Microwave oven

A microwave oven and body technology, applied in the field of microwave ovens, can solve the problems of uneven heating, inability to achieve uniform heating, heating, and heating in one place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

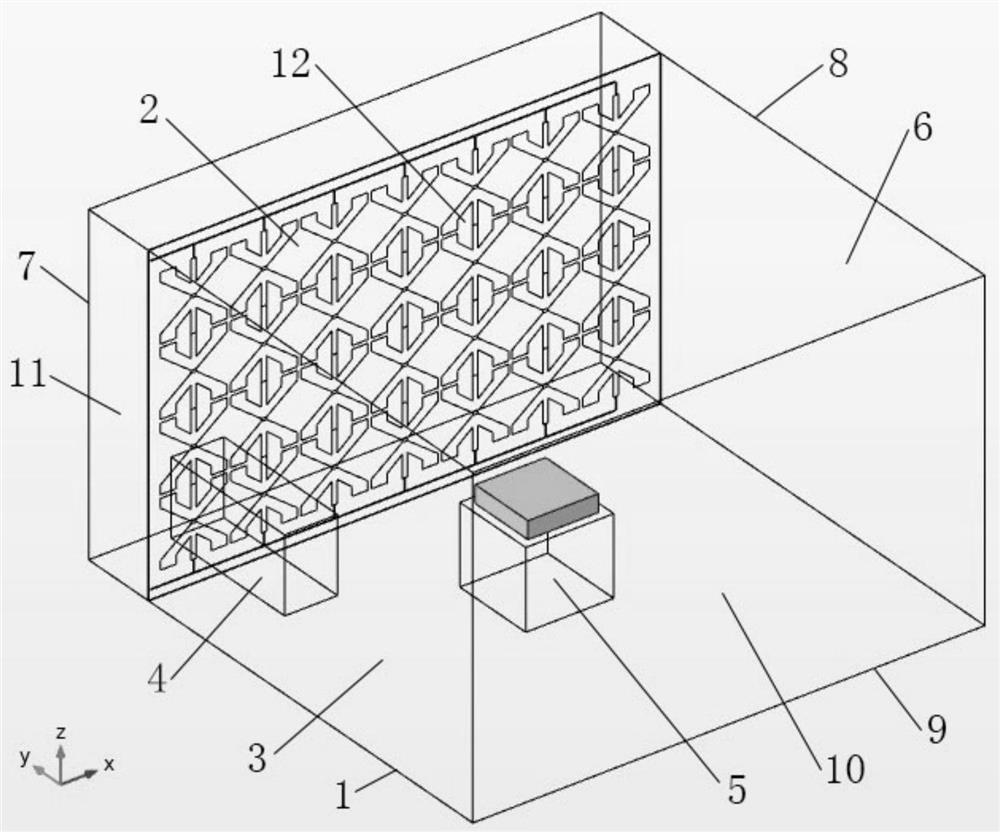

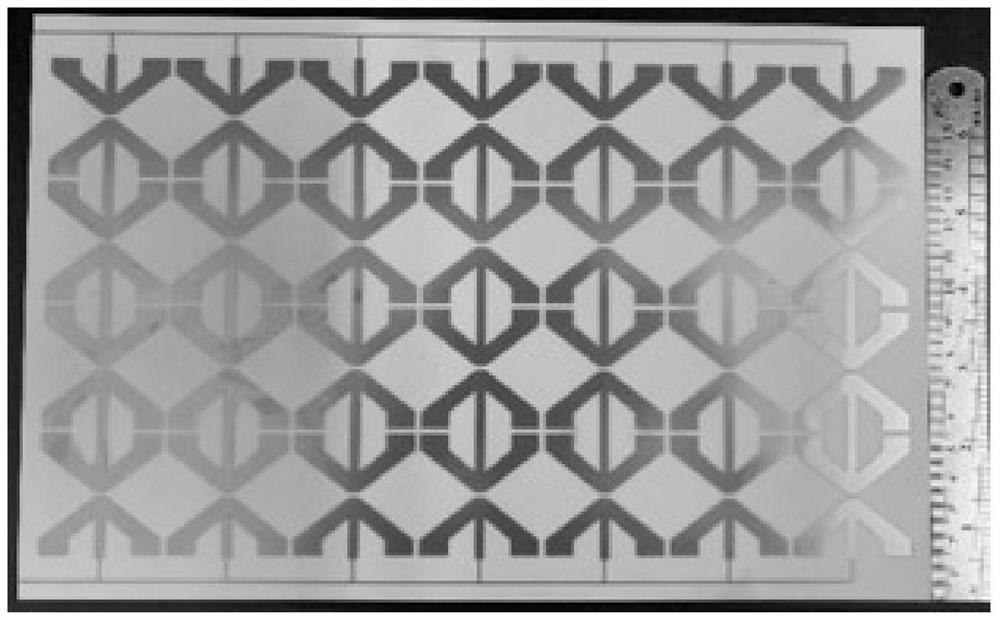

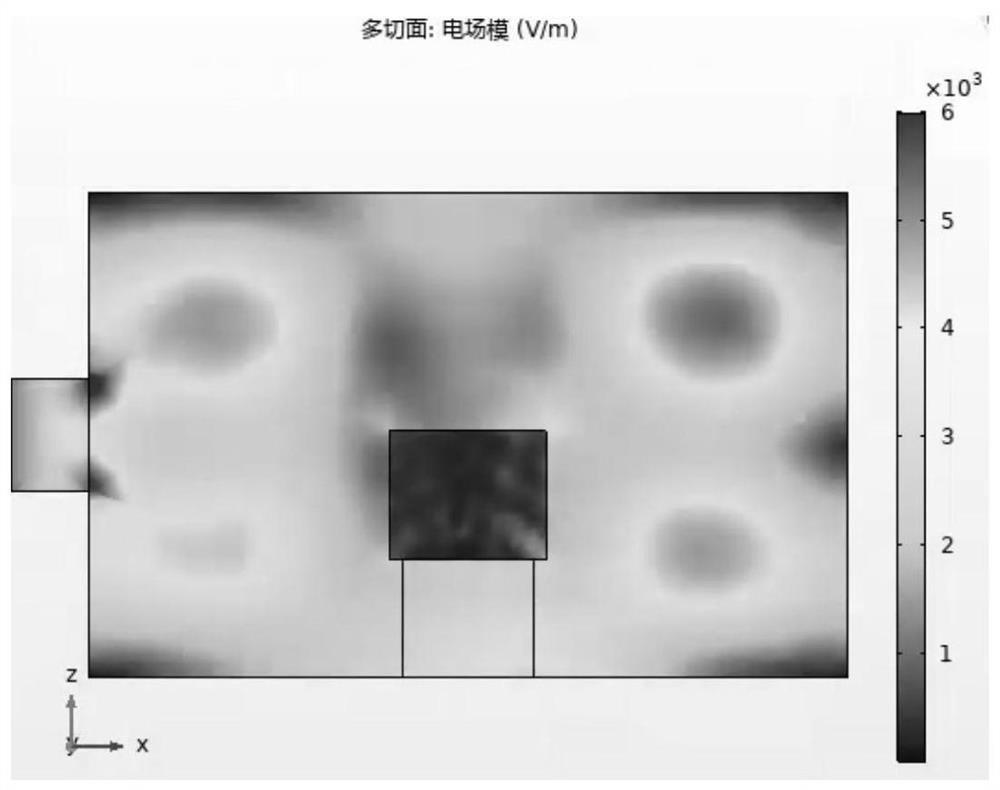

[0033] Such as figure 1 As shown, a microwave oven includes a microwave oven body 1, and an adjustable frequency selection surface 2 is arranged inside the microwave oven body 1, and the adjustable frequency selection surface 2 is arranged near the rear side wall 7 of the microwave oven body 1 (or according to According to actual needs, it is arranged on the left side wall 3, the right side wall 6, the upper side wall 8 or the lower side wall 9), one adjustable frequency selection surface 2 can be used, and multiple adjustable frequency selection surfaces 2 can also be used, adjustable The frequency selection surface 2 corresponds to the side wall one by one; in this embodiment, the distance between the adjustable frequency selection surface and the rear side wall 7 is 2-6 cm, and the adjustable frequency selection surface 2 separates the cavity in the microwave oven body 1 It is formed into a heating area 10 and an electric field boundary change area 11. An object holding pla...

Embodiment 2

[0039] The difference from Embodiment 1 is that in this embodiment, the object-to-be-heated holding platform 5 can rotate by itself in the microwave oven body 1 through a rotating mechanism. It can be understood that the rotation mode of the hot object holding platform 5 can be the rotation mode in the existing microwave oven, and the efficient heating of the microwave oven can be realized through the synergy between the rotation of the hot object holding platform 5 and the frequency selective surface 2, so that Items to be heated can be heated more evenly.

Embodiment 3

[0041] The difference from Embodiment 1 is that in this embodiment, in order to facilitate the cleaning of the interior of the microwave oven body 1, the adjustable frequency selection surface 2 can be set to be detachable, that is, in the microwave oven body 1 Slots are provided on the side walls (the slots are respectively located on the upper side wall 8 or the lower side wall 9 of the microwave oven body 1), and the adjustable frequency selection surface 2 can be directly inserted into the slots for positioning.

[0042] When the user opens the door of the microwave oven body 1, the frequency selection surface 2 can be seen intuitively, and the user pulls the adjustable frequency selection surface 2 by hand, and the adjustable frequency selection surface 2 can be pulled out from the slot , so as to clean the oil on the adjustable frequency selection surface 2, after the cleaning is completed, then insert the adjustable frequency selection surface 2 into the microwave oven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com