Spraying method of graphene coating

A technology of graphene and coatings, applied in anti-corrosion coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of not being able to give full play to the maximum performance of graphene, achieve improved anti-corrosion performance, and change the distribution state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

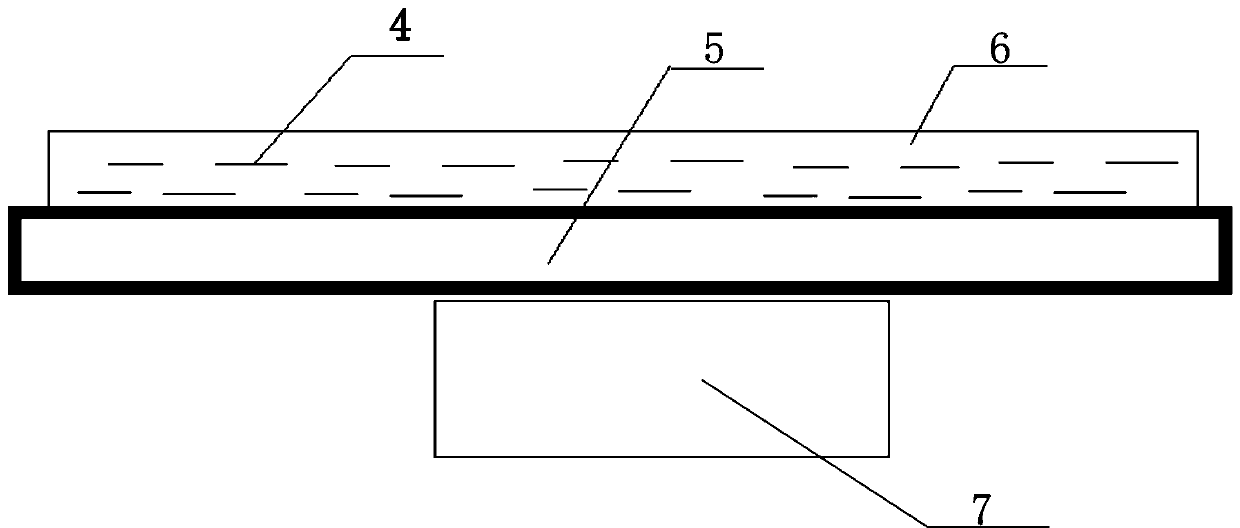

[0015] According to attached figure 2 The spraying method of described graphene coating, concrete steps comprise:

[0016] (1) Set the ultrasonic vibration source 7 on the workpiece B5 to be sprayed, the ultrasonic frequency is 30KHz-1000KHz, and the energy of the ultrasonic wave depends on the specification and shape of the part;

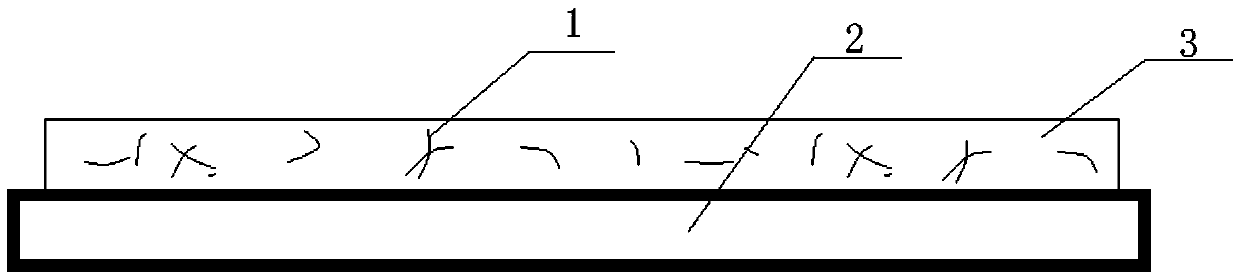

[0017] (2) After implementing the previous step, evenly spray the graphene coating on the surface of the workpiece B5, and under the vibration of the ultrasonic vibration source 7, the graphene microsheets 4B are gradually stretched and spread on the surface of the workpiece B5 for 20-30 minutes Finally, the paint on the surface of the paint layer A3 is dry, and the inside of the paint layer A3 is also in a non-fluid state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com