Efficient supported bimetallic or polymetallic catalyst and preparation method thereof

A polymetallic catalyst and bimetallic technology, which is applied in the fields of catalysis science and technology and material preparation, can solve problems such as difficulty in scaling up, and achieve the effects of saving equipment costs, improving reaction activity and product selectivity, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

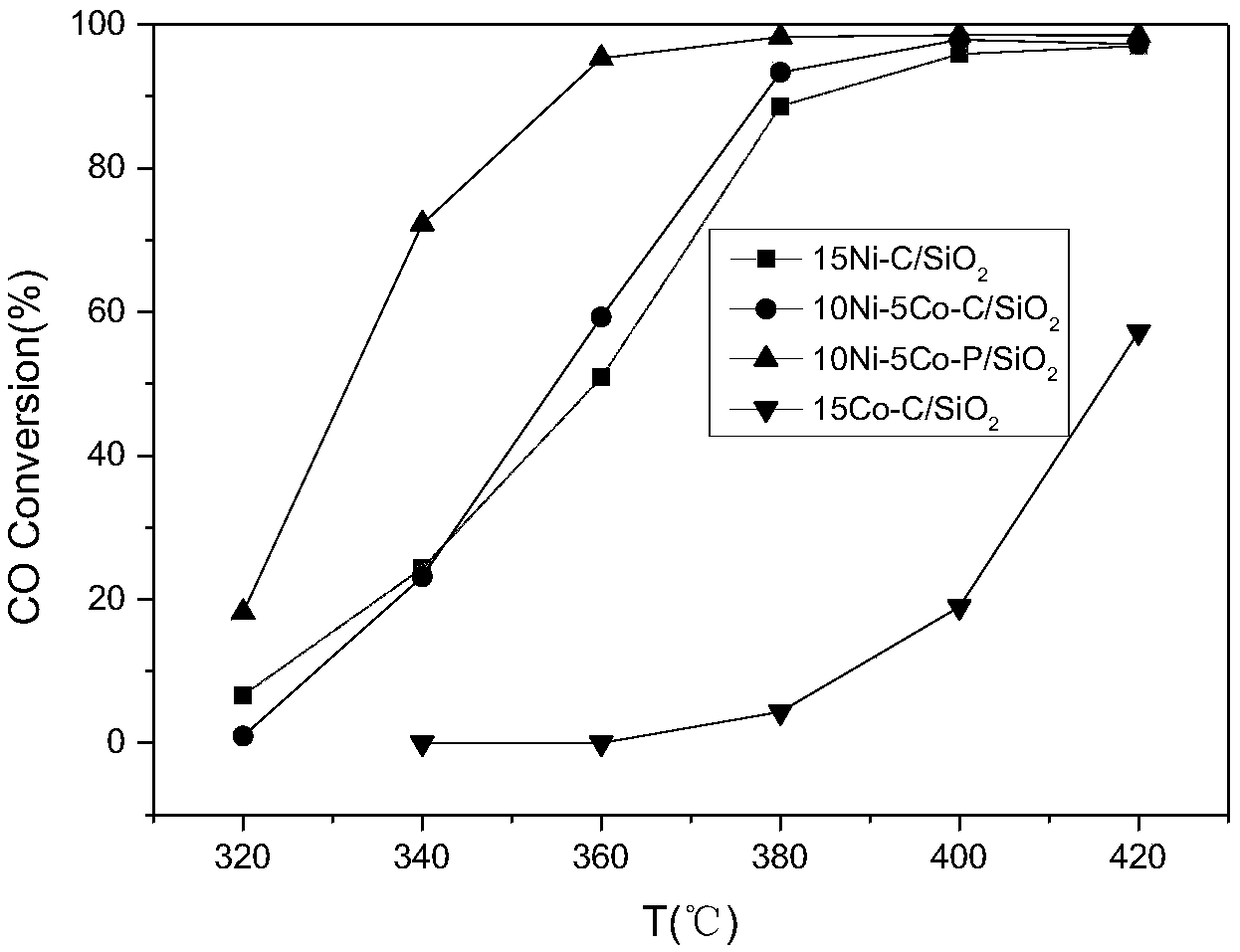

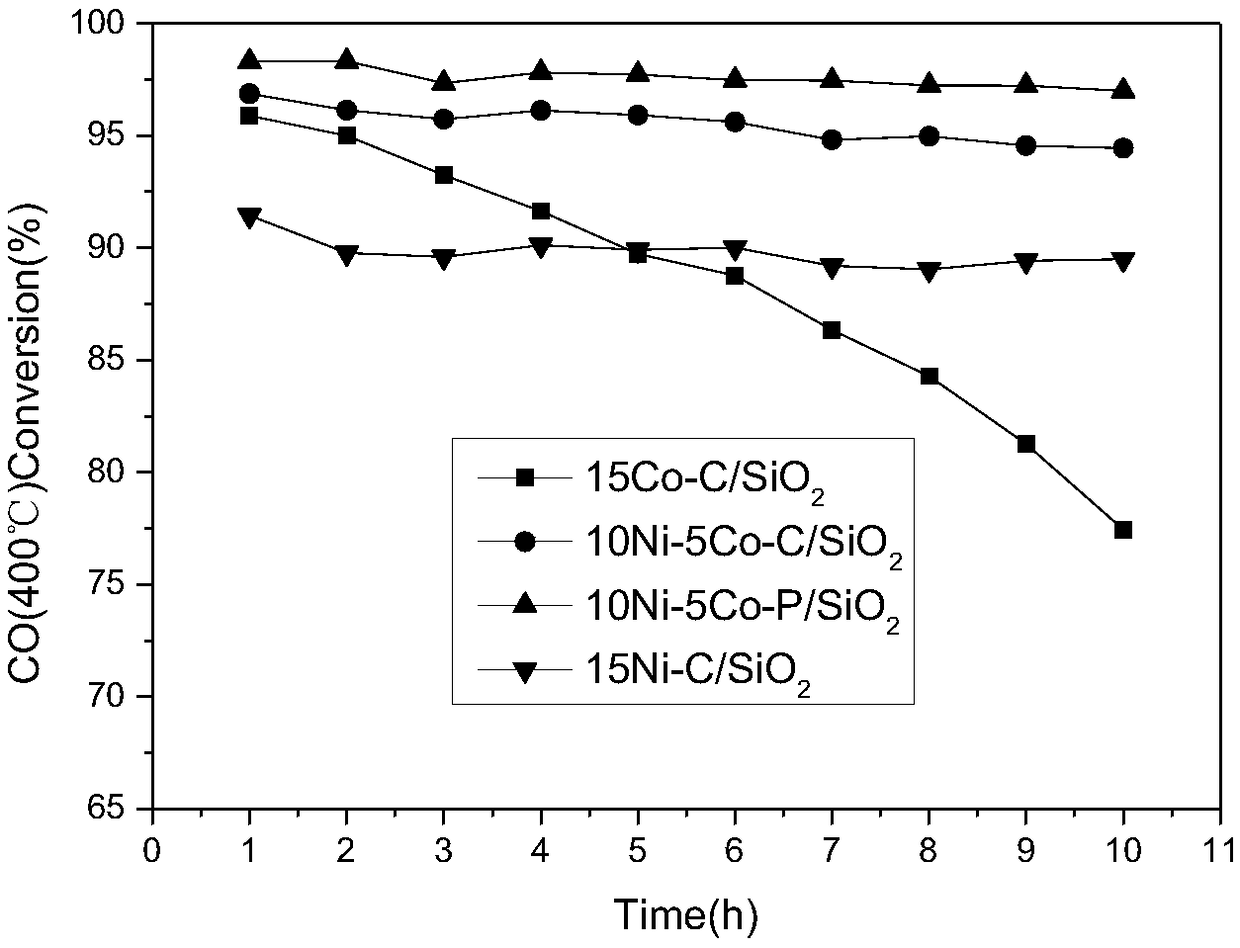

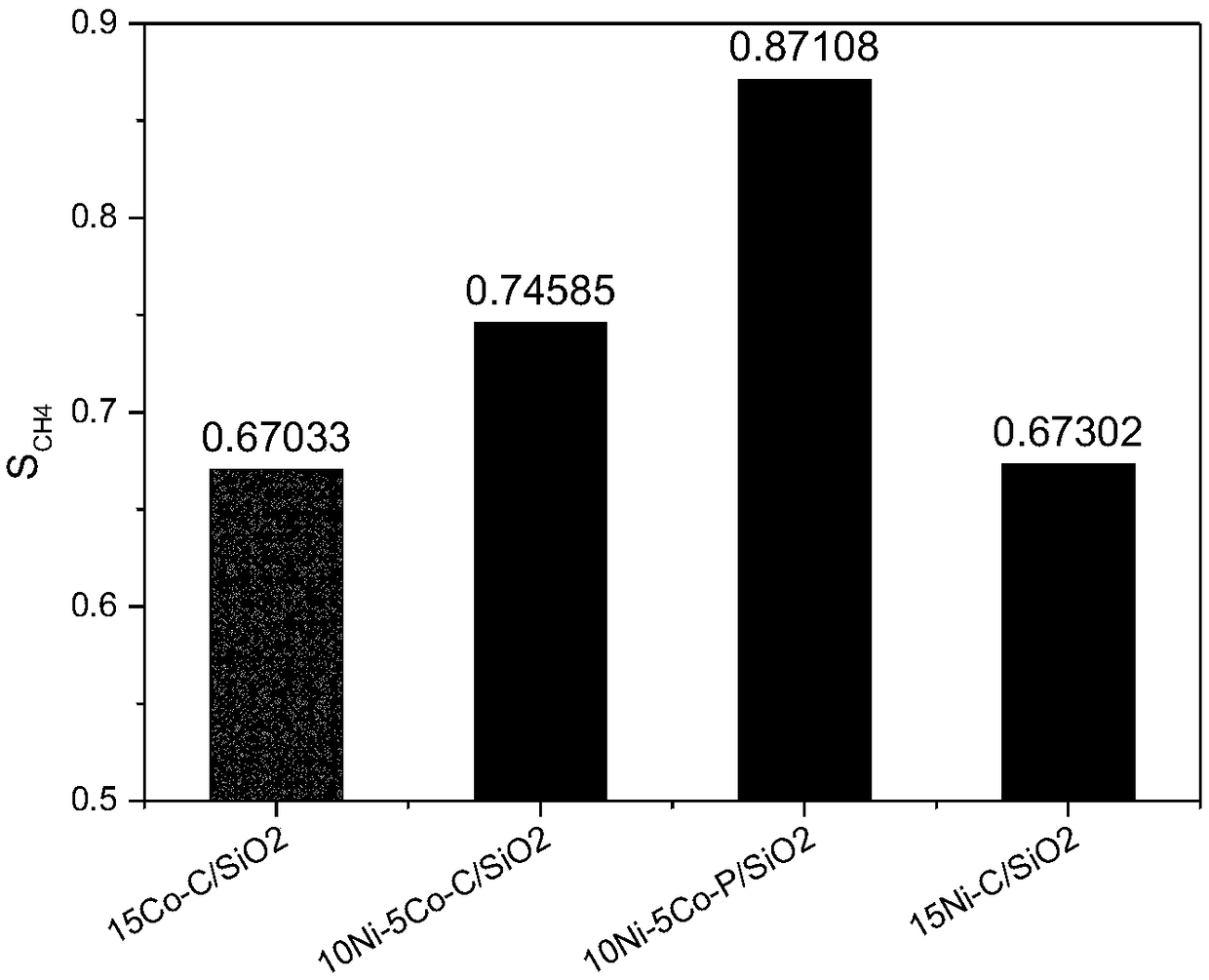

[0037] Weigh 3g SiO 2 The carrier was calcined at 500°C for 4h, and 1.7487g of Ni(NO 3 ) 2 ·6H 2 O and 0.8710g of Co(NO 3 ) 2 ·6H 2 O was dissolved in an appropriate amount of deionized water, and the carrier was slowly poured into the solution and stirred evenly, and then stood at room temperature for 12h. Put the equal-volume impregnated precursor into an electric blast drying oven, adjust the temperature to 110°C and dry for 12 hours. Take 1.5g of the dried powder and grind it thoroughly, put it into the plasma reactor for DBD intermittent treatment, increase the voltage to 100V, adjust the current to 3A, keep it for 3min, take it out after fully grinding and cooling, stir evenly for the next treatment , 20 times in total. Finally, it was fired in a muffle furnace at 500 °C for 4 h. The obtained catalyst is labeled as 10Ni-5Co-P / SiO 2 .

Embodiment 2

[0039] Weigh 3g SiO 2 The carrier was calcined at 500°C for 4h, and 1.3990g of Ni(NO 3 ) 2 ·6H 2 O and 1.1466g of Co(NO 3 ) 2 ·6H 2 O was dissolved in an appropriate amount of deionized water, and the carrier was slowly poured into the solution and stirred evenly, and then stood at room temperature for 6h. Put the equal-volume impregnated precursor into an electric blast drying oven, and adjust the temperature to 110 °C for 24 h to dry. Take 1.5g of the dried powder and grind it thoroughly, put it into a plasma reactor for DBD intermittent treatment, increase the voltage to 120V, adjust the current to 3A, keep it for 3min, take it out after fully grinding and cooling, stir evenly for the next treatment , 25 times in total. Finally, it was fired in a muffle furnace at 500 °C for 4 h. The obtained catalyst is labeled as 8Ni-7Co-P / SiO 2 .

Embodiment 3

[0041] Weigh 3g SiO 2 The carrier was calcined at 500°C for 4h, and 1.0493g of Ni(NO 3 ) 2 ·6H 2 O and 1.5688g of Co(NO 3 ) 2 ·6H 2 O was dissolved in an appropriate amount of deionized water, and the carrier was slowly poured into the solution and stirred evenly, and then stood at room temperature for 6h. Put the equal-volume impregnated precursor into an electric blast drying oven, and adjust the temperature to 110 °C for 24 h to dry. Take 1.5g of the dried powder and grind it thoroughly, put it into a plasma reactor for DBD intermittent treatment, increase the voltage to 150V, adjust the current to 3A, keep it for 3min, take it out after fully grinding and cooling, stir evenly for the next treatment , 25 times in total. Finally, it was fired in a muffle furnace at 500 °C for 4 h. The resulting catalyst is labeled 6Ni-9Co-P / SiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com