Front windshield water guide plate assembly

A front windshield and water deflector technology, applied in the superstructure sub-assembly, superstructure, transportation and packaging, etc., can solve the problems of low positioning accuracy, difficult installation of wiper motor, low strength, etc. Eliminates the effect of poor wiper wiping and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

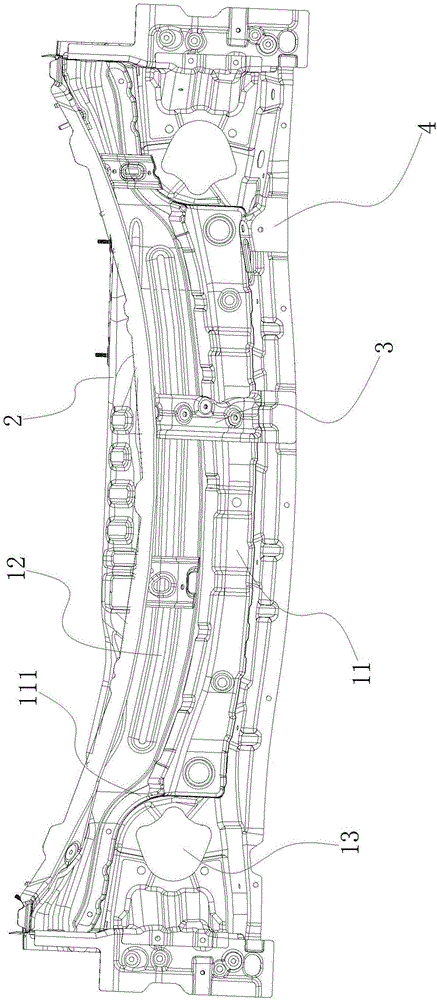

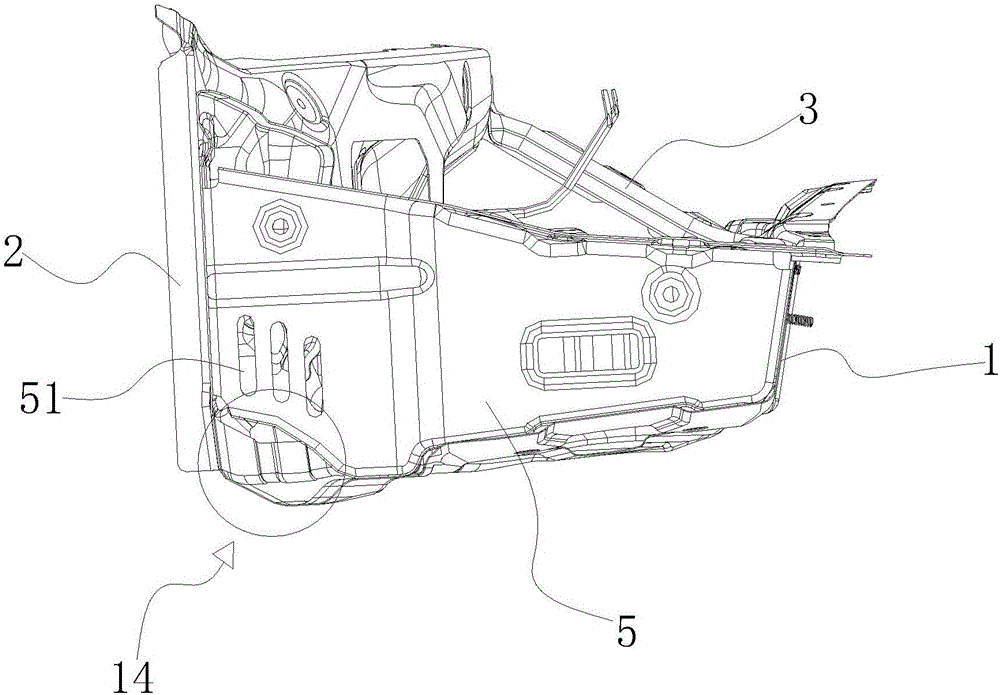

[0008] Such as Figure 1 to Figure 2 As shown, a front windshield water guide assembly includes a U-shaped water guide 1, a front windshield lower beam 2 and a wiper motor mounting bracket; the rear plate of the U-shaped water guide 1 is welded on the front windshield On the lower beam 2, the lower beam 2 of the front windshield is higher than the edge of the rear plate of the U-shaped water guide groove 1, so that the A bracket 3 can be welded on the lower beam 2 of the front windshield; the mounting bracket of the wiper motor includes A Brackets 3 and B brackets 4; the front end of the A bracket 3 is welded on the edge of the front plate of the U-shaped gutter 1, and the rear end of the A bracket 3 is welded on the lower beam 2 of the windshield; the B bracket 4 Welded on the edge of the front plate of the U-shaped gutter 1.

[0009] In the above technical solution, by designing the wiper motor mounting bracket into combined A bracket 3 and B bracket 4, the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com