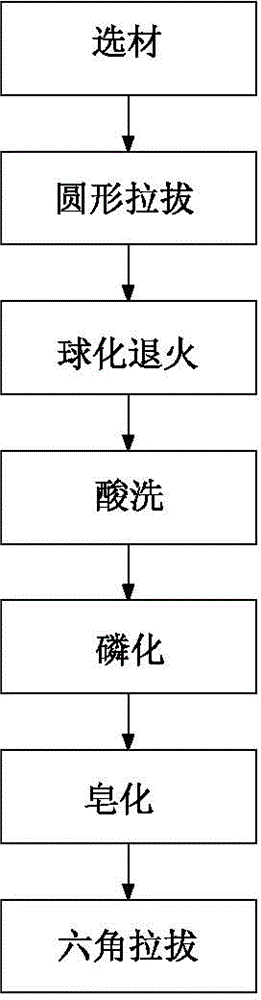

Production process of alloy steel material for high-strength internal hexagonal wrench

A hexagonal wrench and production process technology, applied in the field of wire processing, can solve the problems of low plastic deformation ability of products, inability to meet customer bending forming requirements, time-consuming and energy-consuming production process, etc., to improve labor productivity and shorten spheroidizing annealing. Softening time process, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Material selection: 50CrVa material is selected as the base material.

[0032] (2) Circular drawing: the base metal is drawn multiple times by a drawing machine to obtain round wires of required specifications and sizes. The compression rate of each drawing is 10%, and the total compression rate is 40%.

[0033] (3) Spheroidizing annealing: hoist the round wire into the atmosphere protection furnace, and the atmosphere protection furnace is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the round wire is heated to Austrian 20°C above the tenite transformation temperature, keep warm for 4 hours, then slowly cool at 10°C / hour to 20°C below the austenite transformation temperature, hold for 3 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C .

[0034] (4) Pickling: Use an acid solution to remove the scale on the surf...

Embodiment 2

[0040] (1) Material selection: 50CrVa material is selected as the base material.

[0041] (2) Circular drawing: The base metal is drawn multiple times by a drawing machine to obtain round wires of the required size. The compression rate of each drawing is 15%, and the total compression rate is 44.8%.

[0042] (3) Spheroidizing annealing: hoist the round wire into the atmosphere protection furnace, and the atmosphere protection furnace is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the round wire is heated to Austrian 25°C above the tenite transformation temperature, hold for 5 hours, then slowly cool at 10°C / hour to 25°C below the austenite transformation temperature, hold for 3.5 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C .

[0043] (4) Pickling: Use an acid solution to remove the scale on the surface of the wire. ...

Embodiment 3

[0049] (1) Material selection: 50CrVa material is selected as the base material.

[0050] (2) Circular drawing: The base metal is drawn multiple times by a drawing machine to obtain round wires of required specifications and sizes. The compression rate of each drawing is 20%, and the total compression rate is 48.8%.

[0051] (3) Spheroidizing annealing: hoist the round wire into the atmosphere protection furnace, and the atmosphere protection furnace is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the round wire is heated to Austrian 30°C above the tenite transformation temperature, keep warm for 6 hours, then slowly cool at 10°C / hour to 30°C below the austenite transformation temperature, hold for 4 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C .

[0052] (4) Pickling: Use an acid solution to remove the scale on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com