Chemical-resistant and scratch-resistant polypropylene composite material and preparation method thereof

A technology of chemical resistance and composite material, applied in the field of scratch-resistant polypropylene composite material and its preparation, chemical resistance, can solve the problems of complex steps, low production efficiency, uncontinuous process, etc., to improve scratch resistance , good chemical resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

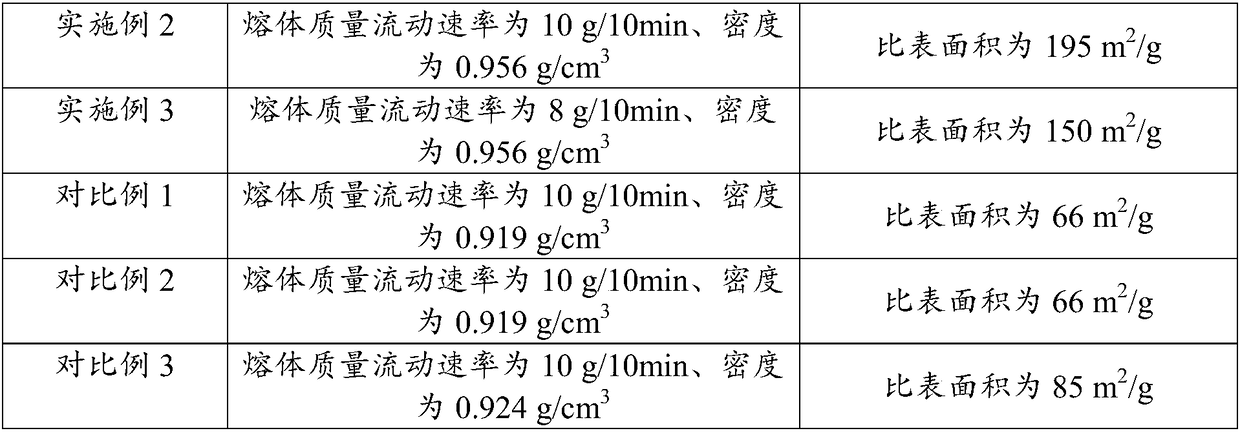

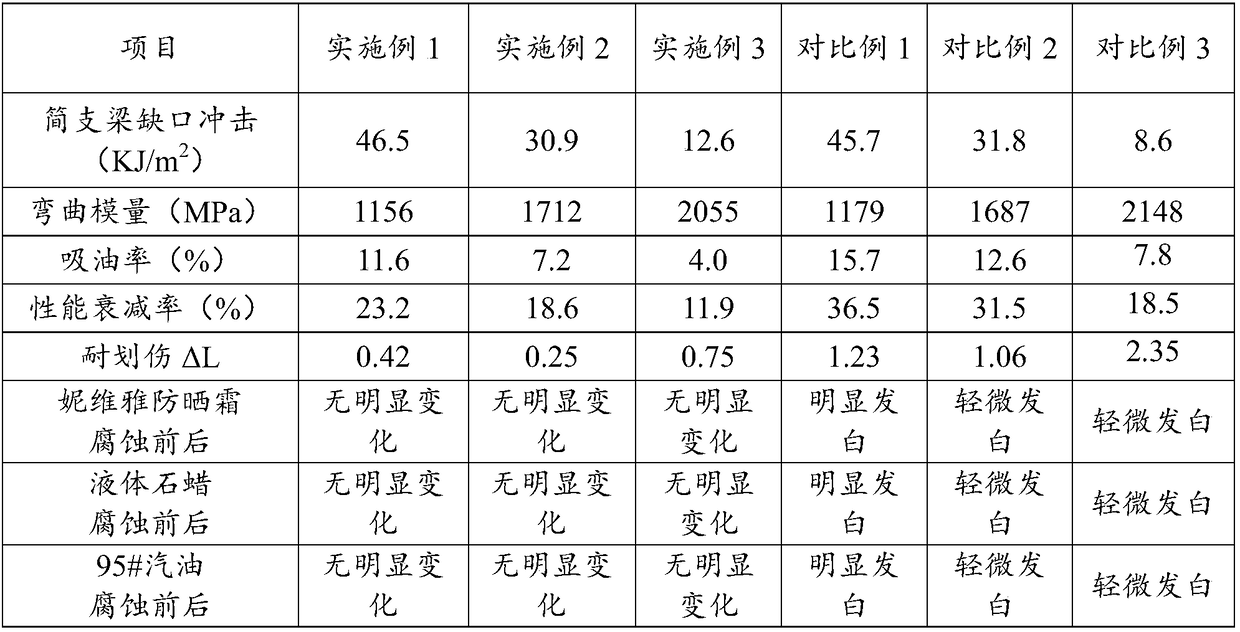

[0047] The present embodiment sets experimental group 1~8 and matched group 1~5, the formula of experimental group 1~8 and matched group 1~5 and the performance data that measure are as shown in table 4 (the test method of each performance is the same):

[0048] Table 4 The formulas of experimental groups 1 to 8 and the control group 1 to 5 and the measured performance data results

[0049]

[0050]

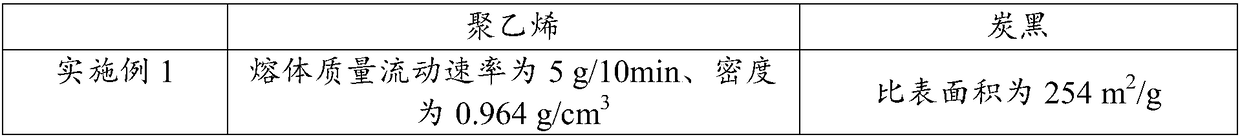

[0051] Among them, the performance indicators of PE and carbon black used in experimental groups 1-8 and control groups 1-5 are shown in Table 5:

[0052] Table 5 Performance indicators of PE and carbon black used in experimental groups 1-8 and control groups 1-5

[0053]

[0054] It can be seen from Table 4 and Table 5 that the experimental group 1 selected high-density, low-melt mass flow rate PE as the modified component, the control group 1 did not use PE modification, and the control groups 2 and 3 used high-density, high-density PE. Melt mass flow rate PE is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com