A speed-controllable rotary measuring water automatic filling device

An automatic filling and rotating device technology, applied in mixers with rotating containers, adjustable connections, transportation and packaging, etc., can solve the problems of uneven measurement of water, affecting the liquor yield and quality of distilled liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

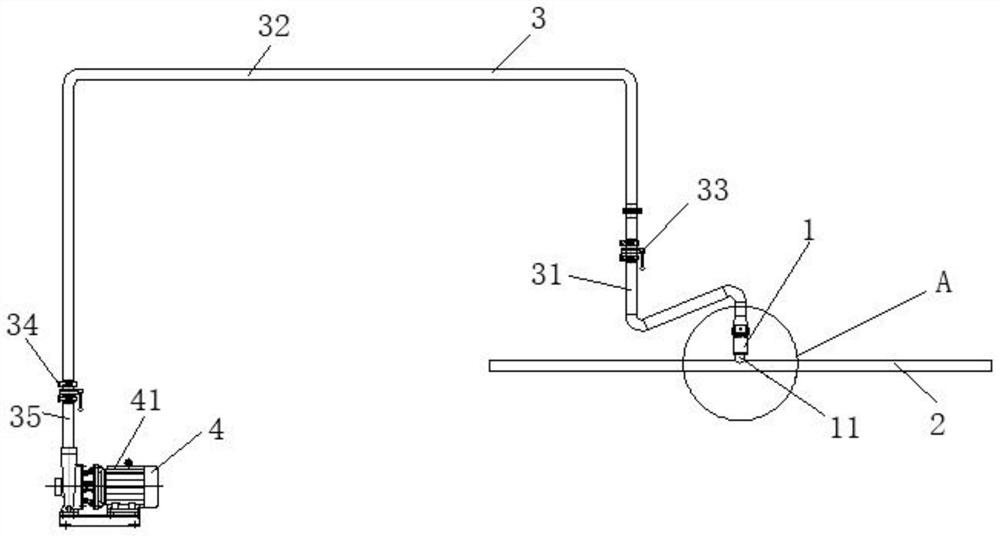

[0075] The embodiment of the present invention provides a speed-controllable automatic filling device for rotating and measuring water, such as Figure 1-5 as shown,

[0076] It includes a rotating device 1, a first distribution pipe 2, a diversion pipe group 3, and a water measuring power device 4;

[0077] One end of the rotating device 1 is connected to the water inlet at the upper end of the first cloth pipe 2, and several water outlet holes are arranged on the first cloth pipe, and the other end of the rotating device 1 is connected to the water outlet of the diversion pipe group 3 , the water inlet of the guide tube group 3 is connected to the water outlet of the water measuring power device 4 .

[0078] Wherein, the first distribution pipe is a structure with both ends closed, and the water is only discharged through the water outlet; the first distribution pipe can be a straight pipe (a straight round pipe, or a straight pipe of other shapes) or a curved pipe. tubes ...

Embodiment 2

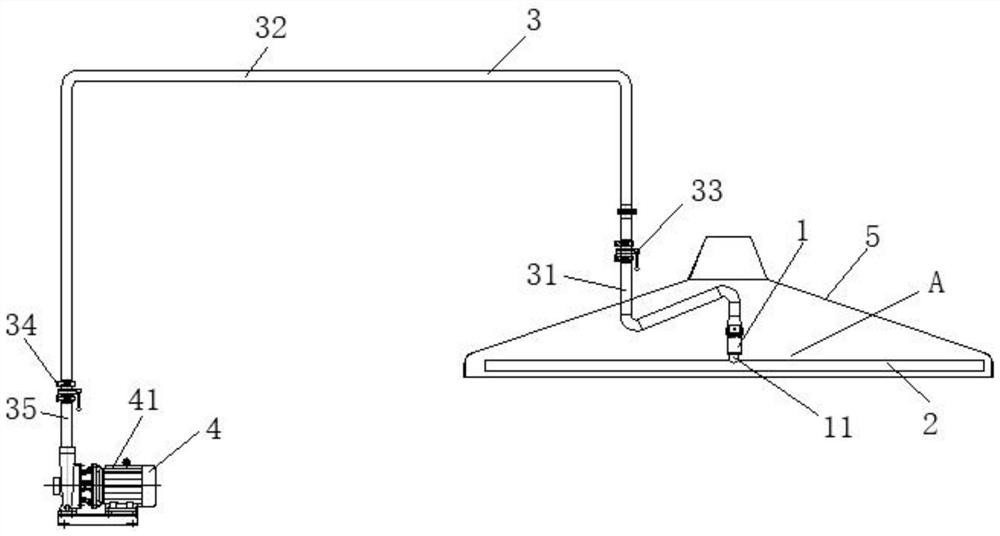

[0088] On the basis of embodiment 1;

[0089] Such as figure 2 As shown, the first distribution pipe 2 is arranged inside the retort cover 5 , and the draft tube group 3 is fixedly connected to the retort cover 5 near the retort cover 5 .

[0090] The working principle and beneficial effects of the above-mentioned technical scheme are:

[0091] In this embodiment, the water measuring and distributing device is fixed inside the retort cover, so that the automatic water measurement process can be carried out in the wine retort before the wine is placed in the retort, and there is no need to open the retort cover. In addition, high-temperature water can be added quantitatively and evenly, which can promote the re-expansion of starch and improve the gelatinization rate. And because there is no need to open the steamer cover 5 to add slurry water, the pressure and temperature in the steamer can be maintained, thereby saving steam and reducing the danger of personnel operation. ...

Embodiment 3

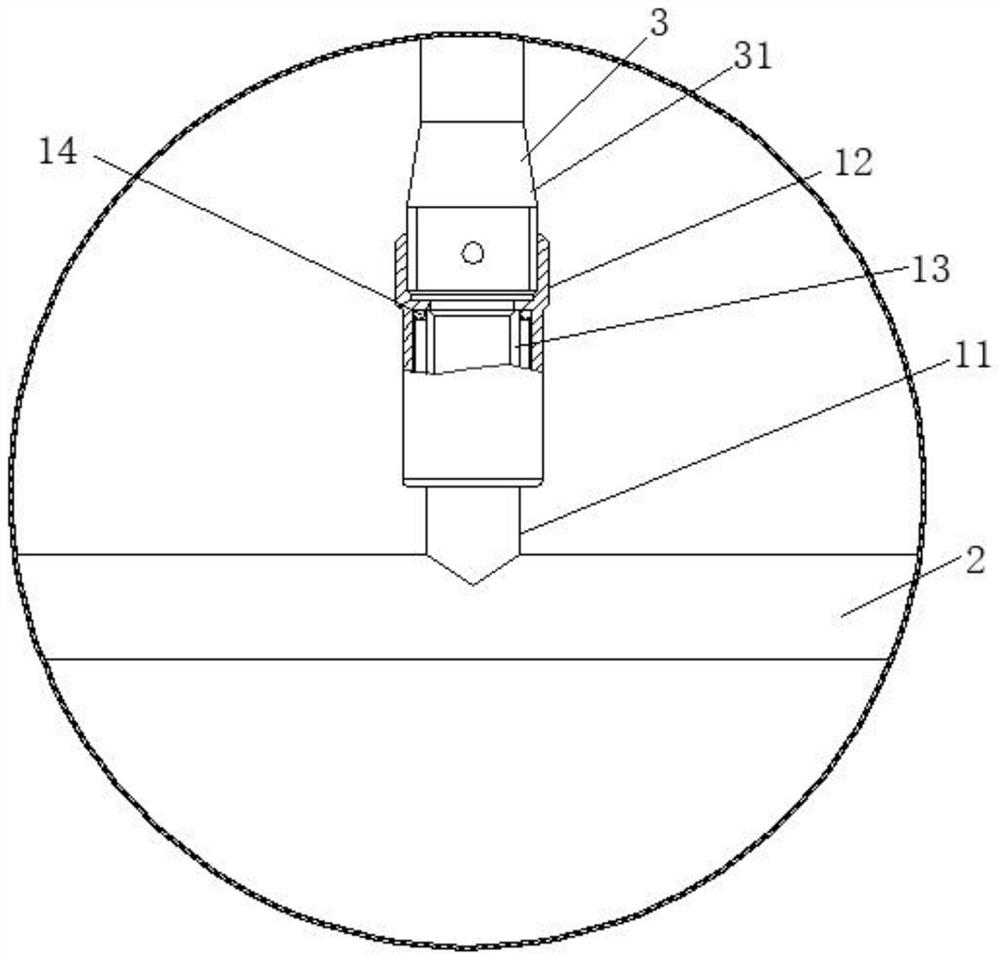

[0095] On the basis of embodiment 1 or 2, such as image 3 As shown, the rotating device 1 includes:

[0096]Rotating shaft 11, the lower end of which is fixedly connected to the water inlet at the upper end of the first distribution pipe 2, and the inner part of the rotating shaft 11 is provided with flow passages passing through its upper and lower ends;

[0097] The outer rotating tube 12, the upper part of the outer rotating tube 12 is fixedly sleeved on the outside of the water outlet of the diversion tube group 3;

[0098] The inner rotating tube 13 is located inside the outer rotating tube 12, the upper end of the inner rotating tube 13 communicates with the water outlet of the diversion tube group 3, and the lower end of the inner rotating tube 13 is fixedly connected with the upper end of the rotating shaft 11 (or select the upper part of the rotating shaft to be fixedly connected to the inside of the inner rotating tube), and balls are arranged between the outer rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com