCN108425085AHigh strengthImprove the binding effectMolten spray coatingTransportation and packagingThermal sprayingUltimate tensile strength

The invention discloses composite CuNiIn powder, a preparation method and an application thereof. The composite CuNiIn powder comprises a dispersion strengthening phase and a self-lubricating phase. The preparation method comprises the following steps that ball milling and mixing on In powder, nickel-coated molybdenum disulfide powder and A12O3 dispersion strengthening Cu powder are carried out soas to prepare mixed raw materials; a spray drying granulator is adopted to carry out centrifugal atomization granulation on the mixed raw materials to prepare dried granules; and vacuum sintering iscarried out on the dried particles, and then the dried particles are crushed and screened to obtain the composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing the dispersion strengthening phase and the self-lubricating phase by adopting a thermal spraying method. The distribution state of the self-lubricating phase is changed, the strength and the toughness of the coating are improved, the generation of micro-cracks of the coating is effectively avoided, the self-lubricating service life of the coating is prolonged, and the composite CuNiIn powder has a good application value in the industries of aviation engines, gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

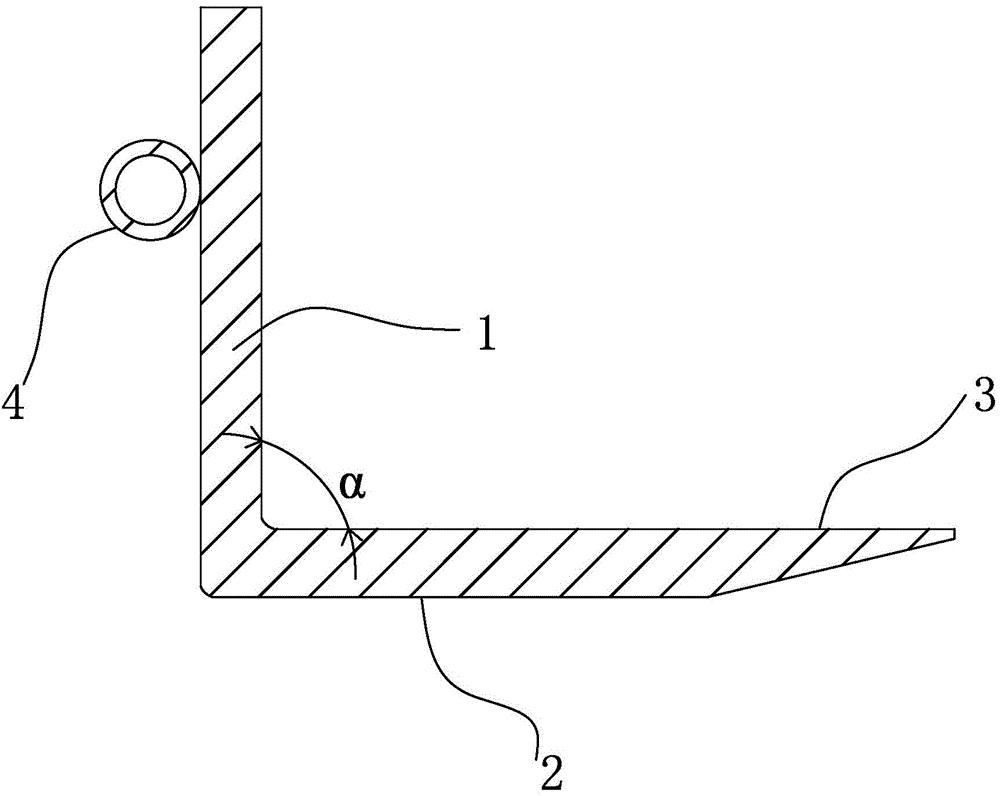

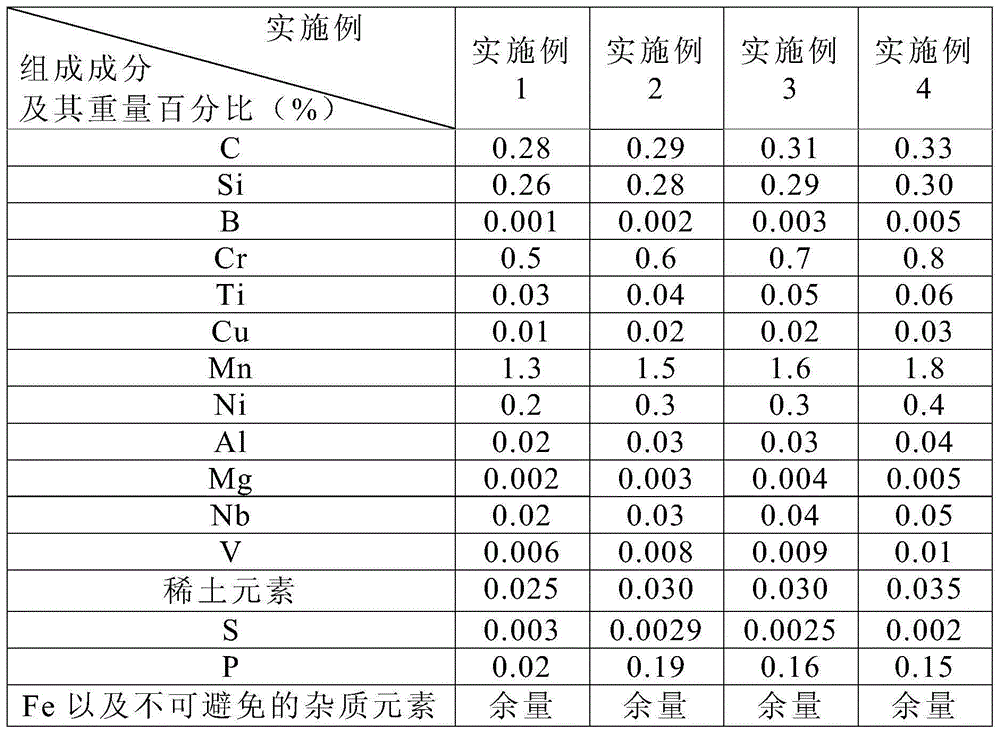

Forklift fork and preparation method thereof

InactiveCN104555826AImprove performanceChange shapeLifting devicesRare-earth elementMedium frequency

The invention discloses a forklift fork, which comprises a vertical part, a horizontal part and a fork tooth arranged at the front end of the horizontal part, the forklift fork is made of steel material, and the steel material is mainly composed of C, Si, B, Cr, Ti, Cu, Mn, Ni, Al, Mg, Nb, V, rare-earth elements, S, P, the balance of Fe and inevitable impurities. A preparation method of the forklift fork includes the following steps: the materials are first prepared into the steel meeting requirement, a needed section is then cut out, so that a rough blank I is obtained, the rough blank I then undergoes medium-frequency heating pretreatment and is then bent into the vertical part and the horizontal part of the forklift fork until an included angle Alpha is formed between the vertical part and the horizontal part of the forklift fork, and after back sawing, head cutting, sleeve welding, grinding, ultrasonic flaw detection, heat treatment, primary shot-blasting grinding, corrective grinding and secondary shot-blasting grinding, the forklift fork is obtained. The properties of the forklift fork produced by the invention, such as strength, toughness, wear resistance and weldability, are good, the safety coefficient is high, and the service life is long.

Owner:NINGBO RENBA FORK

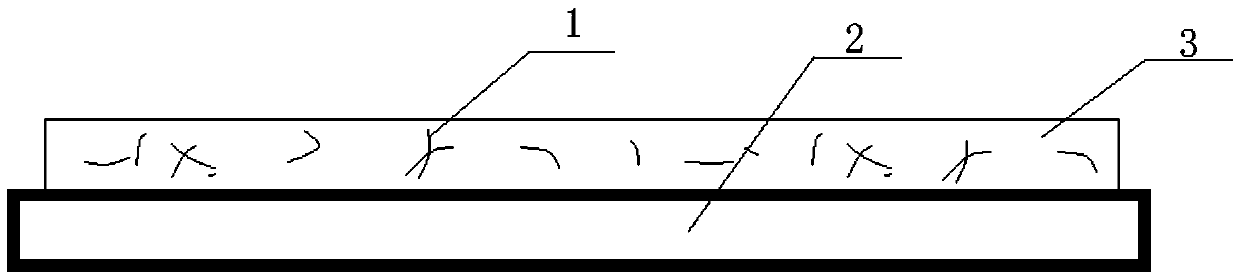

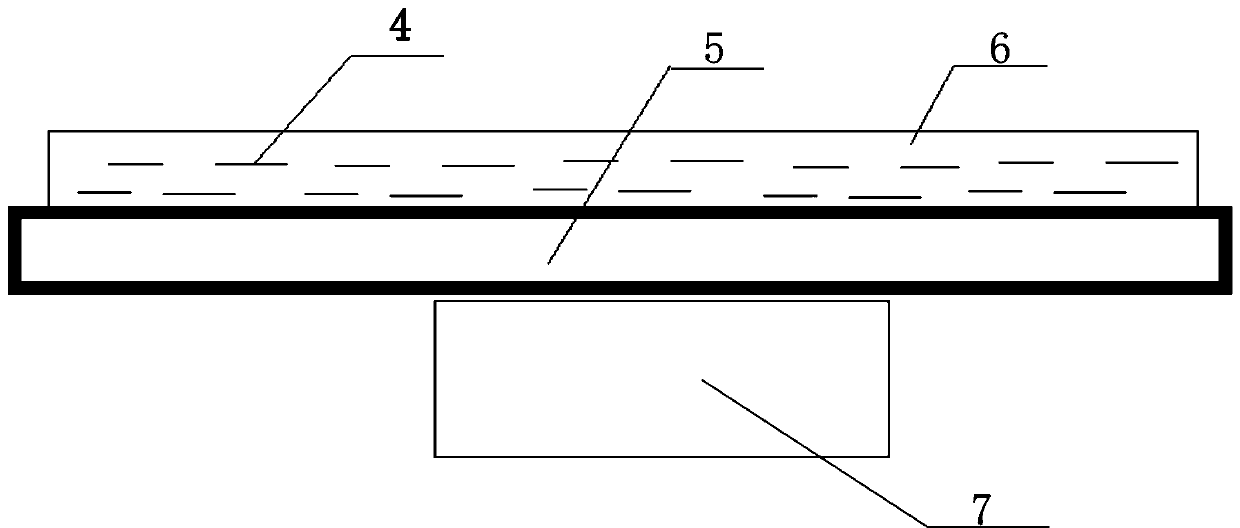

Spraying method of graphene coating

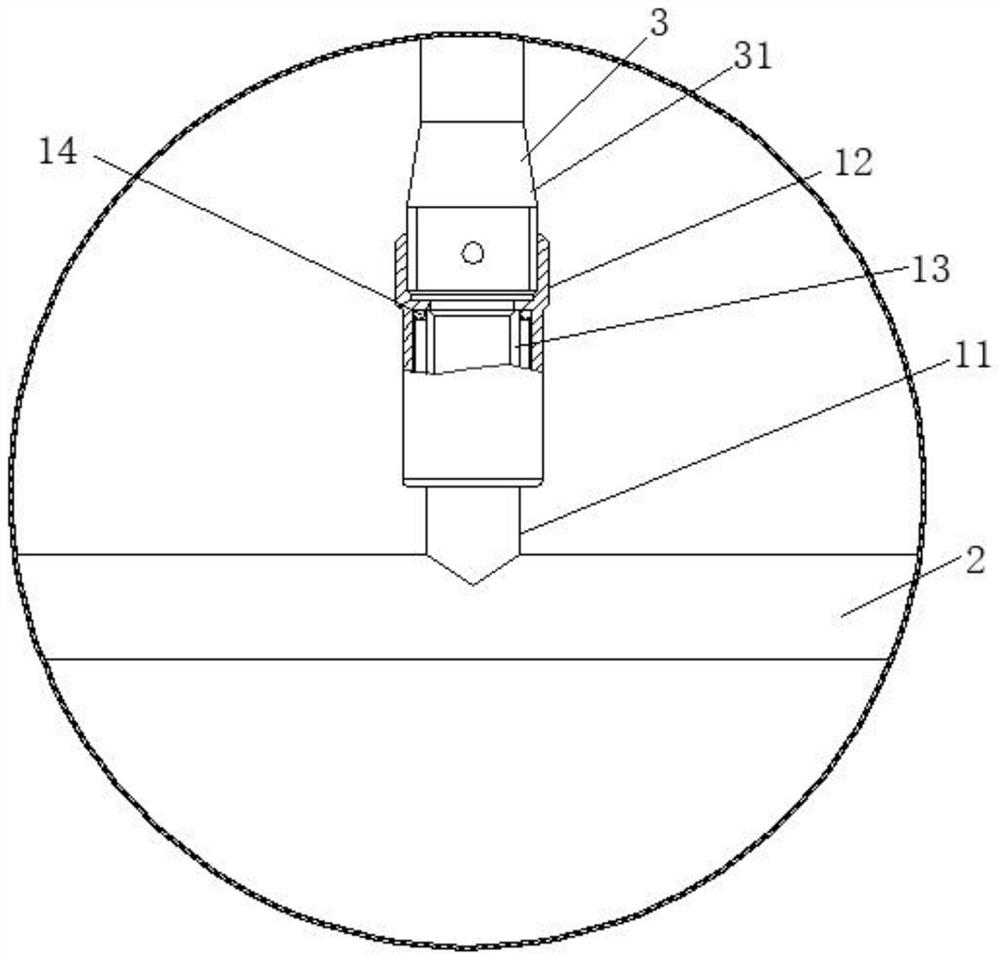

InactiveCN107812679AChange distribution statusImprove anti-corrosion performancePretreated surfacesAnti-corrosive paintsGraphene coatingViscous flow

The invention discloses a spraying method of a graphene coating, and relates to the spraying method of coatings. The spraying method comprises the specific steps that an ultrasonic vibration source 7is arranged on a to-be-sprayed workpiece B5, and ultrasonic frequency is 30 KHz to 1000 KHz; after the step, the graphene coating is uniformly sprayed to the surface of the workpiece B5, the ultrasonic vibration source 7 vibrates for 20 min to 30 min, and a coating layer B6 is waited to be dried; and the graphene coating is generally dried. According to the spraying method, during the spraying process, ultrasonic vibration energy is applied to the sprayed workpiece, graphene microchips in the coating in a viscous flow state are gradually extended and are spread on the surface of the workpieceunder action of ultrasonic vibration, the distribution state of the graphene microchips of the coating is changed, and corrosion resistance is improved.

Owner:洛阳菁洲纳米科技有限公司

Extrusion molding processing equipment and processing technology for outer sheath of electric wire and cable

ActiveCN113074520AEasy dischargeAvoid accumulation inside the cable jacketDrying solid materials without heatDrying gas arrangementsCold airEngineering

The invention relates to extrusion molding processing equipment and processing technology for an outer sheath of an electric wire and cable. The extrusion molding processing equipment comprises a bottom plate, a spin-drying device and a draining device, wherein the spin-drying device is installed on the bottom plate, and the draining device is installed in the spin-drying device. The process for carrying out extrusion molding processing on the outer sheath of the electric wire and cable by using the processing equipment specifically comprises the following steps of extrusion molding, water cooling, fixed-length cutting, spin-drying and draining, and cold air drying. Through joint cooperation of the spin-drying device and the draining device, spin-drying and draining treatment work of the cable sheaths is completed; a plurality of placing frames are arranged in the spin-drying device, so that gaps between the cable sheaths are large, drainage of water is facilitated; and by changing the relative positions of a draining barrel and the placing frames, the shape of the cable sheath in the spin-drying process can be adjusted, and the situation that water is accumulated in the cable sheath is avoided.

Owner:揭西县锦生电线电缆实业有限公司

Preparation method of corrosion-resistant, antibacterial, anti-biofouling and multifunctional metal-based protective coating

ActiveCN109207984BChange distribution statusDoes not change the microstructurePressure inorganic powder coatingChemical reactionBiofouling

The invention belongs to the field of composite coating preparation, and particularly relates to a preparation method of a corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating. Through the method, firstly, nano-silver is formed on a graphene oxide-OH functional group through a chemical reaction in an in-situ synthesis mode, and graphene / nano-silver composite powder is obtained through reduction; secondly, the graphene / nano-silver composite powder and metal powder are ball-milled, metal / graphene / nano-silver composite powder is formed, and then stress relief annealing is conducted under inert gas protection; and finally, the composite powder is deposited into the protective coating through a cold spraying technology. Through the method, by adjusting the chemical reaction conditions, the particle size distribution of the metal powder, the weight ratio of metal / graphene / nano-silver and the ball-milling time, the distribution state of the graphene / nano-silver in the metal-based composite coating is changed, and thus the multifunctional metal-based protective coating with good corrosion resistance, antimicrobial property and biofouling property is prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

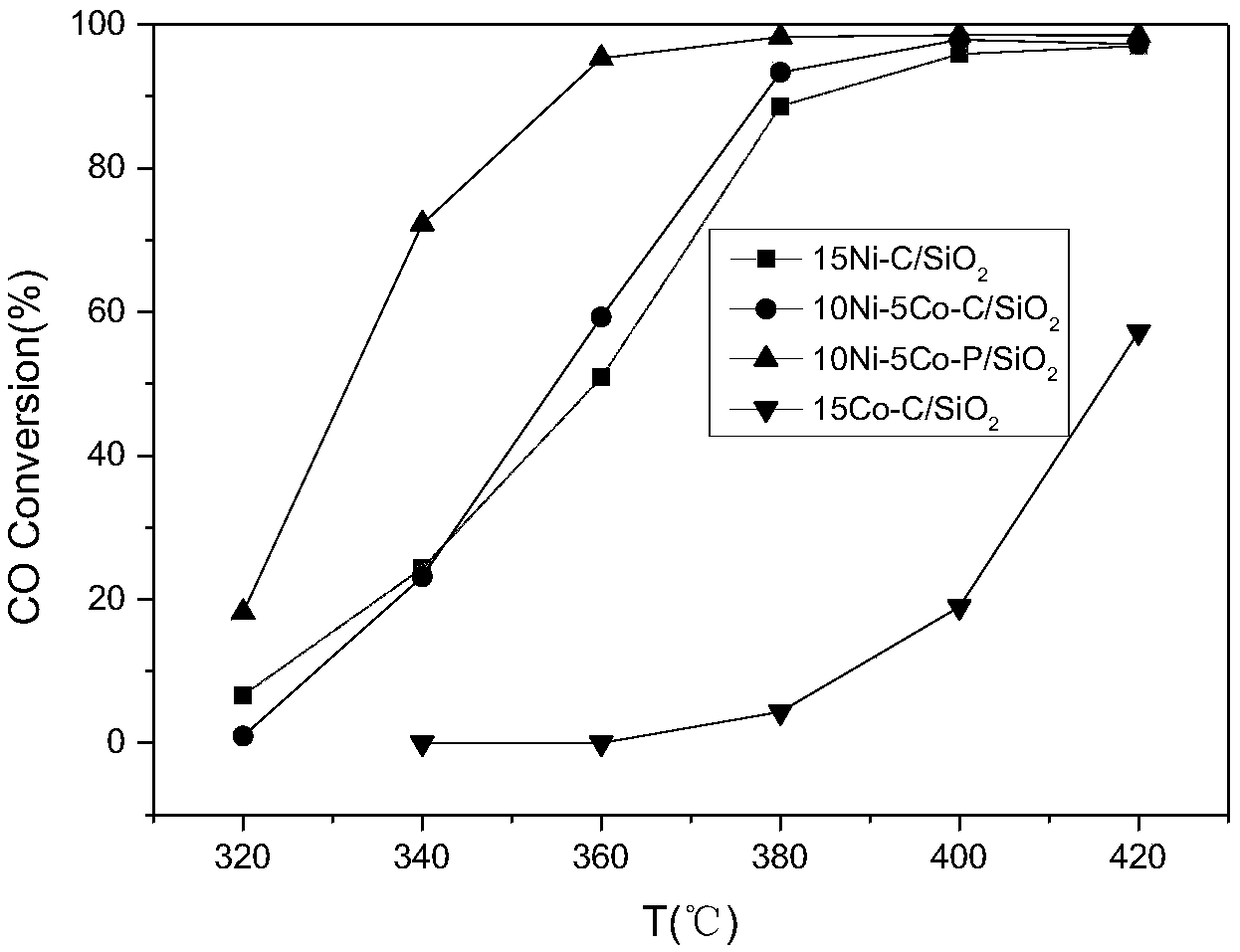

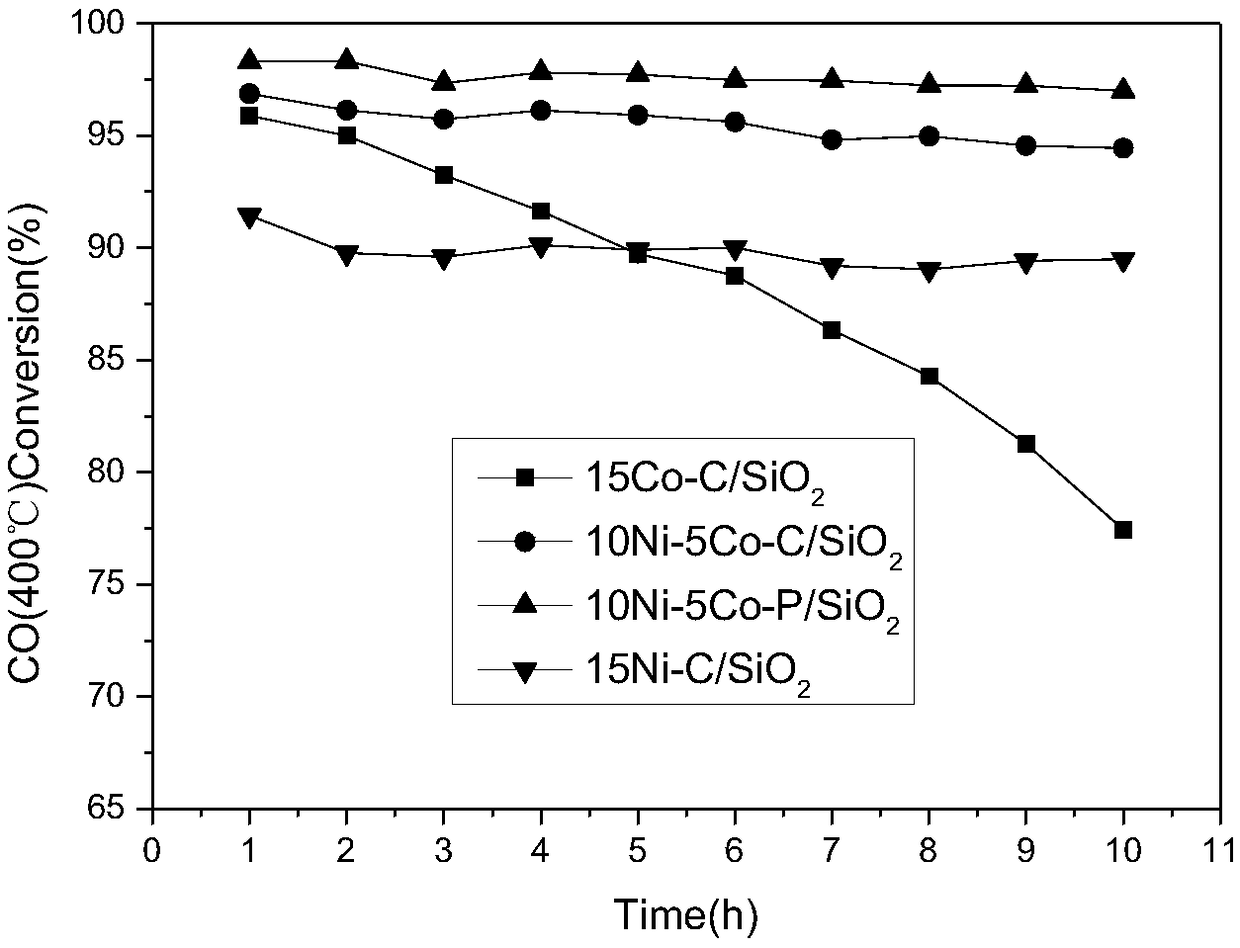

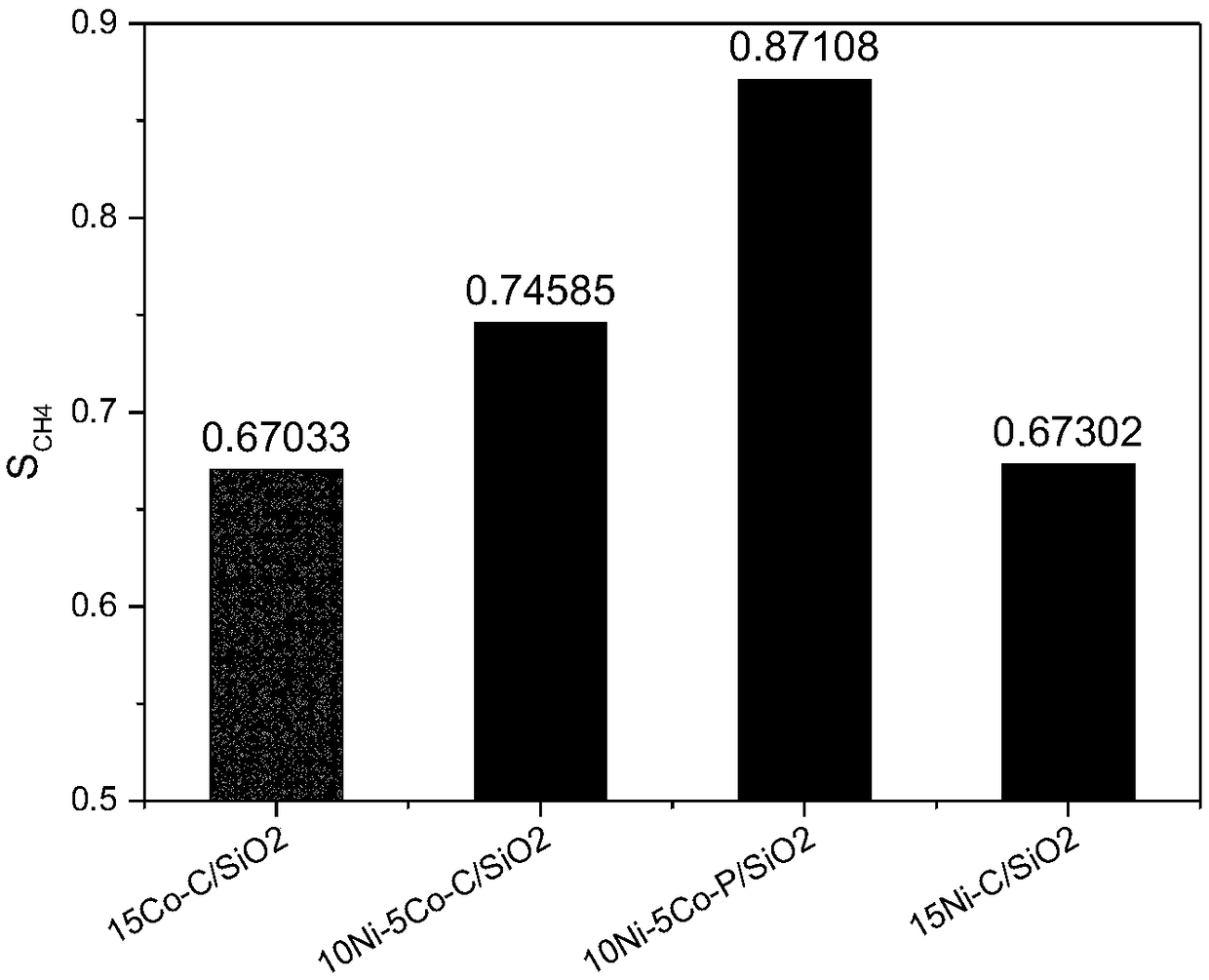

Efficient supported bimetallic or polymetallic catalyst and preparation method thereof

InactiveCN109012674AChange distribution statusLow equipment requirementsMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsPlasma technologyDielectric barrier discharge

The invention discloses an efficient supported bimetallic or polymetallic catalyst and a preparation method thereof, the efficient supported bimetallic or polymetallic catalyst is prepared by equivalent-volume impregnation. The method is characterized in that a dielectric barrier discharge plasma technology, as a new green technology operated at low temperature, can change the distribution state of metals in the bimetallic or polymetallic catalyst on a carrier very well, so that a special structure with one or more metals enriched on the surface of the catalyst and other one or more metals enriched in the inner part of the catalyst can be formed. The method can have a positive impact on the surface composition, structure, size and catalytic performance of the catalyst, and can significantly improve the activity, stability and effective product selectivity of the catalyst. The method is suitable for strengthening the preparation of various supported catalysts loaded on different materials. The method using a dielectric barrier discharge plasma for strengthening the preparation of the catalysts has the advantages of short preparation time, low energy consumption and environment friendliness.

Owner:NORTHWEST UNIV

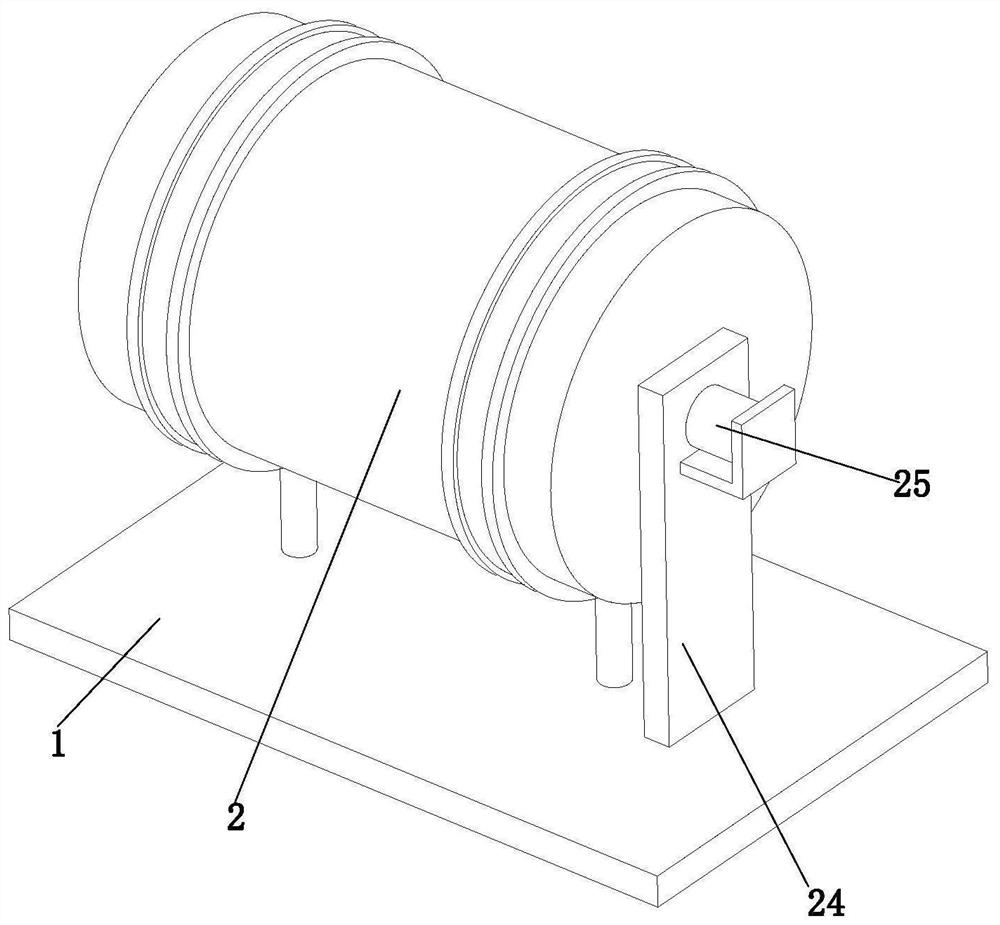

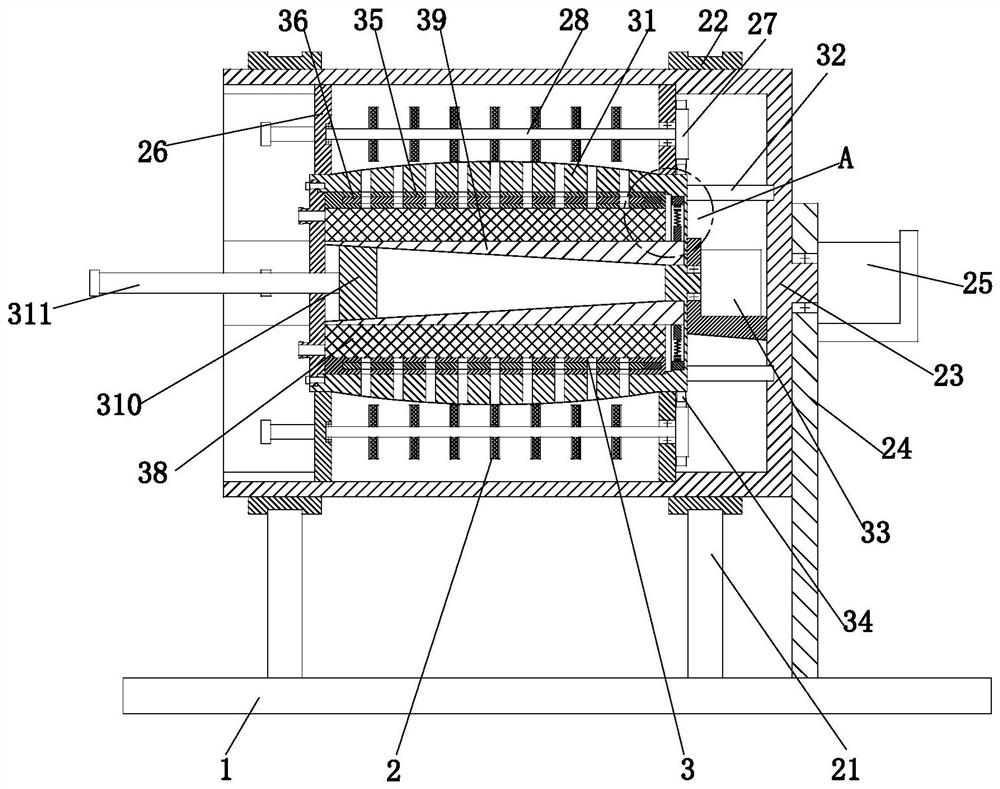

Grinding device for magnetic powder

InactiveCN107470007AAlternately change the distribution stateChange distribution statusGrain treatmentsMagnetic powderEngineering

The invention belongs to a powder material grinding device, in particular to a magnetic powder grinding device, comprising a grinding tank, a grinding body and a grinding base, wherein the grinding tank, the grinding body and the grinding base together form a grinding chamber; the grinding body can be driven by an external motor to grind along the The axial movement and rotation of the tank; the grinding tank is a conductor and connected to an external alternating current generator. It can realize the dispersion of magnetic powder in the grinding process and realize the uniformity of grinding.

Owner:WUXI HOUFA AUTOMATIC EQUIP CO LTD

Preparation method of hericium erinaceus fermented beverage

PendingCN110537655AFull of nutritionImprove stabilityFood ingredient as antioxidantFood homogenisationDietary fiberBearded tooth

The invention relates to the technical field of hericium erinaceus beverages, in particular to a preparation method of a hericium erinaceus fermented beverage. The preparation method comprises the following steps: (1) alkalization microwave treatment, (2) acidification enzymolysis; (3) homogenization, (4) fermentation and (5) stabilization treatment. The hericium erinaceus fermented beverage is rich in nutrition, not only can supplement nutrient substances such as vitamins, minerals and dietary fibers required by a human body, but also can supplement activated lactobacillus required by the human body, regulates intestinal health, further has good stability, is not prone to being hydrolyzed or oxidized, has the fragrance of lactic acid and hericium erinaceus, and is harmonious in odor.

Owner:贵州山环菌草科技有限公司

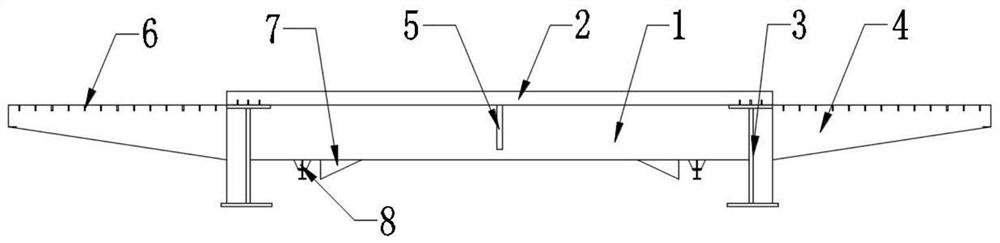

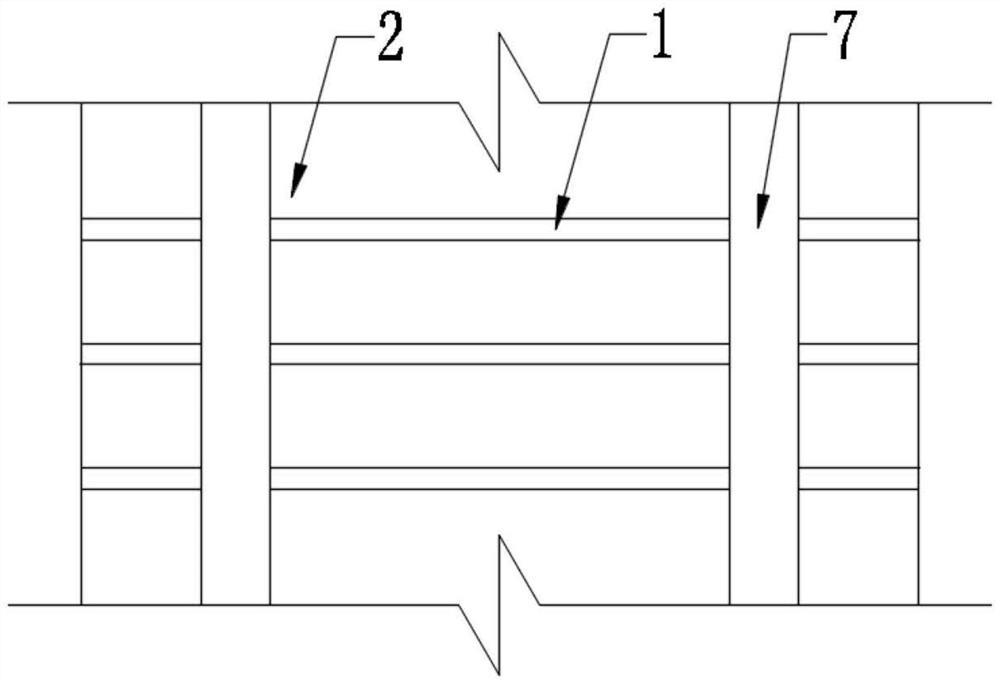

Cable-stayed bridge steel plate composite beam capable of resisting vortex-induced vibration

InactiveCN113502729AChange distribution statusImprove wind resistanceCable-stayed bridgeBridge structural detailsBridge deckEngineering

The invention discloses a cable-stayed bridge steel plate composite beam capable of resisting vortex-induced vibration, which comprises a bridge deck slab, steel main beams are fixedly arranged at two ends of the bottom of the bridge deck slab, steel cross beams are fixedly arranged between the steel main beams, steel cantilevers are fixedly arranged at the side ends of the steel main beams, and maintenance rails are arranged at the bottom ends of the steel main beams. A stabilizing plate perpendicular to the steel cross beams is fixedly arranged between the middles of the steel cross beams, and flow guiding devices located on the inner sides of the overhauling rails are symmetrically arranged at the bottom ends of the steel cross beams. The flow guiding device is a right-angle triangular prism, the long right-angle side of the section of the flow guiding device is attached to the steel cross beam, the short right-angle side is perpendicular to the steel cross beam, and the bevel edge inclines downwards from the inner end of the flow guiding device. The invention aims to provide the cable-stayed bridge steel plate composite beam, which can solve the wind vibration problem of the cable-stayed bridge, change the air flowing state and improve the wind-resistant stability.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Forging Process of Abnormal Microstructure of Raw Material of tc18 Titanium Alloy

ActiveCN105441845BChange distribution statusWell organizedHeating/cooling devicesPhase changeTitanium alloy

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

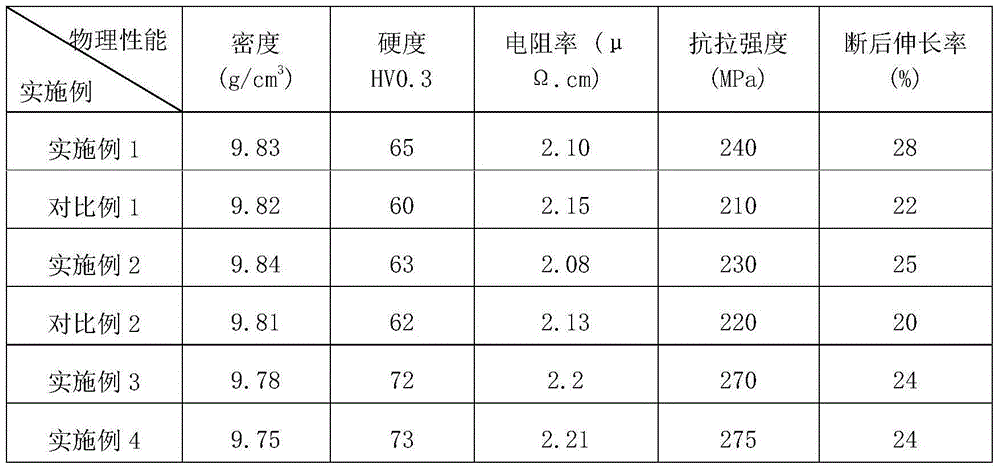

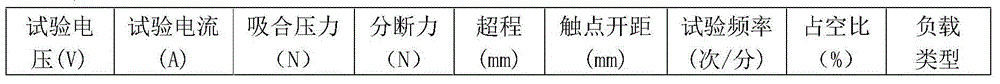

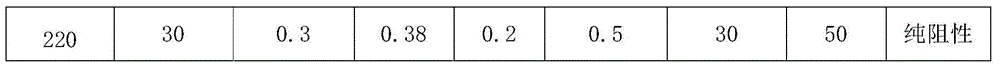

Process for preparing silver tin oxide contact material through powder rolling method

ActiveCN103710556AChange distribution statusHigh bonding strengthMetal/alloy conductorsSilver particlesBonding strength

The invention discloses a process for preparing a silver tin oxide contact material through a powder rolling method. The process specifically comprises the following steps: rolling mixed powder of silver oxide into a flaky material with thickness of 0.1-0.6 mm through a rolling mill, and carrying out isostatic pressing, sintering and extruding the obtained flaky material to obtain the silver tin oxide contact material; the diameters of rollers of the rolling mill are 60-200 mm, the gap between two rollers is 0.1-0.6 mm, and the rolling speed is 2-10 m / min. According to the process disclosed by the invention, powder rolling technology is introduced into the conventional powder metallurgic method of preparing silver tin oxide, the mixed powder of silver oxide is rolled by the rolling mill to change the simple distribution state of silver particles and tin oxide particles in the conventional powder metallurgic process, and the tin oxide particles are pressed into the silver particle matrix so as to perfect the bonding strength of silver and tin oxide in the material and improve the mechanical and physical properties and electrical properties of the obtained silver tin oxide contact material.

Owner:桂林金格电工电子材料科技有限公司

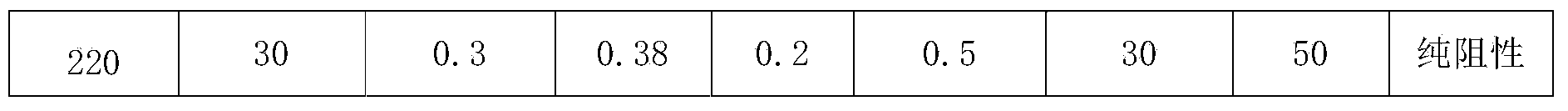

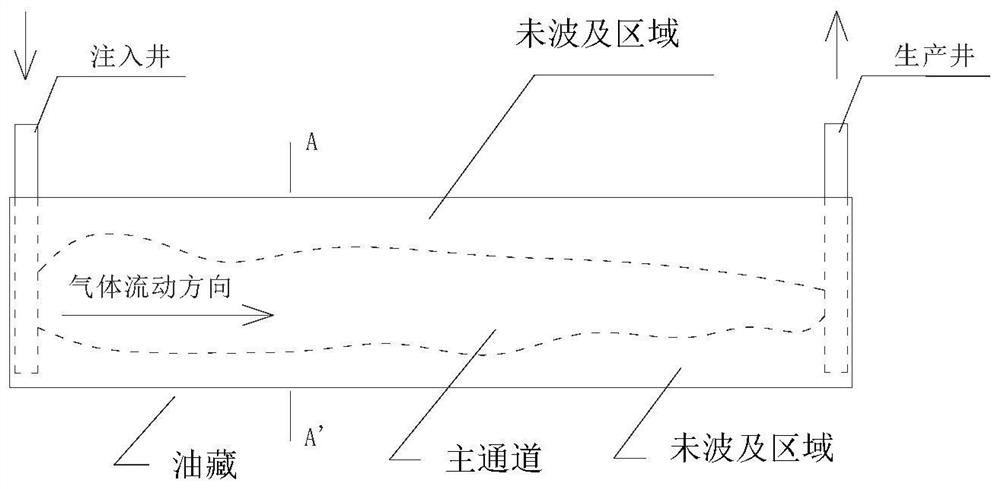

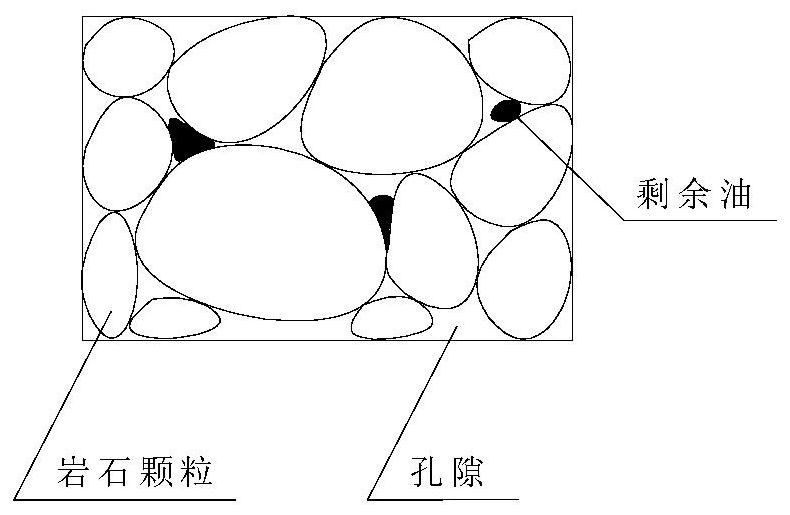

Low-frequency variable-pressure oil reservoir exploitation method, device and system for residual oil in pores

ActiveCN112627784AChange distribution statusImprove recoverySurveyFluid removalThermodynamicsResidual oil

The invention provides a low-frequency variable-pressure oil reservoir exploitation method, device and system for residual oil in pores. The method comprises the steps that a distribution diagram of gas in an oil reservoir and a pressure distribution diagram between injection and production wells in the gas injection process are obtained; according to the distribution diagram of the gas in the oil reservoir and the pressure distribution diagram between the injection and production wells in the gas injection process, the placement position of a low-frequency variable-pressure well shaft device in the oil reservoir is determined; the pressure is intermittently increased and decreased at the preset frequency through the placement position of the low-frequency variable-pressure well shaft device in the oil reservoir, and the distribution state of the residual oil in the oil reservoir at the placement position is changed; and the residual oil in the oil reservoir with the distribution state of the residual oil changed is exploited through a steam injection well and a production well. According to the scheme, the short-time high-pressure effect of a near wellbore zone is caused by the high flow speed of the low-frequency variable-pressure well shaft device, the effects of desorbing the residual oil and changing the direction of a main seepage channel are achieved, and after gas drive fluid channeling, the exploitation degree continues to be increased through a method of expanding the swept volume.

Owner:PETROCHINA CO LTD

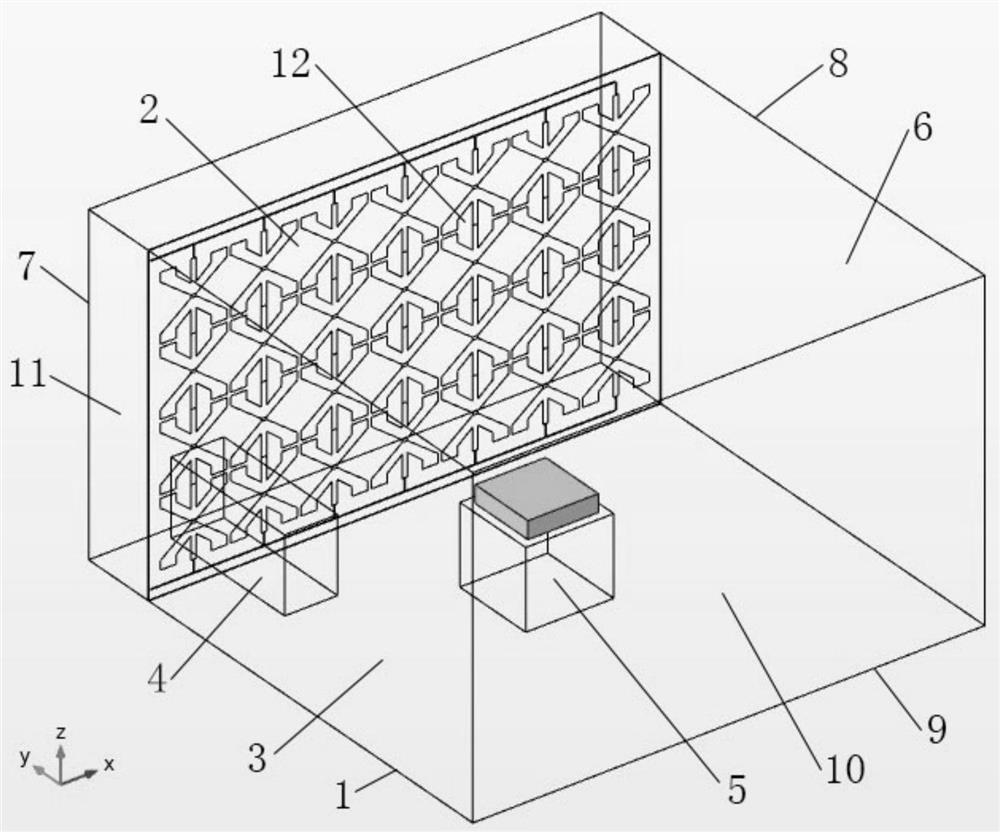

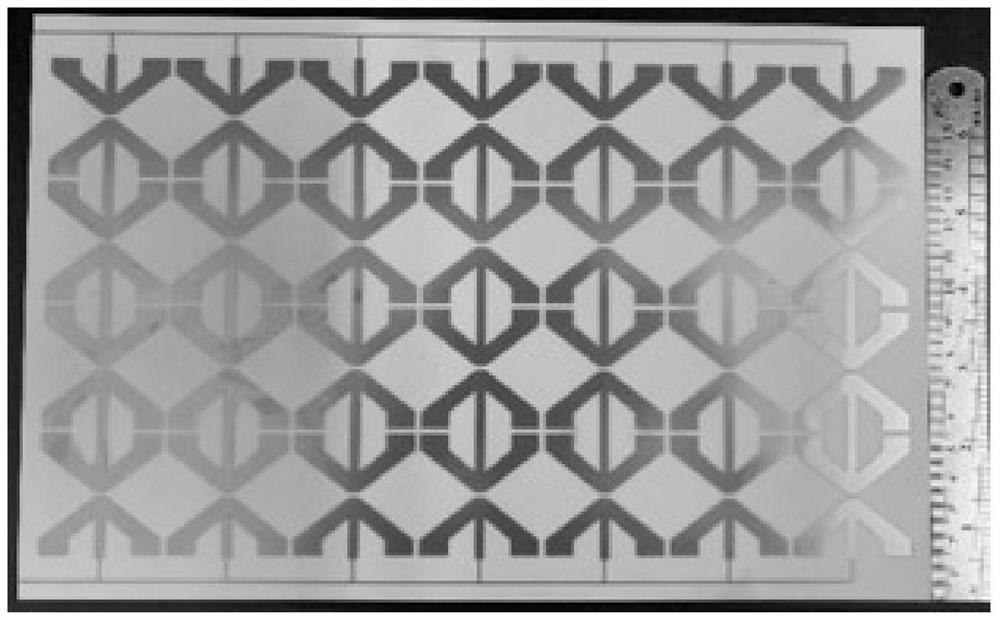

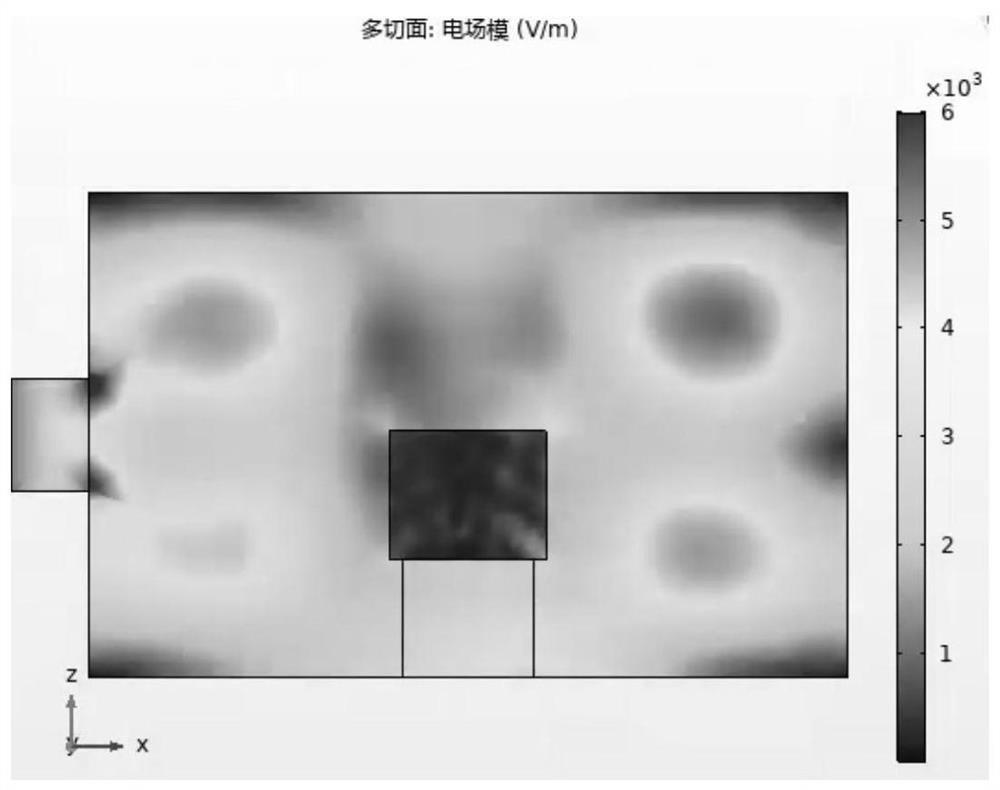

Microwave oven

PendingCN112822809AEasy to cleanChange the size of the spaceDomestic stoves or rangesLighting and heating apparatusMicrowave ovenControl system

The invention discloses a microwave oven. The microwave oven comprises a microwave oven body, a performance-adjustable frequency selection surface is arranged in the microwave oven body, the frequency selection surface is close to the side wall in the microwave oven body, and a cavity in the microwave oven body is divided into a heating area and an electric field boundary change area by the frequency selection surface. The control system on the adjustable frequency selective surface is connected with a controller of the microwave oven body; and a to-be-heated object containing table and a power input port are arranged in the heating area. The frequency selective surface is applied to the microwave oven, and the frequency selective surface is in a transmission or reflection state for microwaves by periodically changing the filtering characteristic of the frequency selective surface, so that the boundary of a microwave field is changed, the distribution state of an electric field in the microwave oven is changed, and the purpose of improving the heating uniformity is achieved.

Owner:四川大学锦城学院

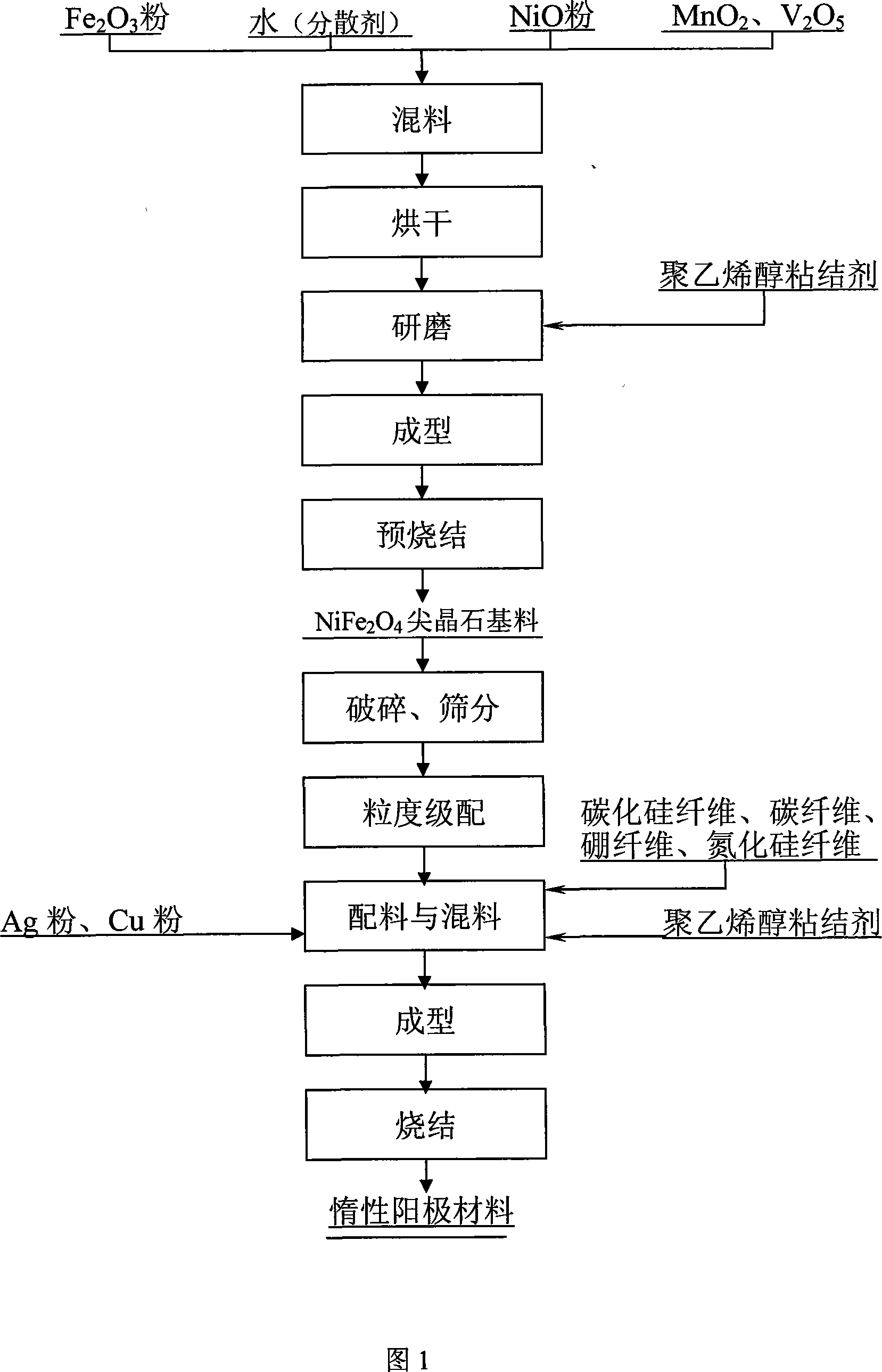

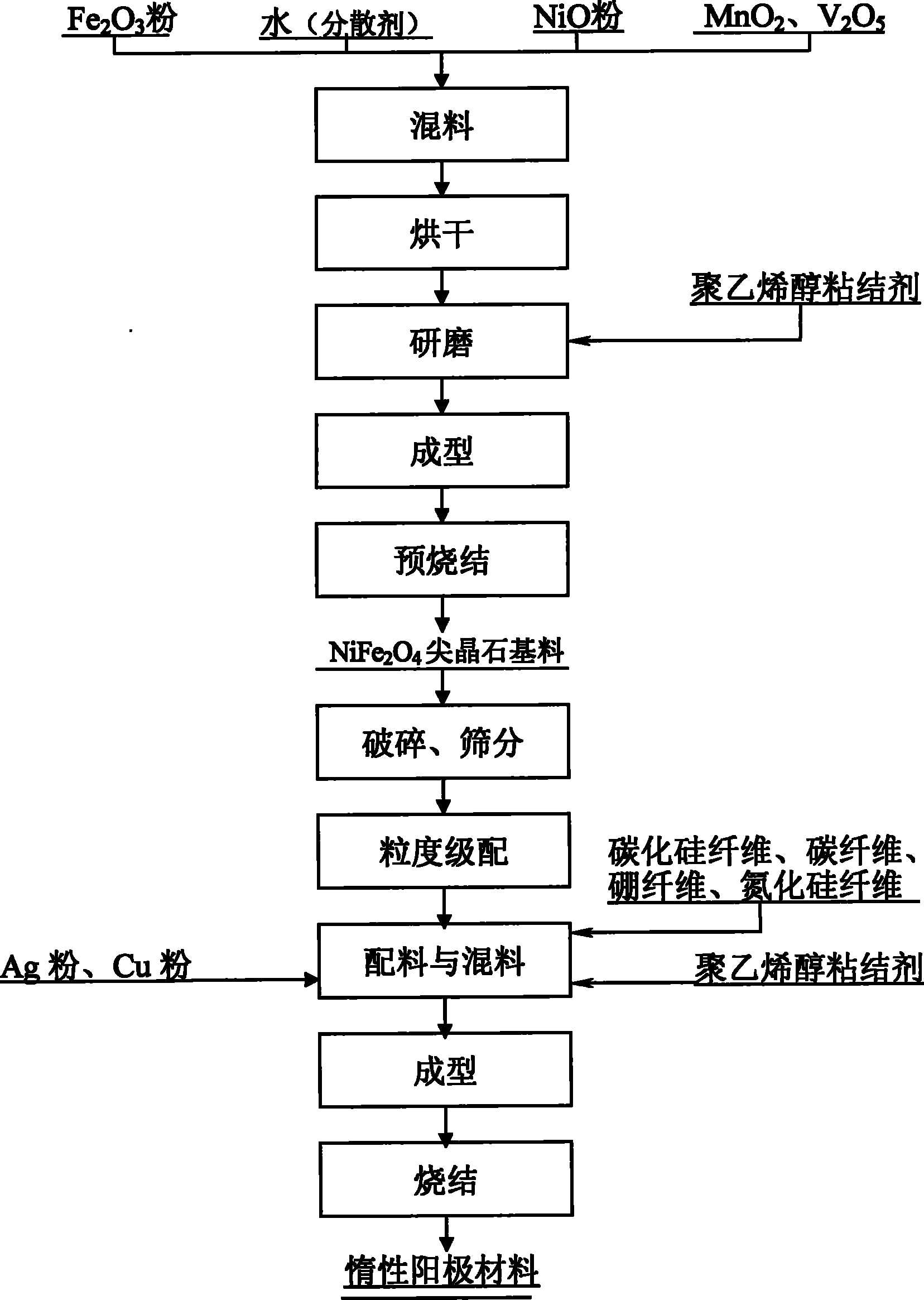

Inert anode material for aluminium electrolysis and method for manufacturing same

The invention relates to an inert anode material for aluminum electrolysis and preparation method. The inert anode material comprises NiFe2O4 ceramic phase, Ag powder or / and Cu powder metallic phase and fiber phase, characterized in that adding MnO2, V2O5 in the ceramic phase, adding carborundum fibre, carbon fiber, boron fibre, silicon nitride fibre in the fibre phase. In the NiFe2O4 ceramic phase, the NiO and F2O3 is taken as raw material, synthesizing NiFe2O4 spinel according to stoichiometric ratio, NiO excessive 15wt%; based on total mass of NiO and Fe2O3, adding at least one of 0.5wt% to 2.5wt% MnO, 1.0wt% to 3.0wt% V2O5 to compose NiFe2O4 spinel base material; after the NiFe2O4 spinel base material is smashed and screened, processing grain size distribution according to crude grainmaterial, mediate grain material and fined powder material. Based on the total mass of the NiFe2O4 spinel base material, adding at least one of 5wt% to 15wt% Ag powder, 5wt% to 30wt% Cu powder, than further adding at least one of 0.5wt% to 5wt% carborundum fibre, 0.5wt% to 5wt% carbon fiber, 0.5wt% to 10wt% boron fibre, 0.5wt% to 10wt% silicon nitride. The product has higher anti-erosion property, thermal-shock resistance, bend strength and anti-impact strength properties.

Owner:NORTHEASTERN UNIV

A kind of composite cuniin powder and its preparation method and application

ActiveCN108425085BSuitable for anti-fretting damage protectionHigh strengthMolten spray coatingTransportation and packagingCrazingBall mill

The invention discloses a composite CuNiIn powder and its preparation method and application. The composite CuNiIn powder contains a dispersion strengthening phase and a self-lubricating phase at the same time. The preparation method comprises: In powder, nickel-coated molybdenum disulfide powder, Al 2 o 3 Dispersion-strengthened Cu powder is ball-milled and mixed to obtain mixed raw materials. The mixed raw materials are centrifugally atomized and granulated by a spray drying granulator to obtain dry granules; the dried granules are vacuum sintered, and then crushed and sieved to obtain composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing a dispersion strengthening phase and a self-lubricating phase by a thermal spraying method. The invention changes the distribution state of the self-lubricating phase, improves the strength and toughness of the coating, effectively avoids the generation of micro-cracks in the coating, improves the self-lubricating life of the coating, and has good advantages for industries such as aeroengines and gas turbines. Value.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

A kind of aluminum alloy composite solder wire for arc welding and preparation method thereof

ActiveCN106238955BImprove wettabilityImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaElectrode potentialRare-earth element

The invention discloses an aluminium alloy composite solder wire for arc welding and a preparation method thereof. The aluminium alloy composite solder wire comprises main materials and auxiliary materials, wherein the main materials comprise the following raw materials: 8 to 12 parts of Al, 6 to 9 parts of Si and 7 to 9 parts of Cu; and the auxiliary materials comprise the following raw materials: 5 to 7 parts of rare earth alloy, 3.5 to 6 parts of Zn, 4 to 5 parts of Mg, 2.7 to 3.8 parts of Mn, 2 to 5 parts of Ni, 4.5 to 5 parts of Ge and 3 to 5 parts of Sr. According to the invention, the aluminium alloy composite solder wire has good wetting property, ideal mechanical property and excellent shear strength, can integrate good wetting property, mechanical property and shear strength, the problem that excellent performances and advantages of solder cannot be integrated is solved, and the applicability of the solder is improved; La, Y and Ce rare earth elements are added in the formula, so that crystal grains can be refined, the distribution state of the structure is changed, the electrode potential of the solder is not changed, while the mechanical property and corrosion resistance of a soldered joint are improved; and Zn, Mg, Mn, Ni, Ge and Sr are added in the formula, and the solid-liquid phase line temperature is remarkably decreased.

Owner:ZHENJIANG SIDA ALLOY MATERIALS

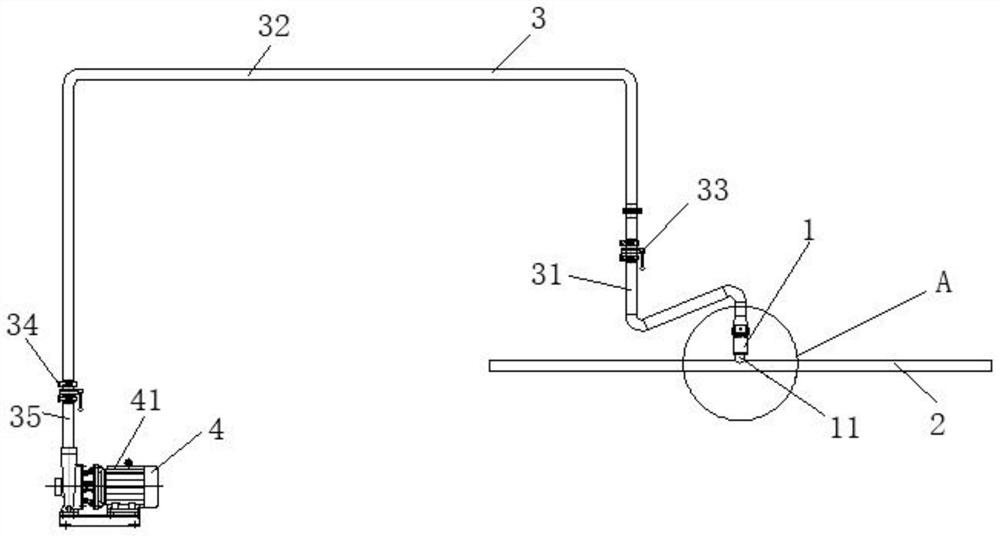

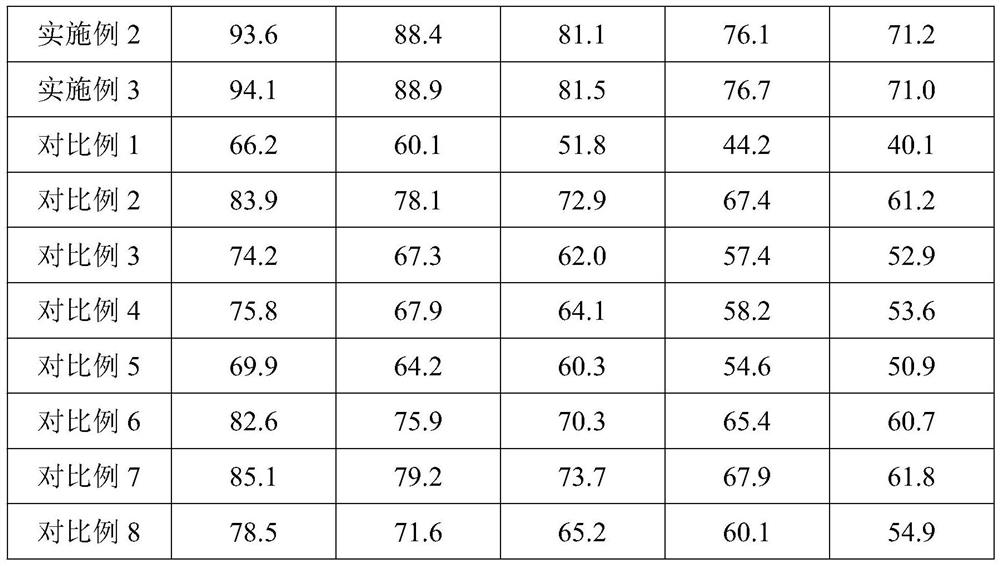

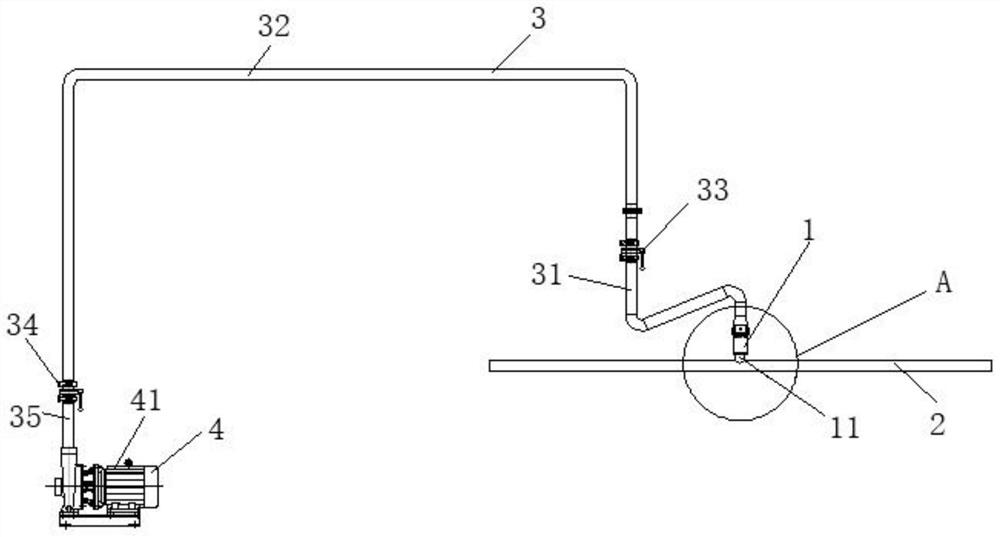

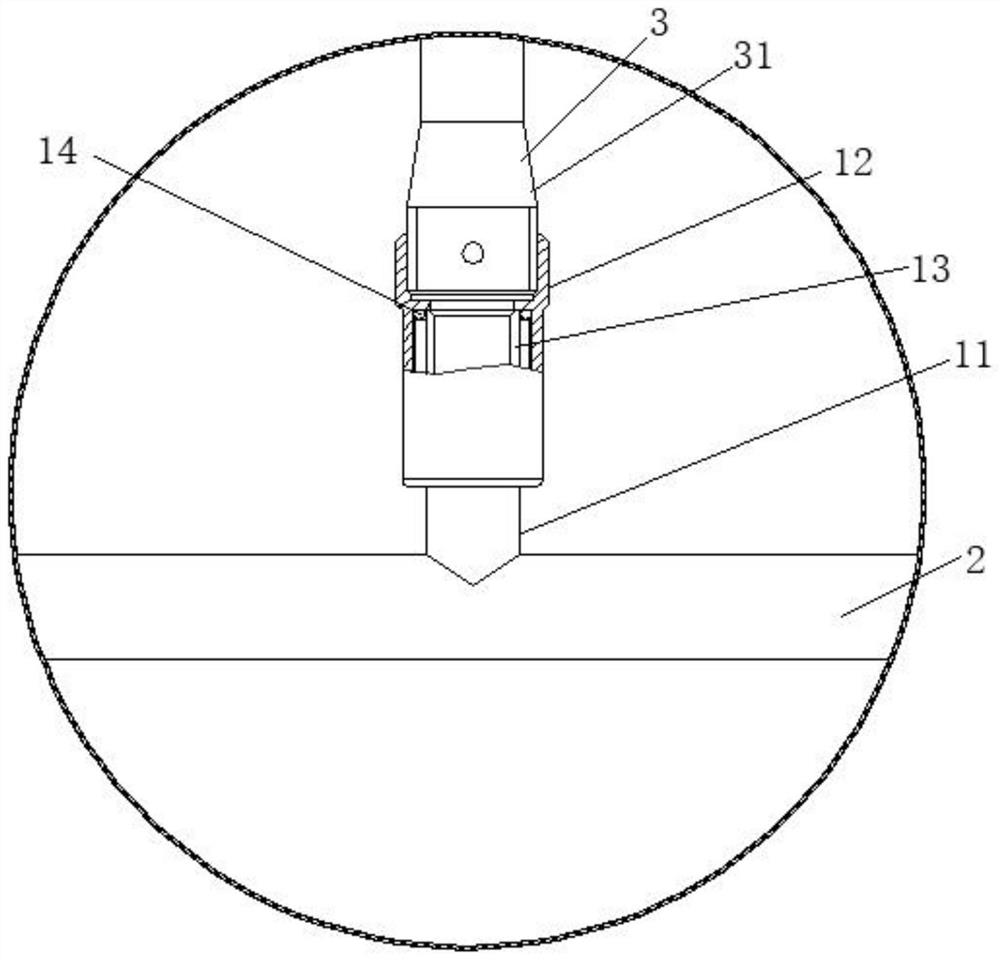

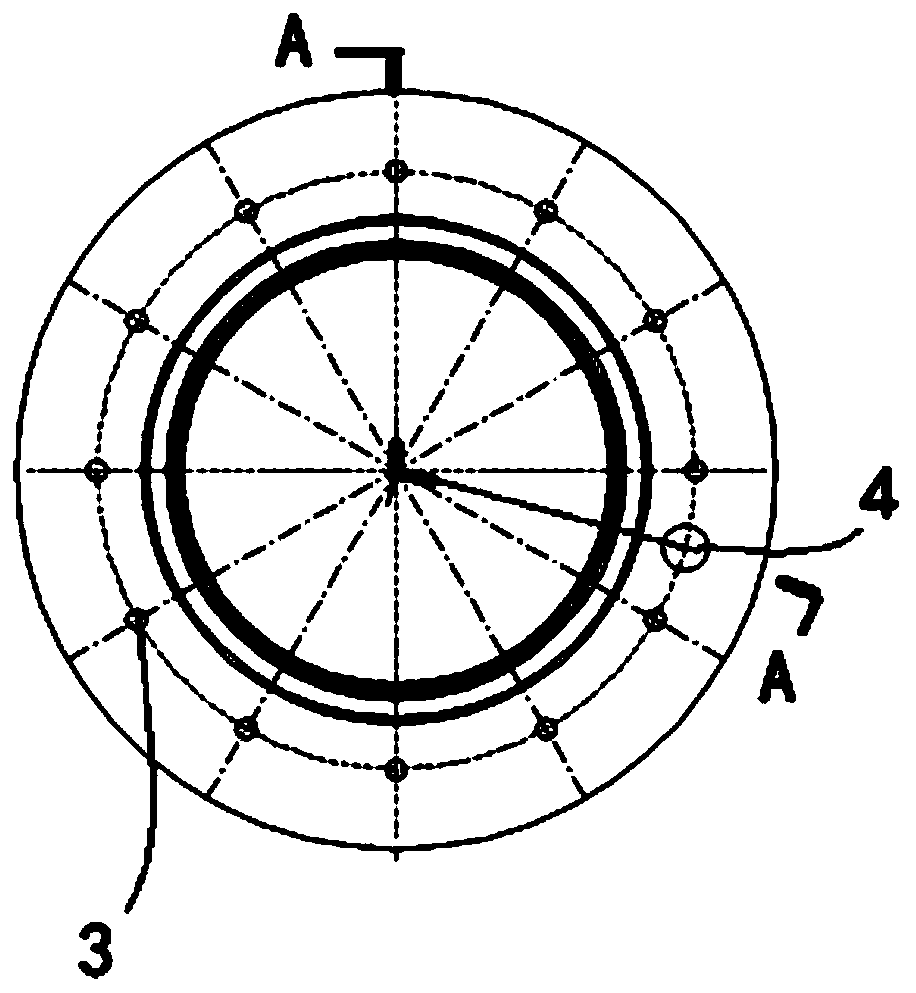

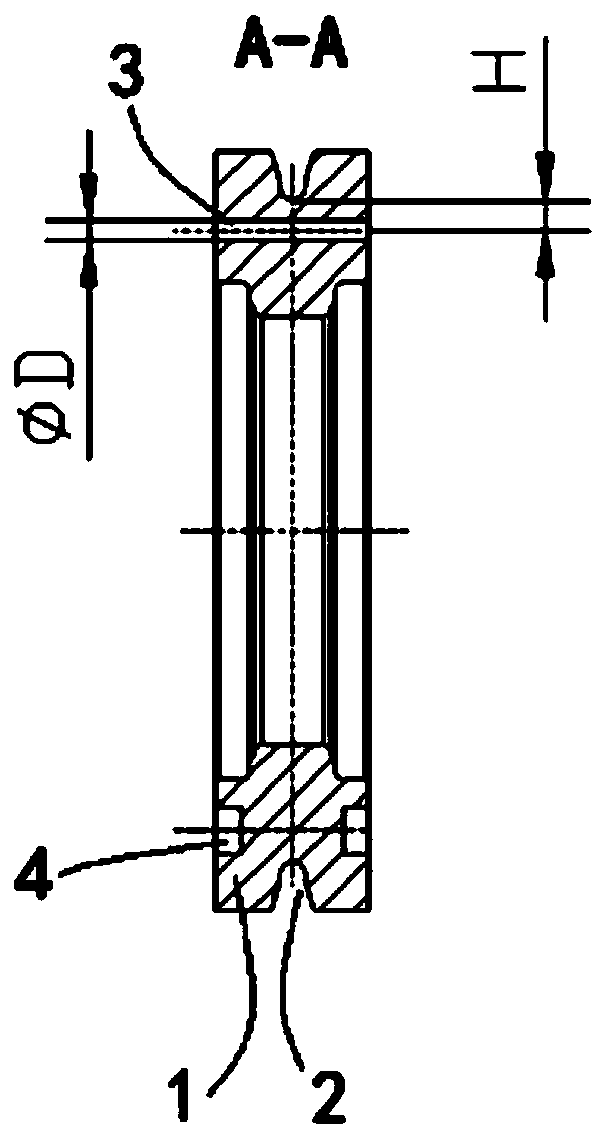

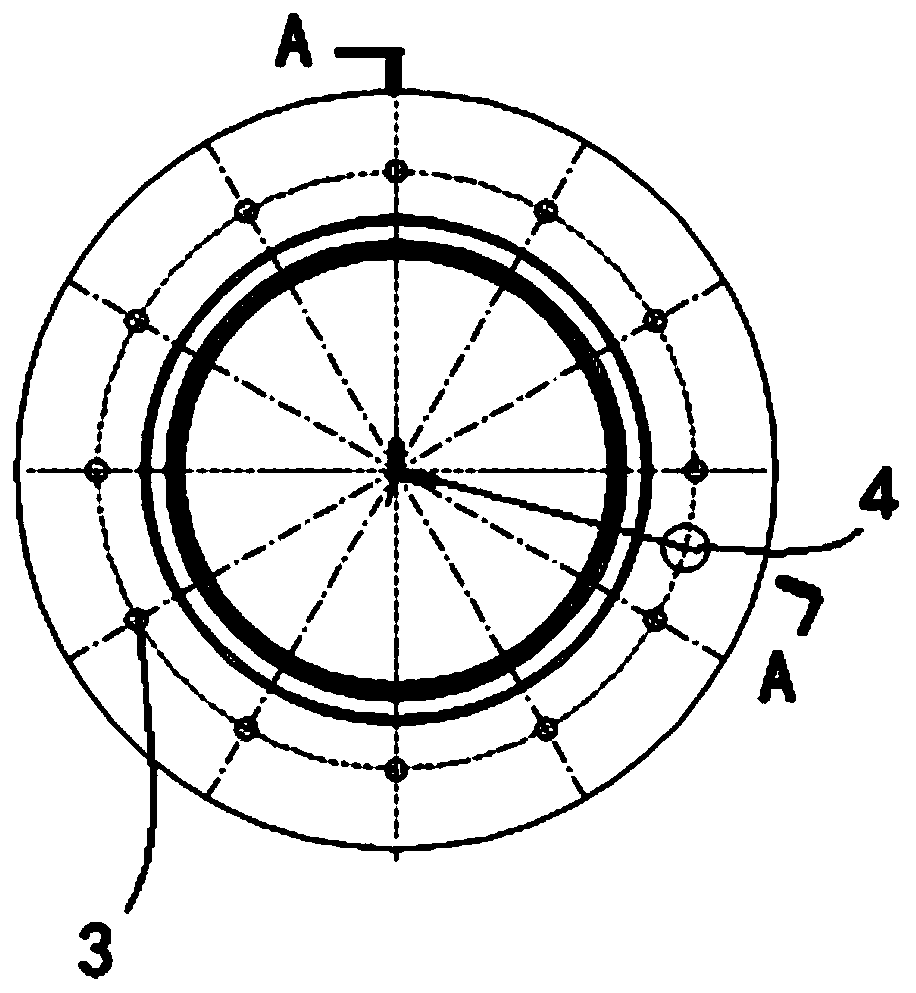

A speed-controllable rotary measuring water automatic filling device

ActiveCN112066262BPromote re-expansionKeep the pressureRotating receptacle mixersTransportation and packagingRotational axisOutfall

The present invention provides a speed-controllable rotating water measuring automatic filling device, which includes a rotating device, a first distributing pipe, a diversion pipe group, and a water measuring power device; one end of the rotating device is connected to the water inlet at the upper end of the first distributing pipe, A number of water outlet holes are evenly arranged on both sides of the first distribution pipe with the rotation axis of the rotating device as the symmetrical center. The other end of the rotating device is connected to the water outlet of the diversion tube group. Water outlet connection. The water measuring power device inputs the water of the water supply system into the diversion tube group, and the diversion tube group inputs the water to the water inlet of the first distribution pipe through the flow channel of the rotating device, and the rotation of the rotating device drives the first distribution pipe to rotate, and the first The water outlet hole on the cloth pipe distributes water; through the first rotating cloth pipe to measure water and distribute water, it can measure water more evenly than fixed water measuring cloth, realize even distribution of water, so that water is evenly distributed and does not accumulate, and automatically Water measurement reduces manual labor intensity, and automatic operation is safe and reliable.

Owner:普瑞特机械制造股份有限公司

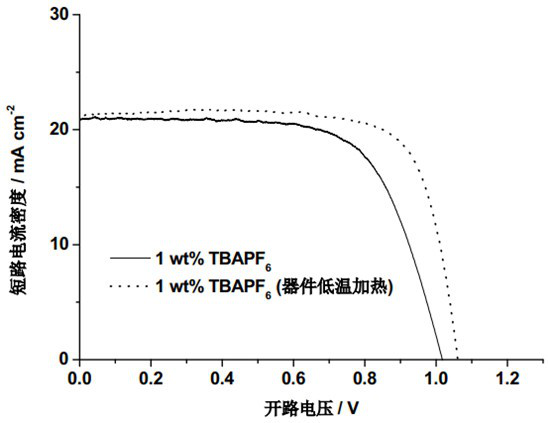

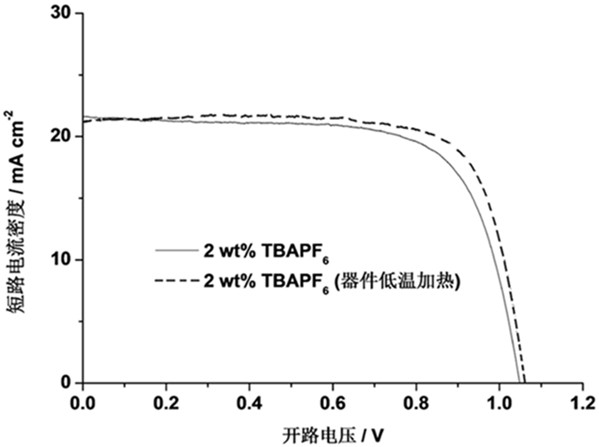

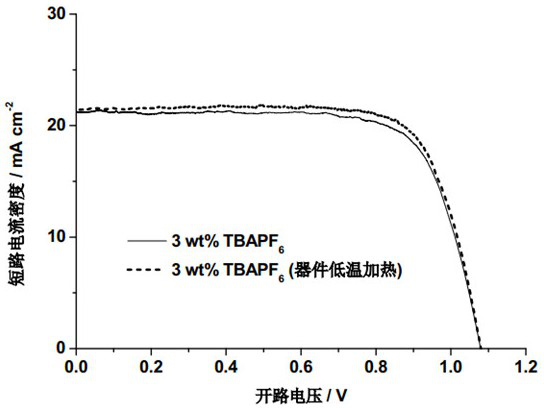

A temperature-induced method for deep doping of hole dopants at low concentrations

ActiveCN112635680BEvenly dispersedInhibit aggregationSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite (structure)Solar battery

The invention discloses a method for deep doping of a temperature-induced hole dopant at a low concentration. The preparation process of a hole transport layer in a perovskite solar cell structure is as follows: the material of the hole transport layer and TBAPF 6 Co-dissolved in dichloromethane to obtain hole transport layer material solution, hole transport layer material solution TBAPF 6 The mass concentration is 1‑4 wt%, and the hole transport layer is prepared on the perovskite film with the corresponding spin coating parameters; the obtained n‑i‑p type perovskite solar cell is subjected to low-temperature heating treatment, and then naturally cooled to room temperature. The present invention adopts TBAPF 6 Doping the material of the hole transport layer as a hole dopant, and performing low-temperature heating treatment on the prepared perovskite solar cells can effectively improve the 6 Photovoltaic performance and stability of solar cells prepared with doped hole transport layer materials.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

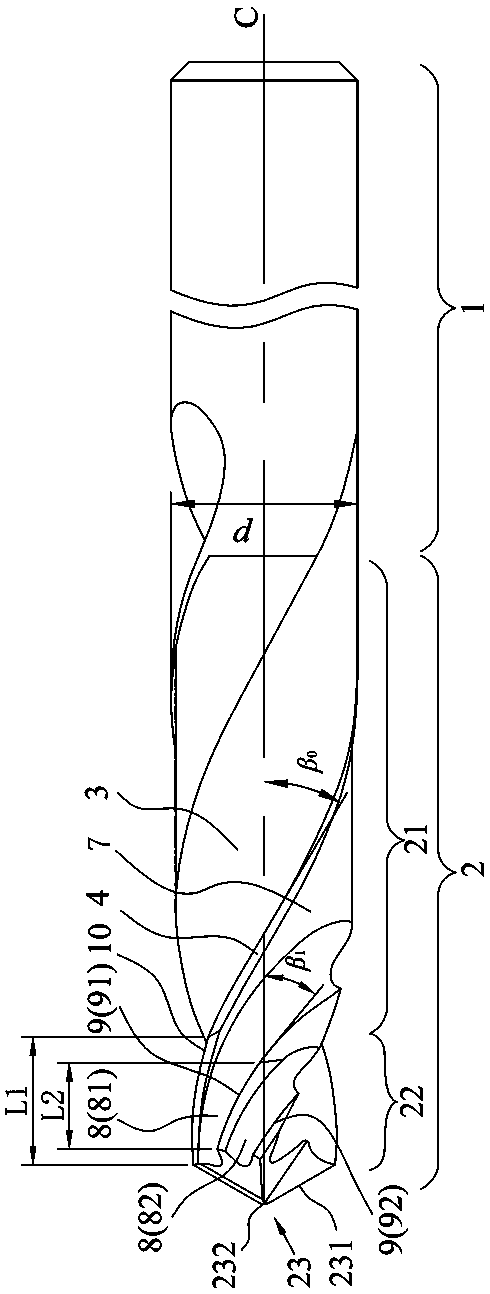

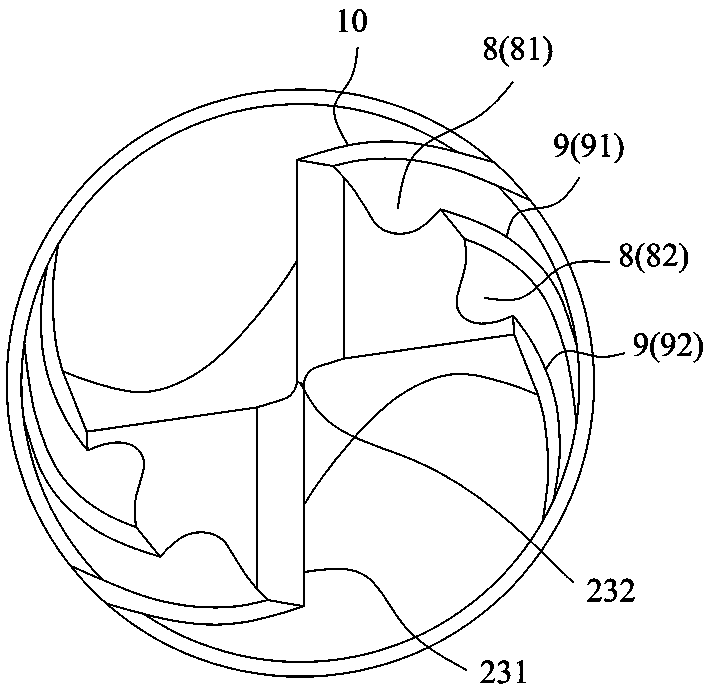

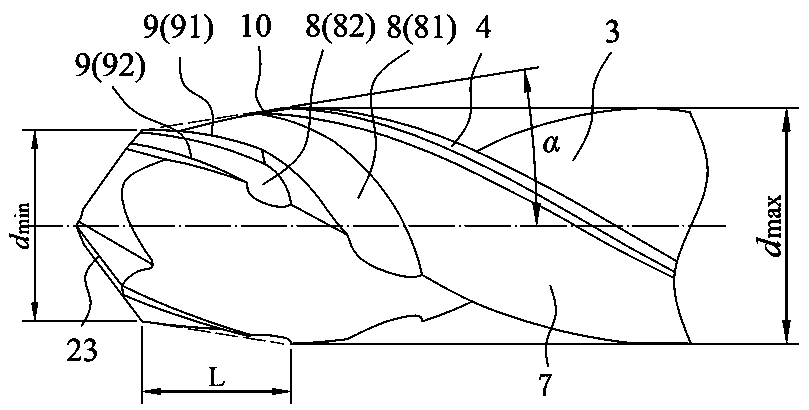

A milling and drilling compound processing tool

ActiveCN107030319BReduce thicknessChange distribution statusTransportation and packagingMilling cuttersPetalEngineering

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

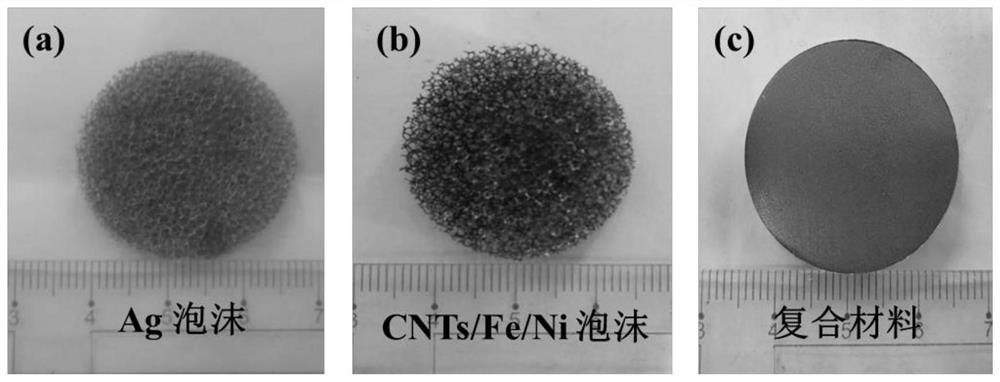

A kind of preparation method and product of copper alloy composite material for electronic packaging

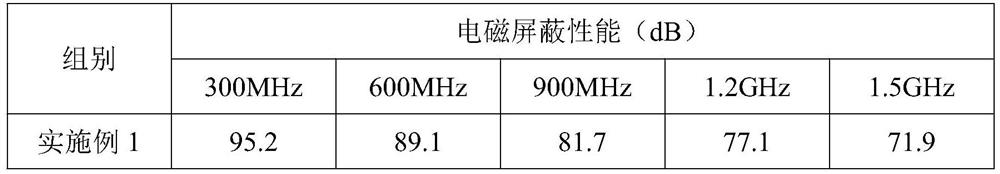

ActiveCN112281019BGood dispersionChange distribution statusElectrolytic coatingsLiquid/solution decomposition chemical coatingCarbon nanotubeElectromagnetic shielding

The invention discloses a method for preparing a copper alloy composite material for electronic packaging and a product thereof. The method comprises the following steps: preparing an electroplating solution; chemically silver-plating polyurethane foam, and removing the polyurethane foam by heat treatment to obtain silver foam; The carbon nanotube / iron / nickel (CNTs / Fe / Ni) composite foam is obtained by electroplating on top, heat-treated; filled with copper powder, cold-pressed, and hot-pressed and sintered to finally obtain a copper alloy composite material. In the present invention, CNTs / Fe / Ni composite foam is used as a three-dimensional skeleton reinforcement phase, and copper powder is filled as a tough phase, and CNTs do not have a large area of agglomeration inside, and its structural integrity is preserved. The copper alloy composite material prepared by the invention has high electromagnetic shielding performance, good thermal conductivity, high tensile strength, good ductility and low expansion coefficient, and meets the performance requirements of the copper alloy used for electronic packaging.

Owner:KUNMING UNIV OF SCI & TECH

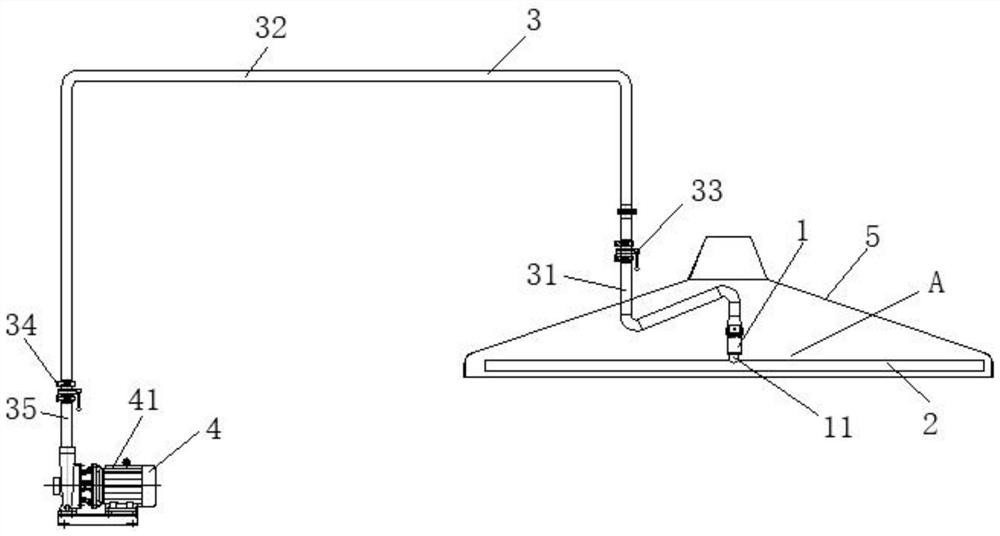

Rotary speed-controllable automatic water measuring and filling device

ActiveCN112066262APromote re-expansionKeep the pressureRotating receptacle mixersTransportation and packagingRotational axisWater discharge

The invention provides a rotary speed-controllable automatic water measuring and filling device. The rotary speed-controllable automatic water measuring and filling device comprises a rotating device,a first distribution pipe, a flow guide pipe unit and a water measuring power device, wherein one end of the rotating device is connected with a water inlet in the upper end of the first distributionpipe; a plurality of water outlets are uniformly formed in the two sides of the first distribution pipe by taking a rotating shaft of the rotating device as the symmetry center; the other end of therotating device is connected with a water outlet of the flow guide pipe unit; and a water inlet of the flow guide pipe unit is connected with a water outlet of the water measuring power device. The water of a water supply system is inputted to the flow guide pipe unit through the water measuring power device, and is inputted to the water inlet of the first distribution pipe via a flow channel of the rotating device; the rotating device rotates to drive the first distribution pipe to rotate, and water is distributed through water discharging holes in the first distribution pipe; compared with fixed type water measurement and distribution, the water measurement distribution based on the rotating first distribution pipe realizes more uniform water measurement, realizes uniform dispersion of water measurement, achieves uniform distribution of water measurement without accumulation, alleviates the labor intensity due to automatic water measurement, and is safe and reliable due to automaticrunning.

Owner:普瑞特机械制造股份有限公司

Extruding wheel of continuous extruding machine

PendingCN110000233AChange distribution statusChange the state of stressExtrusion profiling toolsNonferrous metalEngineering

The invention provides an extruding wheel of a continuous extruding machine, and relates to the technical field of continuous extruding and continuous coating of nonferrous metals such as copper and aluminum. The extruding wheel is provided with at least one annular groove in the circumferential direction, a plurality of cooling through holes penetrating through the extruding wheel are distributedin the circumferential direction of the extruding wheel, a distance is reserved between the center lines of the cooling through holes and the bottoms of the grooves, the axes of the cooling through holes are parallel to the axis of the extruding wheel or a certain spatial angle is reserved between the axes of the cooling through holes and the axis of the extruding wheel, and a pin hole which doesnot penetrate through the extruding wheel is formed in the end surface of the extruding wheel. According to the extruding wheel, by changing a cooling water channel of the extruding wheel, the temperature distribution and the stress state of the extruding wheel are changed while the temperature of the grooves of the extruding wheel is controlled and the softening of the high temperature areas ofthe grooves of the extruding wheel is relieved, stress value of dangerous damage points of the extrusion wheel is reduced, so that the rotating speed of the extruding wheel can be increased, the production efficiency is remarkably improved, the service life of the extruding wheel and a cavity is prolonged, and the operating cost of equipment is reduced.

Owner:大连康丰科技有限公司

A technology for preparing silver tin oxide contact material by powder rolling method

ActiveCN103710556BChange distribution statusHigh bonding strengthMetal/alloy conductorsSilver particlesBonding strength

Owner:桂林金格电工电子材料科技有限公司

A Method for Improving the Quality of Al-cu Dissimilar Metal Friction Stir Welded Butt Joints

ActiveCN108620762BWell formed weldImprove liquidityWelding/soldering/cutting articlesWorkpiece edge portionsFriction weldingButt joint

The invention discloses a method for improving the quality of an Al-Cu dissimilar metal friction stir welding butt joint. The method specifically comprises the steps that the edges of butt-joint sidesof an aluminum welding part and a copper welding part used for welding are firstly machined into engaged sawtooth sides, then the welding parts on the two sides are in butt joint along the sawtooth sides, and then friction stir welding is carried out. The treatment method is simple, only simple machining is needed, and cost is low; welding seam forming of Al-Cu dissimilar metal friction stir welding can be obviously improved, and the metal mixing degree and the plastic flow behavior of Al-Cu dissimilar metal in the welding process are improved; and meanwhile, the area of an Al-Cu welding interface is increased, the bearing capacity of the joint is increased, the distribution state of a brittle IMC along the interface is changed, and the mechanical performance of the joint is obviously improved.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

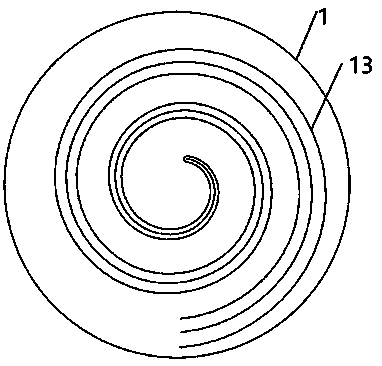

Water collector provided with surface cooling device

InactiveCN109629631AImprove water collection effectReduce wearDrinking water installationSurface coolingTemperature control

The invention discloses a water collector provided with a surface cooling device. The water collector comprises a water collector housing and the cooling device. The cooling device comprises an aluminum alloy top shell, a base, a rechargeable lithium battery, a rectangular thin-walled water pipe, a circulating water pump, a refrigerating device, a micro temperature control board and a micro boosting chip, wherein the aluminum alloy top shell is attached to the surface of an inner cavity of the water collector housing, the rectangular thin-walled water pipe is laid on the inner surface of the aluminum alloy top shell in a coiled state, and the two ends of the rectangular thin-walled water pipe are connected with the circulating water pump and the refrigerating device respectively to form aclosed cooling circulation loop; a plurality of temperature sensors are arranged on the inner surface of the aluminum alloy top shell, and the micro boosting chip, a cooling fan and the temperature sensors are connected with the micro temperature control board. By means of the water collector, the water collecting effect of a super-hydrophobic surface can be improved; the surface temperature of the water collector housing is reduced through an internal micro refrigerating system to achieve the effects of reducing the temperature of the super-hydrophobic surface, increasing the temperature difference and improving the water collecting effect.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com